Polycarboxylate superplasticizer with excellent slump retention, higher water-reducing rate and capable of perfecting concrete performance and preparation method thereof

A technology of slump retention and water reducing agent, applied in the field of concrete, can solve the problems of poor concrete strength and durability, low concrete fluidity, and small compactness, and achieve the effects of reducing water-cement ratio, improving compactness, and full response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

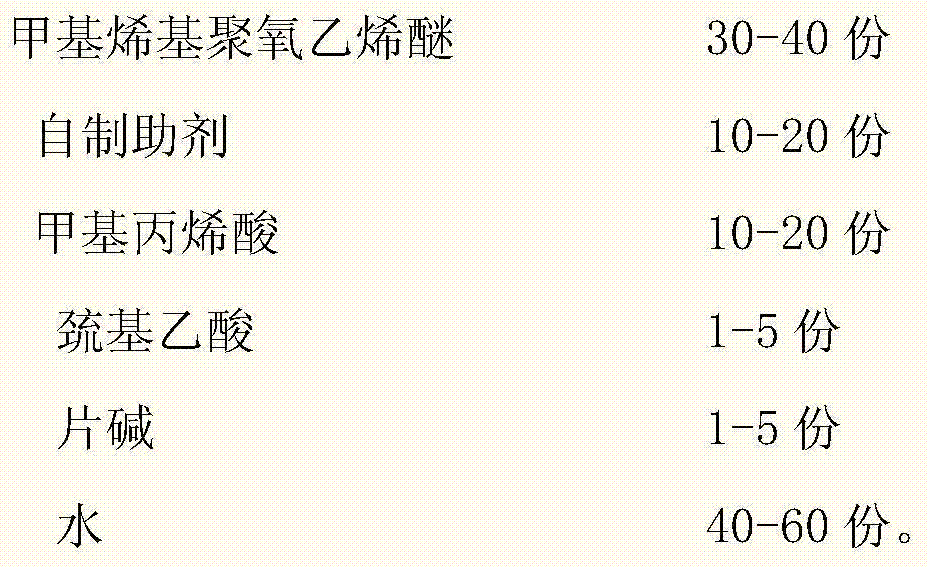

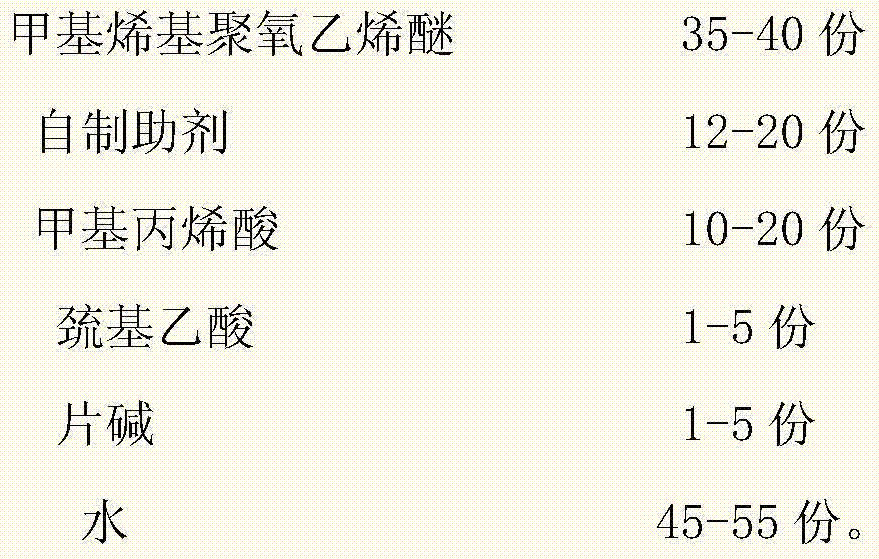

[0021] Raw material ratio:

[0022] 35 parts of methyl alkenyl polyoxyethylene ether, 15 parts of self-made additives, 15 parts of methacrylic acid, 2 parts of thioglycolic acid, 2 parts of caustic soda, 45 parts of water.

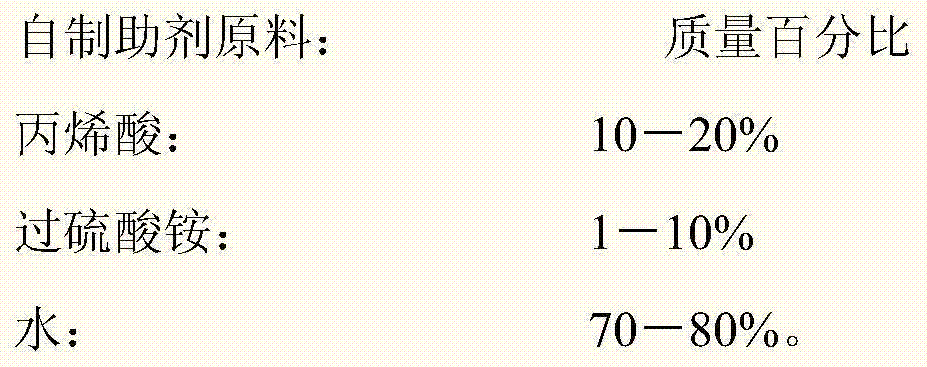

[0023] Homemade additives: 15% acrylic acid, 5% ammonium persulfate, 80% water.

[0024] The preparation steps include: (1) Weighing the raw materials of each component of the formula ratio; (2) heating water half of the formula ratio to 25-35°C, then adding methyl alkenyl polyoxyethylene ether and self-made auxiliary agents, and stirring While raising the temperature to 50°C; (3) After stirring and reacting the material in step (2) at 50°C for 1 hour, add dropwise to the reaction system a solution prepared by methacrylic acid, thioglycolic acid and water with the other half of the formula ratio, the above solution The dropping time is completed within 4 hours; (4) the reaction system of step (3) is maintained at 50°C for 1 hour, then cooled to 30°C and a...

Embodiment 2

[0026] Raw material ratio: 40 parts of methyl vinyl polyoxyethylene ether, 10 parts of self-made additives, 20 parts of methacrylic acid, 5 parts of thioglycolic acid, 5 parts of caustic soda, and 50 parts of water.

[0027] Preparation aids: 20% acrylic acid, 10% ammonium persulfate, 70% water.

[0028] The preparation method is the same as in Example 1.

Embodiment 3

[0030] 32 parts of methyl alkenyl polyoxyethylene ether, 20 parts of self-made additives, 20 parts of methacrylic acid, 4 parts of thioglycolic acid,

[0031] 2 parts of caustic soda, 55 parts of water.

[0032] Homemade additives: acrylic acid 16%, ammonium persulfate 8%, water 76%.

[0033] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com