Amphoteric polycarboxylate water reducing agent and preparation method thereof

A technology of amphoteric polycarboxylic acid and water reducing agent, applied in the field of water reducing agent and its production and preparation, can solve the problems of unfavorable large-scale production and application, poor operability, complex synthesis process, etc., and achieve good pure pulp Liquidity, abundant sources, and comprehensive cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

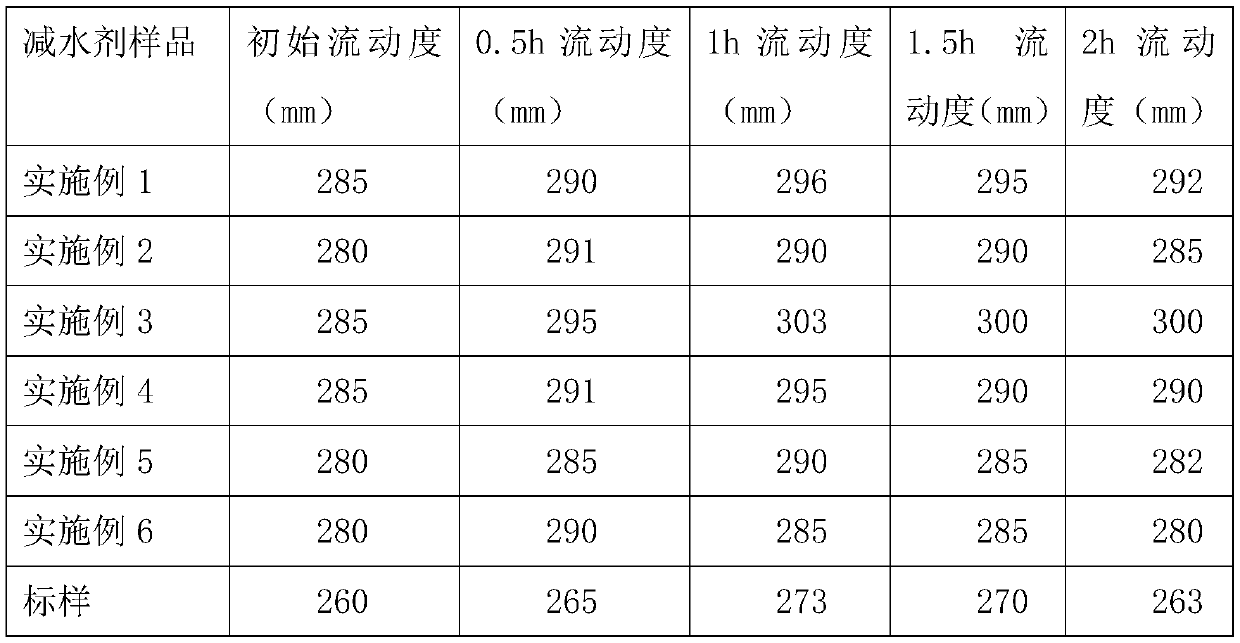

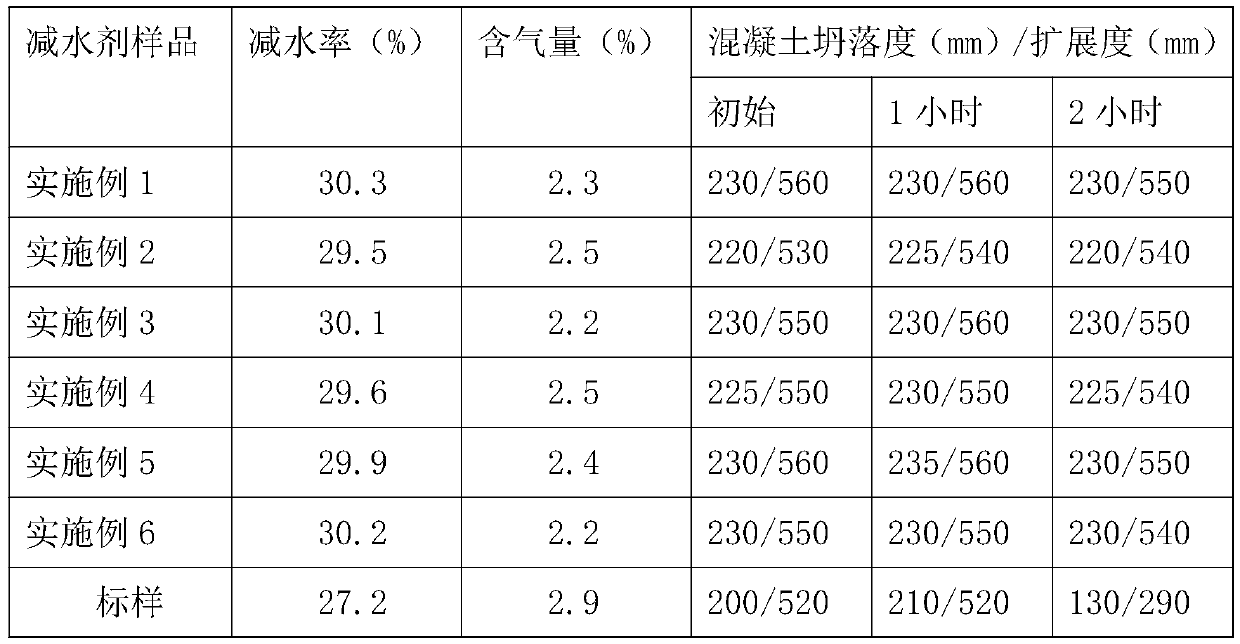

Examples

preparation example Construction

[0047] The present invention also provides a preparation method of amphoteric polycarboxylate water reducer, comprising the following steps:

[0048] 1) Pretreatment of polyether monomers: take out the polyether monomers, place them in water, and use an initiator to make the polyether monomers generate free radicals to form polyether monomers with free radicals;

[0049] Specifically, the polyether monomer is taken out, placed in water at 25° C. to 35° C. and stirred, and an initiator is used to make the polyether monomer generate free radicals to form a polyether monomer with free radicals.

[0050] Through this temperature, the preliminary conditions for the redox initiation system can be formed, which can effectively reduce the activation energy of the reaction, so that the polymerization of functional monomers can be carried out at a lower temperature.

[0051] 2) Preparation of component I: mixing carboxylic acid monomers, amides, unsaturated esters, and cationic monomers...

Embodiment 1

[0061] In this embodiment, the preparation of amphoteric polycarboxylate water reducer specifically includes:

[0062] 1) Pretreatment of polyether monomers: Add 430 g of prenol polyoxyethylene ether and 390 g of distilled water into a reaction vessel equipped with a stirrer, then add 4 g of hydrogen peroxide solution, stir to dissolve it, and form polyoxyethylene polyoxyethylene ether with free radicals. Polyether monomer; at this point, dissolve the macromer with distilled water.

[0063] 2) Preparation of component I: Mix 28.4g of acrylic acid, 5.1g of acrylamide, 9.3g of methyl acrylate, 14.9g of methacryloyloxyethyltrimethylammonium chloride, and 8.3g of hydroxyethyl acrylate to prepare Component I;

[0064] 3) Preparation of component II: Mix 1 g of vitamin C, 2 g of mercaptopropionic acid, and 33 g of distilled water to prepare component II; at this time, the distilled water can dissolve vitamin C, and adjust the dropwise amount.

[0065] 4) Preparation of amphoteric ...

Embodiment 2

[0069] In this embodiment, the preparation of amphoteric polycarboxylate water reducer specifically includes:

[0070] 1) Pretreatment of polyether monomers: Add 430 g of prenol polyoxyethylene ether and 390 g of distilled water into a reaction vessel equipped with a stirrer, then add 3.5 g of hydrogen peroxide solution, stir to dissolve, and form The polyether monomer;

[0071] 2) Preparation of component I: Mix 28.4g of acrylic acid, 5.1g of acrylamide, 9.3g of methyl acrylate, 14.9g of methacryloyloxyethyltrimethylammonium chloride, and 8.3g of hydroxyethyl acrylate to prepare Component I;

[0072] 3) Preparation of component II: Mix 0.6 g of vitamin C, 1.6 g of mercaptopropionic acid, and 33 g of distilled water to prepare component II;

[0073] 4) Preparation of amphoteric polycarboxylate water-reducer: Add component I and component II dropwise to the reactor respectively, the dropping time of component I is controlled within 2.5h, and the dropwise addition of component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com