Cement grinding aid and preparation method thereof

A technology of cement grinding aids and water reducers, which is applied in the field of cement grinding aids and can solve problems such as sulfur deficiency and difficult cement water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

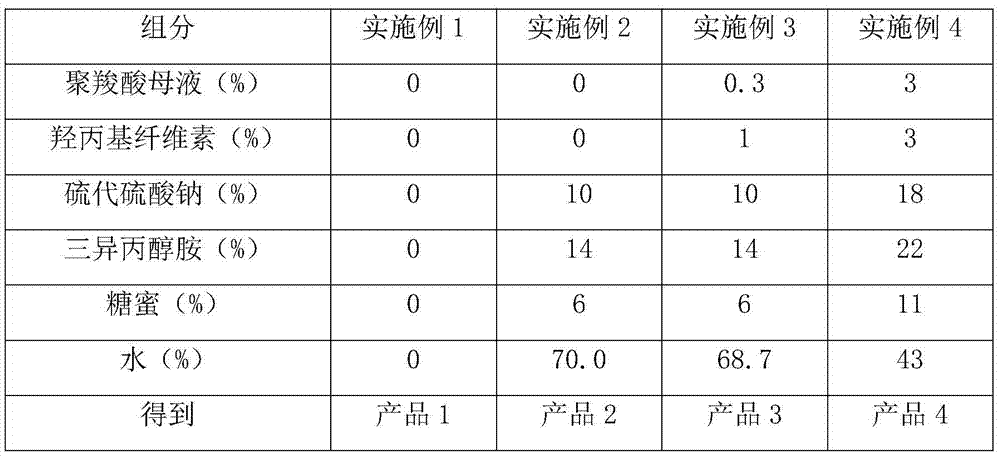

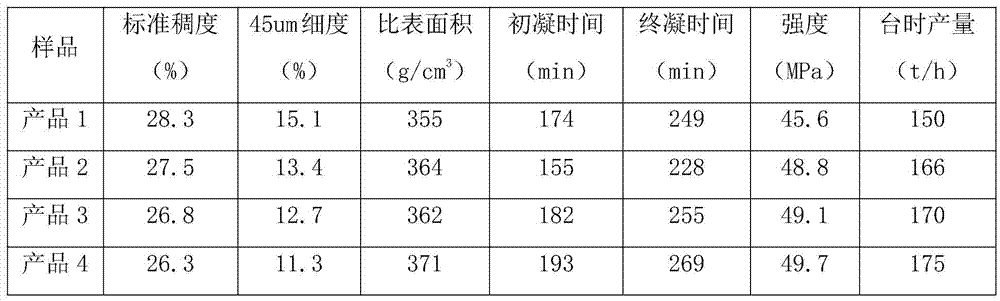

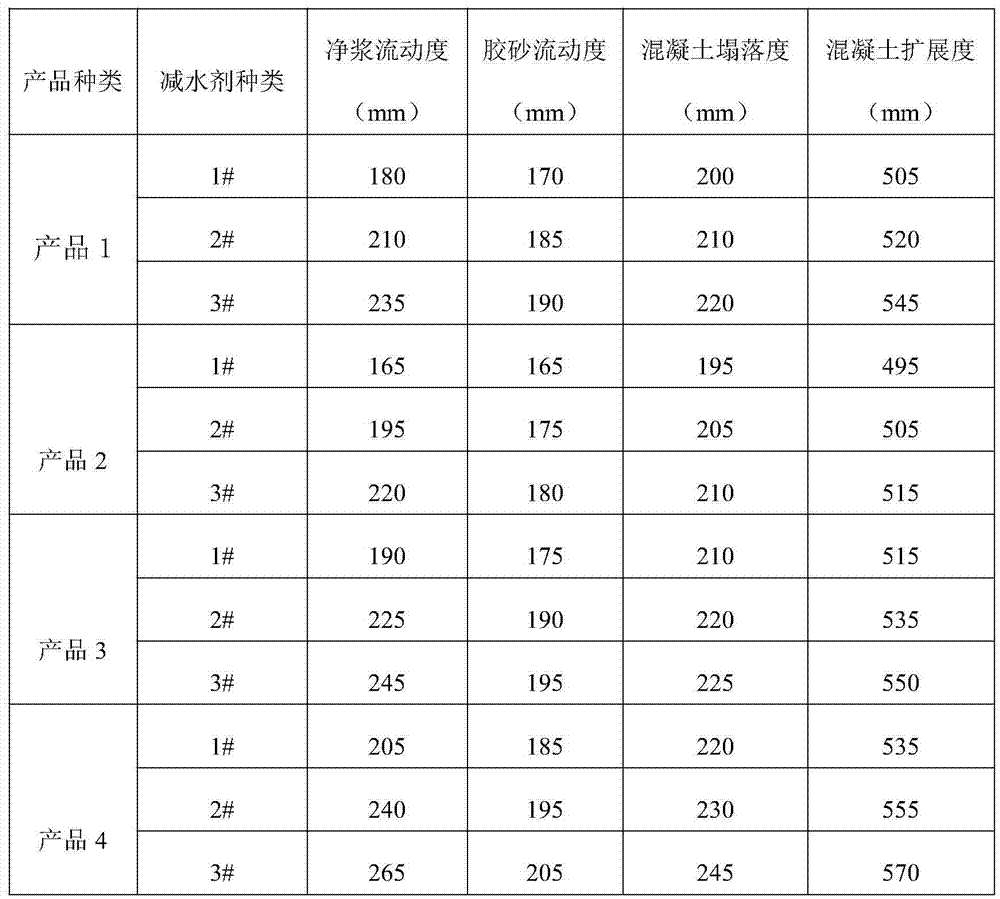

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0020] The invention provides a cement grinding aid, the components and the mass percentage of the components are: 0.3-3% of polycarboxylic acid mother liquor, 1-3% of hydroxypropyl cellulose, 6-11% of molasses, modified diethanol 14-22% of monoisopropanolamine, 10-18% of sodium thiosulfate, and the balance is water.

[0021] During preparation, first inject water into the first pre-dissolved kettle, add hydroxypropyl cellulose while stirring, stir for 30 minutes, and prepare a cellulose solution with a mass percentage of 3% for later use; Add polycarboxylic acid mother liquor and ammonium thiosulfate to the remaining water while stirring, then add molasses, modified diethanol monoisopropanolami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com