Patents

Literature

55 results about "Slump flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

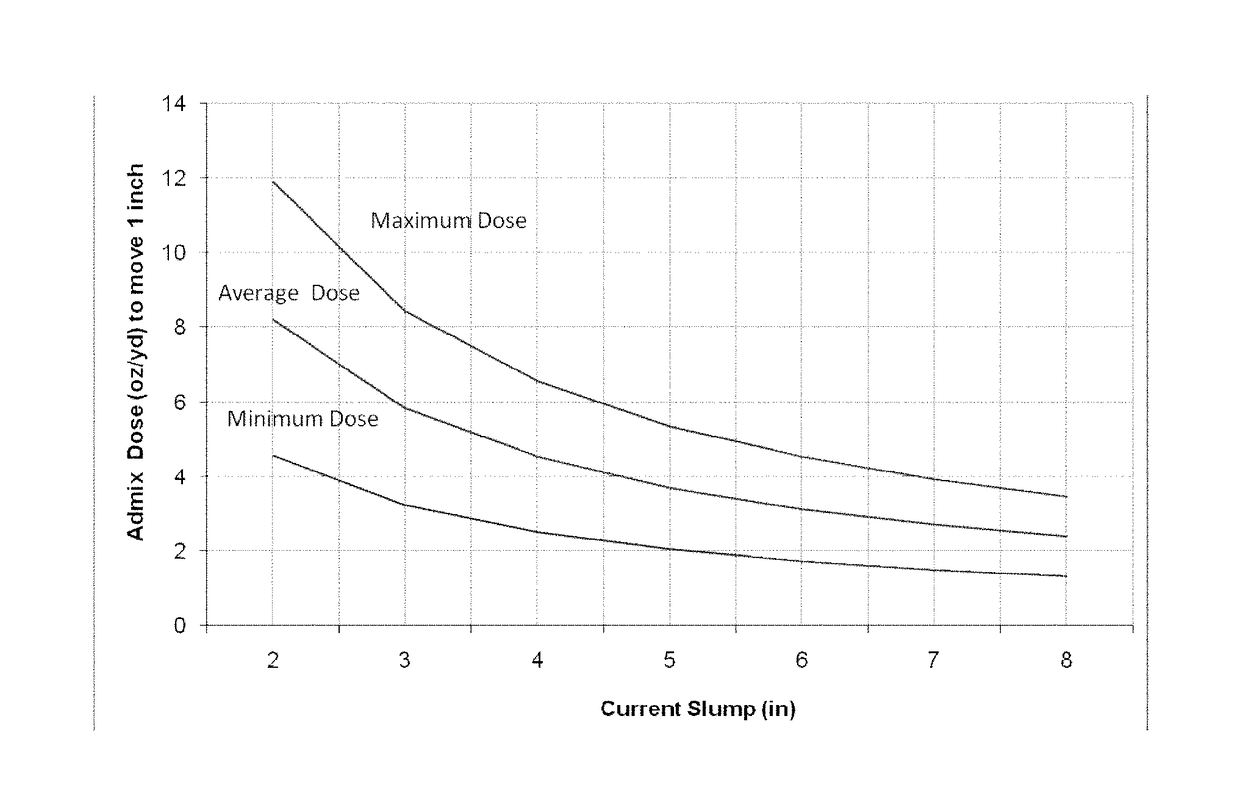

Method for adjusting concrete rheology based upon nominal dose-response profile

ActiveUS8311678B2Increased complexityAvoid overdoseSampled-variable control systemsControlling ratio of multiple fluid flowsEngineeringLookup table

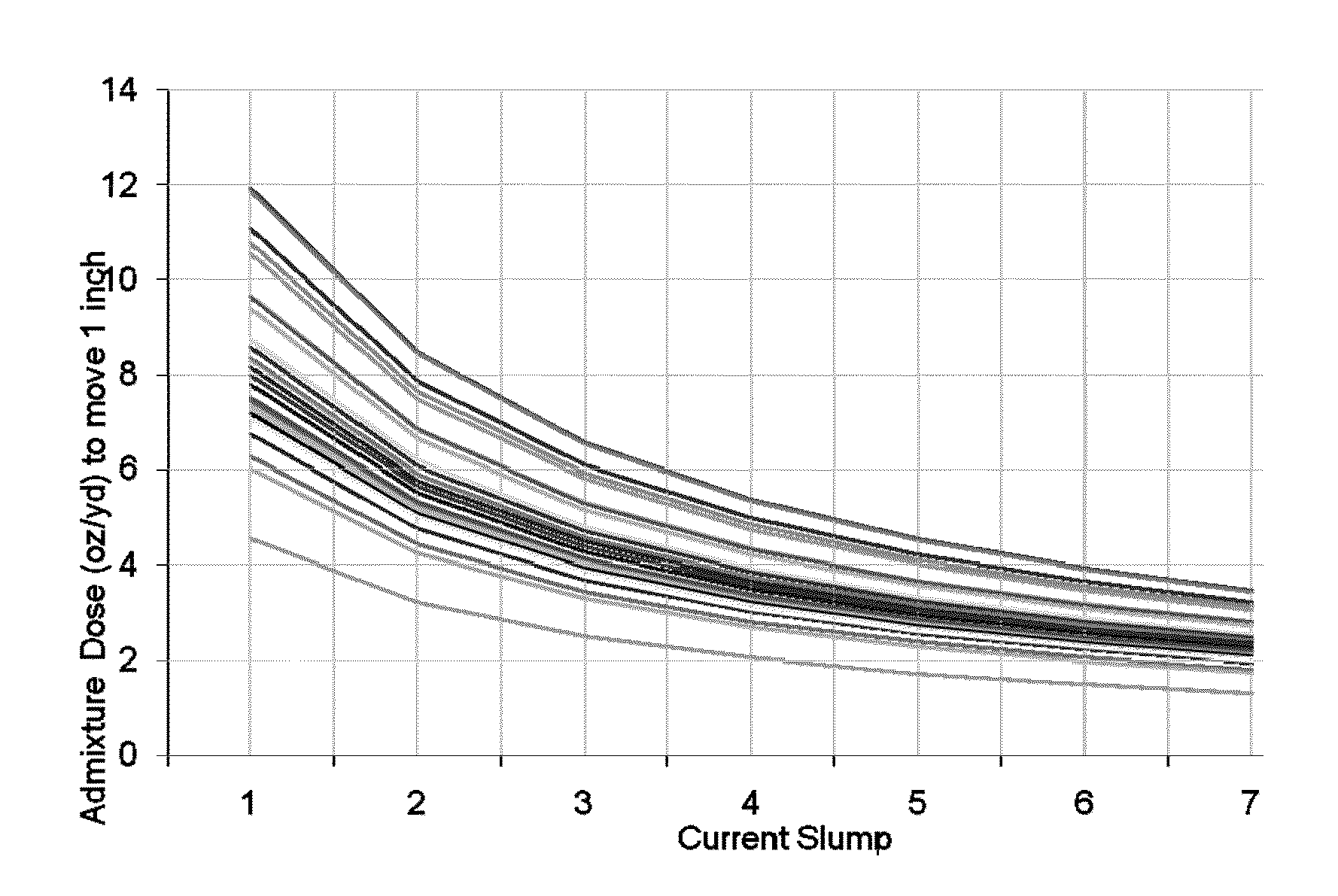

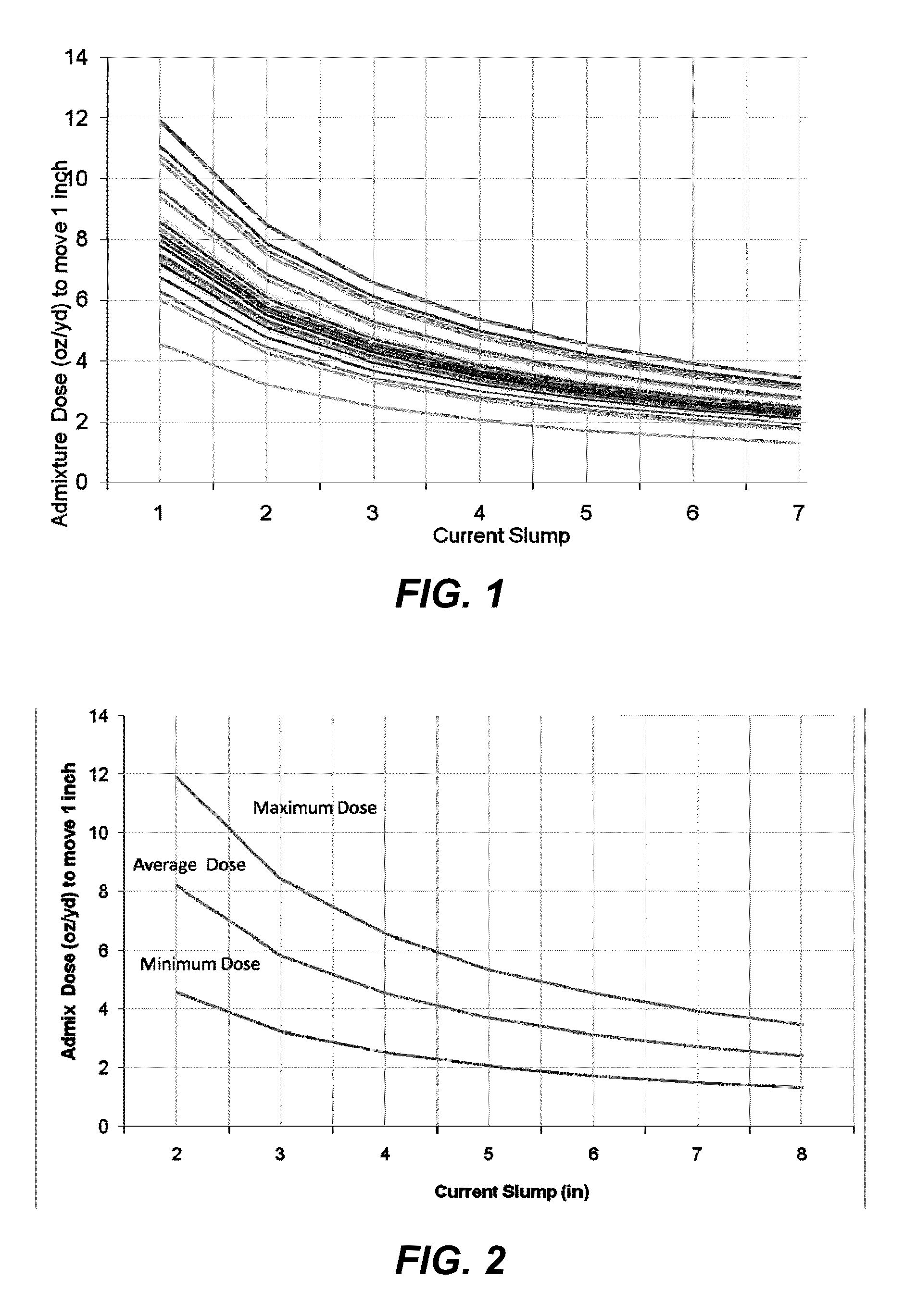

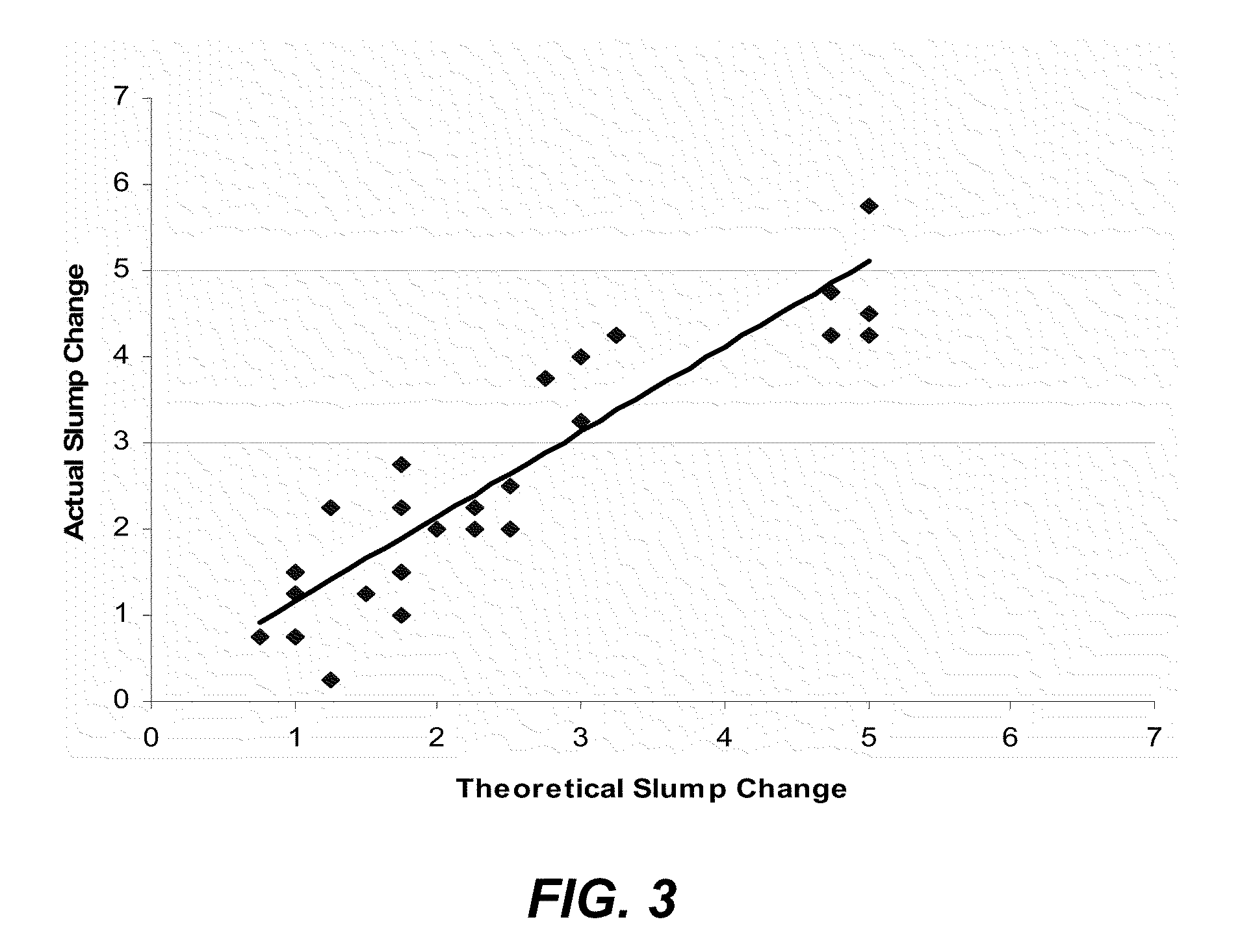

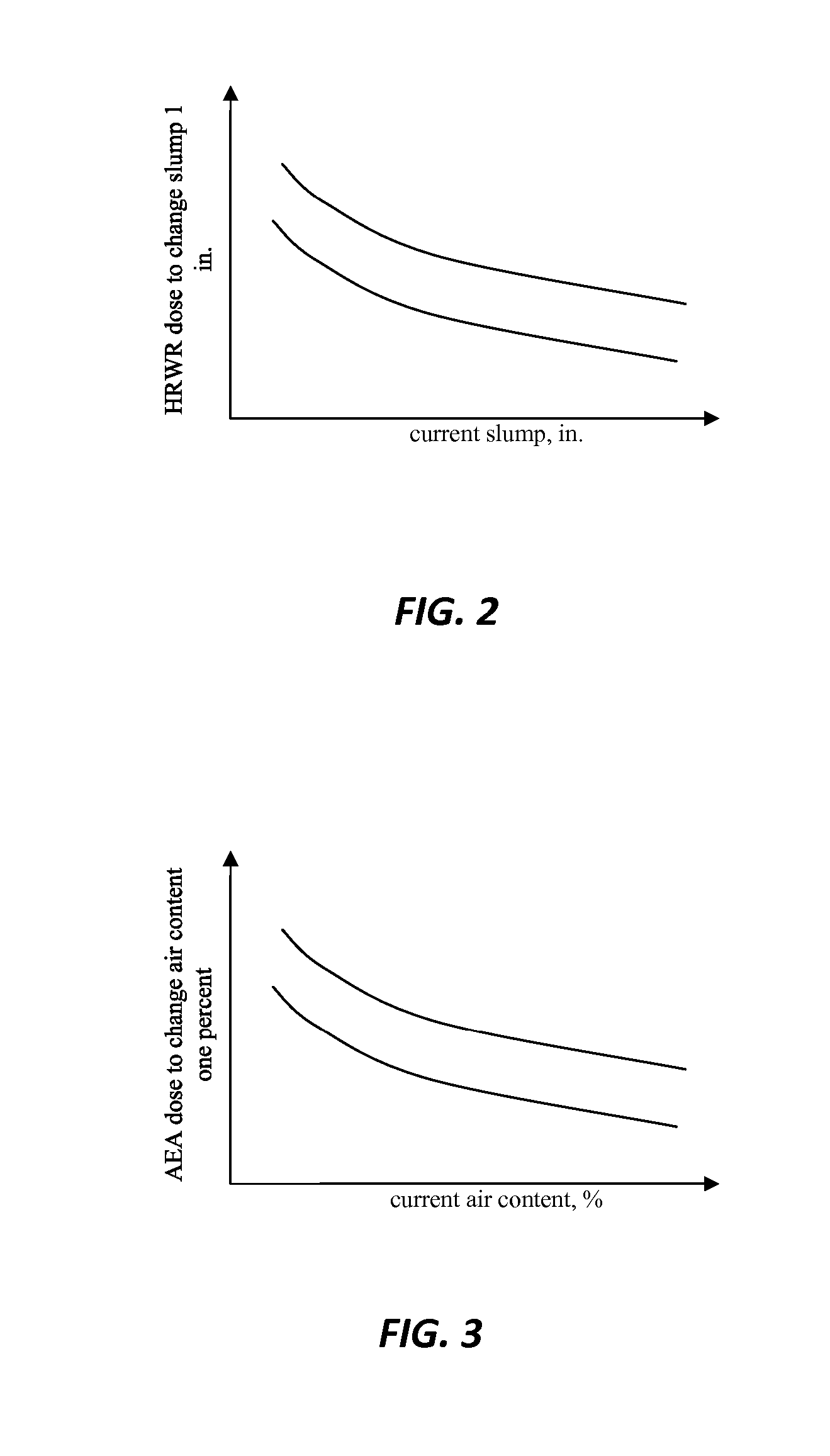

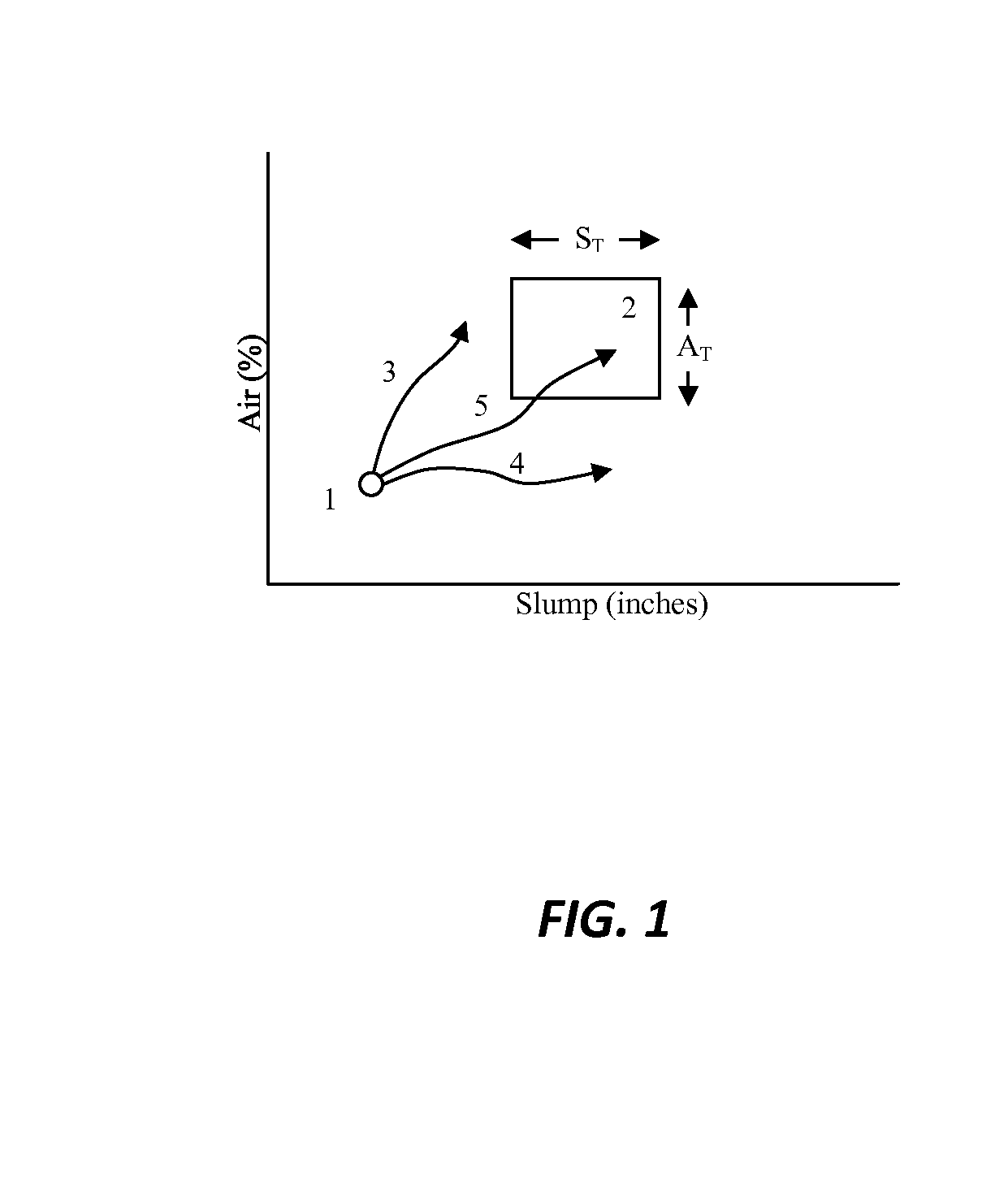

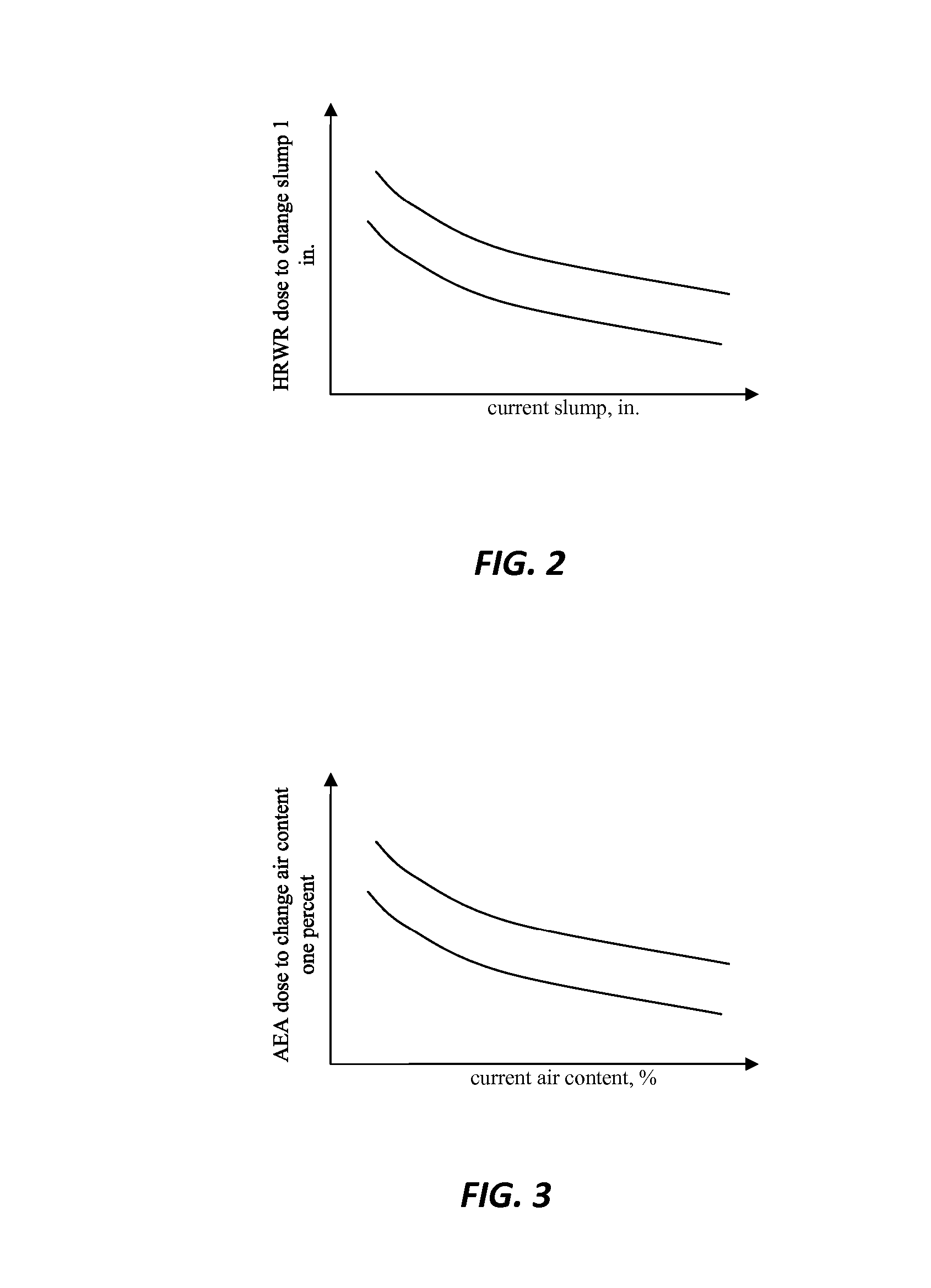

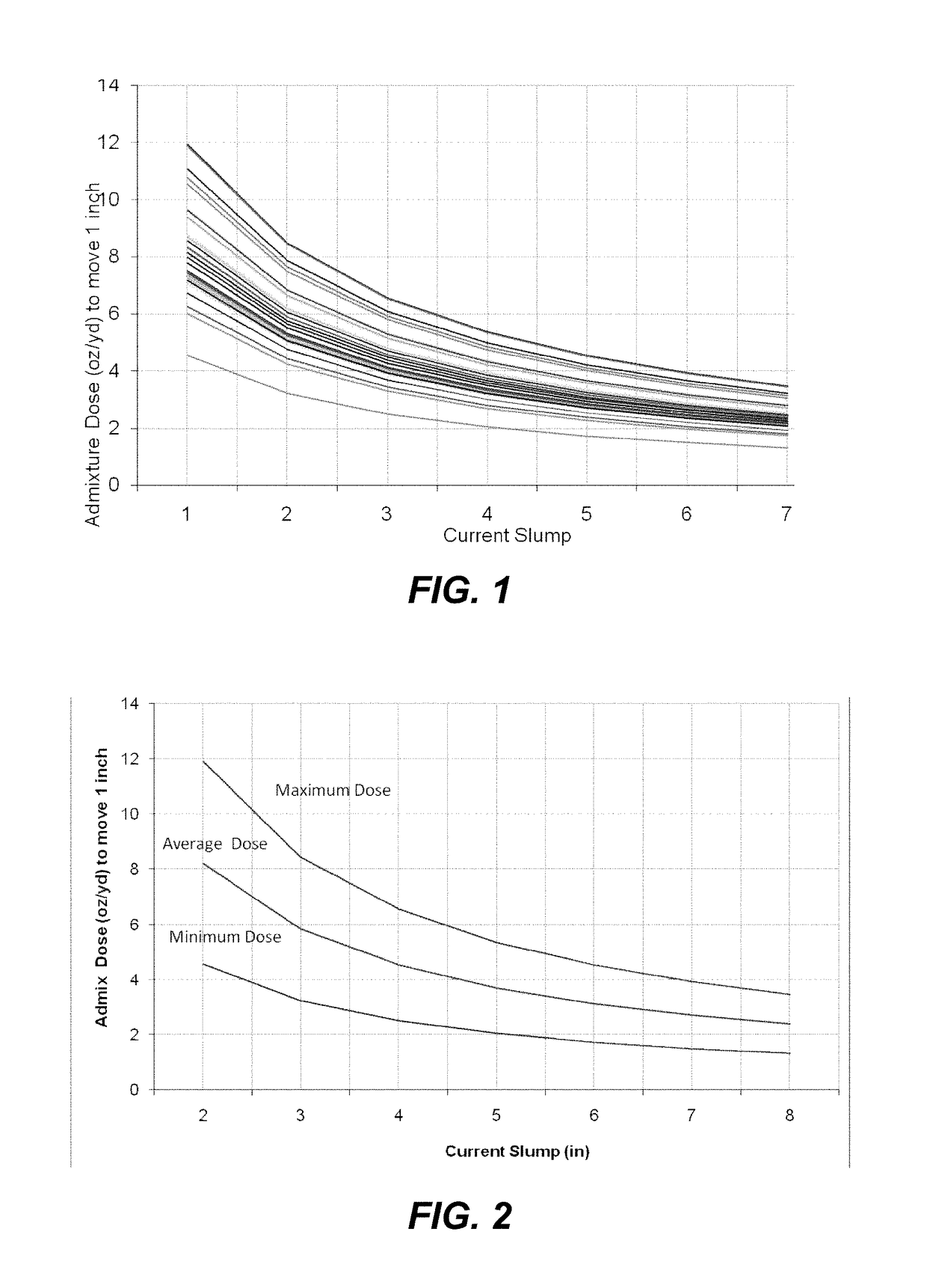

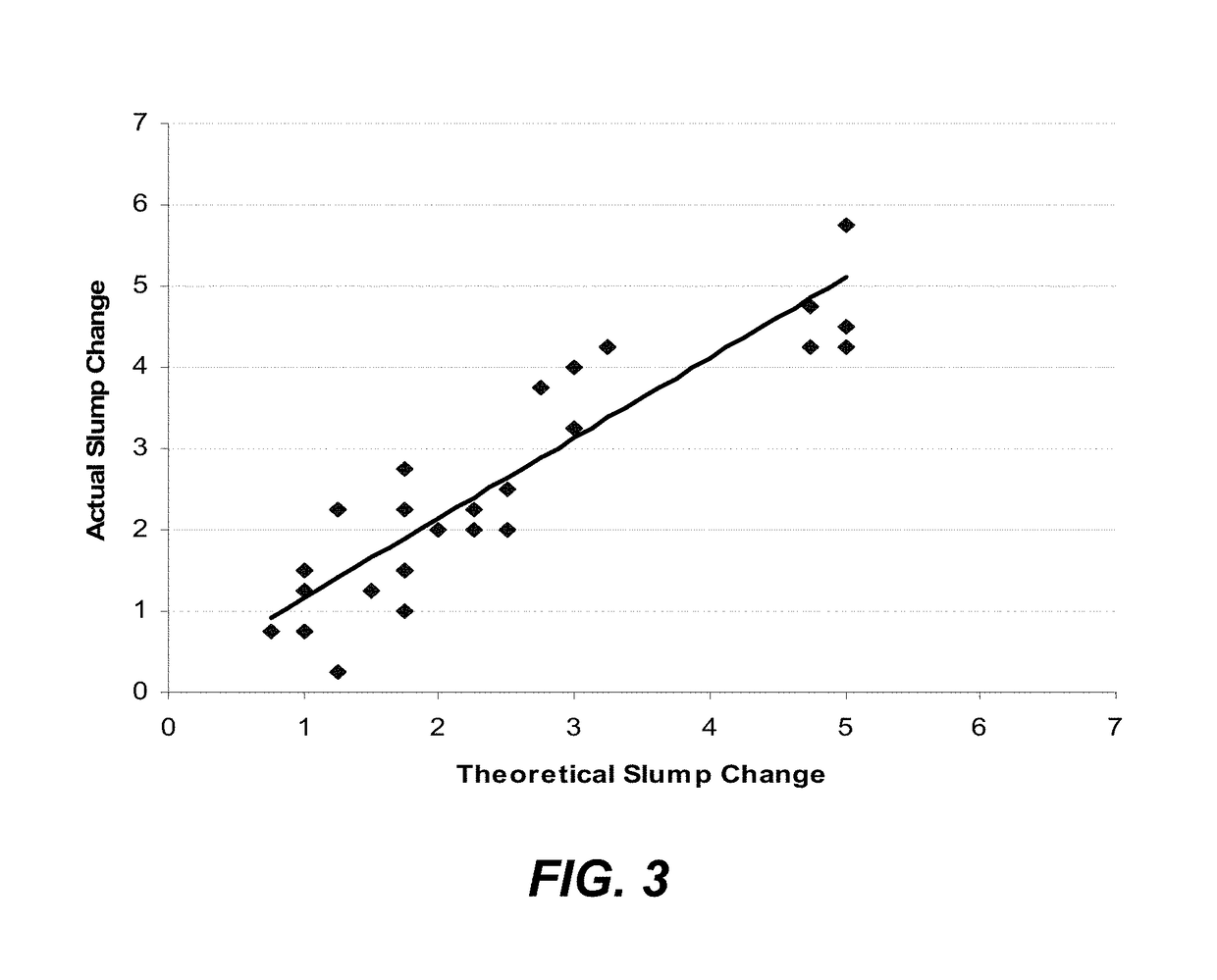

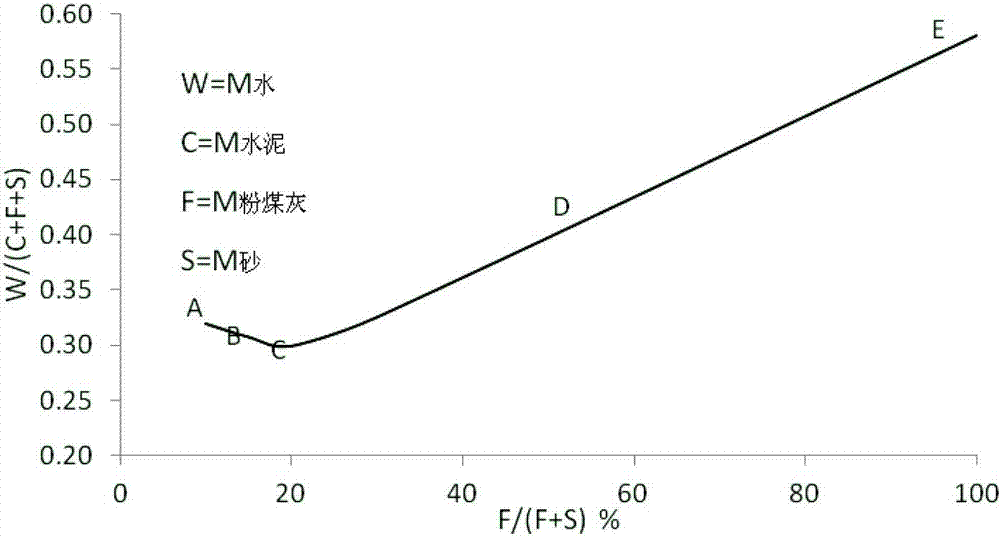

The invention relates to a method for adjusting concrete rheology requiring only that load size and target rheology value be selected initially rather than requiring inputs into and consultation of a lookup table of parameters such as water and hydration levels, mix components, temperature, humidity, aggregate components, and others. Dosage of particular rheology-modifying agent or combination of rheology-modifying agents is calculated based on a percentage of a nominal dose calculated with reference to a nominal dose response (“NDR”) curve or profile. The NDR profile is based on a correlation between a rheology value (e.g., slump, slump flow, yield stress) and the rheology-modifying agent(s) dose required to change rheology value by one unit (e.g., slump change from 2 to 3 inches) such that exemplary methods can employ corrective dosing based on the NDR and the measured deviation by the system.

Owner:VERIFI INC

Slump Flow Monitoring

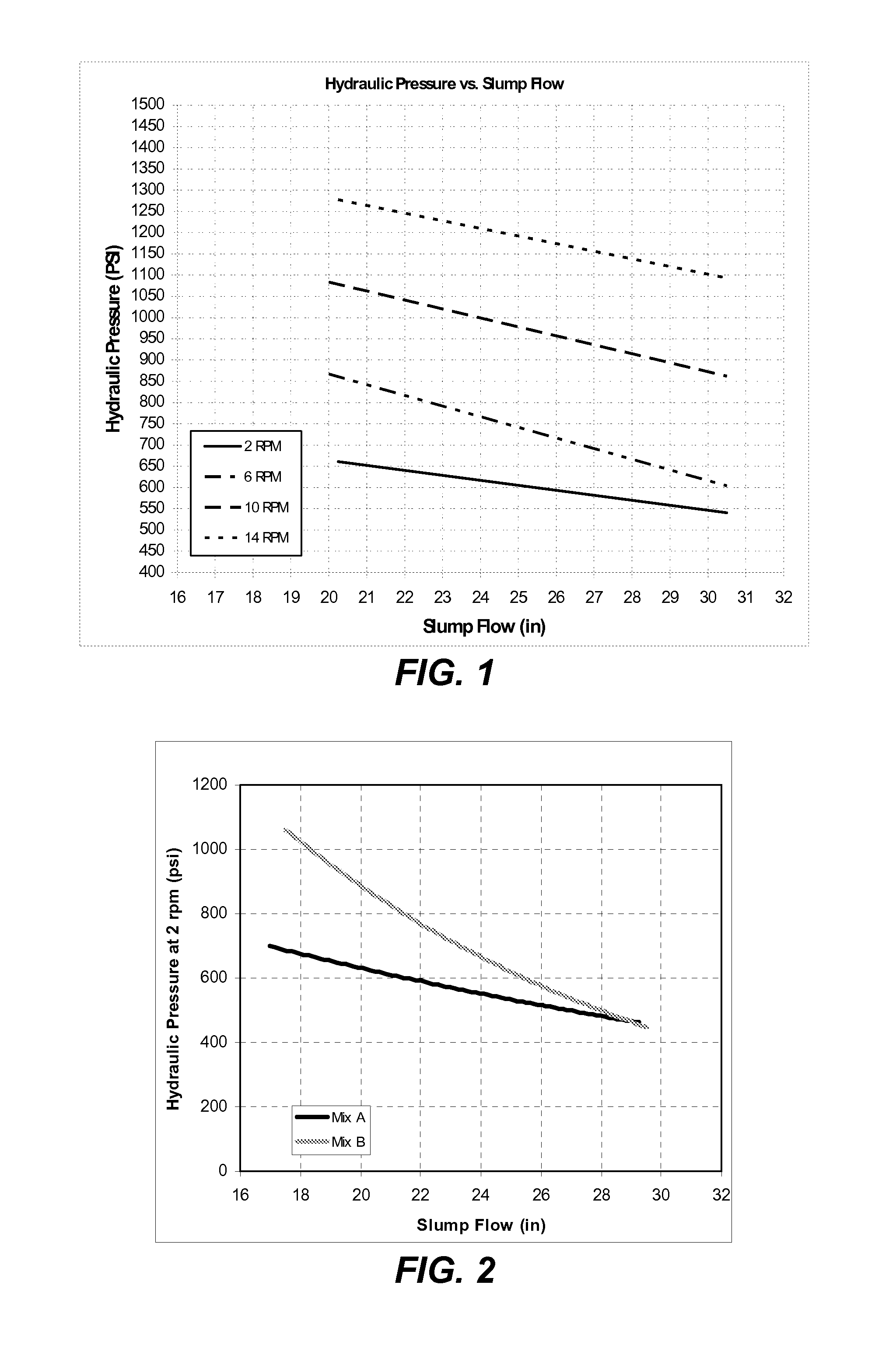

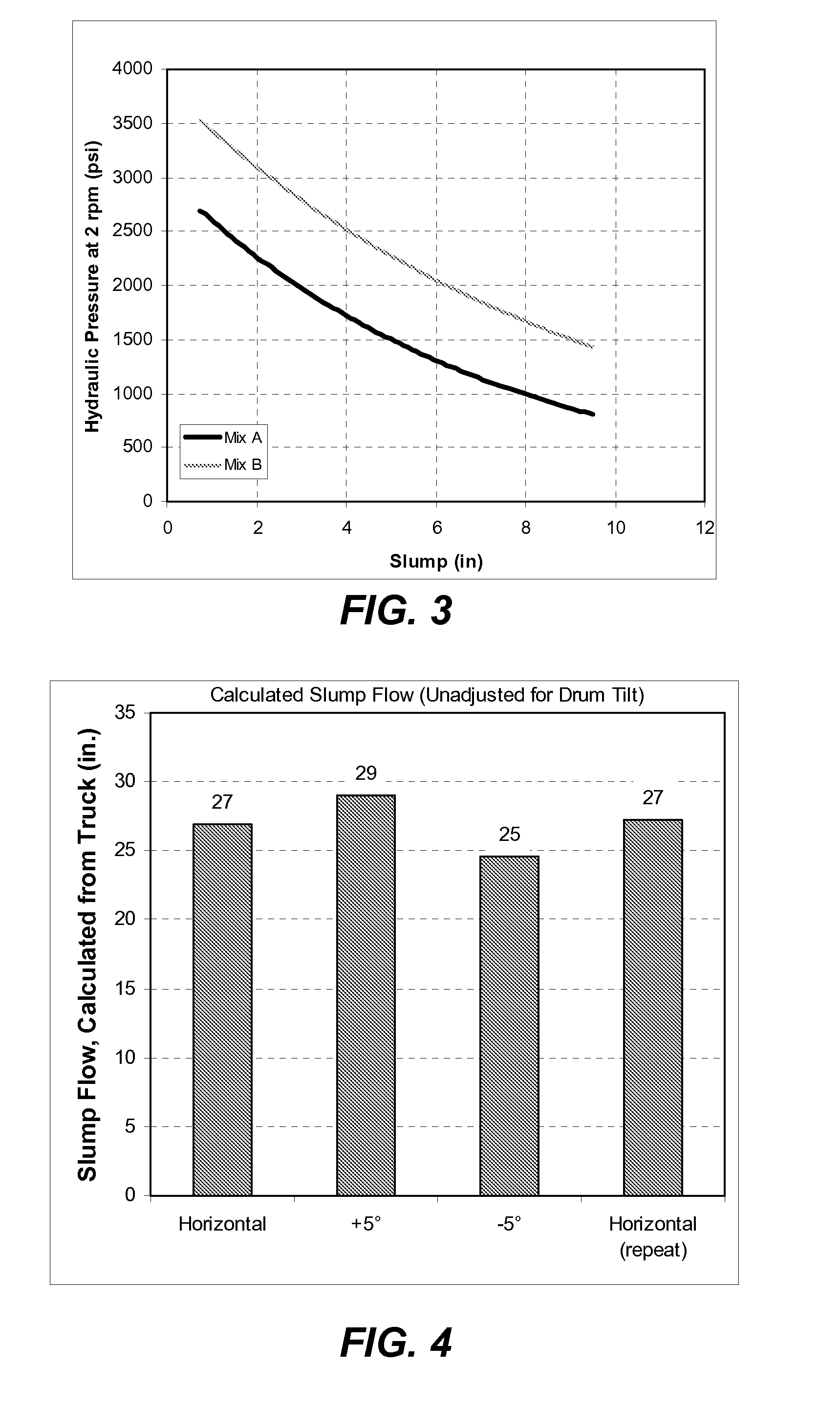

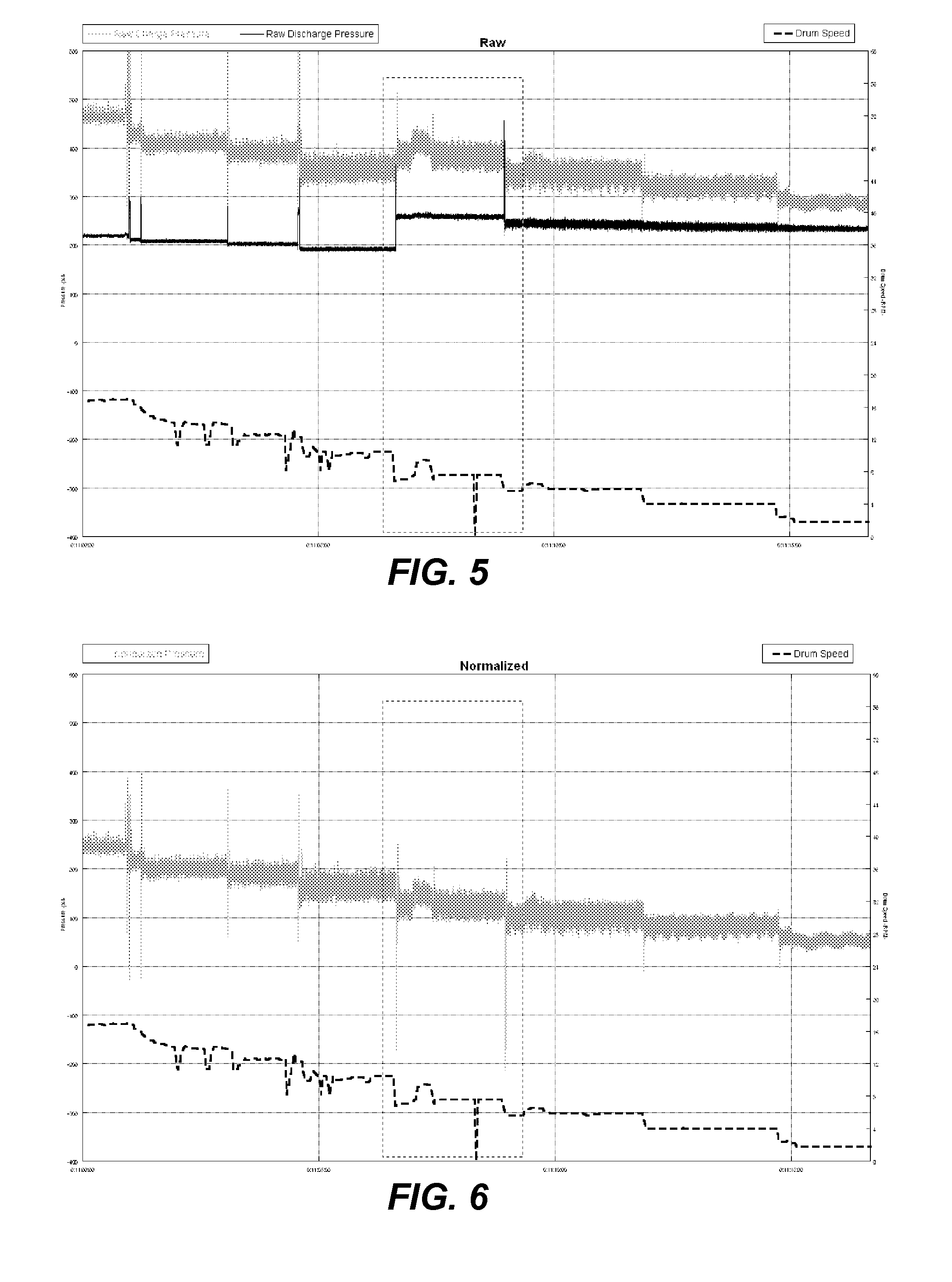

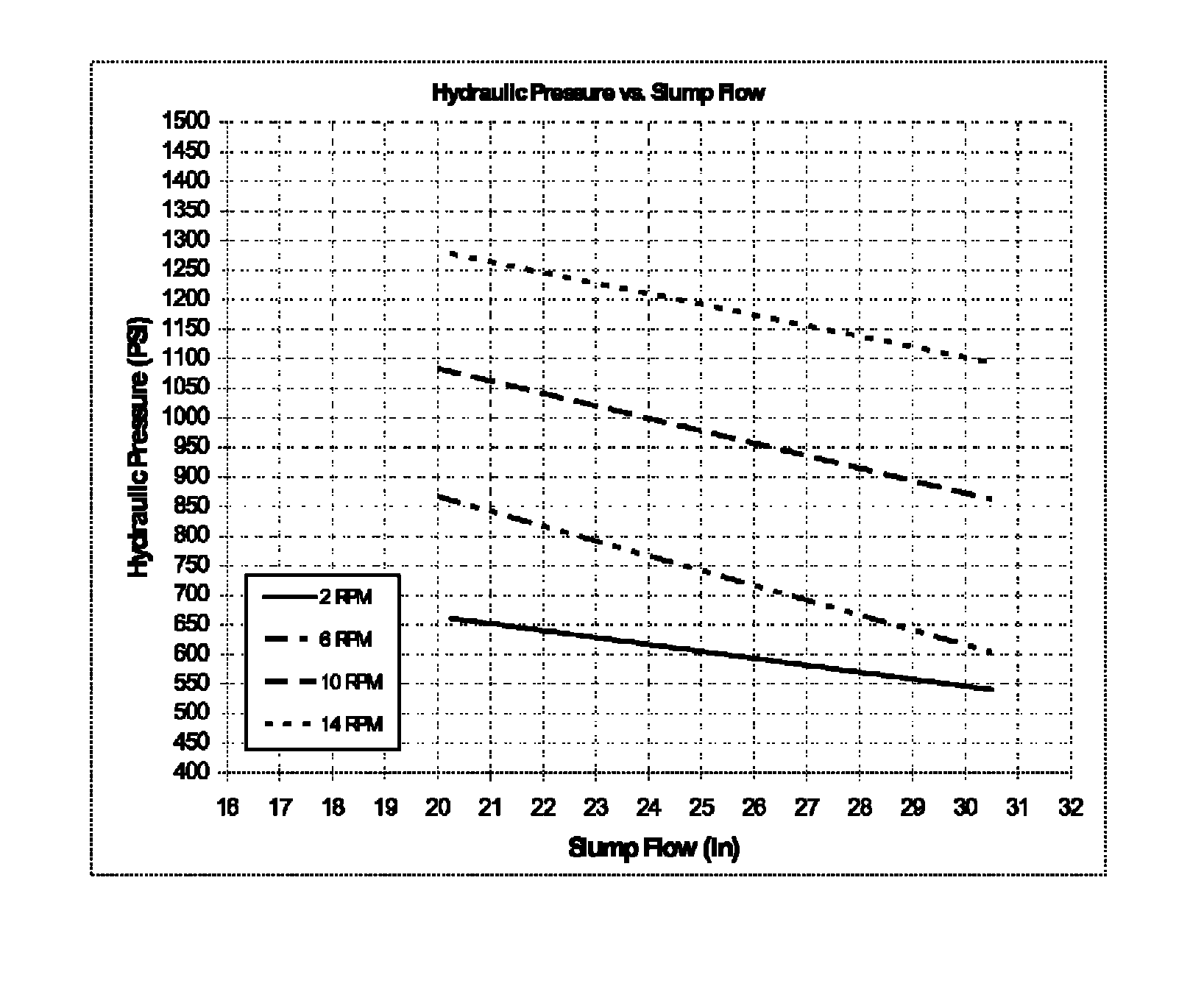

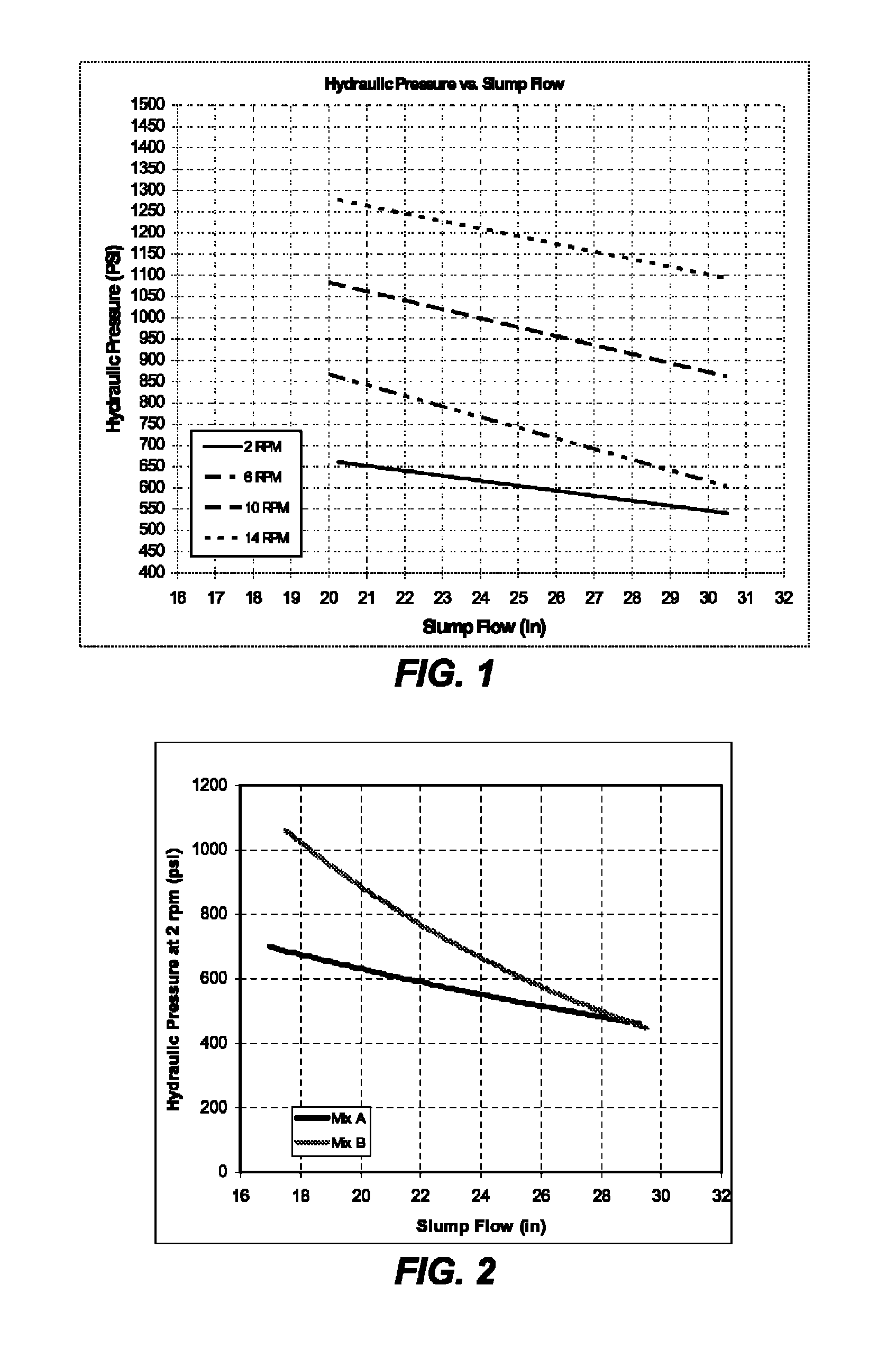

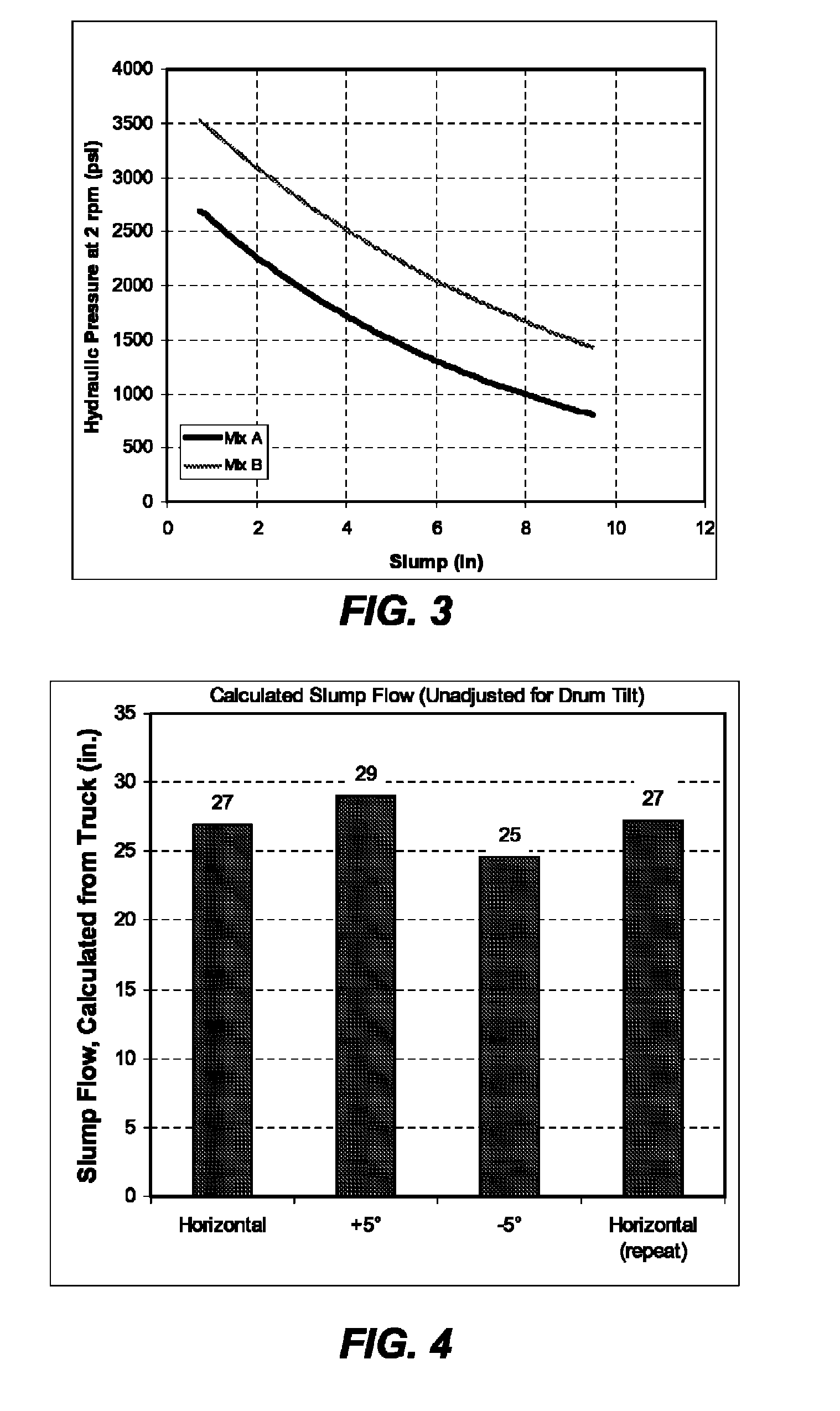

Method and system for monitoring slump flow of hydratable cementitious material such as wet concrete in a rotating mixing drum. Whereas prior art methods use a single value of the hydraulic pressure for turning the drum (such as the average value) and correlating with slump values using the vertical drop measurements of the standard slump test (e.g. ASTM C 143-05), the present invention involves analysis of values corresponding to slump flow of concrete samples, preferably having slump flow values of 16-36 inches when measured using standard slump flow tests (e.g., ASTM C1611-05).

Owner:VERIFI

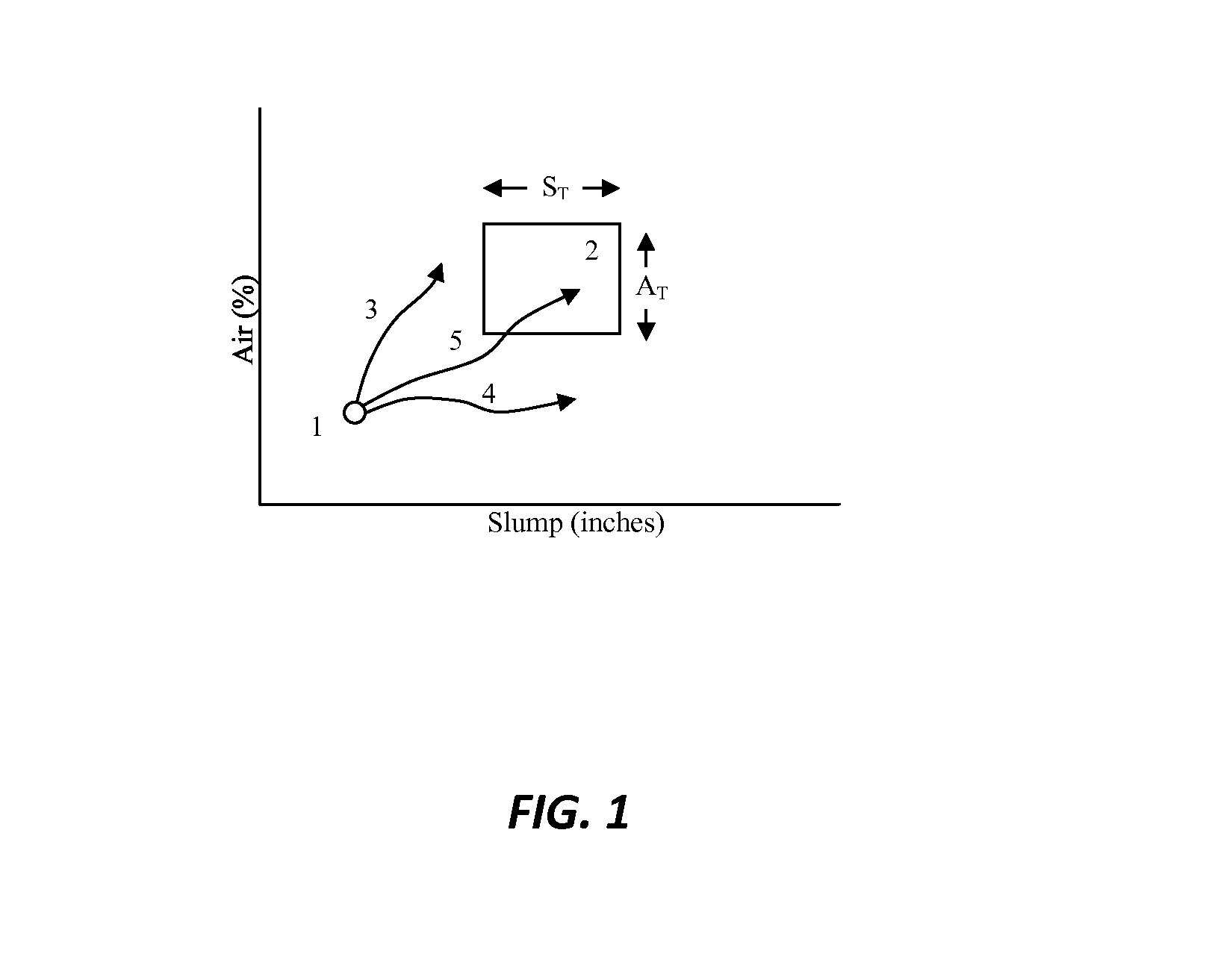

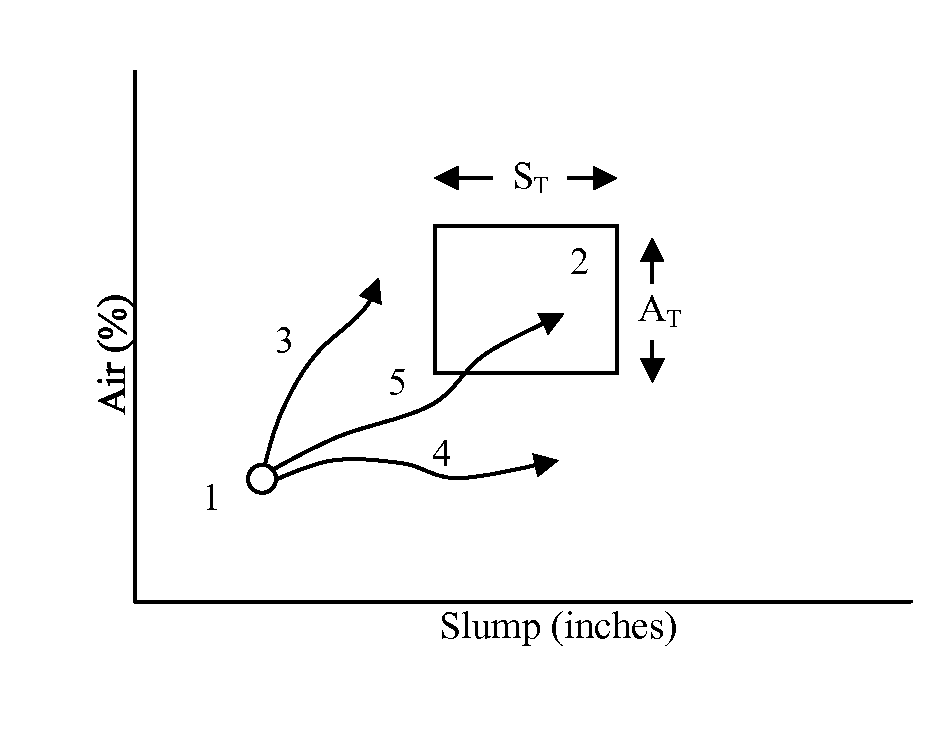

Multivariate management of entrained air and rheology in cementitious mixes

ActiveUS8491717B2Efficiently and accurately updatingHighly inventiveSampled-variable control systemsMixing operation control apparatusHydration reactionBLENDER/MIXER

The invention relates to a method and system for monitoring and adjusting both air content and rheology (e.g., slump, slump flow) properties of a hydratable concrete mix contained within a concrete mixer. The system simultaneously tracks dosage of both rheology-modifying admixture (e.g., polycarboxylate polymer cement dispersant) and air control agent or “ACA” (e.g., air entraining agent) by reference to at least four nominal dose response (“NDR”) curves or profiles, which at least four NDR profiles are based on the respective behaviors of each of the ACA and rheology-modifying agent on air content and rheology.

Owner:VERIFI INC

Slump flow monitoring

Method and system for monitoring slump flow of hydratable cementitious material such as wet concrete in a rotating mixing drum. Whereas prior art methods use a single value of the hydraulic pressure for turning the drum (such as the average value) and correlating with slump values using the vertical drop measurements of the standard slump test (e.g. ASTM C 143-05), the present invention involves analysis of values corresponding to slump flow of concrete samples, preferably having slump flow values of 16-36 inches when measured using standard slump flow tests (e.g., ASTM C1611-05).

Owner:VERIFI INC

Cement dispersant and concrete composition contain the dispersant

[Object] To provide a cement dispersant and a concrete composition containing the cement dispersant, the cement dispersant having a superior effect of decreasing a high concrete paste viscosity while a water reducing effect, a slump flow retention, and rapid strength development are being satisfied in a region having a low water / binder ratio. [Solving Means] The cement dispersant for ultrahigh performance concrete is provided which is a water-soluble amphoteric copolymer obtained by copolymerizing (A) an alkylene oxide adduct of a polyamide polyamine having an unsaturated group, (B) (meta)acrylic acid or a salt thereof, (C) an ester of a short-chain alkylene glycol and (meth)acrylic acid, and (D) an ester of a long-chain alkylene glycol and (meth)acrylic acid at ratios A:B:C:D of 5 to 25:5 to 30:5 to 40:20 to 80 (percent by weight), in which the total is 100% percent by weight. In addition, the concrete composition containing the above cement dispersant is provided.

Owner:TOHO CHEM IND +1

Cement dispersant and concrete composition containing the dispersant

A cement dispersant (especially a dispersant for concretes with ultrahigh performance) comprising as a main component a water-soluble amphoteric copolymer obtained by copolymerizing (A) a polyamide-polyamine of an alkylene oxide adduct thereof with (B) (meth)acrylic acid or an alkali metal, ammonium, or alkanolamine salt thereof and (C) a polyalkylene glycol ester of (meth)acrylic acid in an A / B / C ratio of (10-40) / (10-40) / (50-80) (wt. %); and a concrete composition (especially an ultral high-performance concrete) containing the dispersant. The dispersant satisfies all of a water-reducing effect, slump flow retention, strength development, etc.

Owner:TOHO CHEM IND

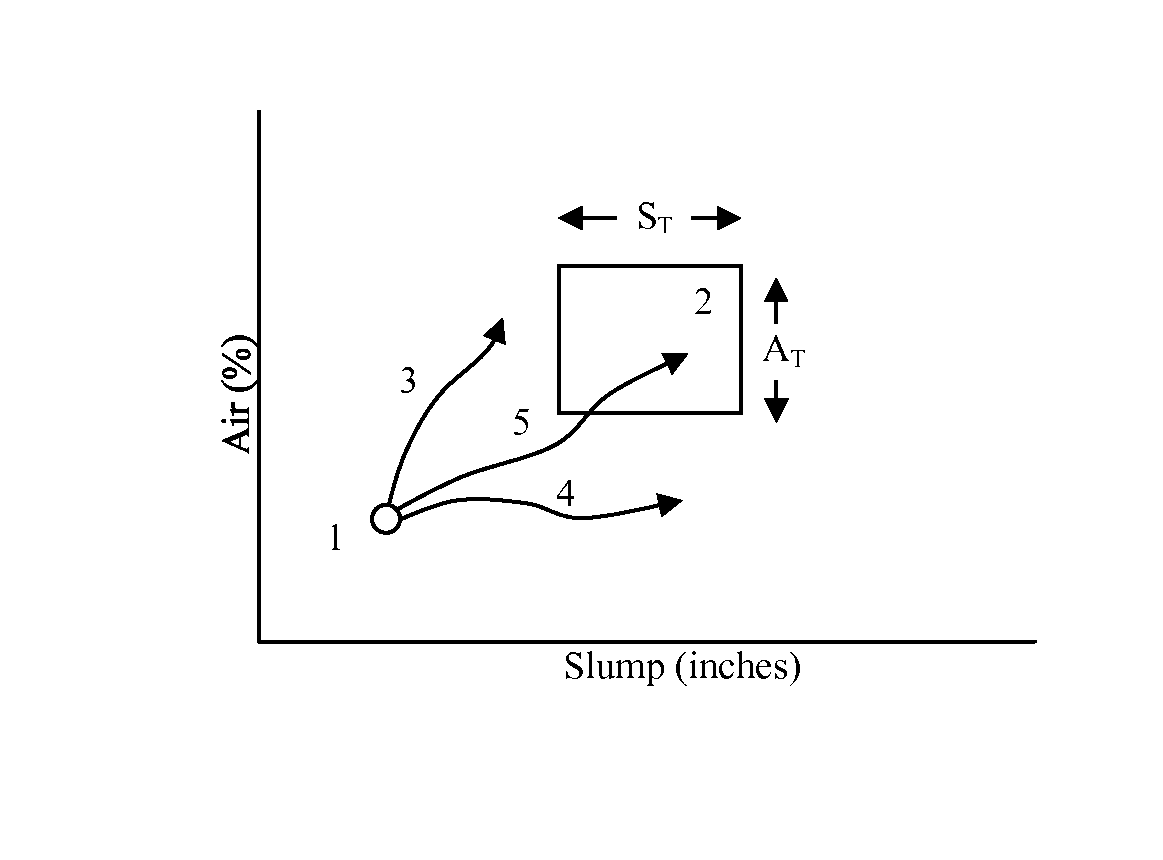

Mixer waveform analysis for monitoring and controlling concrete

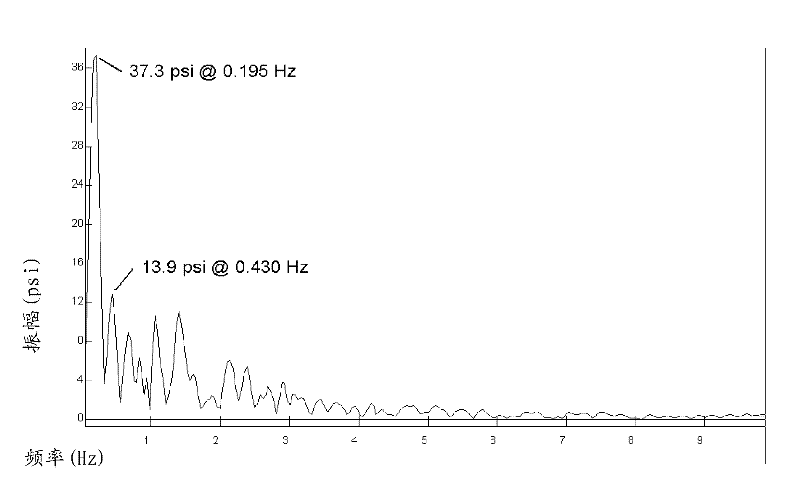

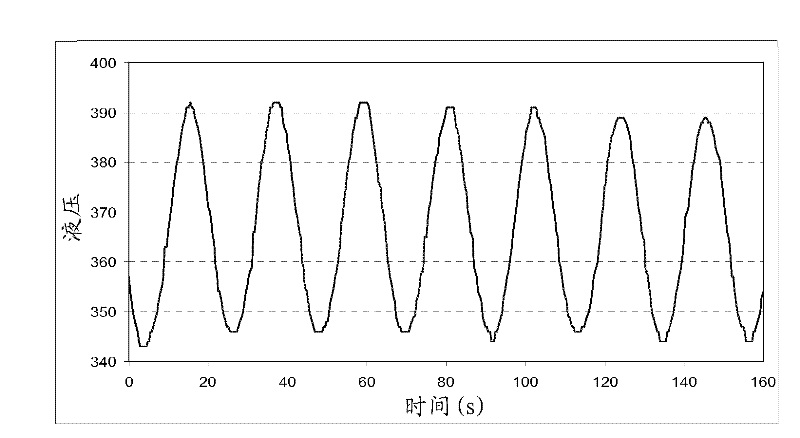

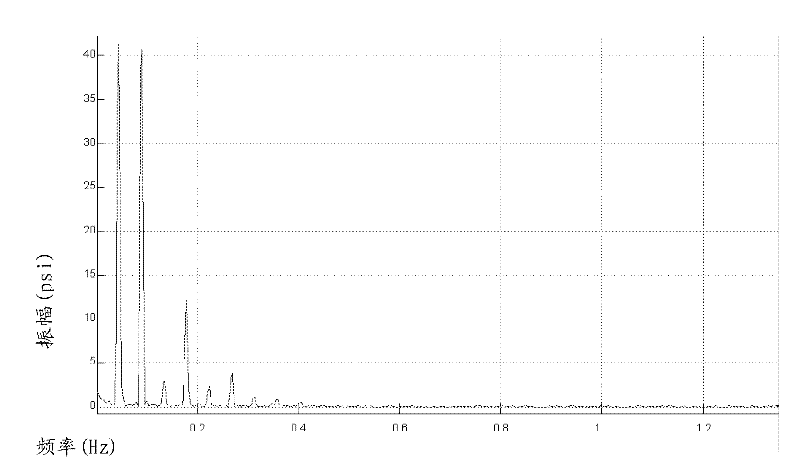

ActiveUS20120020180A1Quick fixEasy to adjustSampled-variable control systemsMixing operation control apparatusWaveform analysisTime domain

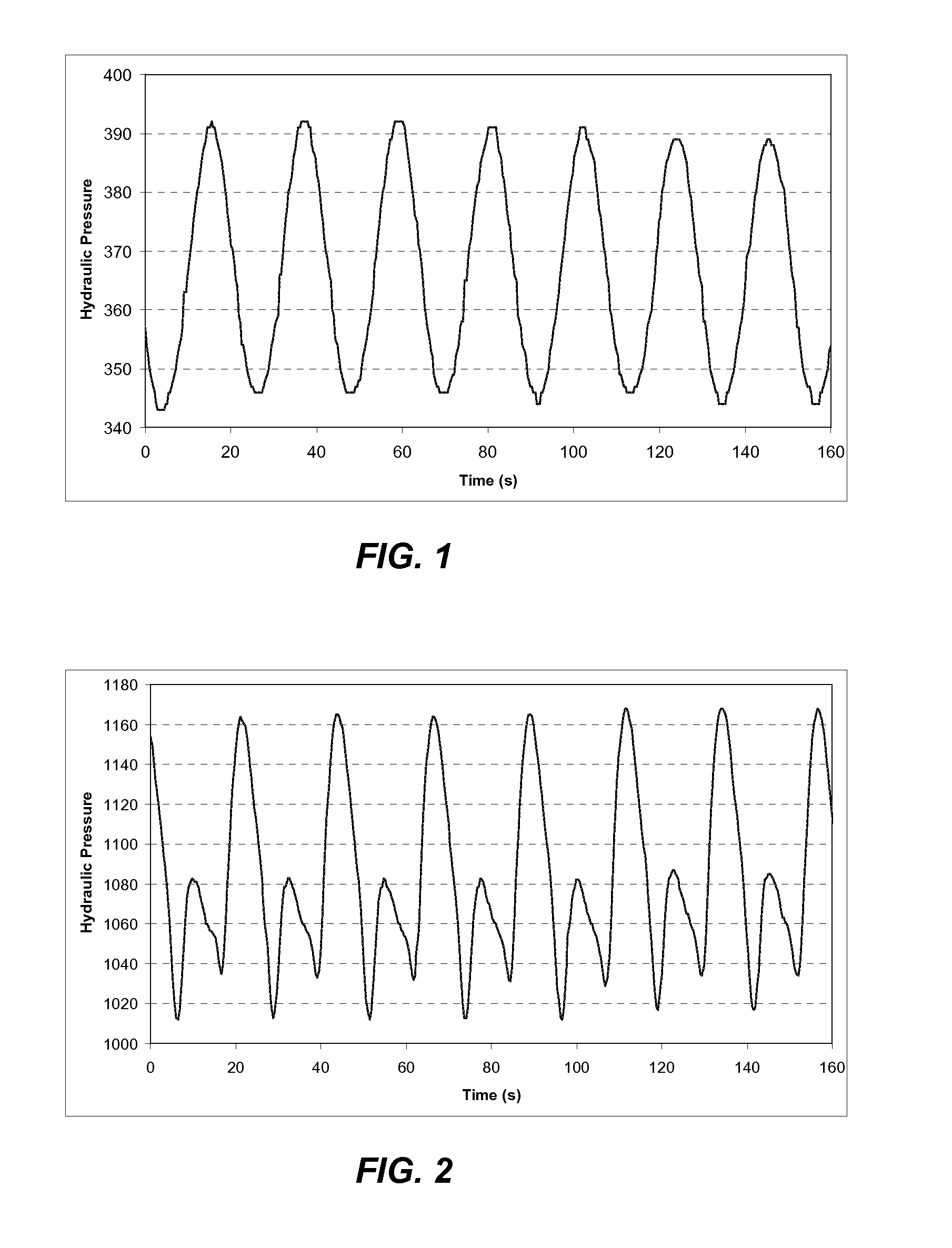

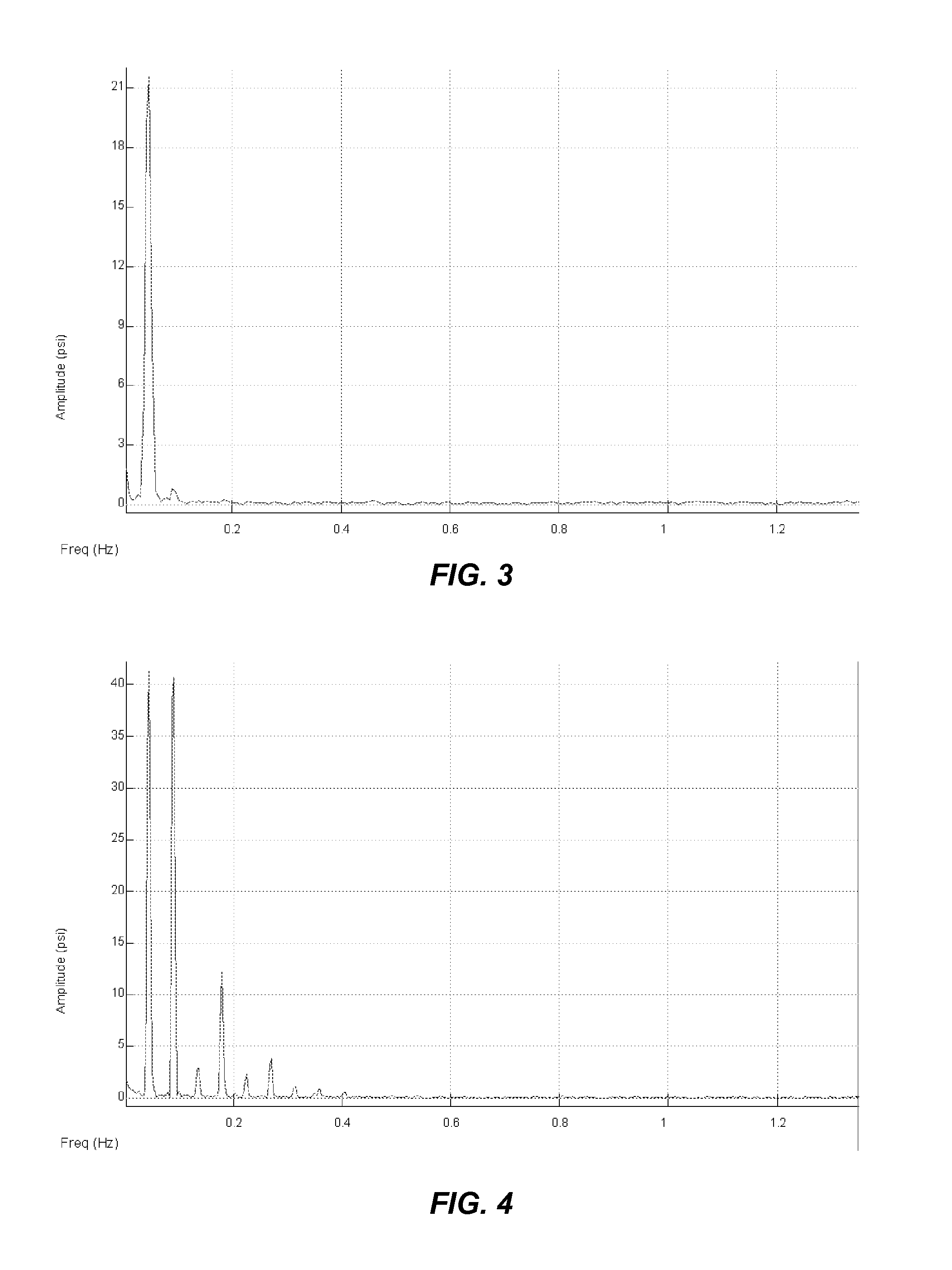

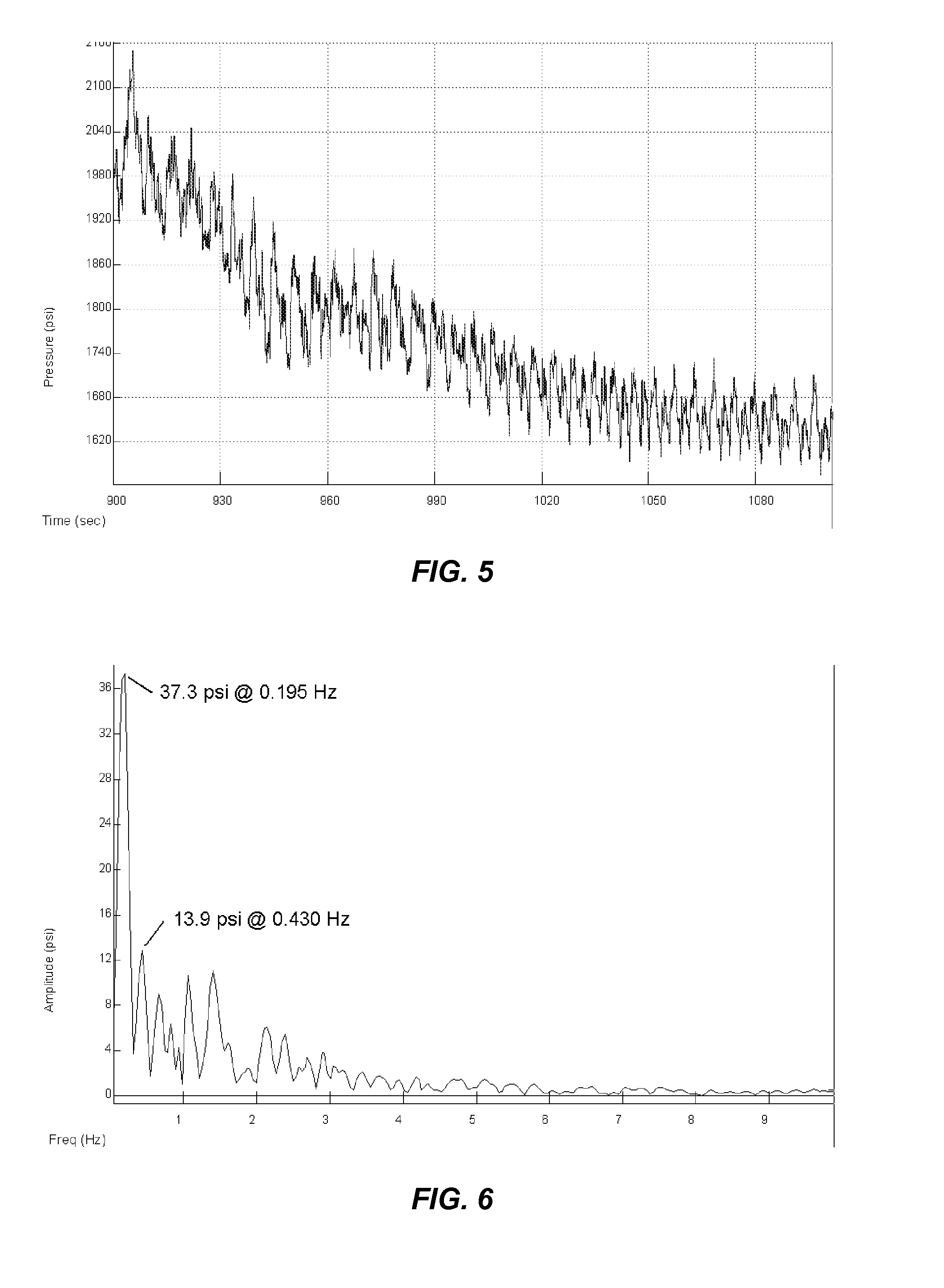

Method and system for motoring and obtaining information about quantity and characteristics of cementitious material In a rotating mixing drum. The present invention involves analysis of a sequence of values corresponding to a waveform reflecting the hydraulic pressure required to turn a concrete mixing drum at successive instances during rotation. Preferred embodiments involve the conversion of this time-domain data into the frequency-domain. Behavior of multiple harmonics can be examined in real time and further information obtained regarding physical properties of the concrete. Rheology or other properties can be adjusted by introducing a liquid into the concrete, based on a comparison between time-domain and / or frequency-domain values derived from a sample concrete in the drum and previously stored time-domain and / or frequency-domain values, which are preferably correlated with physical characteristics of concrete, such as slump, slump flow, load weight, and other factors.

Owner:VERIFI

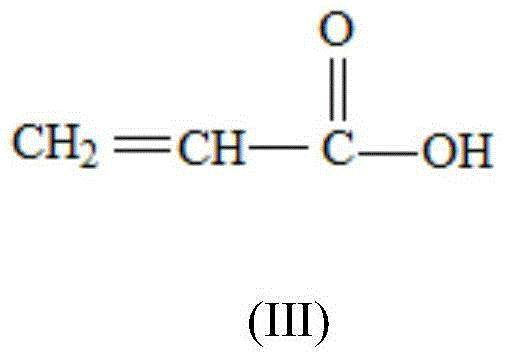

High-adaptability and high-performance polycarboxylic water-reducing agent and preparation method for same

The invention discloses a high-adaptability and high-performance polycarboxylic water-reducing agent, which is obtained by polymerizing a monomer a (methyl allyl polyethenoxy ether or methyl butyl polyethenoxy ether), a monomer b (acrylic acid) and a monomer c (one or a mixture of more than two of maleic anhydride, methacrylic acid, sodium methallyl sulfonate and the like) in an aqueous solution system under the action of an initiator. The prepared high-performance polycarboxylic water-reducing agent has high adaptability with cement, and also has higher adaptability with concrete aggregate, particularly concrete prepared from manufactured sand; compared with an ordinary polycarboxylic water-reducing agent, the prepared polycarboxylic water-reducing agent has the advantages that the slump flow of concrete is higher under the condition that the slump of the concrete is kept the same, and the concrete can freely flow more favorably.

Owner:CCCC FOURTH HARBOR ENG INST +3

Multivariate management of entrained air and rheology in cementitious mixes

ActiveUS20130145967A1Efficiently and accurately updatingHighly inventiveCement mixing apparatusControl apparatusRheometryAir entrainment

The invention relates to a method and system for monitoring and adjusting both air content and rheology (e.g., slump, slump flow) properties of a hydratable concrete mix contained within a concrete mixer. The system simultaneously tracks dosage of both rheology-modifying admixture (e.g., polycarboxylate polymer cement dispersant) and air control agent or “ACA” (e.g., air entraining agent) by reference to at least four nominal dose response (“NDR”) curves or profiles, which at least four NDR profiles are based on the respective behaviors of each of the ACA and rheology-modifying agent on air content and rheology.

Owner:VERIFI

Non-dispersible concrete for underwater and underground construction

InactiveUS20080257221A1Low costImprove pore structureSolid waste managementCoatingsFineness modulusSuperplasticizer

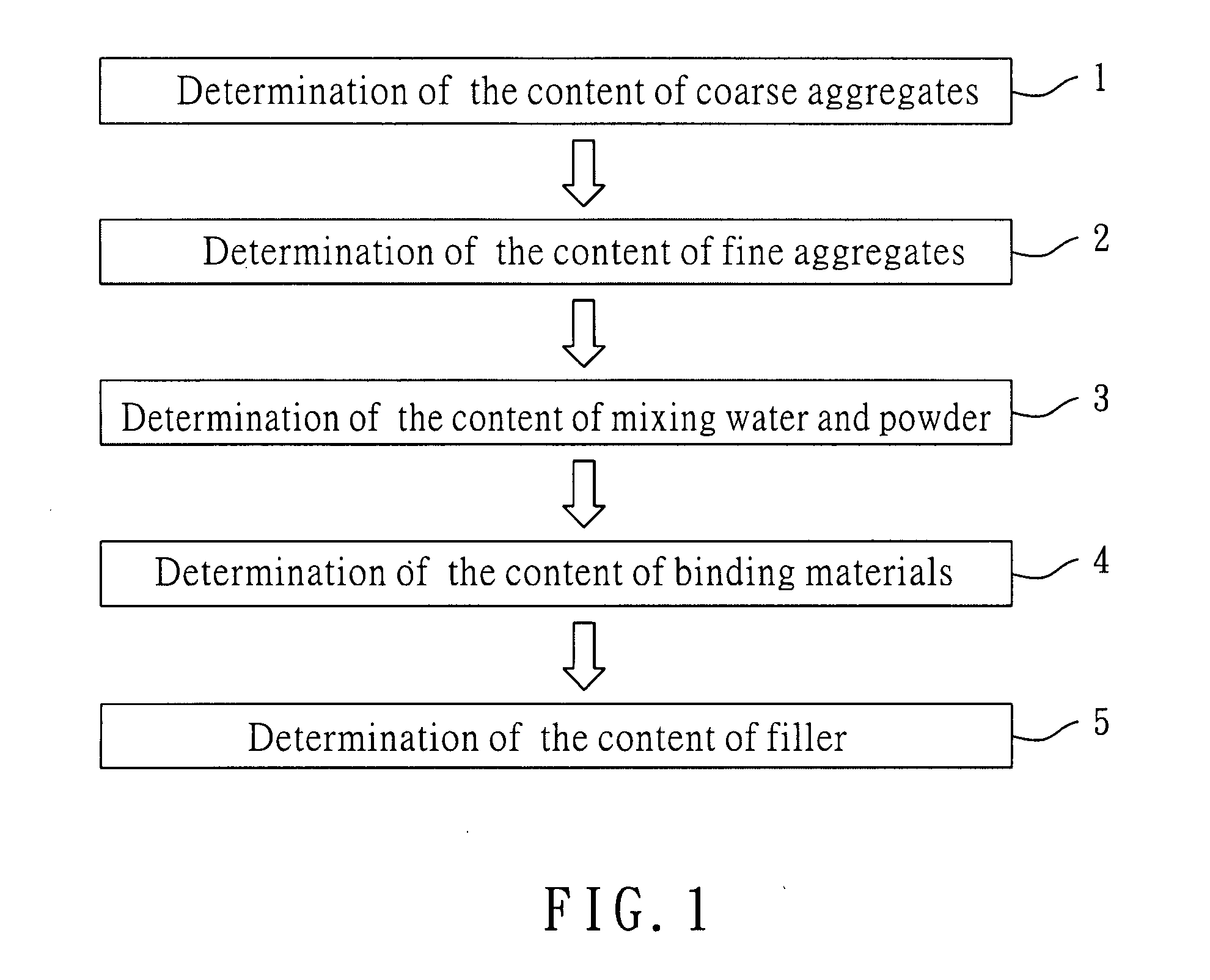

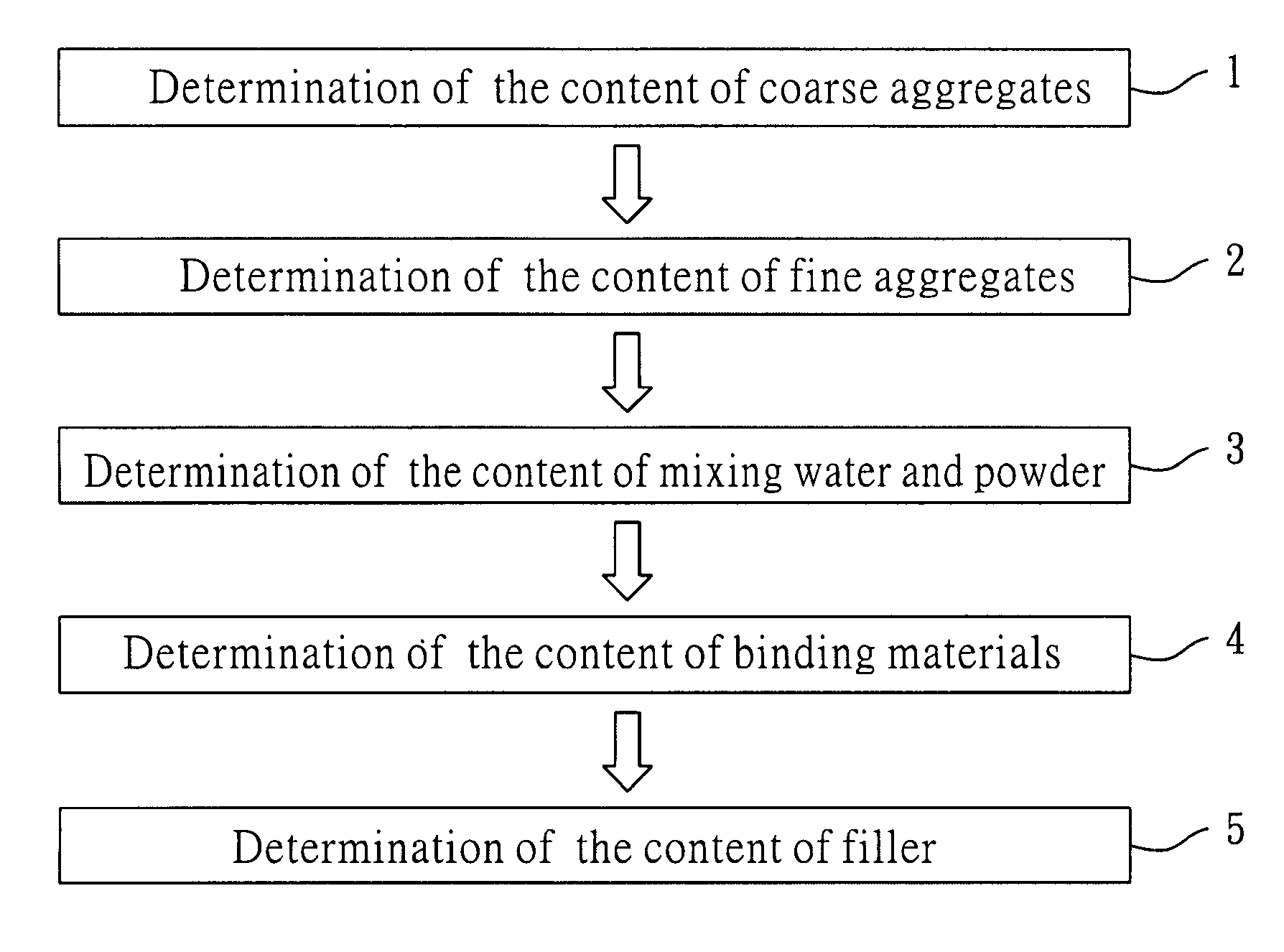

A non-dispersible concrete for underwater and underground construction is disclosed, whose composition primarily comprises: coarse aggregate in a range of from 600 to 1200 kgw / m3; fine aggregate 500 to 1100 kgw / m3, with a fineness modulus (F.M.) in a range of from 2.2 to 3.2; powder 300 to 700 kgw / m3; mixing water 140 to 300 kgw / m3; and cohesion-enhancing admixture (for example, polyacrylamide, PAA) whose solid content is 0.1 to 5.0 wt % of the powder. In addition, a SCC for underwater and underground construction is also developed and has excellent property of self-consolidation (its test value is 400 to 750 mm in slump flow spread test) and an appropriate compressive strength (between 14 to 70 MPa), so as can be widely applied to underwater and underground construction, whose composition further includes superplasticizer with solid content 0.1 to 3.0 wt % of the powder. Also, it covers: water to binder ratio (W / B) of 0.22 to 1.00, paste volume 0.25 to 0.60 m3, and water / powder volume ratio 0.5 to 2.95.

Owner:JAU WEN CHEN

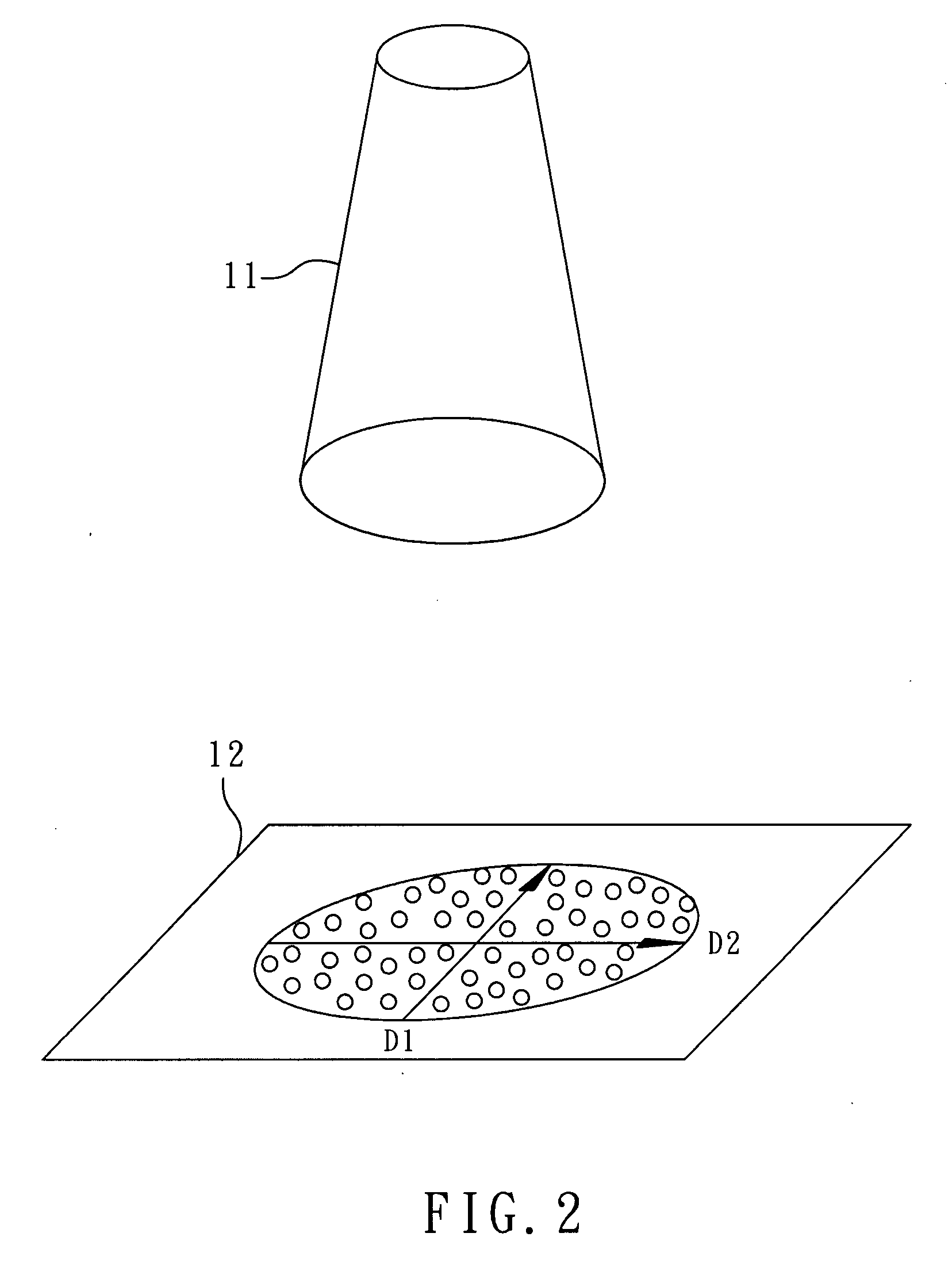

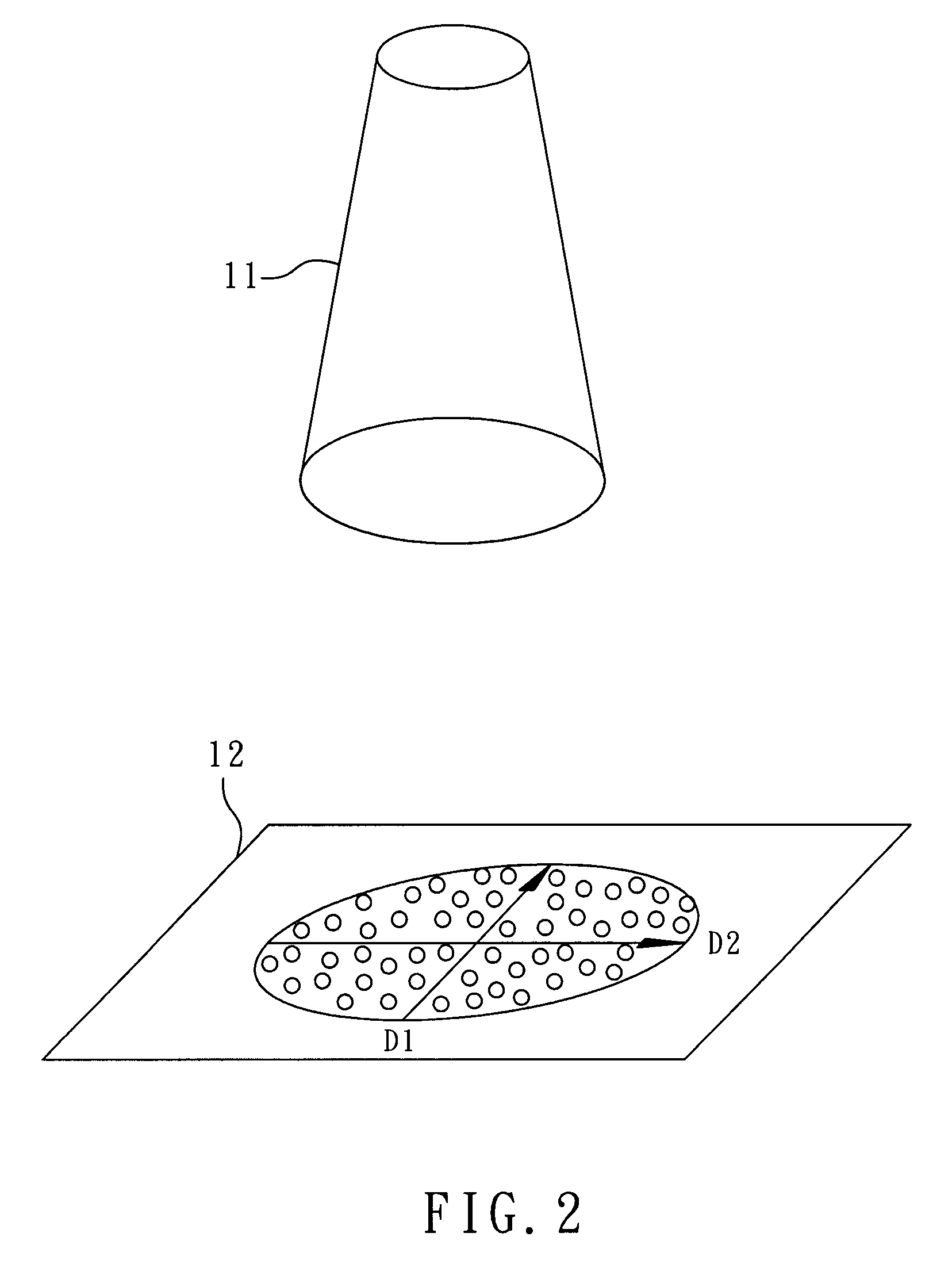

Automatic testing system used for testing fresh mixing performance of concrete

ActiveCN103196794AComprehensive work assessmentEasy to installFlow propertiesMaterial analysis by optical meansCrack resistanceSimulation

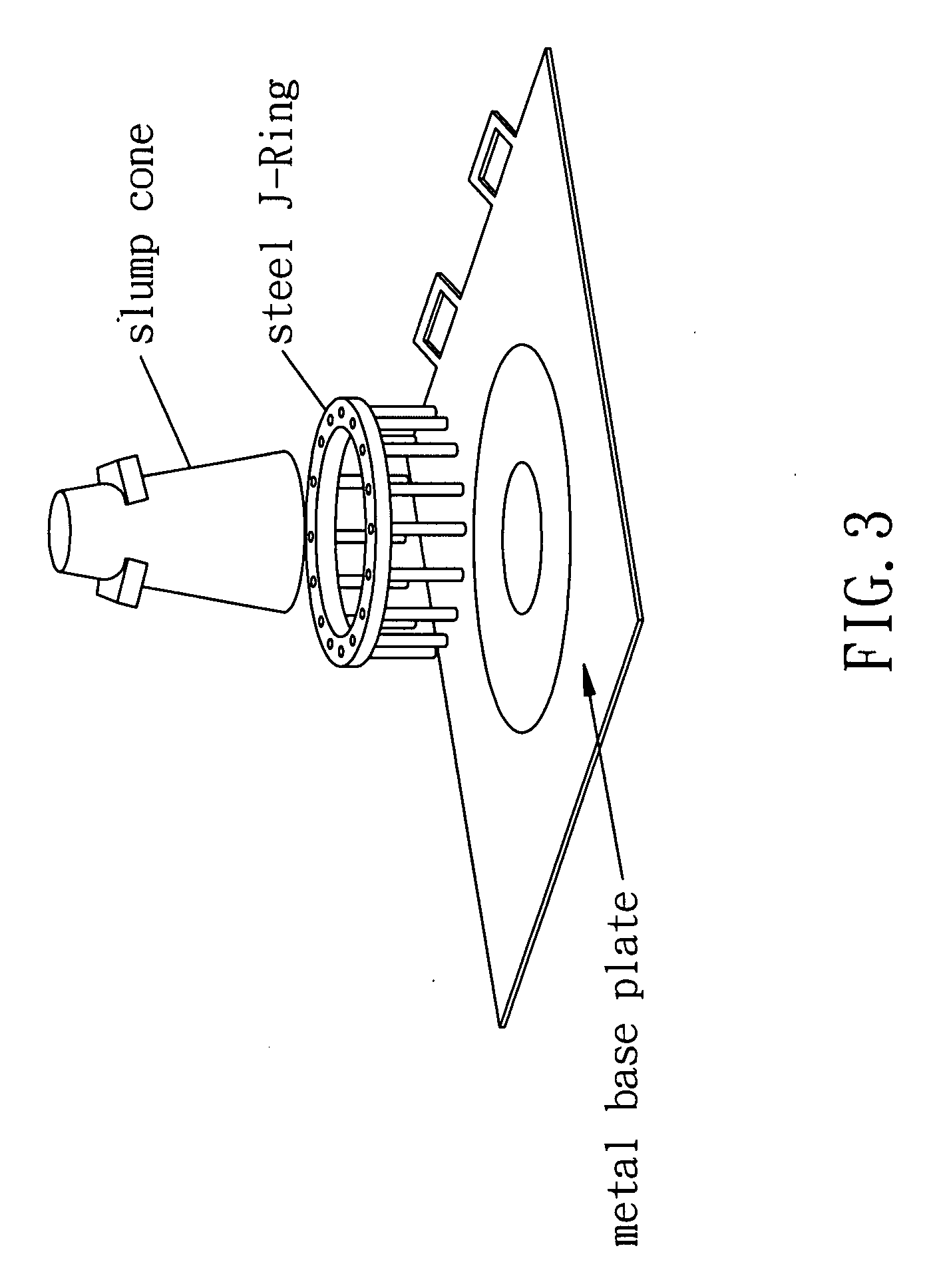

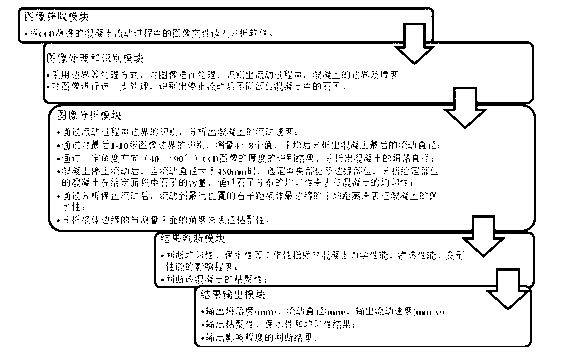

The invention provides an automatic testing system used for testing the working performance of freshly mixed concrete, and is used for solving the problem that the working performance of the concrete can only be tested by slump and visual inspection currently and the working performance of the concrete can not be accurately and comprehensively evaluated. The automatic testing system comprises a charge coupled device CCD image collection sensor, a mounting bracket and a data processing system, wherein the data processing system comprises an image obtaining module, an image processing and identifying module, an image analyzing module, a result judging module and an output module. When being used for performing automatic flow tests such as slump according to the national standard, the automatic testing system provided by the invention can be used for accurately and comprehensively obtaining the working performance of the concrete including the slump, slumping flow diameter, flow velocity, uniformity, water-retaining property, and the like, and the automatic testing system can be also used for researching the effect degrees of mechanical property, crack resistance and permeability according to the built-in working performance so as to comprehensively master and evaluate the working performance of the concrete to provide a reference frame for controlling the concrete quality on construction sites.

Owner:SOUTHEAST UNIV

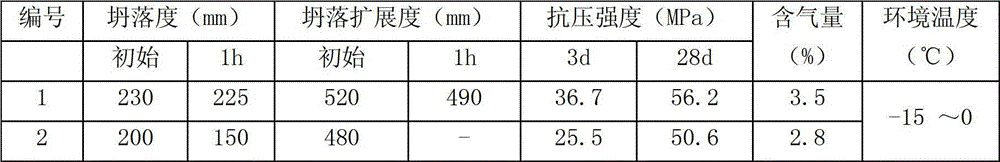

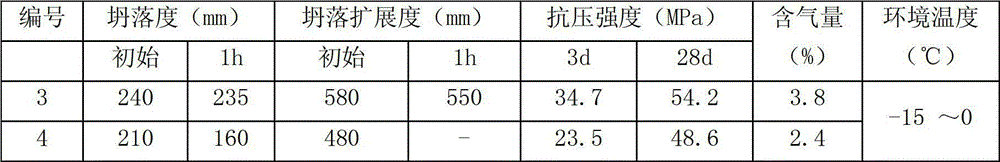

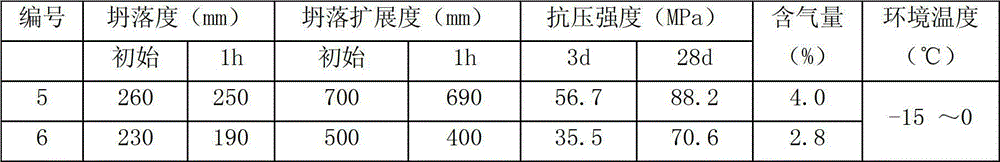

Compound admixture for heat curing-free concrete in winter construction

The invention discloses a compound admixture for heat curing-free concrete in winter construction. The compound admixture consists of the following components in parts by mass: 28-40 percent of high performance superplasticizer, 3-10 percent of early strength admixture, 5-15 percent of antifreezing agent, 3-7 percent of plant fiber intermediate-acting water-reducing agent MPA for retaining plastic and controlling the thickening, 0.02-0.5 percent of defoaming agent, 0.02-0.1 percent of PC-II for bleeding air and the balance of water. The compound admixture disclosed by the invention can be used for concrete with the intensity of C35 and over C35, does not need heat curing during winter construction and has the addition amount of 1-2 percent of that of gel material; and the compound admixture has the advantages of enabling the concrete to have upper flow regime, favorable cohesiveness, favorable water-retaining property, favorable slump loss, early strength under low temperature, good apparent mass of concrete and the like. According to the compound admixture, the initial slump flow is over 500mm, the early strength is obviously increased without influencing the development of later strength, the template cycle is prolonged and the curing cost of the concrete is reduced.

Owner:TIANJIN RES INST OF BUILDING SCI

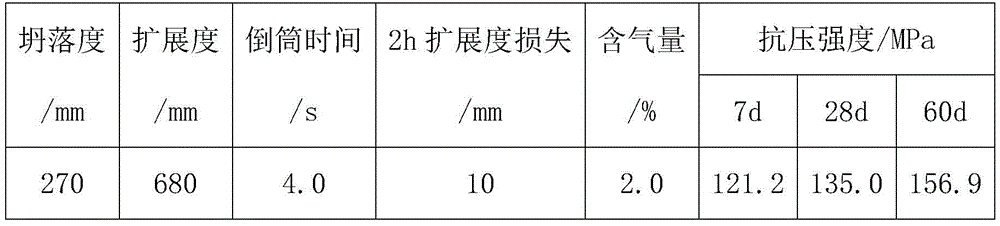

Preparation method of ultra-high-strength steel fiber reinforced concrete for super-high pumping

The invention provides a preparation method of ultra-high-strength steel fiber reinforced concrete for super-high pumping. According to the method, the ultra-high-strength steel fiber reinforced concrete with the strength grade of C150 is prepared by changing proportion of a cementing material and a feeding sequence and can be prepared with conventional production process through a mixing plant, and the problem that concrete with the strength grade of C150 or higher cannot be produced with the conventional process is solved. Common Portland cement as well as coarse and fine aggregate is adopted, and the cement is prepared through technological approaches such as reduction of a water-binder ratio, density enhancement and the like under double-doping actions of a polycarboxylate superplasticizer and a superfine mineral admixture. The prepared concrete has good working performance, the slump flow is 670-700 mm, and loss is basically avoided within 2 h; the viscosity is low, and rewinding time is 3.2-4.2 s; 28 d compressive strength reaches the strength grade of C150, and requirements for pumping construction of super high-rise buildings with height of 600 m or higher can be met.

Owner:中建西部建设北方有限公司 +1

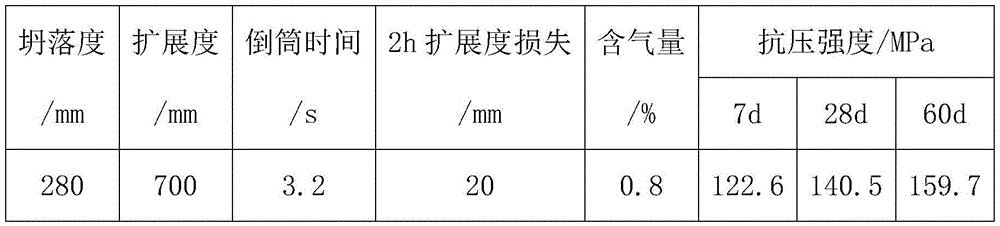

160MPa super-strength concrete with high cracking resistance and high fluidity

ActiveCN104860613AFunctional requirements for bulletproof penetrationImprove crack resistanceSolid waste managementHigh strength concreteFiber

The invention relates to 160MPa super-strength concrete with high cracking resistance and high fluidity to meet performance requirements such as premixing production, on-site pumping construction and anti-bounce capability. The concrete comprises the following components by weight (kg / cm<3>): 645-680kg of cement, 280-300kg of mineral powder, 160-190kg of coal ash, 252-283kg of silica ash, 980-1,080kg of natural sand, 238-260kg of steel fiber, 40-48kg of an additive and 160-169kg of mixing water, wherein the additive is a high-performance polycarboxylic water reducer. The slump flow of the concrete is kept within 750mm+ / -50mm within 3h, the 56d normal-curing compression strength is above 160MPa, the 56d normal-curing breaking strength is above 25MPa, and the concrete can be produced and prepared in a large scale on the basis of a common concrete mixing technology and can be transported to a construction site within 25km by a mixer truck. According to the 160MPa super-strength concrete, the problems of large-scale automatic production and preparation and remote on-site pumping and pouring construction are solved, and abundant ultrafine natural sand accumulated in the Yangtze River basin can be fully utilized.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

Mixer waveform analysis for monitoring and controlling concrete

Method and system for motoring and obtaining information about quantity and characteristics of cementitious material In a rotating mixing drum. The present invention involves analysis of a sequence of values corresponding to a waveform reflecting the hydraulic pressure required to turn a concrete mixing drum at successive instances during rotation. Preferred embodiments involve the conversion of this time-domain data into the frequency-domain. Behavior of multiple harmonics can be examined in real time and further information obtained regarding physical properties of the concrete. Rheology or other properties can be adjusted by introducing a liquid into the concrete, based on a comparison between time-domain and / or frequency-domain values derived from a sample concrete in the drum and previously stored time-domain and / or frequency-domain values, which are preferably correlated with physical characteristics of concrete, such as slump, slump flow, load weight, and other factors.

Owner:VERIFI INC

Method for adjusting concrete rheology based upon nominal dose-response profile

ActiveUS9789629B2Increased complexityAvoid overdoseControlling ratio of multiple fluid flowsMixing operation control apparatusEngineeringLookup table

Owner:VERIFI INC

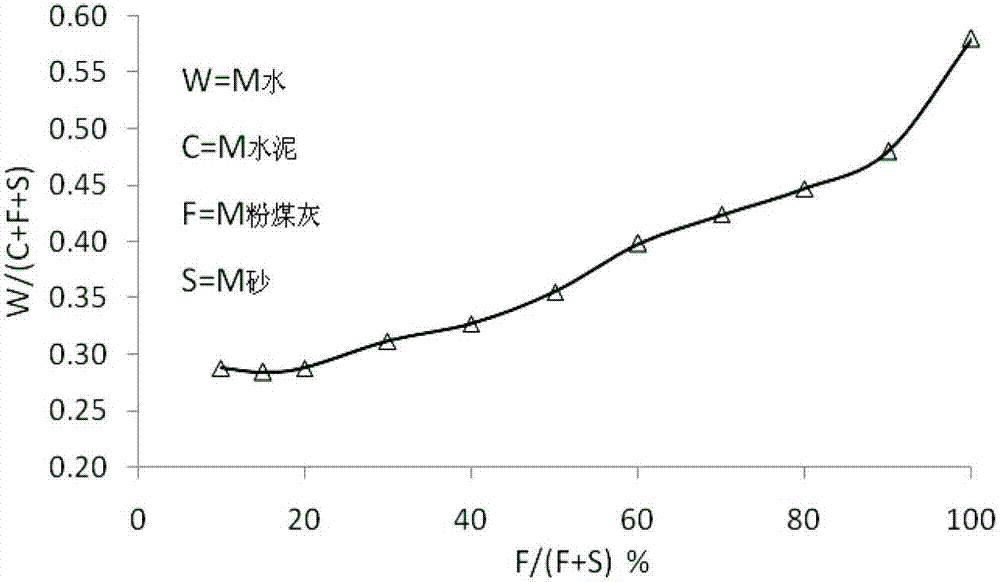

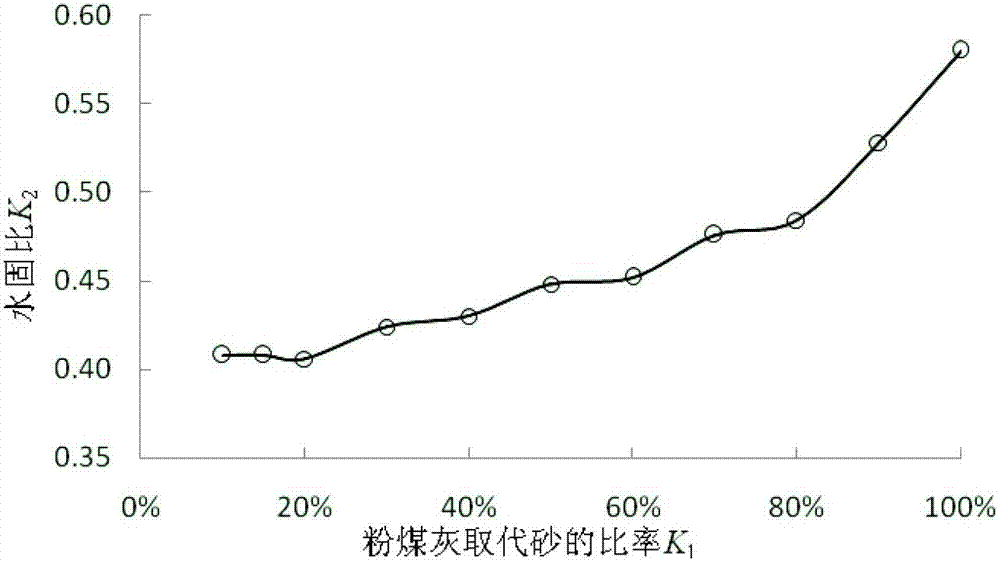

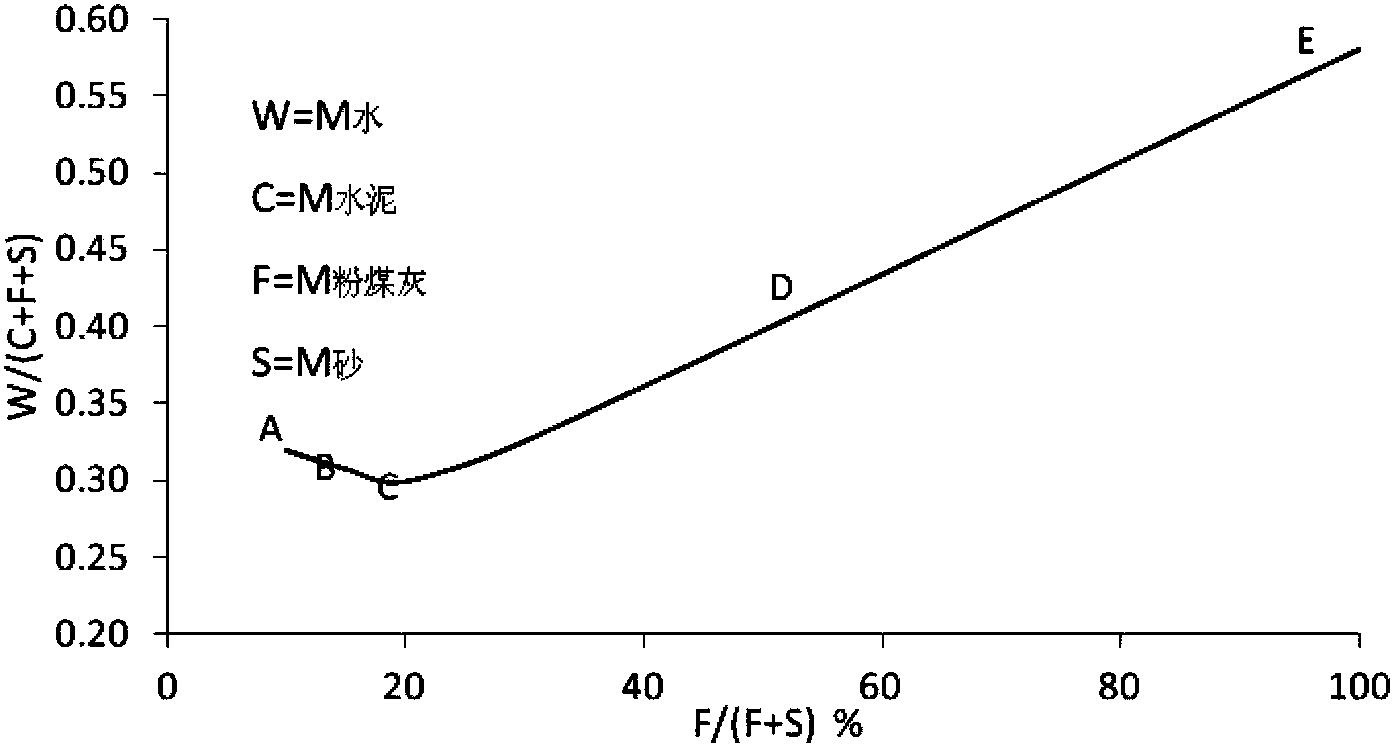

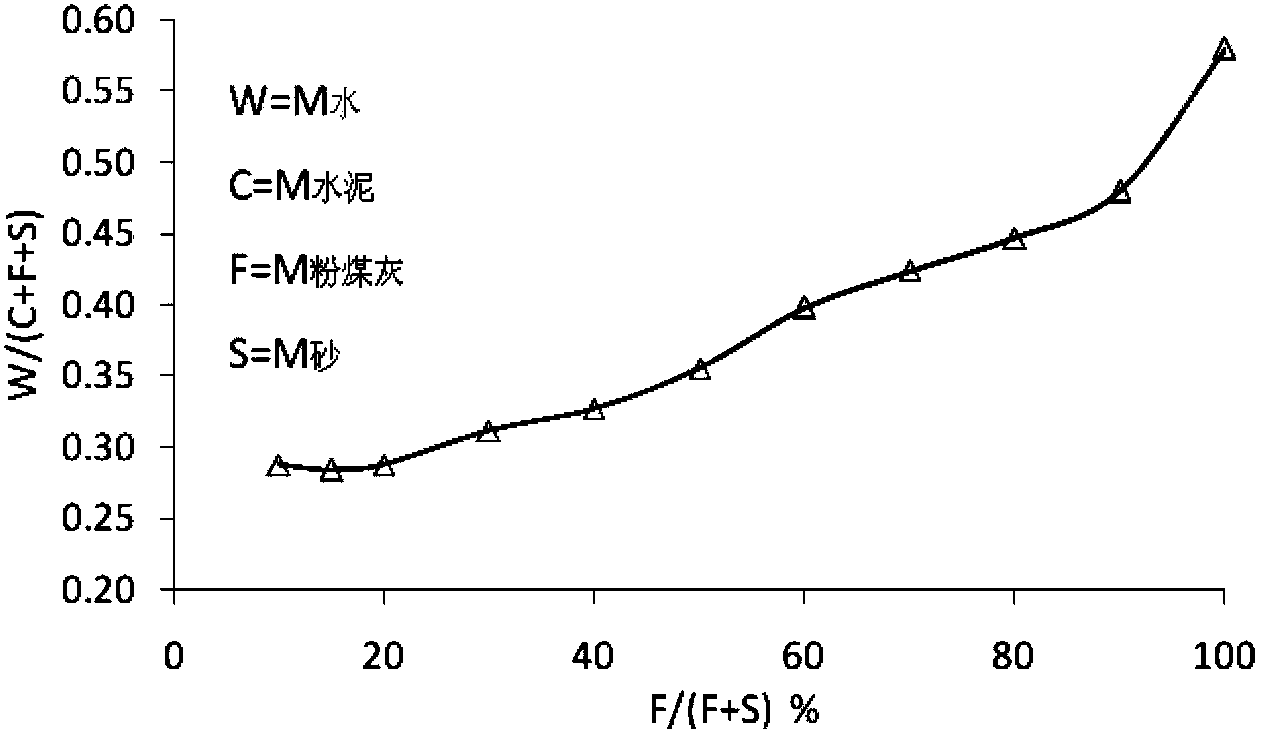

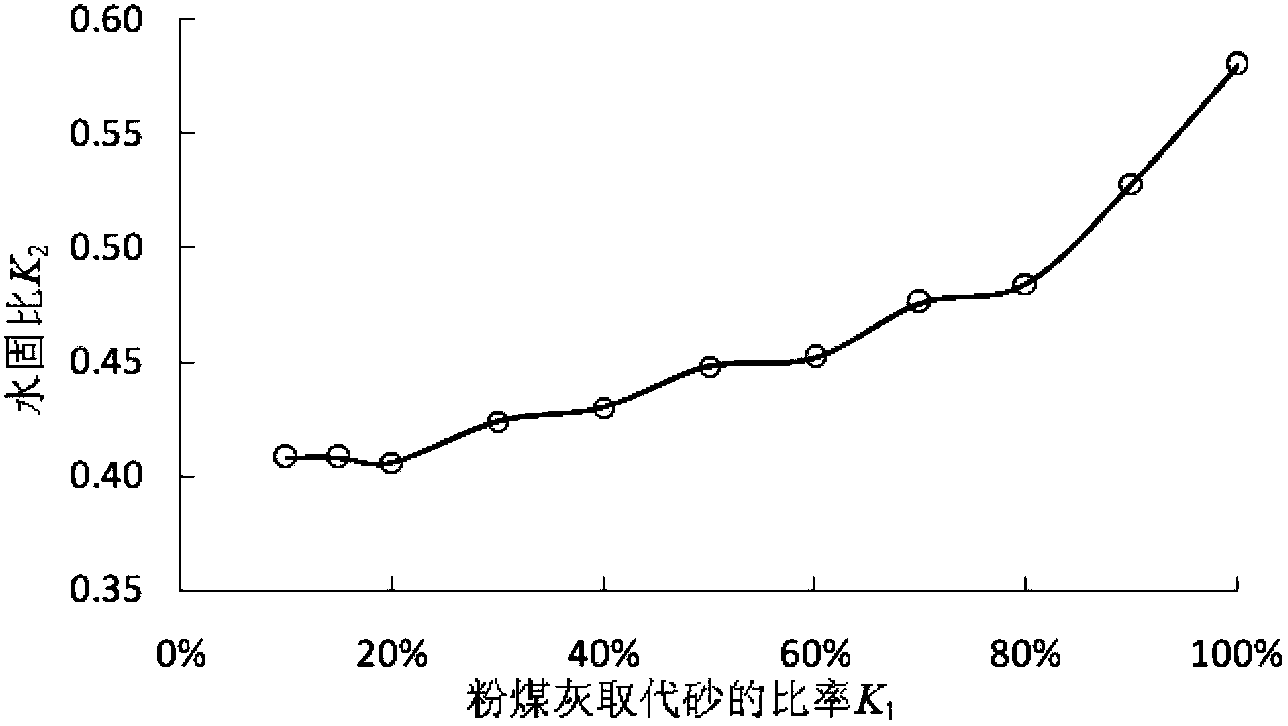

Control method of mix ratio of low-strength backfill materials

The invention relates to the field of concrete engineering, in particular to a control method of the mix ratio of low-strength backfill materials. The control method comprises the following steps: (1) drawing a pulverized fuel ash and sandstone mixed flow curve: the horizontal ordinate of the flow curve is the ratio K1of replacing sandstone with pulverized fuel ash, the longitudinal ordinate is the water-solid ratio K2, and the flow curve is drawn according to the determined slump flow, wherein the water-solid ratio K2 is the ratio of water mass to the sum of cement mass, pulverized fuel ash mass and sandstone mass, and the ratio K1of replacing sandstone with pulverized fuel ash is the ratio of sandstone mass to the sum of sandstone mass and pulverized fuel ash mass; (2) determining the optimal water amount: the optimal water amount point is obtained, and the mixing amount of sandstone and pulverized fuel ash is determined; and (3), determining the mixing amount of cement: the mixing amount of cement and water is determined according to the compressive resistance required actually. CLSM (Controlled Low-Strength Materials) prepared by the control method are dense materials with little gaps, and convenient and easy to construct, the mixture is uniform, and excessive separation does not occur.

Owner:TONGJI UNIV

Non-dispersible concrete for underwater and underground construction

InactiveUS8147609B2Low costSimple structureSolid waste managementCoatingsFineness modulusSuperplasticizer

Owner:JAU WEN CHEN

Method for testing pumpability of concrete mixture

ActiveCN102128760AQuickly judge pumpable performanceAvoid cloggingMaterial testing goodsMaterial weighingSlump flowFilling ratio

The invention relates to a method for testing the pumpability of a concrete mixture, which comprises the following steps: 1) testing and calculating the total content of mortar in concrete and the density of the mortar; 2) calculating the content of the mortar filled in pebble gaps; 3) calculating the mass of the residual filled mortar by subtracting the mass of the mortar filled in pebble gaps from the total mass of the mortar; and 4) calculating the filling ratio of the residual mortar by dividing the mass of the residual filled mortar by the mass of the mortar filled in pebble gaps. Based on the conventional test for the slump, slump flow and the like of the concrete mixture, the invention provides a residual filled mortar content test method for testing the filling ratio of the residual mortar by taking the intimate relationship between the pumpability of the concrete and the content of the residual filled mortar in the concrete into consideration. The method can be used for quickly judging the pumpability of the concrete mixture on the construction site before the concrete mixture is put into the pumped, thereby better guiding the construction, avoiding pump tube blocking in the pumping process and increasing the working efficiency.

Owner:SHANDONG JIANZE CONCRETE

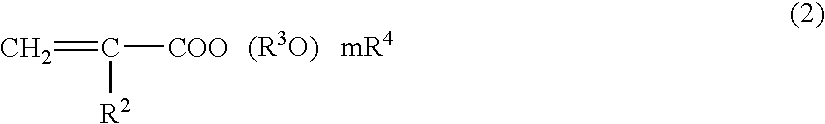

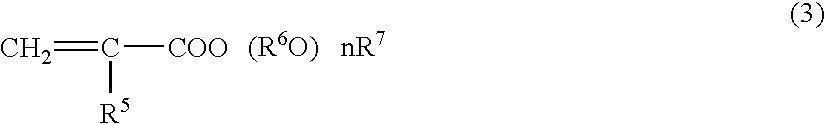

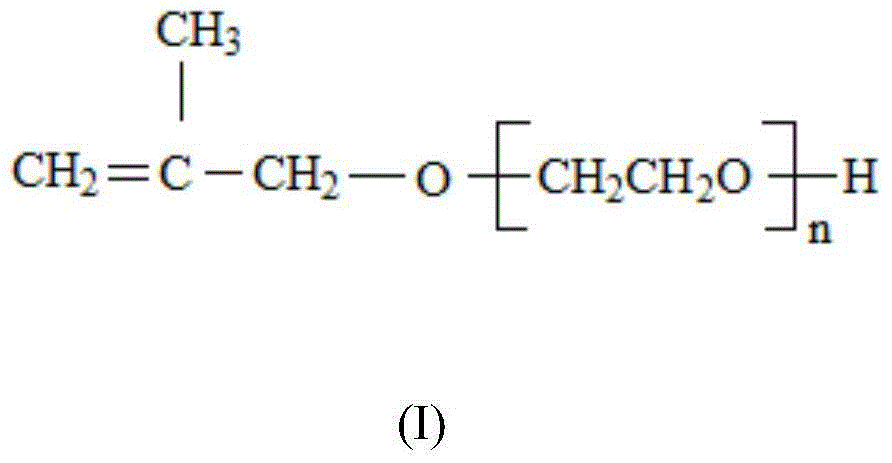

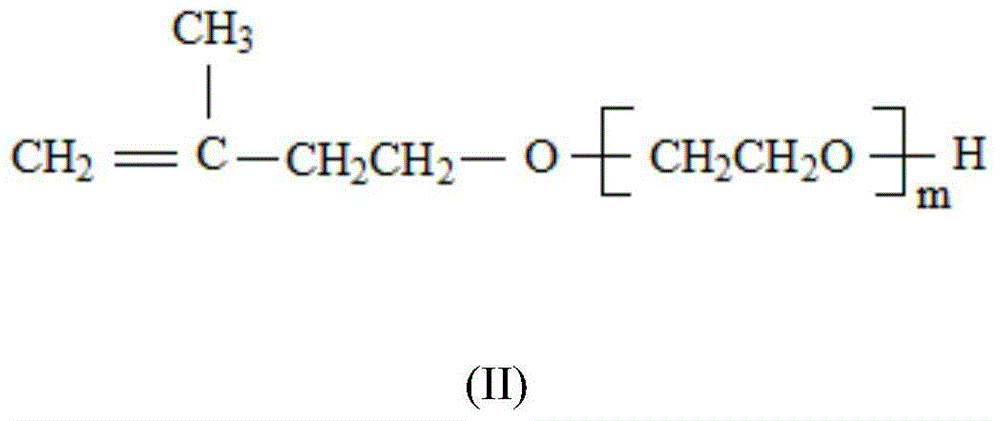

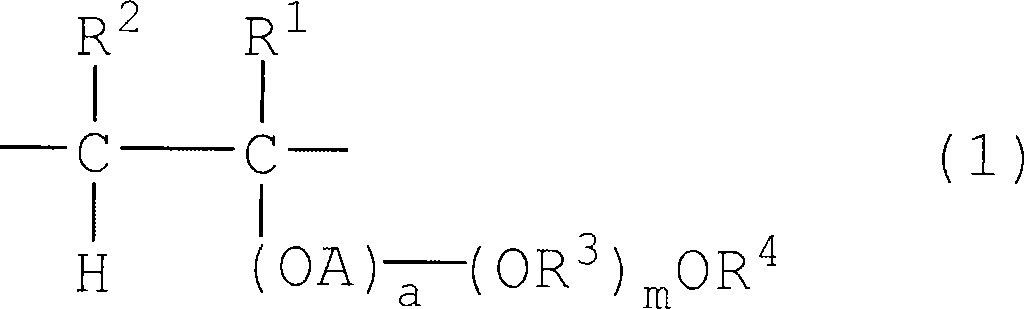

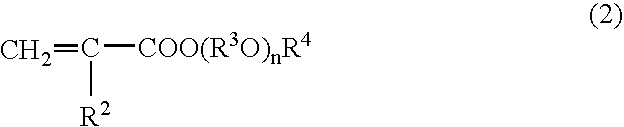

Cement admixture

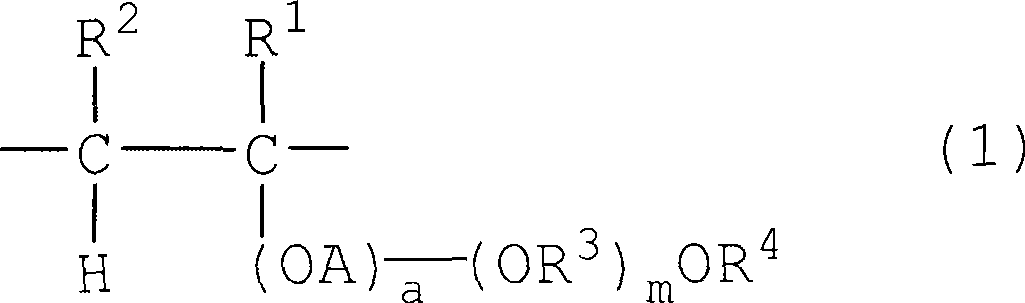

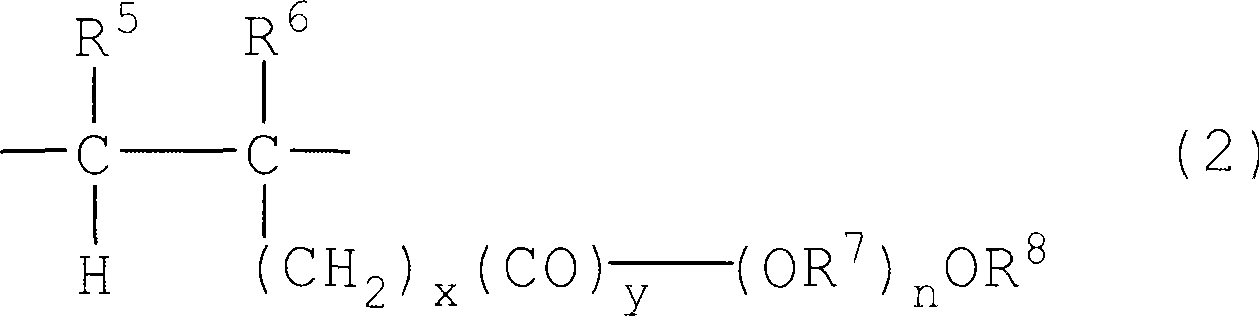

The present invention aims at providing a cement admixture having superior water-reducing performance, along with no decrease in slump and slump flow caused by decrease in fluidity of a cement composition over time. A cement admixture is to be provided, which cement admixture comprises two or more members of polycarboxylic acid-based polymers, wherein said cement admixture comprises at least one polycarboxylic acid-based polymer (A) having a constitutional unit represented by the following formula (1): wherein R1 and R2 independently represent a hydrogen atom, an alkyl group with carbon atoms of 1 to 30, an alkenyl group with carbon atoms of 1 to 30, an aryl group with carbon atoms of 6 to 12; A represents an alkylene group with carbon atoms of 1 to 30 or an arylene group with carbon atoms of 6 to 12; a is 0 or 1; OR3 represents an oxyalkylene group with carbon atoms of 2 to 18, wherein each OR3 may be the same or different each other, provided that when OR3 is in a mixed form of two or more members, each OR3 may be added in a block or random form; R4 represents a hydrogen atom or a hydrocarbon group with carbon atoms of 1 to 30; and m represents an average mole number of oxyalkylene groups added and is in the range of 1 to 300; and at least one polycarboxylic acid-based polymer (B) having a constitutional unit represented by the following formula (2): wherein R5 and R6 independently represent a hydrogen atom, a methyl group; x is an integer in the range of 0 to 2 and y is 0 or 1, provided that x and y are not 0 at the same time; OR7 represents an oxyalkylene group with carbon atoms of 2 to 18, wherein each OR7 may be the same or different each other, provided that when OR7 is in a mixed form of two or more members, each OR7 may be added in a block or random form; R8 represents a hydrogen atom or a hydrocarbon group with carbon atoms of 1 to 30; and n represents an average mole number of oxyalkylene groups added and is in the range of 1 to 300.

Owner:NIPPON SHOKUBAI CO LTD

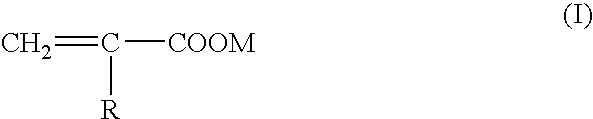

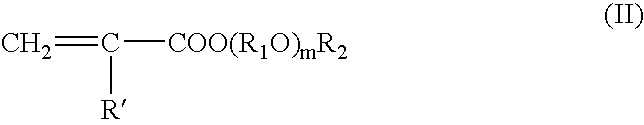

Powdery polycarboxylic-acid cement dispersant and dispersant composition containing the dispersant

A powdery polycarboxylic-acid cement dispersant having a polymer backbone comprising a polyamide-polyamine. It has the effect of being capable of improving water amount reduction, slump flow retention, and concrete strength development. Furthermore, it is effectively prevented from suffering blocking and has excellent solubility in a slurry. It can be evenly mixed with an inorganic powder. The dispersant is characterized in that it comprises a powdery cement dispersant obtained by drying a solution or dispersion of a copolymer having a polymer backbone comprising a polyamide-polyamine to obtain a powder of the copolymer, and that the powder is composed of spherical particles having an average particle diameter of 30-300 [mu]m and a particle size distribution in which particles having a particle size of 50-350 [mu]m account for 70% or more of the total mass amount.

Owner:SIKA LTD +1

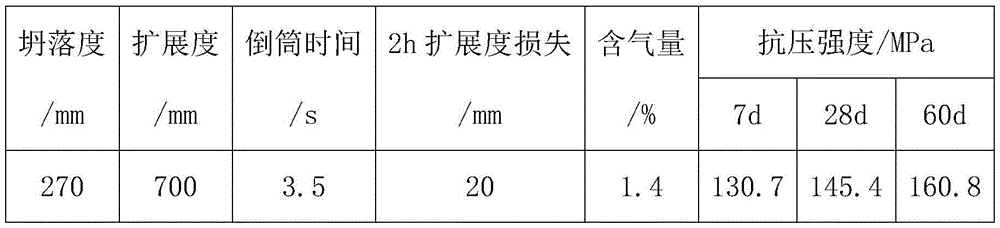

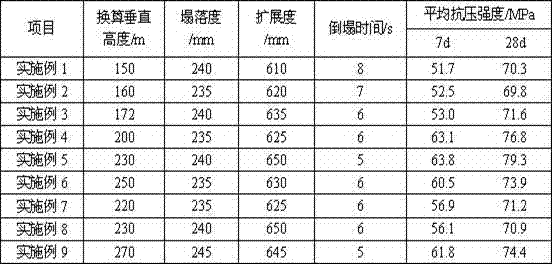

Low viscosity large flowing degree C60 super high-rise pump concrete based on ultrafine sand compounding

The invention discloses a low viscosity large flowing degree C60 super high-rise pump concrete based on ultrafine sand compounding. The super high-rise pump concrete comprises cement, mineral powder, fly ash, ultrafine natural sand, machine-made sand, broken stone, additives, and water. The super high-rise pump concrete can be prepared by a conventional method. The concrete is characterized in that according to the characteristics of premixed concrete in Sichuan and Chongqing areas, ultrafine natural sand and machine-made sand are compounded to obtain second grade medium sand; pebble and broken pebble are compounded according to a certain ratio to 5-25 continuous grading; 28d compressive strength can reach 70 MPa or more; the slump is not less than 240 mm, the slump flow is not less than 620 mm; the slump cone time is not more than 9 seconds, and the concrete has the characteristics of high strength, low viscosity, large flowing degree, easy operation of production mode, and suitability for the pumping of a super high-rise building with a vertical height more than 350 meters.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

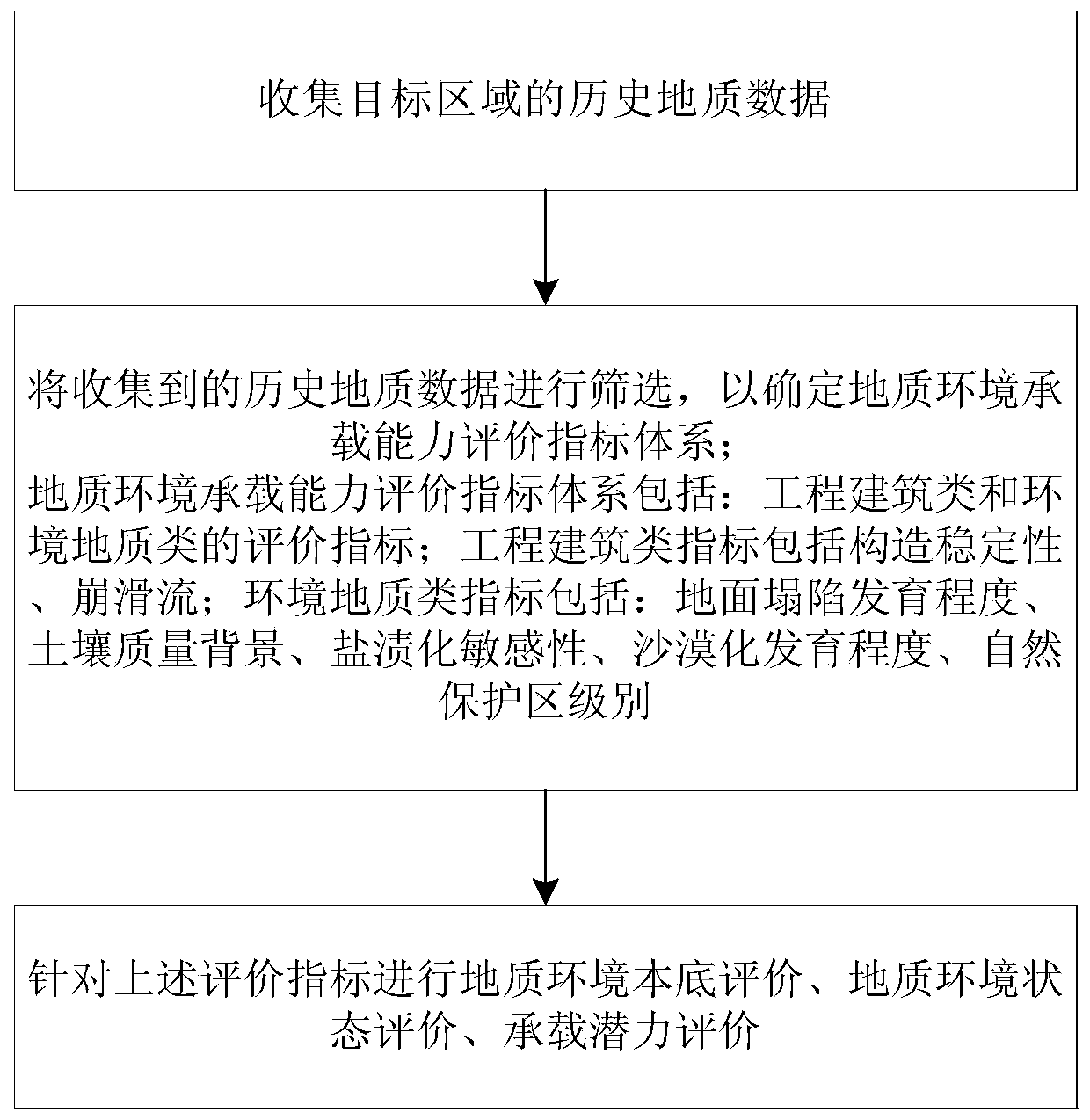

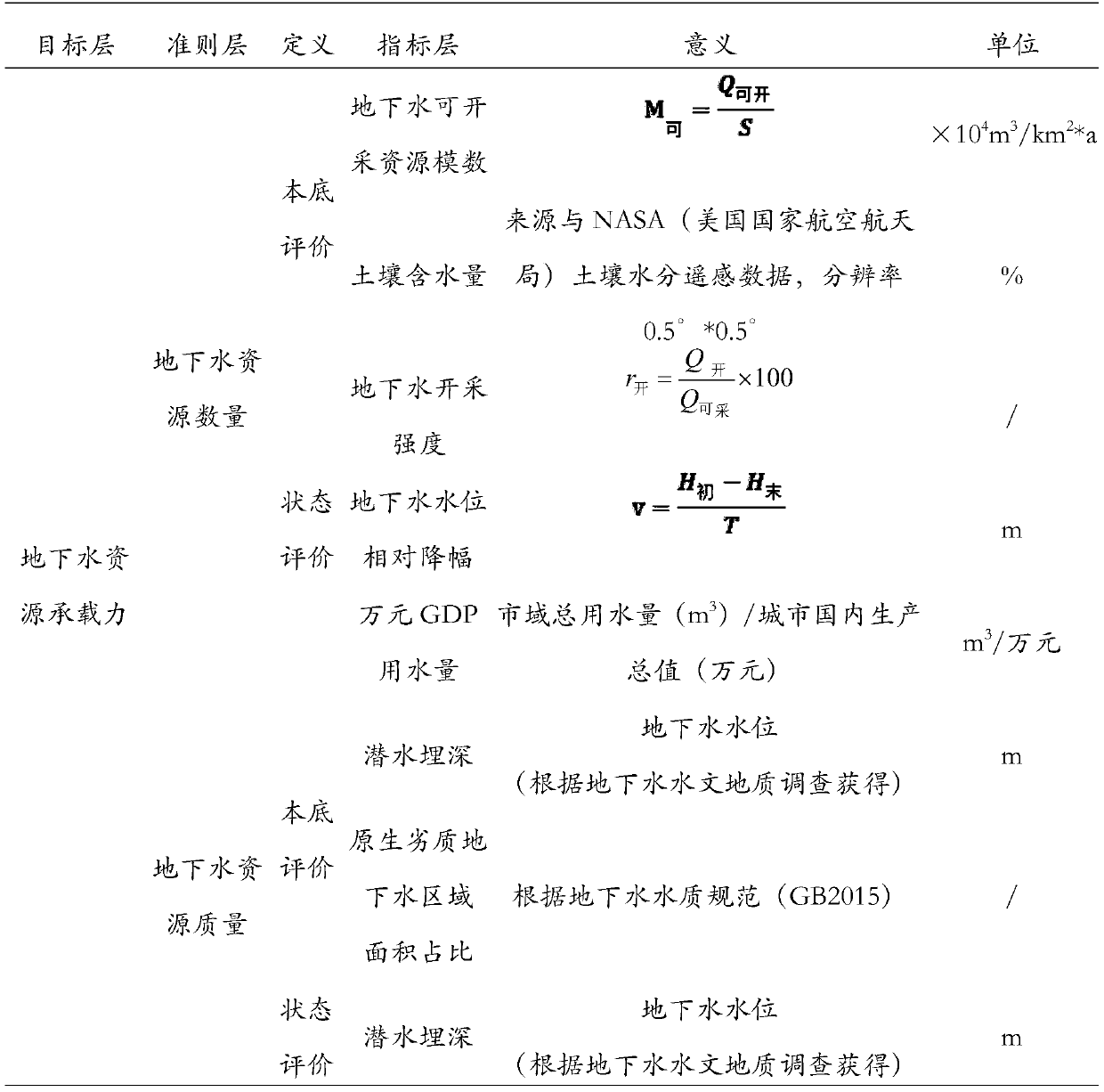

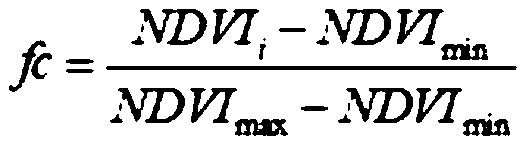

Geological resource evaluation method based on ecological region

InactiveCN109858788AAccurate processingThe processing result is accurateResourcesSoil qualityIndex system

The invention provides a geological resource evaluation method based on an ecological region. The geological resource evaluation method comprises the steps of collecting historical geological data ofa target region; screening the collected historical geological data to determine a geological environment bearing capacity evaluation index system; the geological environment bearing capacity evaluation index system including evaluation indexes of engineering buildings and environmental geology; the engineering construction indexes including structural stability and slump flow; the environmental geology indexes including the surface collapse development degree, the soil quality background, the salinization sensitivity, the desertification development degree and the natural reserve level; and carrying out geological environment background evaluation, geological environment state evaluation and bearing potential evaluation on the evaluation indexes.

Owner:BEIJING NORMAL UNIVERSITY

Self-compacting concrete for road engineering

The invention discloses self-compacting concrete for road engineering. The self-compacting concrete has a porous structure, and the gas content of the concrete is 15-20%. By introducing massive bubbles to self-compacting concrete slurry, consumption of a medium-and-low-strength self-compacting concrete cementitious material and hydration heat are effectively reduced, and the thixotropy, volume stability and microstructure of the concrete are improved. The strength grade of the medium-and-low-strength self-compacting concrete is C10-C50, slump flow can be adjusted within the range of 600-850 mm according to operating requirements, the difference between slump flow and J ring flow is smaller than 20 mm, and separation ratio is smaller than 10%. The self-compacting concrete can be applied to constructional engineering, roadbed and levee crown road engineering, watercourse and channel construction and repair, and rock filling.

Owner:NANJING UNIV OF SCI & TECH

High-strength self-compaction thermal-insulation concrete

InactiveCN104402325AImprove liquidityAchieve self-compacting effectSolid waste managementApparent densityThermal insulation

Disclosed high-strength self-compaction thermal-insulation concrete is prepared by taking a self-compaction concrete technology as a basis, taking sea-mud-texturized high-performance spherical high-strength ceramic particle as an aggregate and scientifically mixing with cement, fly ash, graded sand, water, an efficient water reducer and cellulose ether. The obtained high-strength self-compaction thermal-insulation concrete has the dry apparent density of 1200-2000 Kg / m<3>, the 28-day compressive strength of 15-60 MPa, the heat conduction coefficient of 0.15-0.5 W / (m*K), the slump flow of 650-750 mm, the slump flow time of 3-4 s and the slump of 250 mm or more, also has light weight, high strength, high thermal-insulation performance and self-compaction performance during pouring, is capable of solving the problems that lightweight aggregates float upwards, are separated when being pumped and the like during pouring vibration of conventional high-strength thermal-insulation concrete, and is widely applied to bearing and non-bearing walls, floorslabs, roof boards, wallboards and other in-situ casted and prefabricated parts in energy-saving buildings.

Owner:FUJIAN JIANGXIA UNIV

Powdered Polycarboxylic Acid-Based Cement Dispersant and Dispersant Composition Containing the Dispersant

There is provided a powdered polycarboxylic acid-based cement dispersant containing a polyamide-polyamine in a skeleton of a polymer thereof and a dispersant composition containing the dispersant, the dispersant having improved water reducing ability, slump-flow retention, and strength-developing properties of concrete, enabling effective prevention of blocking, being highly soluble in a slurry, and being homogeneously mixed with an inorganic powder. The powdered polycarboxylic acid-based cement dispersant comprises a powdered cement dispersant obtained by dry-powdering a solution or dispersion of a copolymer containing a polyamide-polyamine in a skeleton of a polymer thereof, wherein the powder has a sphere form, an average particle diameter of 30 to 300 μm, and a particle size distribution in which the mass of particles having a particle diameter of 50 to 350 μm accounts for 70% or more of the total mass of the powder.

Owner:SIKA LTD +1

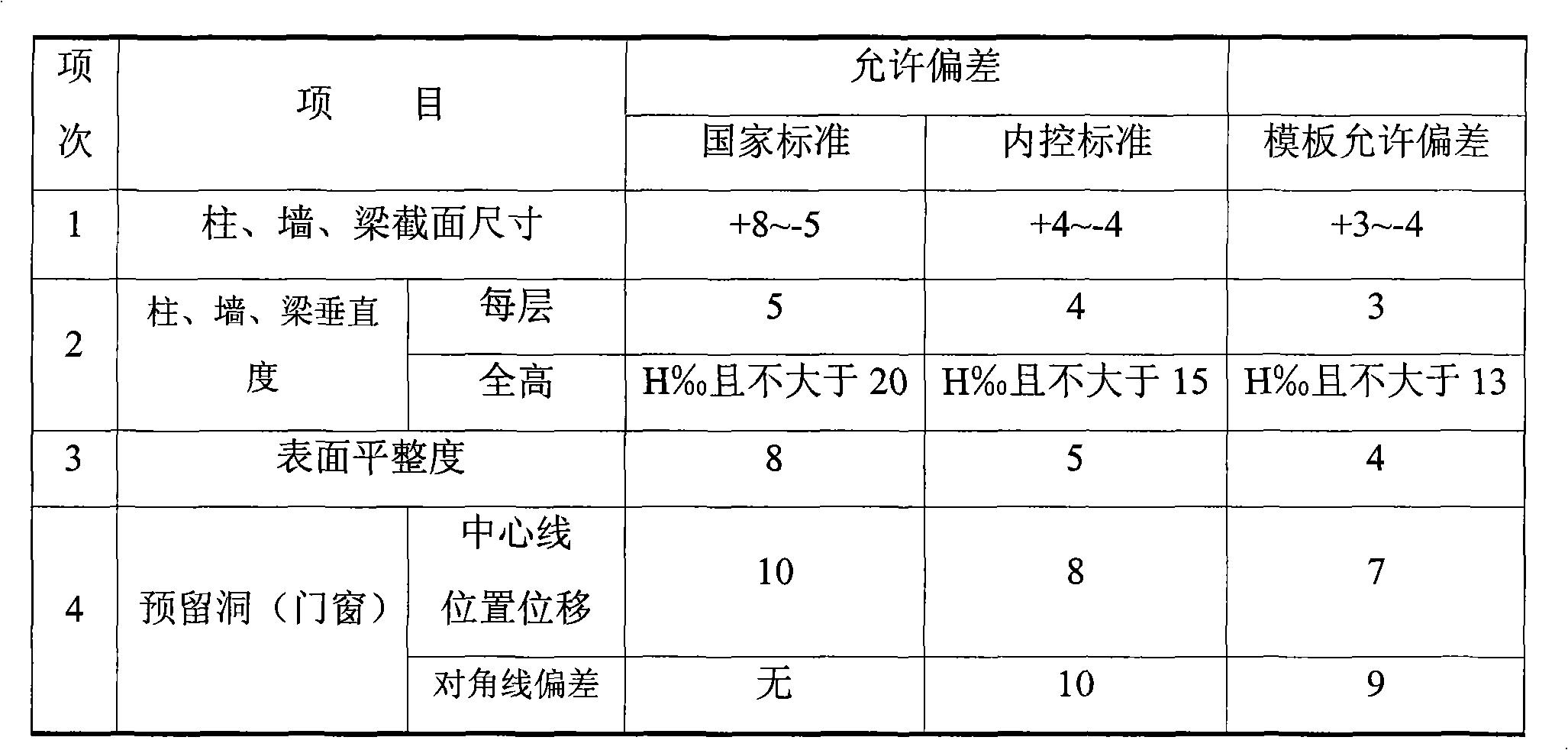

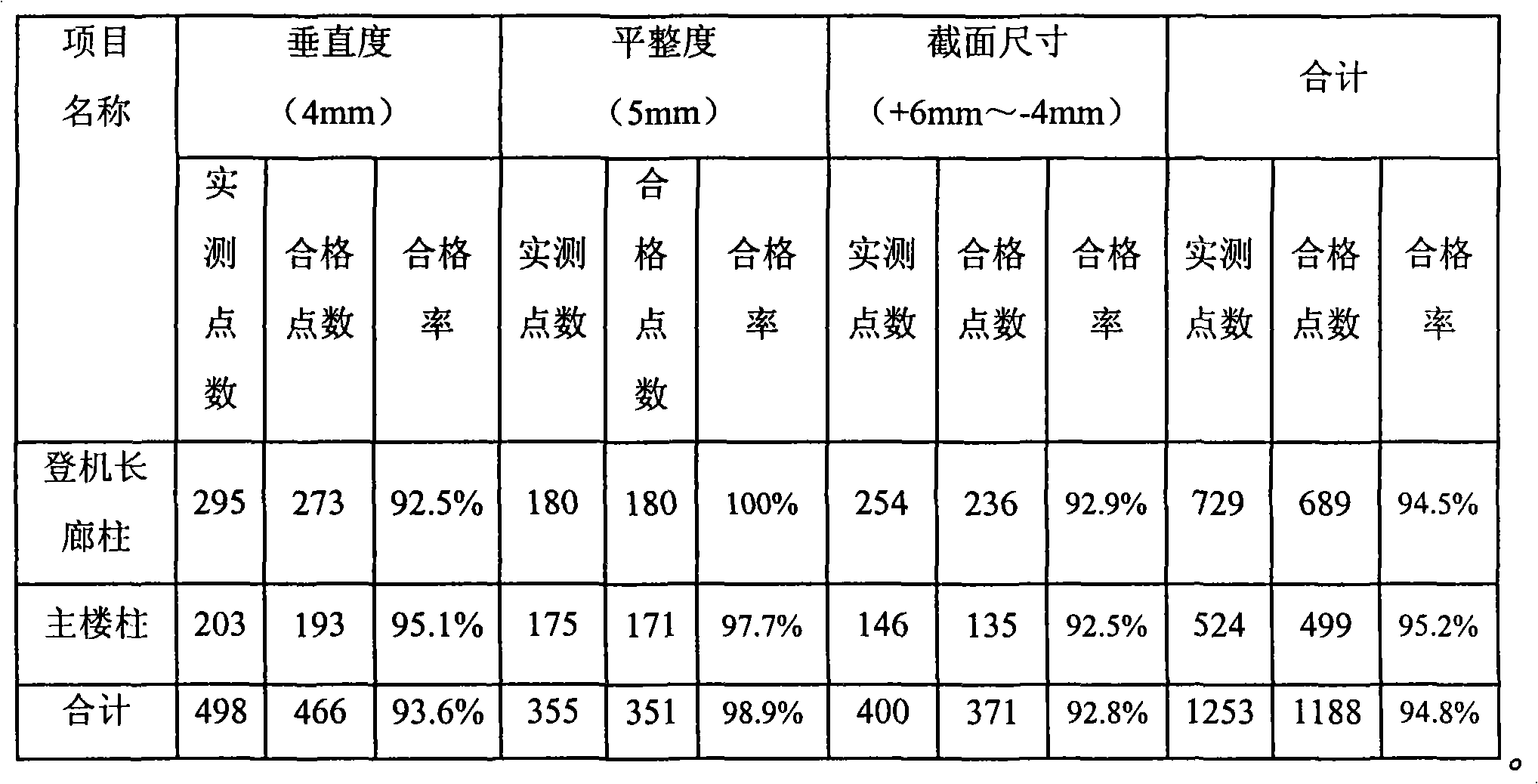

Cement concrete composition for divergence-controlled pouring construction and construction method

The invention discloses a concrete mixture which is applicable to the cast-place construction controlled by slump flow, as well as the construction method thereof. The components of the concrete mixture comprise by weight parts as follows: 250 to 270 kilograms / cubic meter of cement, 160 to 200 kilograms / cubic meter of admixture, 1600 to 2000 kilograms / cubic meter of aggregate, 160 to 190 kilograms / cubic meter of water and 4 to 5 kilograms / cubic meter of additive. The slurry stickiness of the cement is 150 to 600 MPa.s, and the initial setting time of the cement is 8 to 9 hours. The concrete mixture can adopt the conventional construction method to carry out the construction, including the common concrete vibrating method which adopts the slump to control, and can also adopt the construction method which adopts the slump flow to control. The concrete mixture is completely applicable to a high column, the height of which ranges from 2 meters to 15 meters, and adopts the slump flow to control the cast-place construction. The standard of the annex 1 is adopted to detect the constructed column, thereby completely conforming to the related regulations.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +2

Method for testing pumpability of concrete mixture

ActiveCN102128760BQuickly judge pumpable performanceAvoid cloggingMaterial testing goodsMaterial weighingSlump flowFilling ratio

The invention relates to a method for testing the pumpability of a concrete mixture, which comprises the following steps: 1) testing and calculating the total content of mortar in concrete and the density of the mortar; 2) calculating the content of the mortar filled in pebble gaps; 3) calculating the mass of the residual filled mortar by subtracting the mass of the mortar filled in pebble gaps from the total mass of the mortar; and 4) calculating the filling ratio of the residual mortar by dividing the mass of the residual filled mortar by the mass of the mortar filled in pebble gaps. Based on the conventional test for the slump, slump flow and the like of the concrete mixture, the invention provides a residual filled mortar content test method for testing the filling ratio of the residual mortar by taking the intimate relationship between the pumpability of the concrete and the content of the residual filled mortar in the concrete into consideration. The method can be used for quickly judging the pumpability of the concrete mixture on the construction site before the concrete mixture is put into the pumped, thereby better guiding the construction, avoiding pump tube blocking in the pumping process and increasing the working efficiency.

Owner:SHANDONG JIANZE CONCRETE

Control method of mix ratio of low-strength backfill materials

The invention relates to the field of concrete engineering, in particular to a control method of the mix ratio of low-strength backfill materials. The control method comprises the following steps: (1) drawing a pulverized fuel ash and sandstone mixed flow curve: the horizontal ordinate of the flow curve is the ratio K1of replacing sandstone with pulverized fuel ash, the longitudinal ordinate is the water-solid ratio K2, and the flow curve is drawn according to the determined slump flow, wherein the water-solid ratio K2 is the ratio of water mass to the sum of cement mass, pulverized fuel ash mass and sandstone mass, and the ratio K1of replacing sandstone with pulverized fuel ash is the ratio of sandstone mass to the sum of sandstone mass and pulverized fuel ash mass; (2) determining the optimal water amount: the optimal water amount point is obtained, and the mixing amount of sandstone and pulverized fuel ash is determined; and (3), determining the mixing amount of cement: the mixing amount of cement and water is determined according to the compressive resistance required actually. CLSM (Controlled Low-Strength Materials) prepared by the control method are dense materials with little gaps, and convenient and easy to construct, the mixture is uniform, and excessive separation does not occur.

Owner:TONGJI UNIV

Concrete composition and method for preparing the same

InactiveUS20190375683A1Effective and stableImprove stabilitySolid waste managementSlump flowMaterials science

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com