Low viscosity large flowing degree C60 super high-rise pump concrete based on ultrafine sand compounding

A technology for pumping concrete and ultra-fine sand, applied in the field of building materials, can solve problems such as poor morphology, and achieve the effects of reducing production costs, reducing porosity, and reducing cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

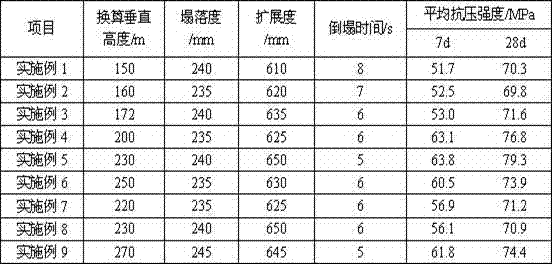

[0052] The present invention has carried out a series of trials on concrete by using cementitious materials and mineral admixtures, different proportions of sand and admixtures, and obtained the mix proportions shown in Table 3. However, if other different reducing The modification of the admixture of the water rate in various equivalent substitution forms falls within the scope of the claims of the present invention.

[0053] Table 3. C60 fully machine-made sand ultra-high pumping concrete mix ratio

[0054] project

S95 mineral powder

Class II fly ash

sand ratio

stone ratio

Admixture

water

Example 1

408

69

53

0

8:2

6:4

10.6

159

Example 2

408

69

53

0

7:3

6:4

10.6

159

Example 3

408

69

53

0

6:4

6:4

10.9

159

Example 4

392

69

53

16

8:2

6:4

11.6

159

Example 5

392

69

53

16

7:3

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com