Compound admixture for heat curing-free concrete in winter construction

A technology for compounding admixtures and concrete is applied in the field of concrete admixtures, which can solve the problems of insignificant improvement of concrete early strength and speed up project progress, and achieve the effects of reducing concrete maintenance cost, improving formwork cycle and good apparent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

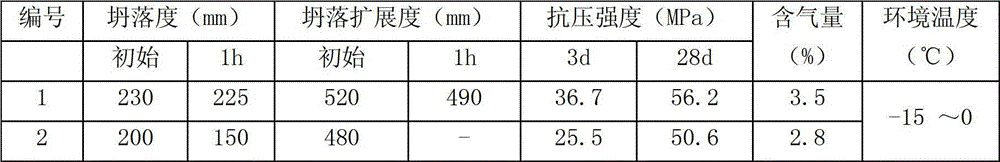

Embodiment 1

[0017] A composite admixture for winter construction heat-free curing concrete, which consists of the following components in parts by mass: 30% high-performance water reducer (21% of polyether polycarboxylate high-performance water reducer (MPC -Ⅱ), 9% polyester polycarboxylate superplasticizer (MPC-I), 8% early strength agent (including 4% triethanolamine, 4% calcium formate), 7% antifreeze Calcium nitrate, 3% plant fiber medium-effect water reducer MPA, which plays the role of plastic-preserving and coagulation adjustment, 0.05% defoamer tributyl phosphate, 0.02% PC-II (modified rosin thermal polymer), and the balance is water.

[0018] Concrete ratio (mass ratio)

[0019] number 1

[0020] Cement: Mineral powder (S95): Fly ash (Class II): Sand: Gravel: Water: A kind of composite admixture for winter construction heat-free curing concrete of the present invention=350:90:40:720:994:170: 9.6

[0021] number 2

[0022] Cement: Mineral powder (S95): Fly ash (Class II): San...

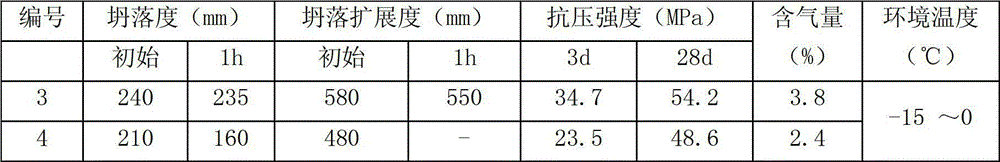

Embodiment 2

[0026] A composite admixture for winter construction heat-free curing concrete, which consists of the following components in parts by mass: 35% high-performance water reducer (24.5% of polyether polycarboxylate high-performance water reducer (MPC -Ⅱ), 10.5% polyester polycarboxylate high-performance superplasticizer (MPC-I)), 10% early strength agent (including 5% triethanolamine, 5% sodium acetate), 7% antifreeze Ethylene glycol, 3% plant fiber medium-effect water reducer MPA, which plays the role of plastic-preserving and coagulation adjustment, 0.1% polyoxyethylene ether, defoamer, 0.02% PC-Ⅱ, which plays the role of entraining air, and the balance for water.

[0027] Concrete Proportion

[0028] number 3

[0029] Cement: mineral powder (S95): fly ash (grade II): expansion agent: sand: gravel: water: a kind of composite admixture for winter construction heat-free curing concrete of the present invention=320:100:40:20:763 :997:170:7.2

[0030] number 4

[0031] Cement:...

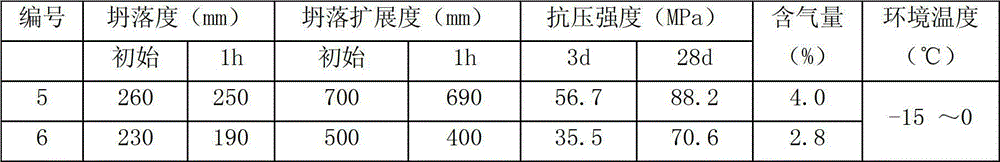

Embodiment 3

[0035] A composite admixture for winter construction heat-free curing concrete, which consists of the following components in parts by mass: 40% high-performance water-reducer (28% of polyether polycarboxylate high-performance water-reducer (MPC -Ⅱ), 12% polyester polycarboxylate high-performance superplasticizer (MPC-I)), 10% early strength agent (including 5% triethanolamine, 5% calcium oxalate), 7% antifreeze Sodium thiocyanate, 3% plant fiber medium-effect superplasticizer MPA, 0.1% defoamer polyoxypropylene ether, 0.02% PC-II, air-entraining The amount is water.

[0036] Concrete Proportion

[0037] number 5

[0038] Cement: Silica fume: Mineral powder (S95): Fly ash (Class I): Sand: Gravel: Water: A composite admixture for winter construction heat-free curing concrete=340:40:130:80:763:930: 150:11.8

[0039] number 6

[0040] Cement: silica fume: mineral powder (S95): fly ash (grade I): sand: gravel: water: naphthalene antifreeze and water reducer = 340:40:130:80:76...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com