High-adaptability and high-performance polycarboxylic water-reducing agent and preparation method for same

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of polycarboxylic acid water reducing agent, can solve the problems of general slump-retaining mother liquor and large loss of concrete slump, etc. Good, free-flowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

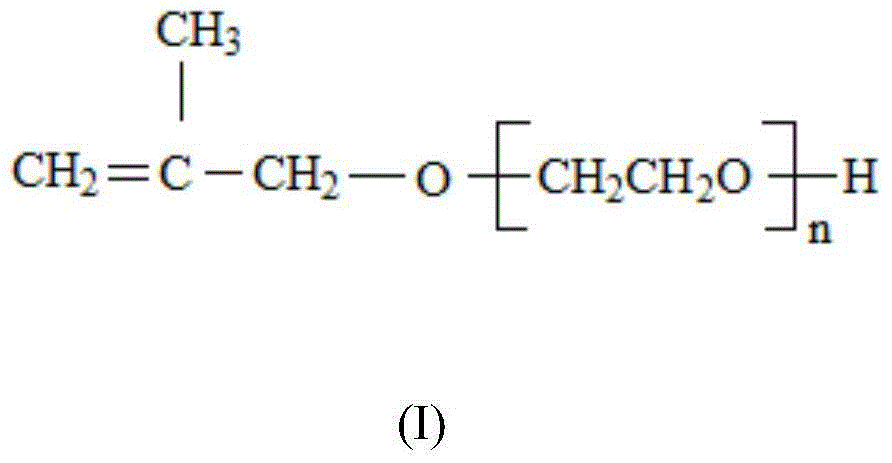

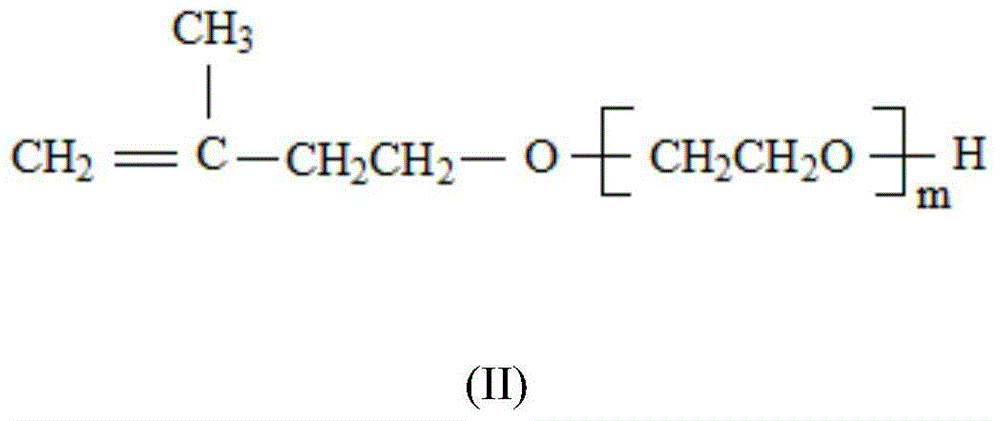

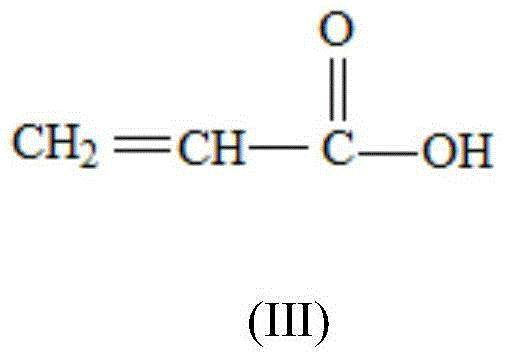

[0044]

[0045]

[0046] Add 200 g of monomer a with a concentration of 60% and 15 g of deionized water into a reaction vessel equipped with a stirrer, a reflux condenser, and a drop-adding device, stir and heat, and pass nitrogen to remove oxygen. When the temperature of the reaction vessel rises to 80°C, simultaneously start dropwise adding liquid A consisting of 0.5232g of monomer c, 10.80g of monomer b, and 22.50g of water and liquid B consisting of 1.0464g of ammonium persulfate and 39.00g of water ; control the dropping speed, A solution is dripped in 3 hours, B is dripped in 3.5 hours, after the B solution is added dropwise, keep warm for 2h, then cool down to 40°C, adjust the pH to 6 with 35% concentration NaOH solution, and obtain the concentration of 45% wide adaptability polycarboxylate superplasticizer, recorded as HSPC-1.

Embodiment 2

[0048]

[0049] Add 180 g of monomer a and 142.5 g of deionized water into a reaction vessel equipped with a stirrer, reflux condenser, and drop-adding equipment, stir and heat, and pass nitrogen to remove oxygen. When the temperature of the reaction vessel rises to 80°C, simultaneously start dropwise adding liquid A consisting of 6.2784g of monomer c, 16.20g of monomer b, and 33.0g of water and liquid B consisting of 1.1772g of ammonium persulfate and 64.5g of water ; control the dropping speed, A solution is dripped in 3 hours, B is dripped in 3.5 hours, after the B solution is added dropwise, keep warm for 2h, then cool down to 40°C, adjust the pH to 6 with 35% concentration NaOH solution, and obtain the concentration of 45% wide adaptability polycarboxylate superplasticizer, recorded as HSPC-2.

Embodiment 3

[0051]

[0052]Add 240 g of monomer a with a concentration of 60% and 8 g of deionized water into a reaction vessel equipped with a stirrer, a reflux condenser, and a drop-adding device, stir and heat, and pass nitrogen to remove oxygen. When the temperature of the reaction vessel rises to 60°C, add a solution consisting of 1.12 g of 30% hydrogen peroxide and 8 g of water. After stirring for 5 minutes, start to dropwise add 14.37 g of monomer c, 10.81 g of monomer b, 40.0 g of Liquid A composed of water and liquid B composed of 0.4359g ascorbic acid, 0.71g mercaptopropionic acid, and 52g water; control the dripping speed, the dripping of liquid A is completed in 3 hours, and the dripping of liquid B in 3.5 hours. After the addition of liquid B is completed, keep warm After 2 hours, the temperature was lowered to 40°C, and the pH was adjusted to 6 with a 35% NaOH solution to obtain a wide-adaptability polycarboxylate superplasticizer with a concentration of 45%, which was des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com