Method for preparing cement water-reducing agent by using byproduct of organic pigment intermediate CLT acid

A technology of organic pigments and intermediates, which is applied in the field of organic chemical synthesis, can solve the problems of high cost, and achieve the effects of high fluidity, simple synthesis process, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

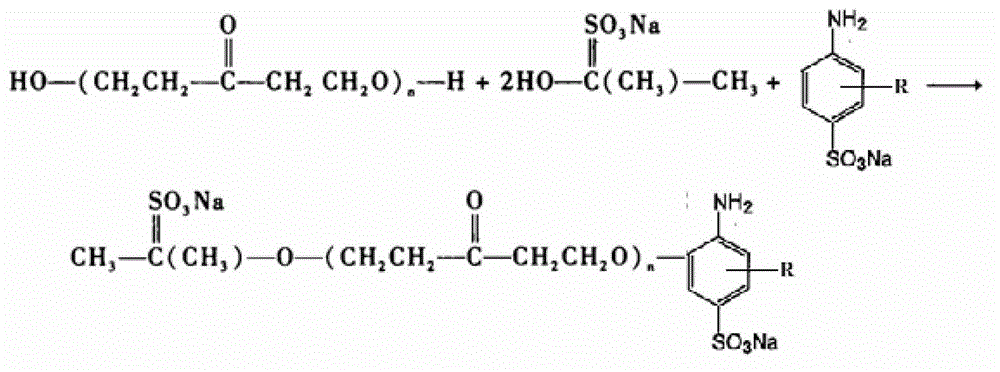

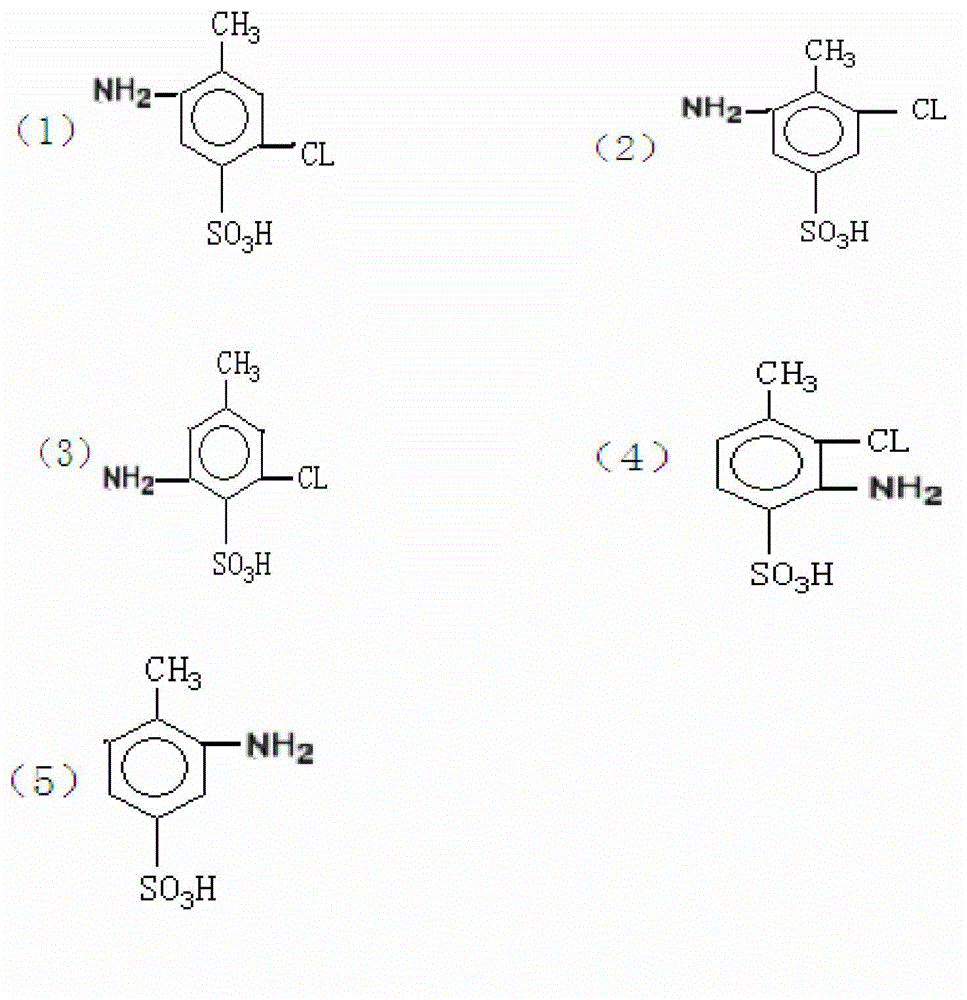

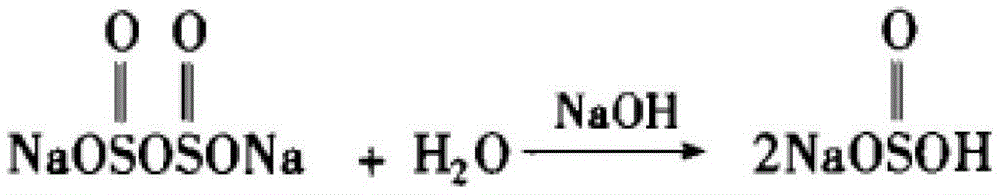

Method used

Image

Examples

Embodiment 1

[0042] In a jacketed reactor with a reflux condenser, add 2 mol of CLT acid isomer mixture, 5 mol of anhydrous sodium sulfite, 10 mol of acetone, 40 mol of deionized water, raise the temperature to 40°C, and reflux for 2 hours; use 30% Caustic soda solution to adjust the pH value of the system to 10; add 20mol formaldehyde dropwise, and control the temperature to 50°C; after the dropwise addition, raise the temperature to 80°C, and reflux for 3 hours; cool down to room temperature, and obtain a new type of aliphatic high-efficiency cement superplasticizer crude liquid . Filter to obtain a novel aliphatic superplasticizer liquid product with a solid content of 30%. A new type of high-efficiency cement water-reducer is obtained by compounding the aliphatic high-efficiency water-reducer liquid product with the commonly used sulfamic acid high-efficiency cement water-reducer with a solid content of 30% in the market at a weight ratio of 7:1.

Embodiment 2

[0044] In a jacketed reactor with a reflux condenser, add 3 mol of CLT acid isomer mixture, 3.5 mol of anhydrous sodium sulfite, 10 mol of acetone, 50 mol of deionized water, heat up to 50°C, and reflux for 1 hour; % caustic soda solution to adjust the pH value of the system to 11; add 20mol formaldehyde dropwise, and control the temperature to 60°C; after the dropwise addition, raise the temperature to 82°C, and reflux for 5 hours; cool down to room temperature; obtain a new type of aliphatic high-efficiency cement superplasticizer crude liquid. Filter to obtain a novel aliphatic superplasticizer liquid product with a solid content of 35%. A new type of high-efficiency cement water-reducer is obtained by compounding the aliphatic high-efficiency water-reducer liquid product with the commonly used sulfamic acid high-efficiency cement water-reducer with a solid content of 35% in the market at a weight ratio of 4:1.

Embodiment 3

[0046]In a jacketed reactor with a reflux condenser, add 2 mol of CLT acid isomer mixture, 10 mol of anhydrous sodium sulfite, 15 mol of acetone, 40 mol of deionized water, raise the temperature to 55°C, and reflux for 3 hours; use 30% Adjust the pH value of the system to 13 with caustic soda solution; add 20mol formaldehyde dropwise, and control the temperature to 70°C; after the dropwise addition, raise the temperature to 90°C, and reflux for 6 hours; cool down to room temperature; obtain a new type of aliphatic high-efficiency cement superplasticizer crude liquid . Filter to obtain a novel aliphatic high-efficiency water reducer liquid product with a solid content of 40%. A new type of high-efficiency cement water-reducer is obtained by compounding the aliphatic high-efficiency water-reducer liquid product with the commonly used sulfamic acid high-efficiency cement water-reducer with a solid content of 40% in the market at a weight ratio of 2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com