A hyperbranched glycoside polycarboxylate water reducer and its preparation method and application

A technology of chained glycoside polycarboxylate and water reducer, which is applied in the field of hyperbranched polycarboxylate water reducer, can solve the problems of concrete bleeding and segregation, various types of cement, poor cement adaptability, etc., and achieve high fluidity, High water reduction rate and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Add a certain amount of methyl methacrylate (MMA) and polyethylene glycol monomethyl ether (MPEG) with a molar ratio of 3:1 into the three-necked flask of the reaction vessel, use cyclohexane as the reaction solvent, and use t-butyl as the catalyst Lithium alkoxide (the dosage is 1% of the molar weight of methyl methacrylate) and polymerization inhibitor phenothiazine (the dosage is 0.1% of the molar weight of methyl methacrylate), under the conditions of 70-80°C and air The reaction was carried out with constant stirring. After 4-5 hours of reaction, the mixed system after the reaction is distilled off under reduced pressure to remove the reaction solvent and unreacted MMA to obtain the macromonomer MAMPEG.

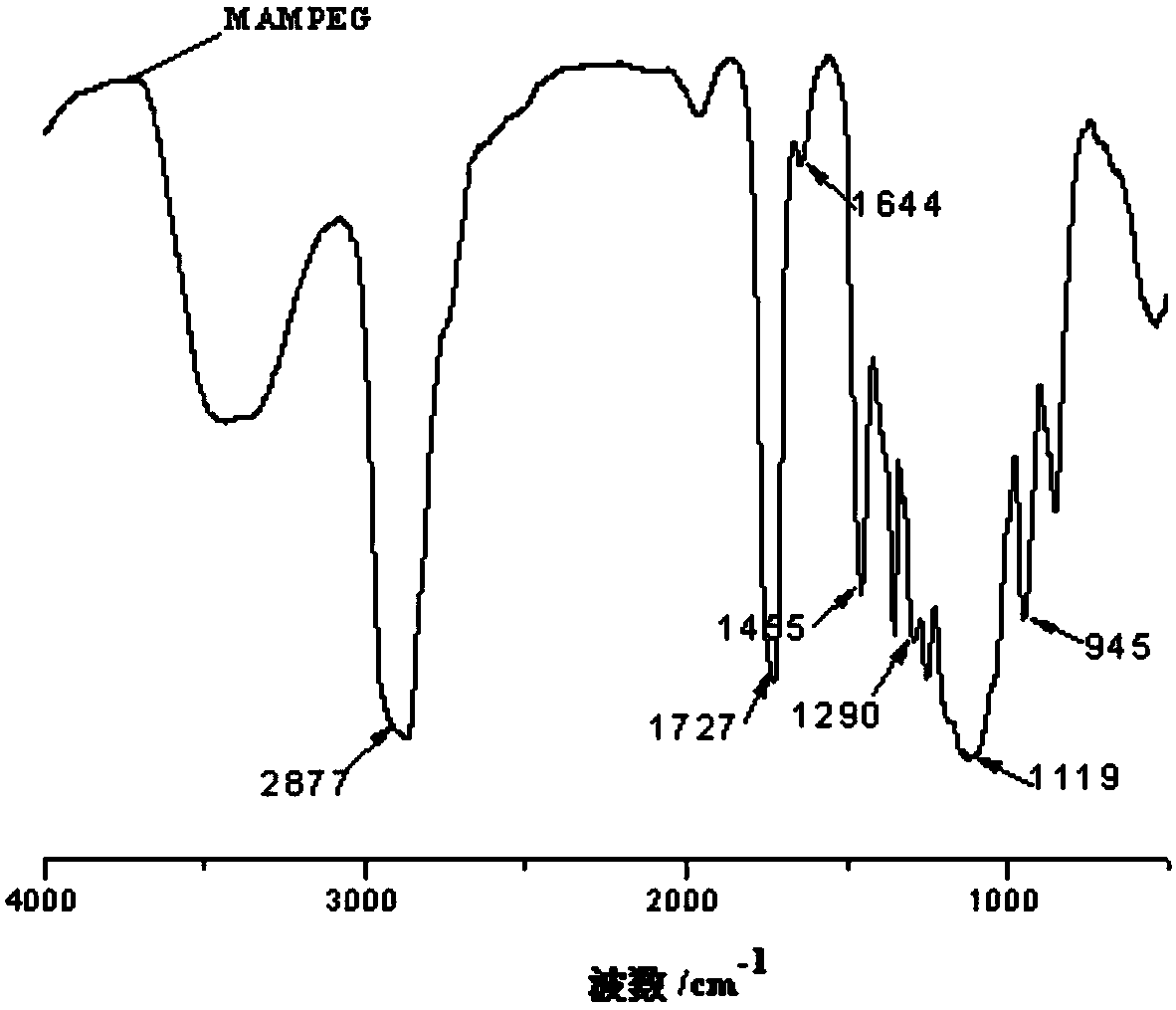

[0038] The infrared absorption spectrum of MAMPEG is as follows figure 1 shown, from figure 1 As can be seen in , at 1644cm -1 The place is the stretching vibration peak of olefinic double bond C=C; 945cm -1 is the out-of-plane bending vibration absorption ...

Embodiment 2

[0046] 1. Add a certain amount of methyl methacrylate (MMA) and polyethylene glycol monomethyl ether (MPEG) with a molar ratio of 3:1 into the three-necked flask of the reaction vessel, use cyclohexane as the reaction solvent, and use t-butyl as the catalyst Lithium alkoxide (the dosage is 1% of the molar weight of methyl methacrylate) and polymerization inhibitor phenothiazine (the dosage is 0.1% of the molar weight of methyl methacrylate), under the conditions of 70-80°C and air The reaction was carried out with constant stirring. React for 4 to 5 hours. After the reaction, the mixed system is distilled under reduced pressure to remove the reaction solvent and unreacted MMA, and the macromonomer MAMPEG is obtained;

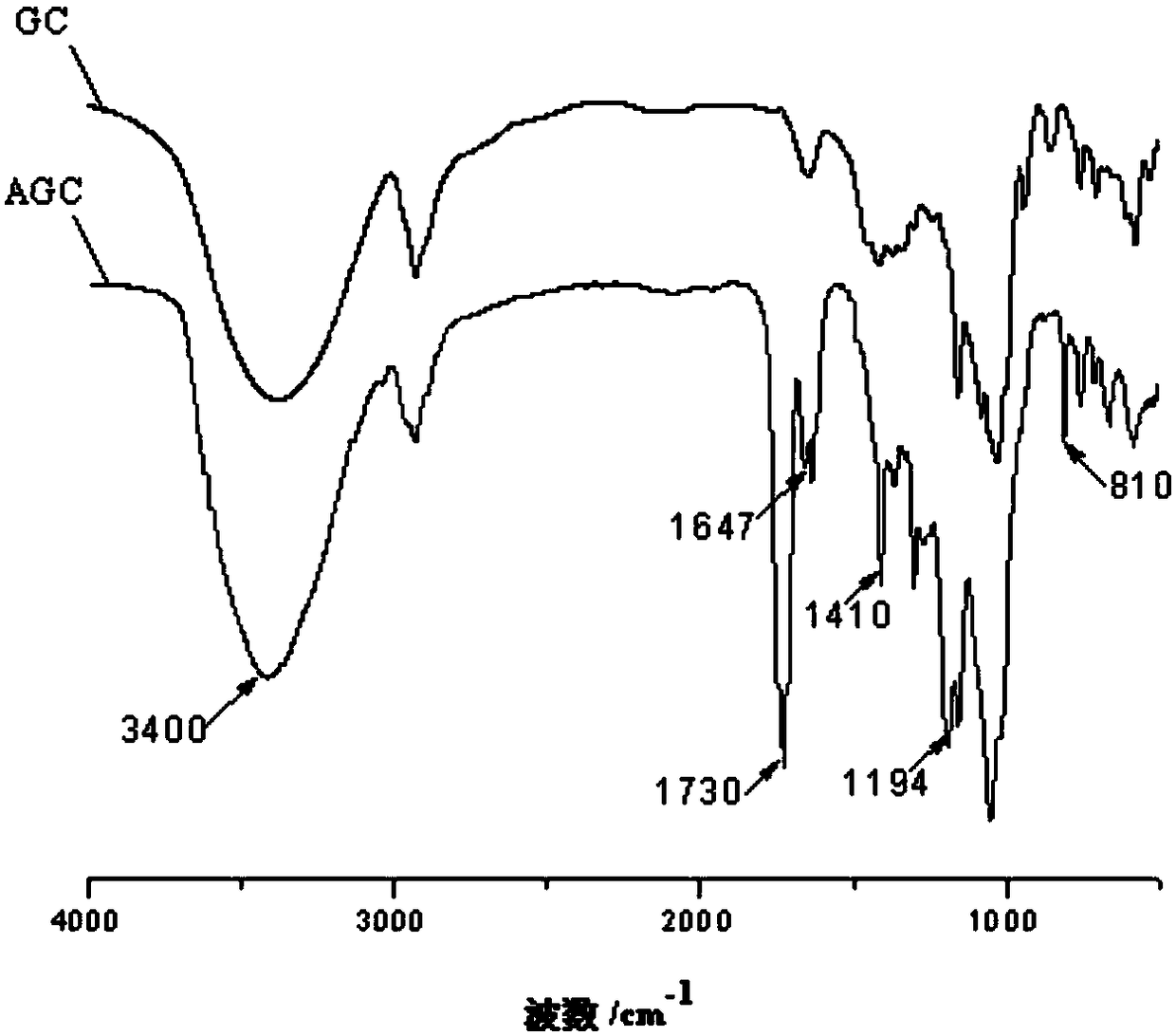

[0047] 2. Add a certain amount of glycoside (GC) and solvent N,N'-dimethylformamide (DMF) into the three-necked flask of the reaction vessel, and slowly dissolve the excess acryloyl chloride dissolved in DMF under the condition of an ice-water bath. Add it drop...

Embodiment 3

[0051] 1. Add a certain amount of methyl methacrylate (MMA) and polyethylene glycol monomethyl ether (MPEG) with a molar ratio of 3:1 into the three-necked flask of the reaction vessel, use cyclohexane as the reaction solvent, and use t-butyl as the catalyst Lithium alkoxide (the dosage is 1% of the molar weight of methyl methacrylate) and polymerization inhibitor phenothiazine (the dosage is 0.1% of the molar weight of methyl methacrylate), under the conditions of 70-80°C and air The reaction was carried out with constant stirring. React for 4 to 5 hours. After the reaction, the mixed system is distilled under reduced pressure to remove the reaction solvent and unreacted MMA, and the macromonomer MAMPEG is obtained;

[0052] 2. Add a certain amount of glycoside (GC) and solvent N,N'-dimethylformamide (DMF) into the three-necked flask of the reaction vessel, and slowly dissolve the excess acryloyl chloride dissolved in DMF under the condition of an ice-water bath. Add it drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com