Preparation method of high-performance forward osmosis membrane

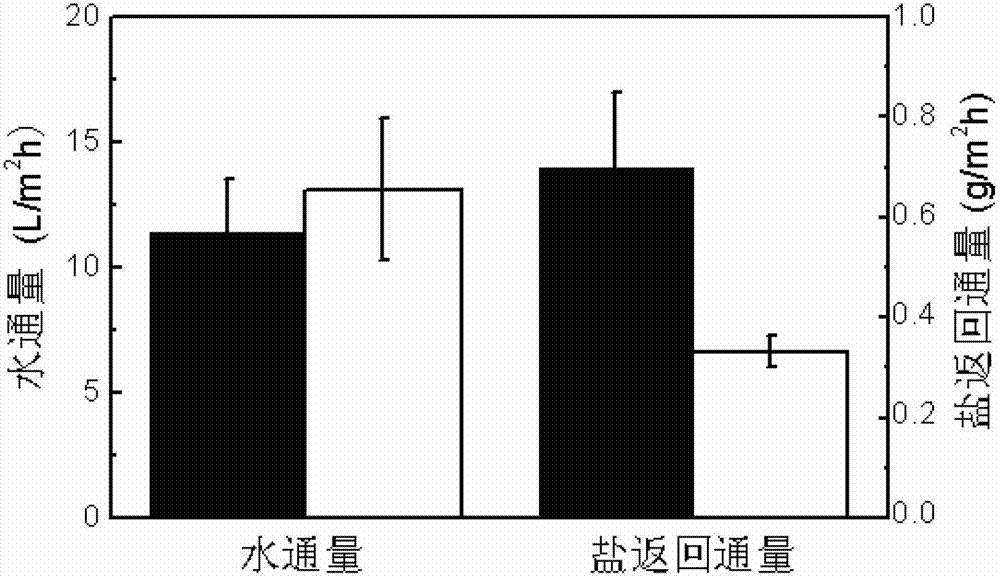

A forward osmosis membrane, high-performance technology, applied in the field of membrane modification, can solve the problem of high salt back-mixing flux, achieve the effects of high reuse rate, low reagent price, and good market promotion prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

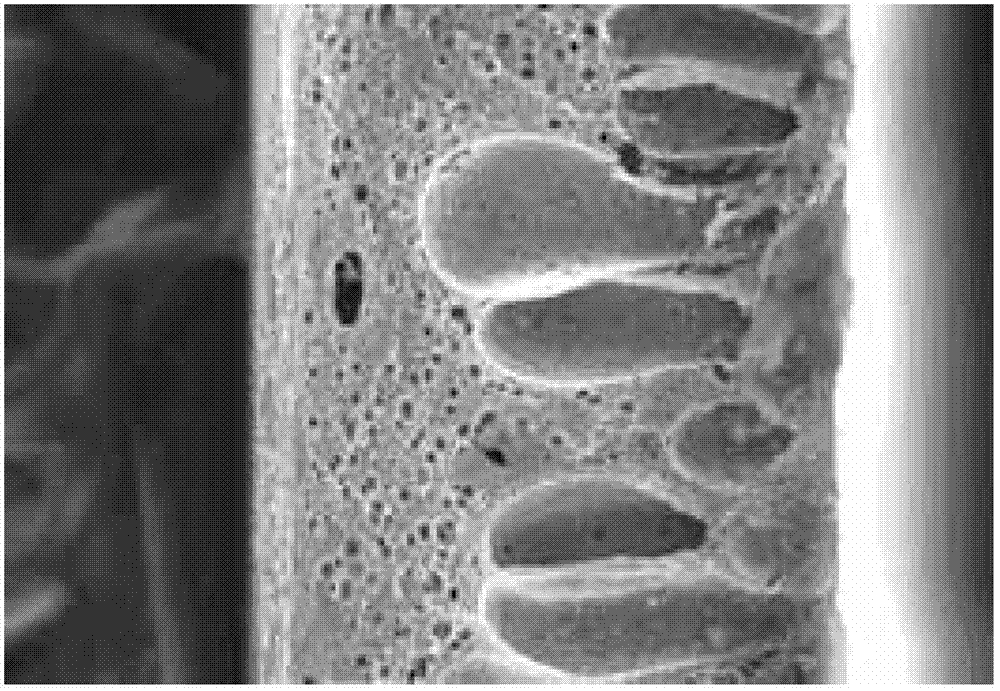

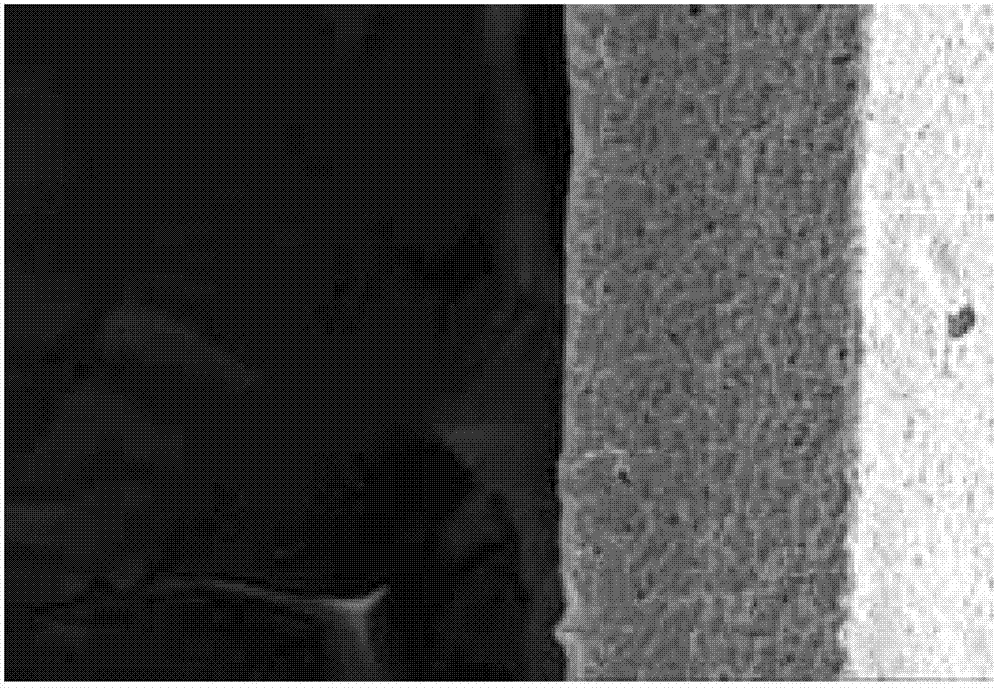

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: the preparation method of the high-performance forward osmosis membrane of this embodiment is realized according to the following steps:

[0017] 1. Mix the film-forming polymer, additives and solvents according to the ratio of parts by weight (15-25): (0-12): (63-85), and prepare a film-casting solution after sealing, stirring and defoaming, and then Using phase inversion method to make flat membrane or hollow fiber membrane;

[0018] 2. Soak the flat membrane or hollow fiber membrane prepared in step 1 in a hot water bath at 50-100°C for 0.5-12 hours, and then put it in a temperature of 5-50°C, a pH value of 2-11, and a concentration of Soak in an organic solution of 50-20000 mg / L for 0.5-12 hours, take it out and wash it with deionized water for 3-5 times, put it into an aqueous solution of glycerol with a volume concentration of 20-70% and soak it for 0.5-3 hours, take it out and dry it in the air. Store in a dry box to complete the prepara...

specific Embodiment approach 2

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, the film-forming polymer, additive and solvent are mixed at a weight ratio of 15:0:85. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in Step 1, the film-forming polymer, additives and solvents are mixed at a ratio of parts by weight of 25:12:63. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com