Preparation method and application of modified silica fume material

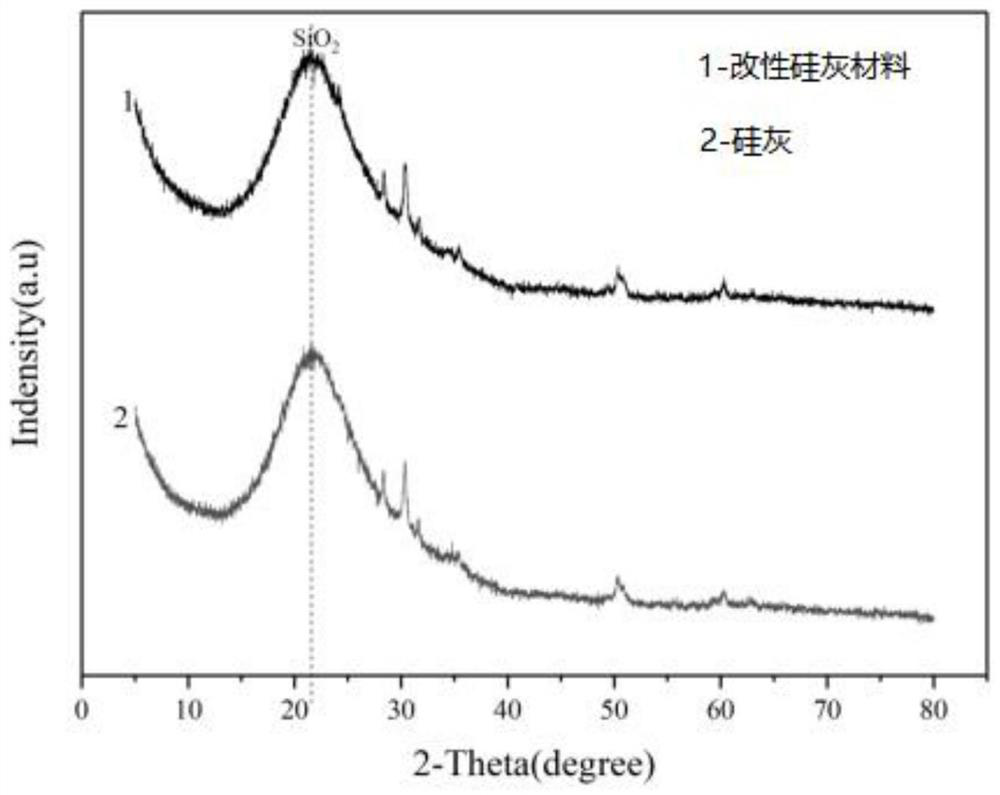

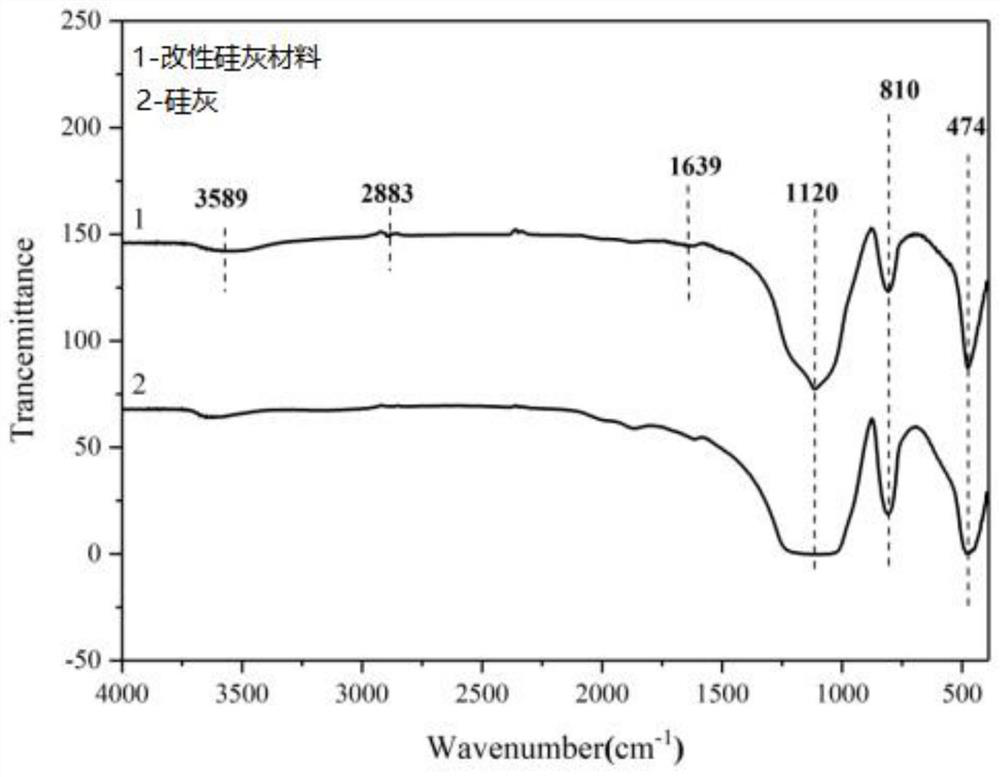

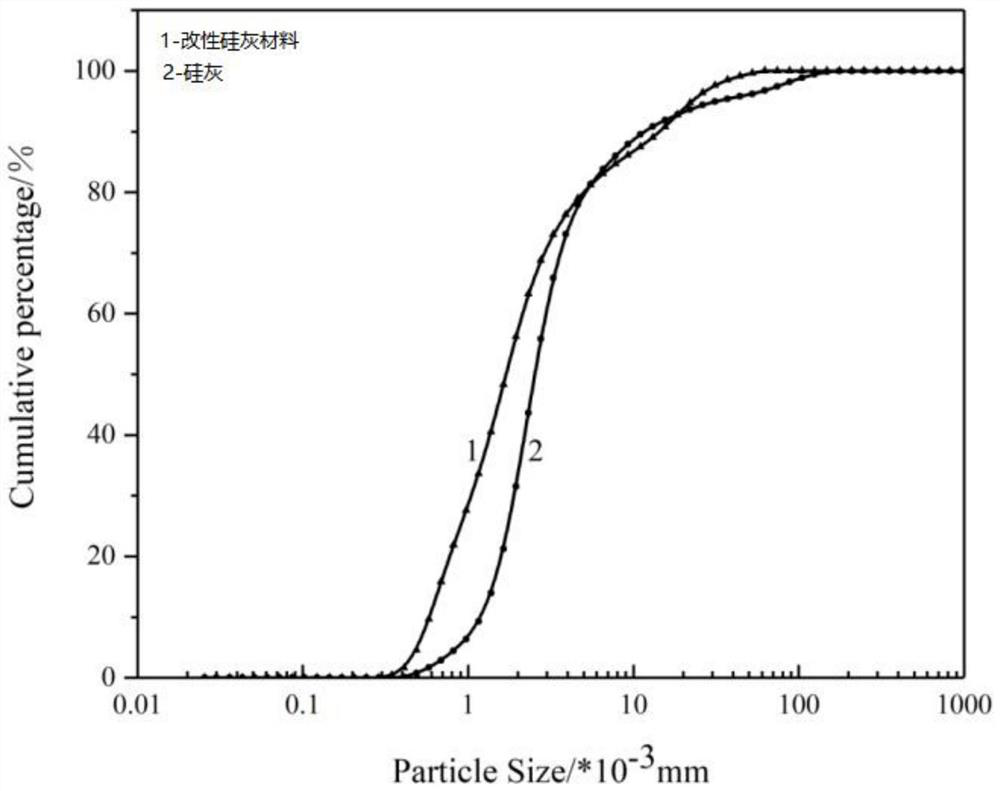

A technology for modifying silicon and silica fume, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of secondary agglomeration, consumption of silica fume, complicated process, etc., and achieve a dense structure of hardened slurry , The effect of particle size distribution concentration and dispersion improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method of preparing a modified silica ash material, comprising the steps of:

[0031] (1) Add silica ash to anhydrous ethanol, the mass ratio of silicon ash and absolute ethanol is 1: 4, ultrasonic dispersion is uniform, and is obtained from silica ash dispersion;

[0032] (2) Add the silane coupling agent KH 550 to deionized water, the mass of the silane coupling agent is 0.4% of the mass of the silica ash, the mass of deionized water is 50% of the water-free ethanol mass, stirring at a rotational speed of 100R / min. Uniform, obtain a silane coupling agent hydrolyzing;

[0033] (3) Add the silane coupling agent hydrolyzing solution to the silicon ash dispersion of step (1), and the vessel port is sealed in a water bath at 70 ° C, and magnetic stirring (900 r / min, time is 1.5 h. After the mixture was completed, filtered, washed with deionized water, and finally dried the filter residue at 60 ° C, and after polishing, the modified silica ash material was obtained.

[00...

Embodiment 2

[0039] A method of preparing a modified silica ash material, comprising the steps of:

[0040] (1) Add silica ash to anhydrous ethanol, the mass ratio of silica ash and absolute ethanol is 1: 3, ultrasonic dispersion is uniform, resulting in a silica fly dispersion;

[0041] (2) The silane coupling agent KH792 is added to deionized water, and the mass of the silane coupling agent is 0.6% of the mass of the silica ash, the mass of deionized water is 50% of the quality of the aqueous ethanol, and the mixing of 100R / min is stirred. Uniform, obtain a silane coupling agent hydrolyzing;

[0042] (3) The silane coupling agent hydrolyzing is added to the silicon ash dispersion of step (1), and the vessel port is sealed in a water bath at 60 ° C, and magnetic stirring (rotational speed is 900R / min, time is 1 h) After the stirring was completed, the filter residue was cleaned with deionized water, and finally dried the filter residue at 60 ° C, and after polishing, the modified silica a...

Embodiment 3

[0045] A method of preparing a modified silica ash material, comprising the steps of:

[0046] (1) Add silica ash to anhydrous ethanol, the mass ratio of silicon ash and anhydrous ethanol is 3: 7, ultrasonic dispersion is uniform, resulting in a silica fly dispersion;

[0047] (2) Add the silane coupling agent KH 570 to deionized water, the mass of the silane coupling agent is 0.8% of the mass of the silica ash, the mass of the deionized water is 50% of the water-free ethanol mass, and the mixing speed of 100R / min is stirred. Uniform, obtain a silane coupling agent hydrolyzing;

[0048] (3) Add the silane coupling agent hydrolyzing solution to the silica ash dispersion of step (1), and the container port is sealed in a water bath placed at 80 ° C, and magnetic stirring (900 r / min, time is 2 h) After the stirring was completed, the filter residue was cleaned with deionized water, and finally dried the filter residue at 60 ° C, and after polishing, the modified silica ash materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com