Main chain carboxy-density-adjustable high-efficiency polycarboxylic acid water reducing agent

A technology of water reducer and polycarboxylate, which is applied in the field of new polycarboxylate water reducer with adjustable main chain carboxyl density, which can solve the problems that do not involve the influence of main chain carboxyl density on the performance of polycarboxylate water reducer , to achieve the effect of improving the fluidity of the net pulp, good dispersibility and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

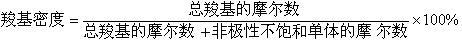

Method used

Image

Examples

Embodiment 1

[0030] Example 1: This high-efficiency polycarboxylate water reducer with adjustable main chain carboxyl density, the main chain is polymerized from maleic anhydride, methacrylic acid, acrylic acid and styrene, wherein the amount of maleic anhydride is 0.5mol, methyl The content of acrylic acid is 50% of the amount of maleic anhydride, the content of acrylic acid is 10% of the amount of maleic anhydride, the content of styrene is 7.7% of the total moles of carboxyl groups, and the amount of ammonium persulfate is 3.0% of the total moles of unsaturated monomers. The side chain is polyethylene glycol monomethyl ether with a relative molecular weight of 2000, the content of which is 19.2% of the total molar number of carboxyl groups, and the main chain and side chain are connected by esterification.

[0031] During the synthesis of polycarboxylate water reducer, 49.0 g of maleic anhydride, 5.6 g of 50% NaOH, H 2 O 55.6 g, start the stirrer, and maintain a rotating speed of 150 re...

Embodiment 2

[0033] Example 2: This high-efficiency polycarboxylate water reducer with adjustable main chain carboxyl density, the main chain is polymerized from maleic anhydride, methacrylic acid, acrylic acid and styrene, wherein the amount of maleic anhydride is 0.5mol, methyl The content of acrylic acid is 30% of maleic anhydride, the content of acrylic acid is 5% of maleic anhydride, the content of α-methylstyrene is 150% of the total moles of carboxyl groups, and the amount of ammonium persulfate is 2.7% of the total moles of unsaturated monomers. %, the side chain is polyethylene glycol monomethyl ether with a relative molecular weight of 3000, the content is 10% of the total molar number of carboxyl groups, and the main chain and side chain are connected by esterification.

[0034] During the synthesis of polycarboxylate water reducer, 49.0 g of maleic anhydride, 5.6 g of 50% NaOH, H 2 O 55.6 g, start the stirrer, and maintain a rotating speed of 150 rev / min, then heat with a water...

Embodiment 3

[0036] Example 3: This high-efficiency polycarboxylate water reducer with adjustable main chain carboxyl density, the main chain is polymerized from maleic anhydride, methacrylic acid, acrylic acid and styrene, wherein the amount of maleic anhydride is 0.5mol, methyl The content of acrylic acid is 40% of maleic anhydride, the content of acrylic acid is 8% of maleic anhydride, the content of styrene is 1% of the total moles of carboxyl groups, and the amount of potassium persulfate is 1.0% of the total moles of unsaturated monomers. It is polyethylene glycol monomethyl ether with a relative molecular weight of 500, and its content is 40% of the total molar number of carboxyl groups. The main chain and side chain are connected by esterification reaction.

[0037] During the synthesis of polycarboxylate water reducer, 49.0 g of maleic anhydride, 5.6 g of 50% NaOH, H 2 O 55.6 g, start the stirrer, and keep the rotating speed of 150 rev / min, then water bath heating. When the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com