Grinding aid for improving adaptability of high-aluminum clinker cement admixture

A technology for cement admixture and high-aluminum clinker, which is applied in the field of grinding aids for improving the adaptability of high-alumina clinker cement admixtures, and can solve the problem of poor adaptability between high-alumina clinker cement and admixtures, and high Problems such as reduction of early strength of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

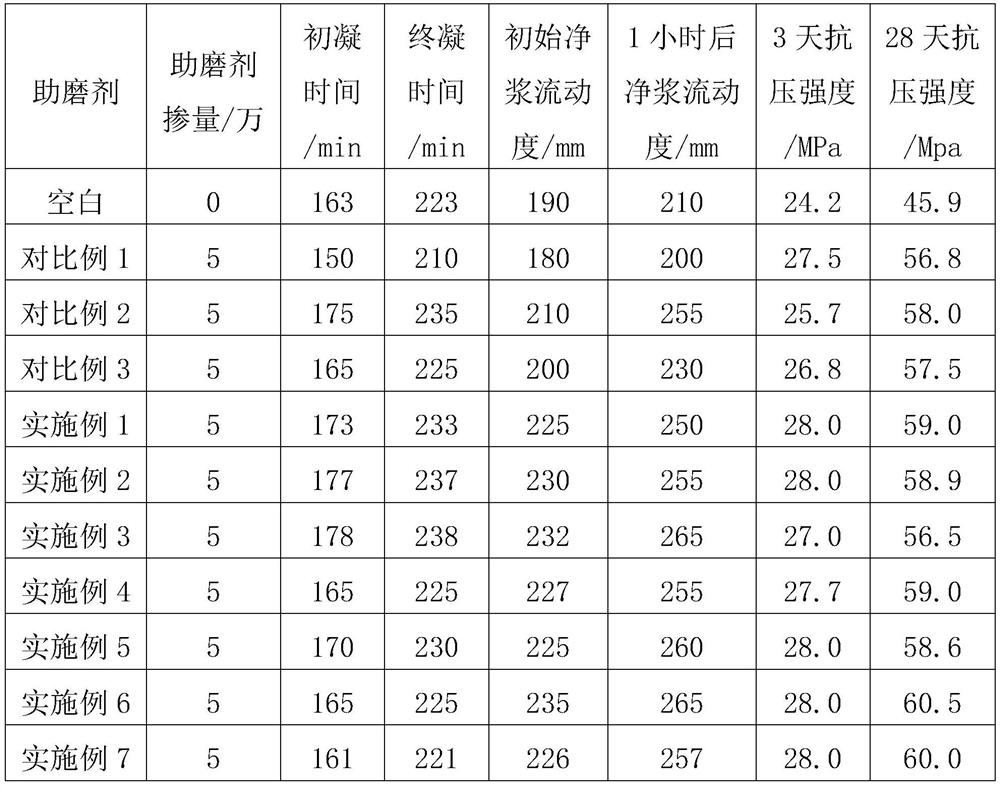

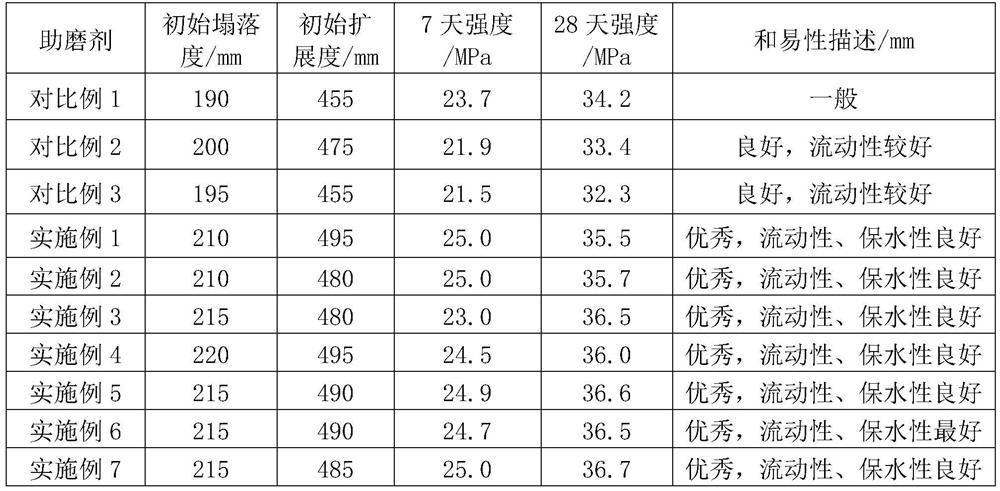

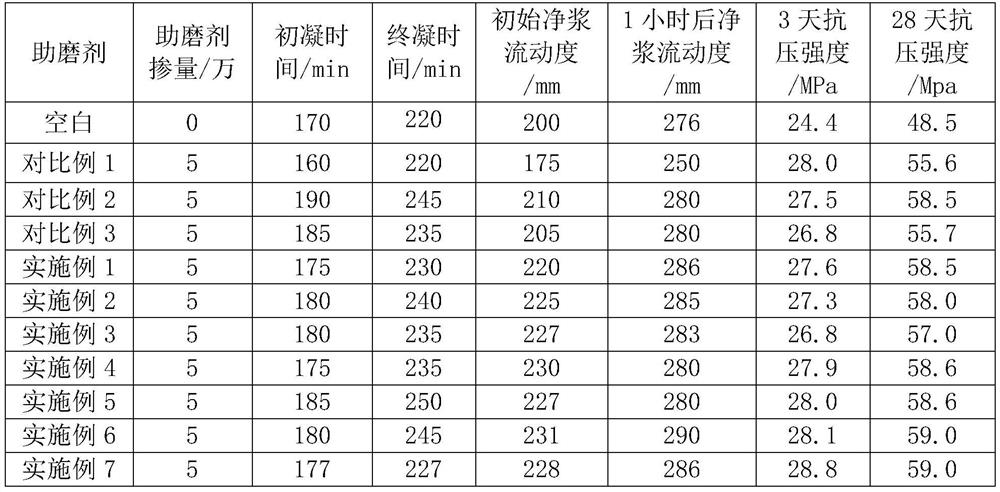

Examples

Embodiment 1

[0040] Preparation of grinding aids to improve the adaptability of high alumina clinker cement admixtures:

[0041] 1.1 Raw materials (by mass percentage):

[0042] Dipolyglycerol 3%, monoethanol diisopropanolamine 27%, hydroxyethylidene diphosphonic acid 2%, anionic polyacrylamide 0.25%, water 67.75%.

[0043] 1.2 Preparation method

[0044] Mix all the raw materials evenly according to the above ratio to obtain the grinding aid.

Embodiment 2

[0046] Preparation of grinding aids to improve the adaptability of high alumina clinker cement admixtures:

[0047] 2.1 Raw materials (by mass percentage):

[0048] Dipolyglycerol 5%, monoethanol diisopropanolamine 25%, hydroxyethylidene diphosphonic acid 3%, anionic polyacrylamide 0.25%, water 66.75%.

[0049] 2.2 Preparation method

[0050] Mix all the raw materials evenly according to the above ratio to obtain the grinding aid.

Embodiment 3

[0052] Preparation of grinding aids to improve the adaptability of high alumina clinker cement admixtures:

[0053] 3.1 Raw materials (by mass percentage):

[0054] Dipolyglycerol 15%, monoethanol diisopropanolamine 15%, hydroxyethylidene diphosphonic acid 5%, anionic polyacrylamide 0.15%, water 64.85%.

[0055] 3.2 Preparation method

[0056] Mix all the raw materials evenly according to the above ratio to obtain the grinding aid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com