Polycarboxylic acid slump retaining agent with low bleeding rate and preparation method thereof

A technology of polycarboxylic acid and slump-retaining agent, which is applied in the field of polycarboxylate slump-retaining agent and its preparation, can solve the problems of large slump loss, poor slump retention, poor workability, etc., and achieve slump retention Good, low slump loss, low bleeding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

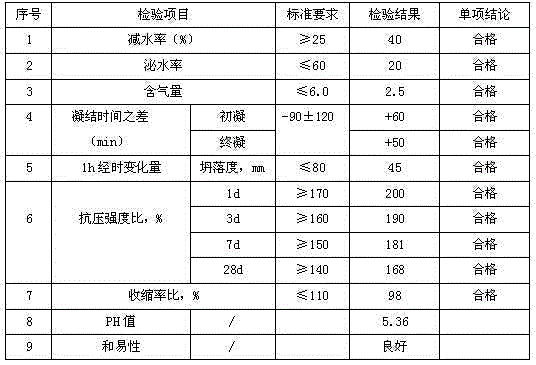

Image

Examples

Embodiment 1

[0020] Formula: 35g of polyoxyethylene acrylic acid, 28g of acrylic acid, 5g of ammonium persulfate, 2.5g of sodium methacrylate, 2.5g of sodium hydroxide, 5g of thioglycolic acid and 130g of purified water.

[0021] Process:

[0022] 1. Weigh the raw materials of each component according to the formula;

[0023] 2. Raise the temperature of purified water with half of the formula ratio to 42°C, then add acrylic acid polyoxyethylene ether to the water, then add acrylic acid and ammonium persulfate with half the formula ratio, and stir to obtain a mixture; heat to heat the temperature of the mixture to 52°C, then add the remaining amount of acrylic acid, stir, and then raise the temperature of the reaction system to 60°C to obtain the heated material;

[0024] 3. Insulate the heated material in step 2 for 2.5 hours, then add the solution of sodium methacrylate, the remaining amount of ammonium persulfate and the remaining amount of purified water dropwise into the...

Embodiment 2

[0026] Formula: 38g of polyoxyethylene acrylic acid, 35g of acrylic acid, 8g of ammonium persulfate, 3g of sodium methacrylate, 3g of sodium hydroxide, 8g of thioglycolic acid and 150g of purified water.

[0027] Process:

[0028] 1. Weigh the raw materials of each component according to the formula;

[0029] 2. Raise the temperature of purified water with half the proportion of the formula to 45°C, then add polyoxyethylene acrylic acid ether to the water, then add acrylic acid and ammonium persulfate with half the proportion of the formula, stir to obtain a mixture; heat to heat the temperature of the mixture to 55°C, then add the remaining amount of acrylic acid, stir, and then raise the temperature of the reaction system to 60°C to obtain the heated material;

[0030] 3. Insulate the material after the temperature rise in step 2 for 3 hours, then dropwise add the solution of sodium methacrylate, the remaining amount of ammonium persulfate and the remaining amo...

Embodiment 3

[0032] Formula: 33g of polyoxyethylene acrylic acid, 25g of acrylic acid, 3g of ammonium persulfate, 2g of sodium methacrylate, 2g of sodium hydroxide, 3g of thioglycolic acid and 120g of purified water.

[0033] Process:

[0034] 1. Weigh the raw materials of each component according to the formula;

[0035] 2. Raise the temperature of purified water with half of the formula ratio to 40-45°C, then add acrylic acid polyoxyethylene ether to the water, then add acrylic acid and ammonium persulfate with half the formula ratio, and stir to obtain a mixture; Heating the temperature to 50-55°C, then adding the remaining amount of acrylic acid, stirring, and then raising the temperature of the reaction system to 58-62°C to obtain the heated material;

[0036] 3. Insulate the heated material in step 2 for 2-3 hours, then add the solution of sodium methacrylate, the remaining amount of ammonium persulfate and the remaining amount of purified water dropwise into the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com