Alkyl polyoxyether and preparation method thereof, and polycarboxylate superplasticizer prepared from alkyl polyoxyether and preparation method thereof

A technology of polyoxyalkyl ether and polycarboxylic acid, applied in the fields of polyoxyalkylene water reducing agent and preparation, polyoxyalkylene ether and preparation thereof, can solve the problem of concrete bleeding and segregation, high production cost and low water reduction rate and other problems, to achieve a good slow-release effect, delay the hydrolysis rate, and improve the water reduction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

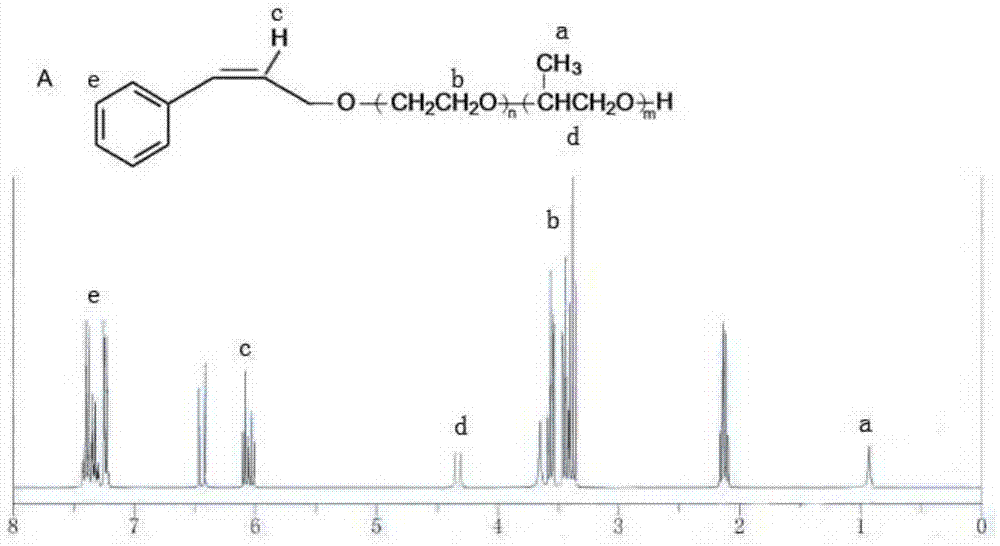

[0041] The synthesis of embodiment 1 monomer A

[0042] Add 26.8g of cinnamyl alcohol and 0.35g of sodium methoxide into the high pressure reactor, seal the equipment, pass nitrogen to replace the air in the high pressure reactor, raise the temperature to 100-120°C, and feed 290g of ethylene oxide raw material, when the temperature rises the pressure drops Initiate the reaction, and then feed 30g of propylene oxide to control the reaction temperature at 110-130°C and the pressure in the kettle at 0.3-0.5MPa.

[0043] After the reaction is completed, the pressure in the kettle gradually drops until it stops falling for 30 minutes, and the material is aged and cooled to obtain the monomer A. NMR of A monomer 1 H spectrum as figure 1 Shown (400MHz, D 2 O).

Embodiment 2

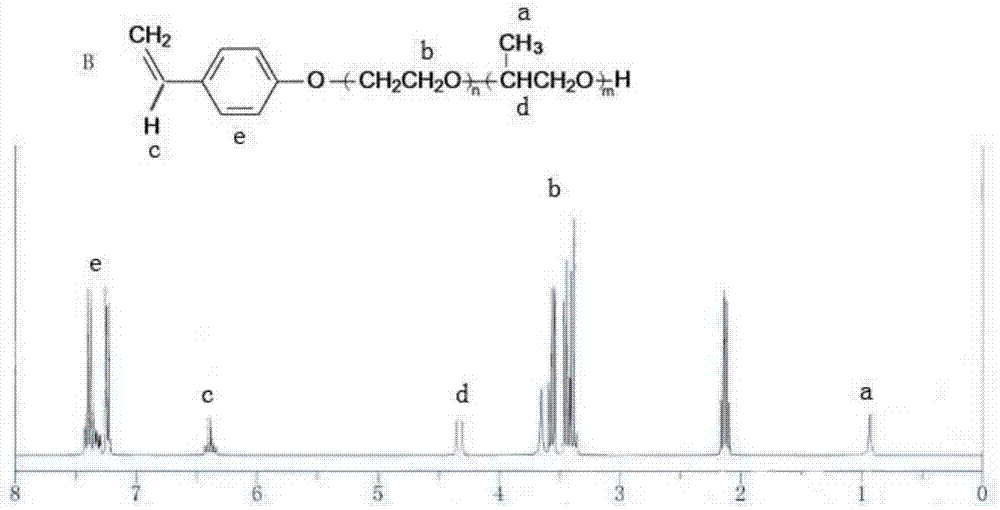

[0044] The synthesis of embodiment 2 monomer B

[0045] Add 20.5g 4-hydroxystyrene and 0.36g sodium methylate in the high-pressure reactor, seal the equipment, pass nitrogen to replace the air in the high-pressure reactor, heat up, to 100-120°C, feed 300g ethylene oxide raw material, when The rise in temperature and the drop in pressure indicate that the reaction is initiated, and then 45g of propylene oxide is introduced to control the reaction temperature at 110-130° C. and the pressure in the kettle at 0.3-0.5 MPa.

[0046] After the reaction is completed, the pressure in the kettle gradually drops until it stops falling for 30 minutes, and then the material is aged and cooled to obtain the B monomer. NMR of B monomer 1 H spectrum as figure 2 Shown (400MHz, deuterated dimethyl sulfoxide).

Embodiment 3

[0047] The preparation of embodiment 3 polycarboxylate superplasticizer

[0048] Add 295g of monomer A, 275g of deionized water, and 3.5g of cyclohexyl acrylate into a 1000ml round-bottomed three-necked flask, stir and dissolve evenly, add 1.8g of hydrogen peroxide with a mass concentration of 30%, and the reaction temperature is 40°C. and B solution, the dropping time is 1h, after the dropwise addition, continue to react for 1h, and then get clear and bright polycarboxylate superplasticizer mother liquor.

[0049] Wherein A solution is formed from 28g of acrylic acid, 20g of deionized water and 0.5g of ascorbic acid; B solution is formed of 1.2g of thioglycolic acid and 30g of deionized water.

[0050] The weight average molecular weight of the obtained polycarboxylate water reducer is about 35700 through gel chromatography test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com