High-activity collagen filler as well as preparation method and application thereof

A collagen and high-activity technology, applied in the field of leather, can solve the problems of reducing the amount of high-activity collagen fillers, tannin extract usage, weak adsorption, and reducing the ability of protein fillers to combine with skin collagen fibers, so as to improve leather quality. The effect of fleshy feeling, promoting adsorption and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

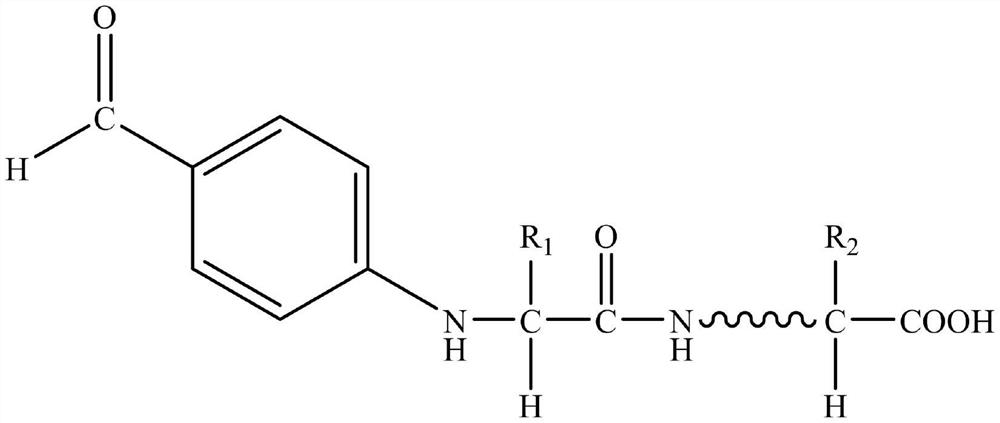

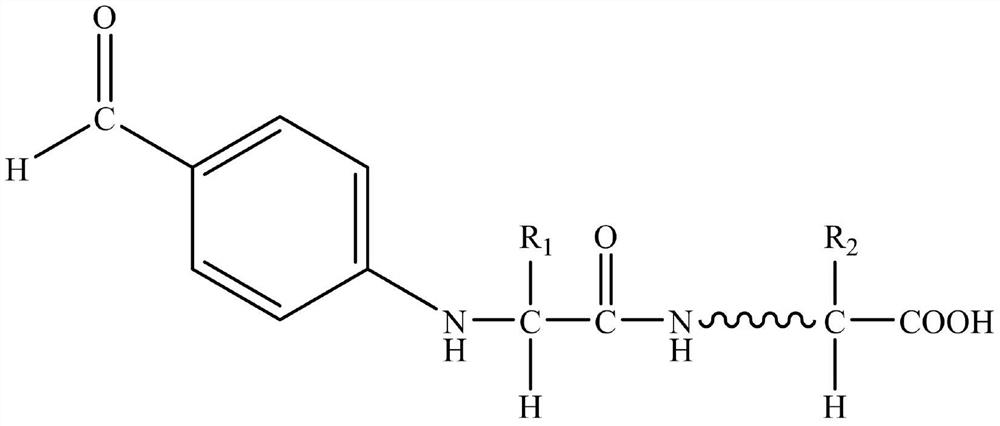

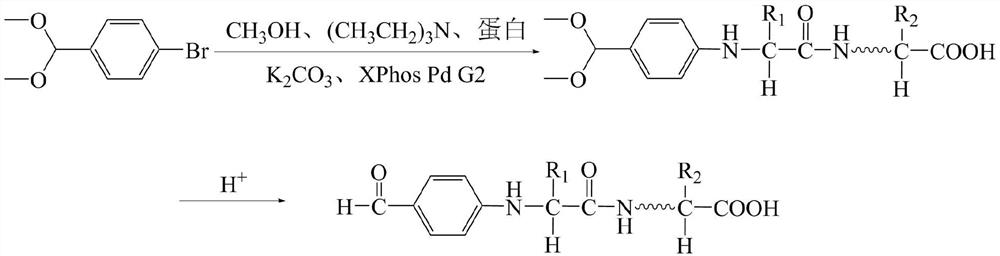

Method used

Image

Examples

Embodiment 1

[0032] A preparation method for a highly active collagen filler, comprising the steps of:

[0033]Step (1): Dissolve 100 parts of leather shavings, 3 parts of potassium hydroxide, and 3 parts of potassium carbonate in 200 parts of water, degrade at 80°C for 4 hours, then cool down to 50°C, add 3 parts of protease, react for 1 hour, and finally Add ethanol in equal parts to water, filter, and vacuum-dry to obtain collagen / potassium carbonate powder;

[0034] Step (2): Dissolve 12 parts of palladium acetate, 3 parts of potassium carbonate, and 30 parts of 2-dicyclohexylphosphine-2',4',6'-triisopropylbiphenyl (CAS: 564483-18-7) Into 1000 parts of tert-butanol, feed nitrogen gas, mix at 72°C for 20 hours, and discharge excess air to prepare a catalyst solution;

[0035] Step (3): Get 38 parts of catalyst solution, 100 parts of collagen / potassium carbonate powder, 8 parts of potassium carbonate, 6 parts of triethylamine, 18 parts of methanol, 115 parts of 4-bromobenzaldehyde dimet...

Embodiment 2

[0037] A preparation method for a highly active collagen filler, comprising the steps of:

[0038] Step (1): Dissolve 100 parts of leather shavings, 5 parts of potassium hydroxide, and 2 parts of potassium carbonate in 320 parts of water, degrade at 70°C for 5 hours, then cool down to 55°C, add 2 parts of protease, react for 2 hours, and finally Add ethanol in equal parts to water, filter, and vacuum-dry to obtain collagen / potassium carbonate powder;

[0039] Step (2): Dissolve 18 parts of palladium acetate, 4 parts of potassium carbonate, and 42 parts of 2-dicyclohexylphosphine-2',4',6'-triisopropylbiphenyl (CAS: 564483-18-7) Into 1000 parts of tert-butanol, feed nitrogen gas, mix at 75°C for 32 hours, and discharge excess air to prepare a catalyst solution;

[0040] Step (3): Take 12 parts of catalyst solution, 100 parts of collagen / potassium carbonate powder, 6 parts of potassium carbonate, 3 parts of triethylamine, 12 parts of methanol, 100 parts of 4-bromobenzaldehyde di...

Embodiment 3

[0042] A preparation method for a highly active collagen filler, comprising the steps of:

[0043] Step (1): Dissolve 100 parts of leather shavings, 8 parts of alkali (potassium hydroxide), and 2 parts of buffer (potassium carbonate) in 480 parts of water, degrade at 80°C for 4 hours, then cool down to 60°C, and add 1 Parts of protease were reacted for 3 hours, and finally ethanol was added in equal parts to water, filtered, and vacuum-dried to obtain collagen / potassium carbonate powder.

[0044] Step (2): Dissolve 8 parts of palladium acetate, 2 parts of potassium carbonate, and 15 parts of 2-dicyclohexylphosphine-2',4',6'-triisopropylbiphenyl (CAS: 564483-18-7) Into 1000 parts of tert-butanol, feed nitrogen, mix at 55°C for 18 hours, and exhaust excess air to prepare a catalyst solution.

[0045] Step (3): Get 25 parts of catalyst solution, 100 parts of collagen / potassium carbonate powder, 8 parts of potassium carbonate, 5 parts of triethylamine, 18 parts of methanol, 110 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com