Preparation method of zinc-air battery catalyst

A technology of air battery and catalyst, which is applied to battery electrodes, fuel cell half-cells, secondary battery-type half-cells, circuits, etc., can solve the problems of low efficiency, high cost, short life, etc., and achieve improved adsorption, Improve the service life and expand the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

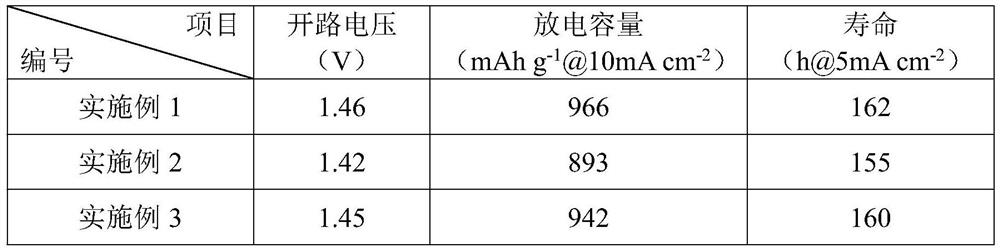

Embodiment 1

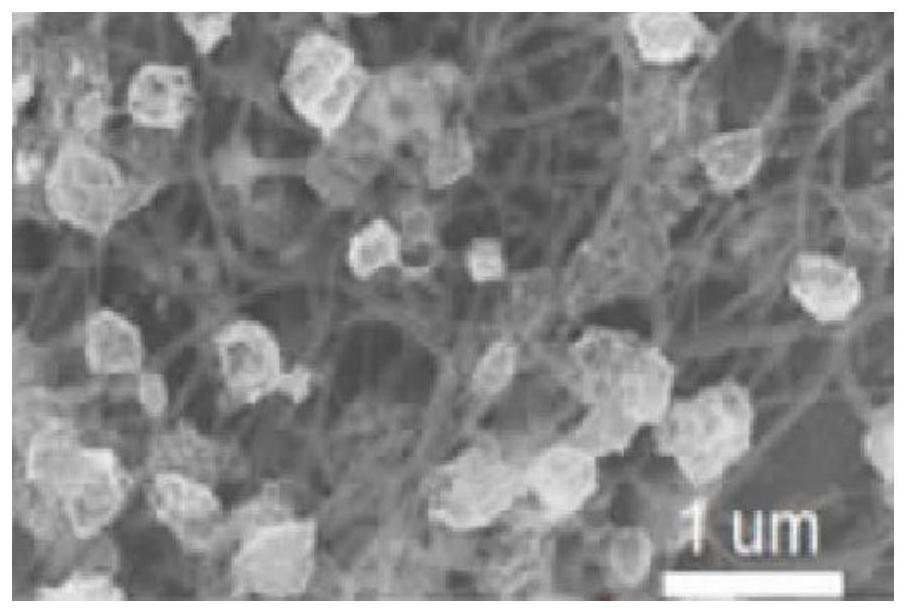

[0027] A preparation method of a zinc-air battery catalyst, specifically comprising the following steps:

[0028] S1: Add 2,5-dihydroxyterephthalic acid and polyacrylonitrile into N,N-dimethylformamide, dissolve it ultrasonically, and then transfer it to a syringe pump. At an injection voltage of 16kV, the injection distance 12cm, and the injection rate was 0.8mL / h on the electrospinning receiving roll to obtain a layer of fiber film I; wherein the mass ratio of 2,5-dihydroxyterephthalic acid to polyacrylonitrile was 0.11:0.44.

[0029] S2: Add cobalt nitrate hexahydrate and polyacrylonitrile into N,N-dimethylformamide, ultrasonically dissolve it, and then transfer it to a syringe pump. The injection voltage is 14kV, the injection distance is 10cm, and the injection rate is Electrospun fiber membrane I was electrospun at 0.6mL / h to obtain a layer of fiber membrane II; wherein the mass ratio of cobalt nitrate hexahydrate to polyacrylonitrile was 1.6:1.8.

[0030] S3: Remove th...

Embodiment 2

[0033] A preparation method of a zinc-air battery catalyst, specifically comprising the following steps:

[0034] S1: Add 2,5-dihydroxyterephthalic acid and polyacrylonitrile into N,N-dimethylformamide, dissolve it ultrasonically, and then transfer it to a syringe pump. At an injection voltage of 18kV, the injection distance 15cm, the injection rate is 1.0mL / h on the electrospinning receiving roll to obtain a layer of fiber film I; wherein the mass ratio of 2,5-dihydroxyterephthalic acid and polyacrylonitrile is 0.19:0.96.

[0035] S2: Add cobalt nitrate hexahydrate and polyacrylonitrile into N,N-dimethylformamide, ultrasonically dissolve it, and then transfer it to a syringe pump. The injection voltage is 16kV, the injection distance is 12cm, and the injection rate is On the electrospun fiber membrane I at 0.8mL / h, a layer of fiber membrane II was obtained; wherein the mass ratio of cobalt nitrate hexahydrate and polyacrylonitrile was 2.9:3.5.

[0036] S3: Remove the fiber m...

Embodiment 3

[0039] A preparation method of a zinc-air battery catalyst, specifically comprising the following steps:

[0040] S1: Add 2,5-dihydroxyterephthalic acid and polyacrylonitrile into N,N-dimethylformamide, dissolve it ultrasonically, and then transfer it to a syringe pump. At an injection voltage of 17kV, the injection distance 13cm, and the injection rate was 0.9mL / h on the electrospinning receiving roll to obtain a layer of fiber film I; wherein the mass ratio of 2,5-dihydroxyterephthalic acid to polyacrylonitrile was 0.16:0.77.

[0041] S2: Add cobalt nitrate hexahydrate and polyacrylonitrile into N,N-dimethylformamide, ultrasonically dissolve it, and then transfer it to a syringe pump. The injection voltage is 15kV, the injection distance is 11cm, and the injection rate is Electrospun fiber membrane I was electrospun at 0.7mL / h to obtain a layer of fiber membrane II; wherein the mass ratio of cobalt nitrate hexahydrate to polyacrylonitrile was 2.3:2.9.

[0042] S3: Remove the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com