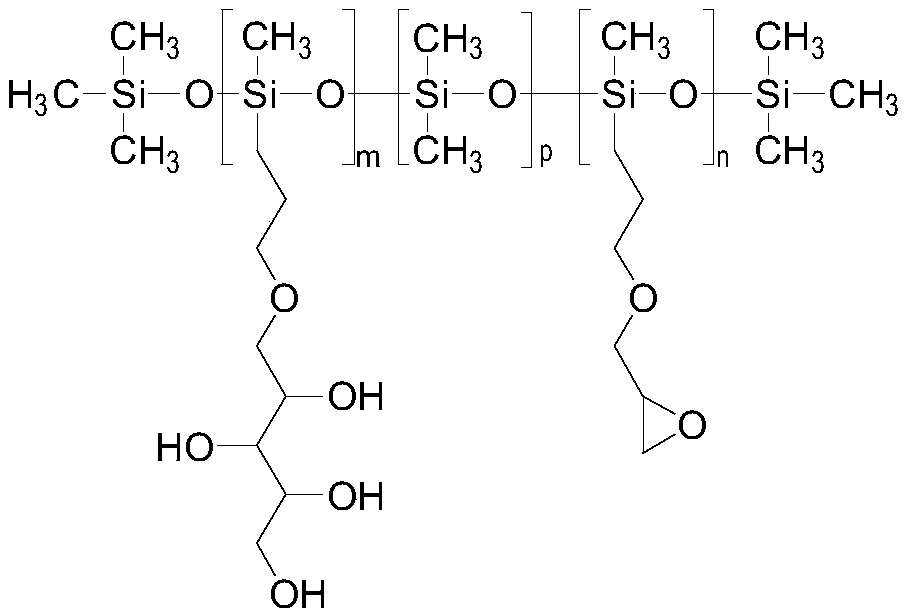

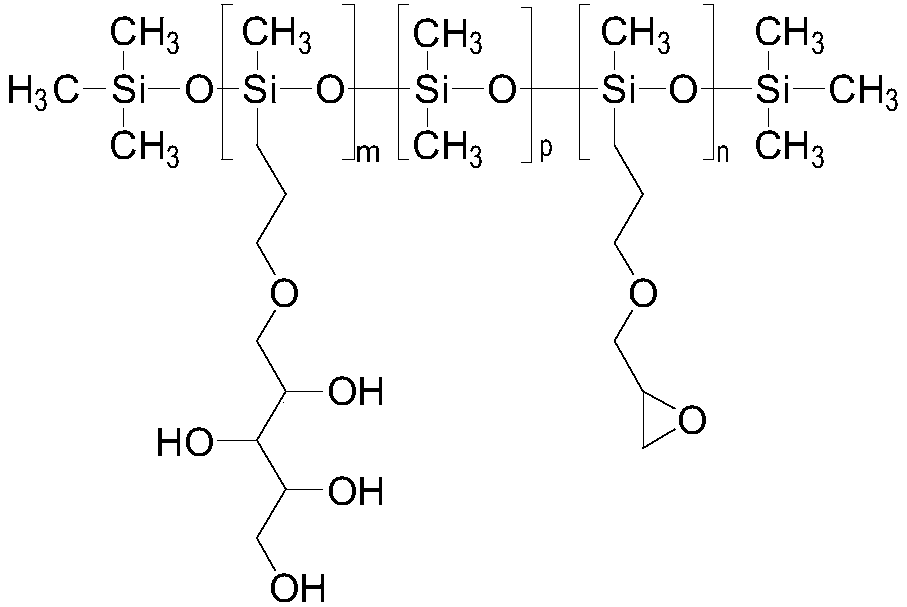

Preparation method of natural alcohol ether modified organic silicon hydrophilic softening agent

An organosilicon and softener technology, applied in the field of preparation of natural alcohol ether-modified organosilicon hydrophilic softeners, can solve problems such as difficulty in meeting requirements, and achieve the effects of low toxicity, improved water washability, and improved adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 100 parts of side chain hydrogen-containing polydimethylsiloxane with a hydrogen content of 0.3%, 48 parts of xylitol monoallyl ether, and 5.7 parts of allyl glycidyl ether to the reaction equipped with a condensation reflux device Put nitrogen into the container, start stirring after 0.5h, add 0.003 parts of chloroplatinic acid catalyst, then heat to 90°C, keep warm for 3h, then cool down to 80°C, add 3.3 parts of N,N,N',N'-tetramethyl Base-1,3-propanediamine, keep warm at 80°C for 1h, cool down to below 50°C and discharge.

Embodiment 2

[0019] Add 100 parts of hydrogen-containing 0.3% side-chain hydrogen-containing polydimethylsiloxane, 50 parts of xylitol monoallyl ether, and 5.5 parts of allyl glycidyl ether into a reaction vessel equipped with a reflux device , blow nitrogen, start stirring after 0.5h, add 0.003 parts of chloroplatinic acid catalyst, then heat to 90°C, keep warm for 3h and cool down to 85°C, add 4.3 parts of N,N,N',N'-tetramethyl- For 1,6-hexanediamine, keep it warm at 85°C for 1 hour, cool down to below 50°C and discharge.

Embodiment 3

[0021] Add 100 parts of hydrogen-containing 0.3% side chain hydrogen-containing polydimethylsiloxane, 45 parts of xylitol monoallyl ether, and 6 parts of allyl glycidyl ether into a reaction vessel equipped with a reflux device , feed nitrogen, start stirring after 0.5h, add 0.005 parts of chloroplatinic acid catalyst, then heat to 90°C, keep warm for 2h, then cool down to 75°C, add 4 parts of bisdimethylaminoethyl ether, keep warm at 75°C After 1.5h, cool down to below 50°C and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com