Solid flaky polycarboxylate superplasticizer and method for preparing same by core-shell emulsion method

A technology of polycarboxylic acid and water reducing agent, which is applied in the fields of cement-based cementitious materials and polycarboxylic acid water reducing agent, can solve the problems of restricting the business area of production enterprises, and achieves advantages of construction and transportation, low transportation cost and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

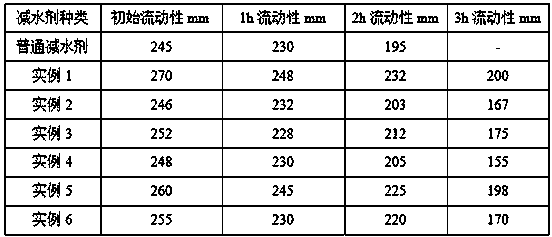

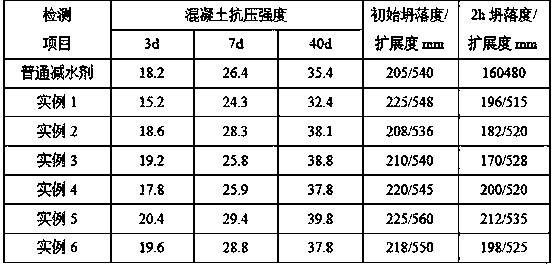

Examples

example 1

[0032] A solid sheet polycarboxylate water reducer, mainly prepared from the following components, the total mass of raw materials is 1000 parts, and each component by weight includes:

[0033] Benzyl methacrylate: 27 parts; the composition of fumaric acid and maleic acid with a mass ratio of 2:1: 8 parts; dibenzoyl peroxide: 0.43 parts; sodium methacrylate: 0.57 parts; Methacryloyloxyethyl phthalic acid monoester (PAMA): 56 parts; the composition of sodium vinylsulfonate and 2-acrylamide-2-methylpropanesulfonic acid with a mass ratio of 1:2: 62 parts ; Vinyl butyl ether polyoxyethylene ether: 820 parts; Sodium polyphosphate: 7 parts; Composition of dimethyl azobisisobutyrate and azobisisobutylimidazoline hydrochloride with a mass ratio of 1:1 : 5.2 parts; Tert-butyl peroxybenzoate: 5.7 parts; Lauryl mercaptan: 3.5 parts; Triisopropanolamine: 4.6 parts;

[0034] A method for preparing solid sheet polycarboxylate water reducer by core-shell emulsion method, said method is carr...

example 2

[0040] A solid sheet polycarboxylate water reducer is prepared from the following components, the total mass of raw materials is 1000 parts, and each component by weight includes:

[0041] Benzyl methacrylate: 26 parts; the composition of fumaric acid and maleic acid with a mass ratio of 2:1: 11 parts; lauryl peroxide: 0.48 parts; sodium methacrylate: 0.62 parts; Acryloyloxyethyl hexahydrophthalic acid monoester (HHMA): 58 parts; 2-acrylamide-2-methylpropanesulfonic acid: 71 parts; methallyl polyoxyethylene ether: 806 parts; Sodium hypophosphite: 8 parts; Azobisisobutylimidazoline hydrochloride: 5.1 parts; tert-butyl peroxyvaleric acid: 5.5 parts; Aliphatic mercaptan: 3.6 parts; Triisopropanolamine: 4.7 parts.

[0042] A method for preparing solid sheet polycarboxylate water reducer by core-shell emulsion method, said method is carried out according to the following steps:

[0043] 1. Preparation of emulsifier: 25-45 parts of deionized water, 11 parts of a composition of fuma...

example 3

[0048] A core-shell emulsion solid sheet polycarboxylate water reducer, which is polymerized by the following components by weight, the total mass of raw materials is 1000 parts, and the components by weight are as follows: 2-phenoxyethyl methyl Acrylic acid esters: 26 parts; the composition of fumaric acid and maleic acid with a mass ratio of 2:1: 9 parts; lauryl peroxide: 0.52 parts; mercaptoethanol: 0.58 parts; Composition of acryloyloxyethyl phthalate monoester (PAMA) and methacryloyloxyethyl hexahydrophthalate monoester (HHMA): 52 parts; sodium vinyl sulfonate: 66 parts; mass Composition of methallyl polyoxyethylene ether and vinyl butyl ether polyoxyethylene ether with a ratio of 2:1: 820 parts; sodium formate: 6 parts; azobisisobutylimidazoline hydrochloride: 5.2 parts; mass Composition of tert-butyl peroxybenzoate and tert-butyl peroxyvalerate in ratio 1:2: 5.8 parts; Aliphatic mercaptan: 3.7 parts; Sodium ethoxide: 5.2 parts.

[0049] A method for preparing solid she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com