Patents

Literature

33results about How to "Reduce long-distance transportation costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

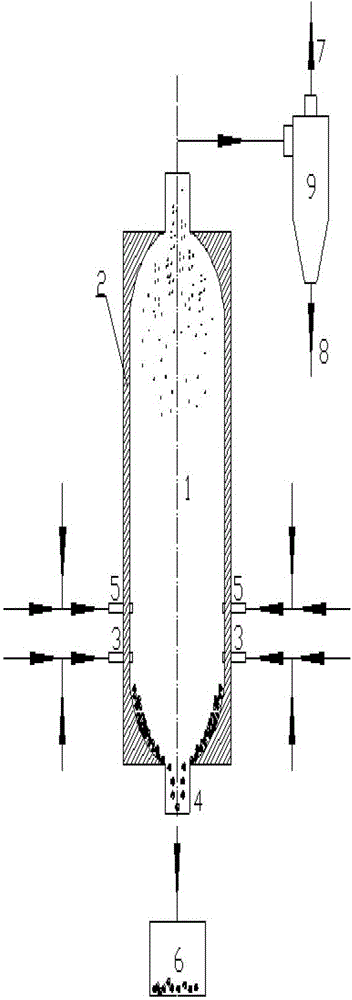

Process and device for quickly preparing powdered active coke for desulfurization by utilizing pulverized coal

ActiveCN103224235ASimple manufacturing processReduce manufacturing costCarbon compoundsOther chemical processesHigh concentrationResource utilization

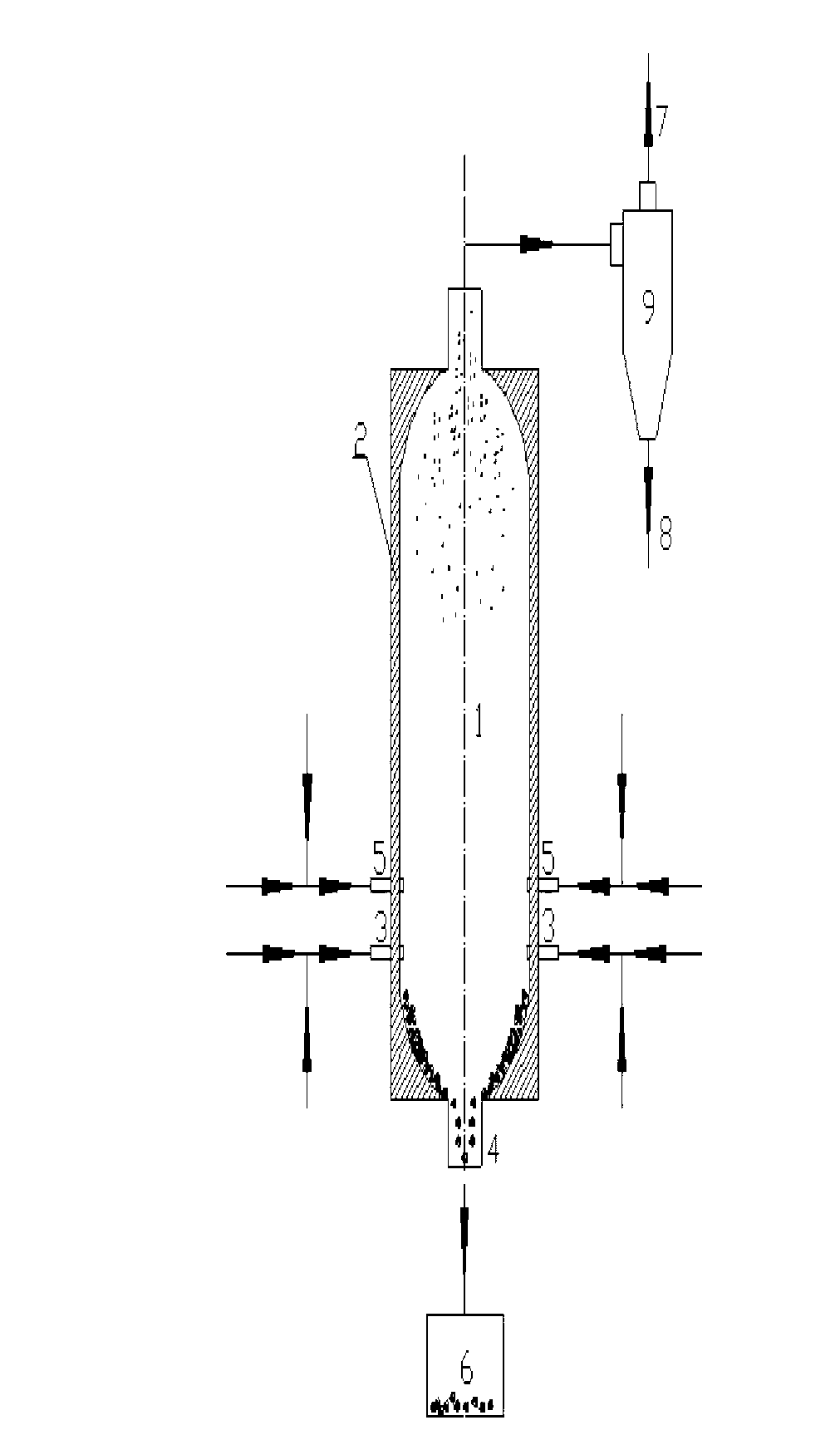

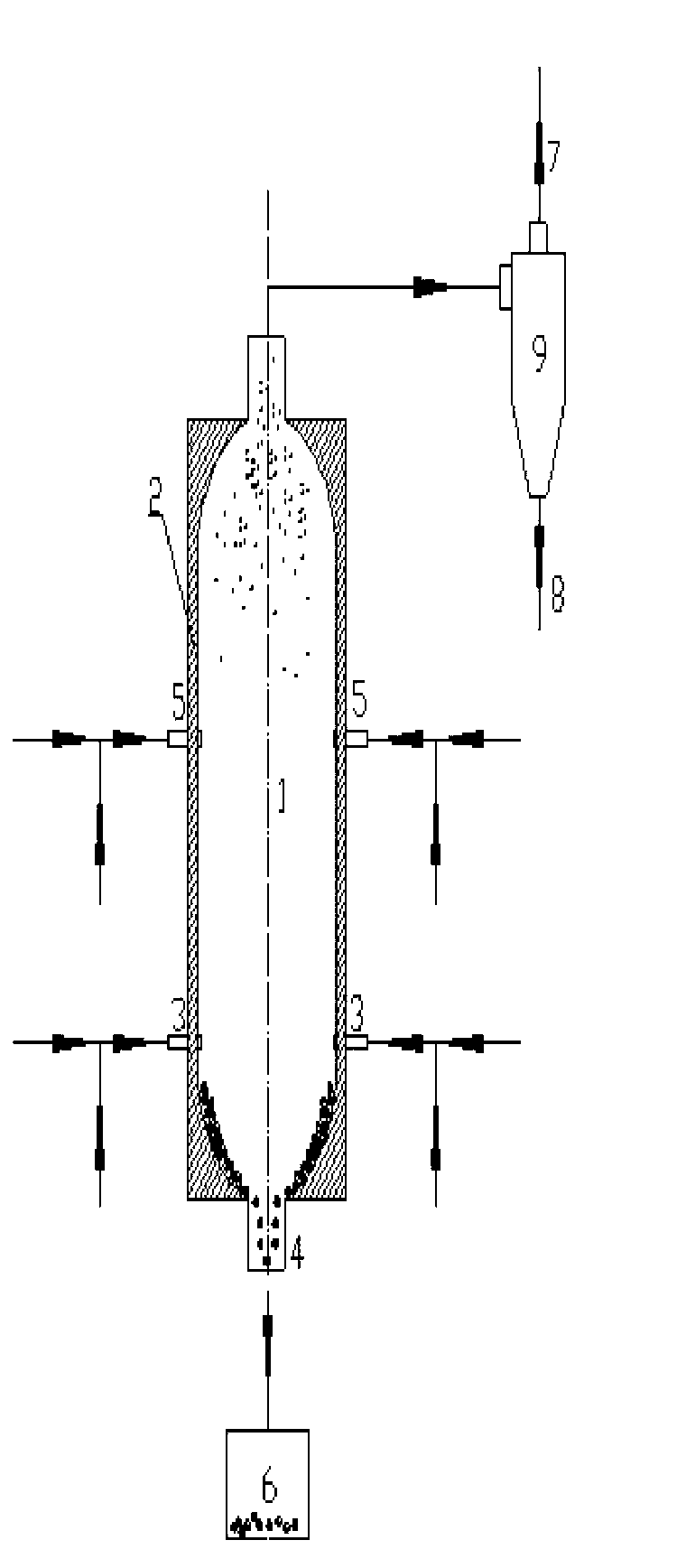

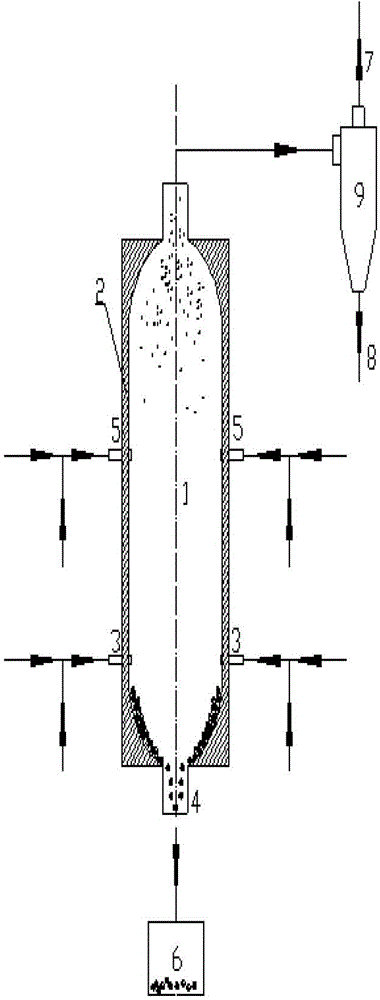

The invention relates to a process and a device for quickly preparing powdered active coke for desulfurization by utilizing pulverized coal. The process and the device are used for producing a powdered active coke product with certain desulfurization performance and reducing combustible gas. According to the process, the powdered active coke for desulfurization and a byproduct reducing gas are prepared from the pulverized coal of 20 to 500 microns by remaining in an entrained-flow bed fast reaction furnace for 1 to 60 seconds. The process and the device has three characteristics that 1, the desulfurization active coke can be prepared by directly utilizing the pulverized coal for combustion of a boiler, so in-situ preparation of a desulfurizing agent of a coal-fired power plant can be realized, and the production cost and the transportation cost of the active coke are reduced; 2, the reducing combustible gas generated in the production process of the active coke can serve as a reburning fuel and is fed into the boiler, so the production quantity of nitric oxide during combustion of the pulverized coal is reduced and the energy efficiency of the whole process is improved; and 3, sulfur dioxide can be recovered and high-concentration sulfur dioxide can be reduced into elemental sulfur, so resource utilization of the sulfur dioxide can be realized.

Owner:SHANDONG UNIV

Seeding medium made of vinasse methane-sludge and preparation method thereof

InactiveCN101606471APromote absorptionInhibitionCultivating equipmentsSoilless cultivationPhylum CyanobacteriaSludge

The invention relates to a seeding medium made of vinasse methane-sludge and a preparation method thereof, not only solving the problem of environment contamination caused by vinasse methane-sludge, but also effectively utilizing vinasse methane-sludge. The seeding medium comprises fresh sludge containing 90 percent of water after methane generated from vinasse in a methane tank, accessories, ferment strain I and ferment strain II, wherein the accessories comprise grass peat, vermiculite and perlite; the ferment strain I comprises saccharomycetes, lactobacillus, high-temperature actinomycetes and bacillus; and the ferment strain II comprises photosynthetic bacteria, lactobacillus, bacillus, saccharomycetes, actinomycetes and terrestrial cyanobacteria. The preparation method comprises the following steps of preparing fresh sludge, dehydrating, adding the ferment strain I for fermentation, adding the ferment strain II for secondary fermentation, air drying, adding accessories, crushing, screening and packing. The vinasse methane-sludge contains 40 to 50 percent of organic matter and 4.3 percent of available nitrogen (N), phosphorus (P) and kalium (K). The seeding medium made of vinasse methane-sludge has better hydrophilicity, and seeding can be carried out after loading the dry seeding medium and spraying water, thus saving both labor and time.

Owner:ANHUI FENGTIAN SEEDLESS WATERMELON TECH

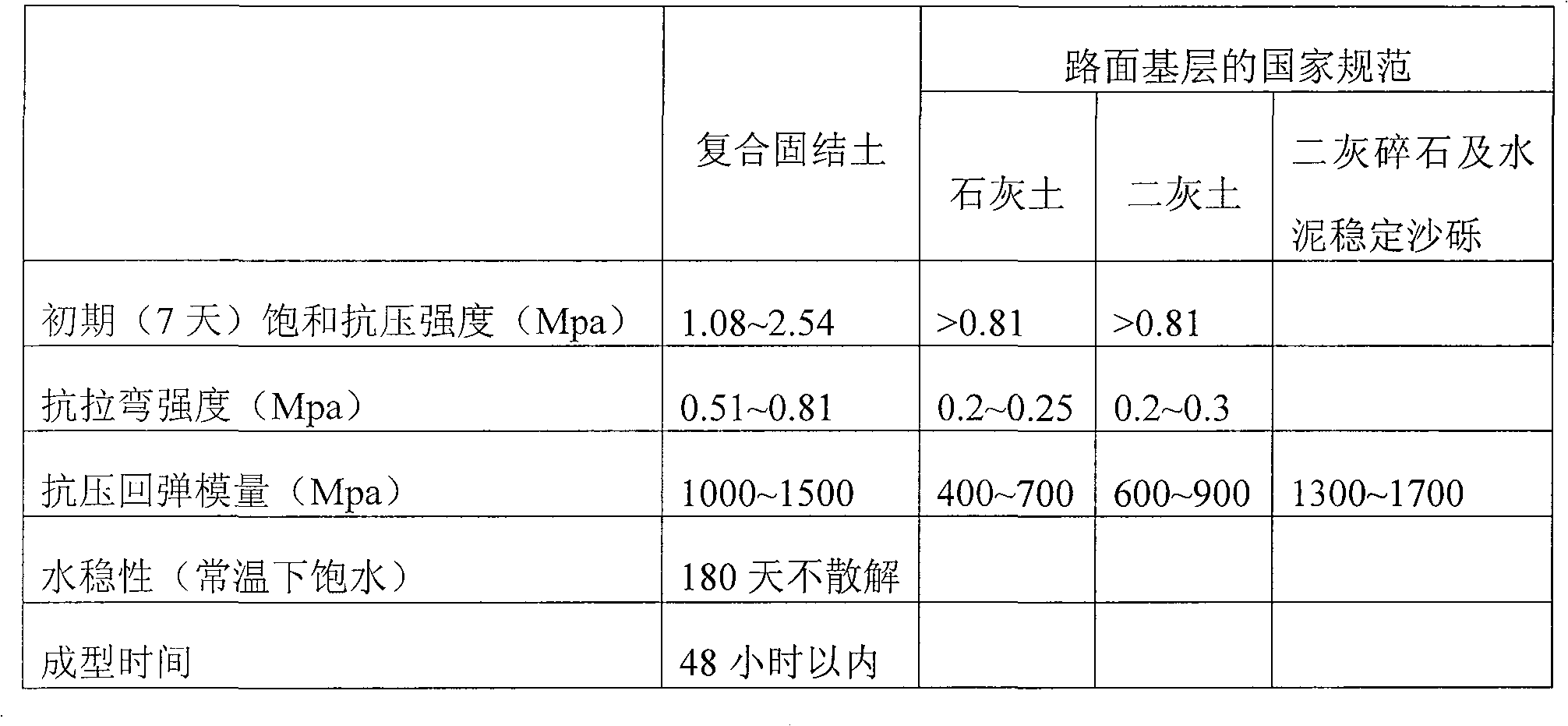

Composite material for consolidated soil pavement base course and construction method thereof

InactiveCN1566533AHigh compressive strengthAvoid damageRoadwaysOrganic fertilisersRoad surfaceMaterials science

Disclosed is a material for composite consolidating earthen road surface and construction method thereof, wherein the said material comprises: sandy soil ranging from 92-98% by wt, 2-8% by wt of cement, ZL-1 liquid curing agent or EN-1 liquid curing agent ranging from 0.1-0.3 permillage of by gross weight of gray soil mixture; or silty soil or clayey soil ranging from 90-96% by wt, 4-10% by wt of lime, ZL-1 liquid curing agent or EN-1 liquid curing agent ranging from 0.1-0.3 permillage by gross weight of gray soil mixture. The material for composite consolidating earthen road surface and its construction method takes extensively distributed soil as main material, reduces 20-50% construction costs, shortens construction time limit, resists freeze, and prolongs available construction time in northern area with early freezing time.

Owner:王涌

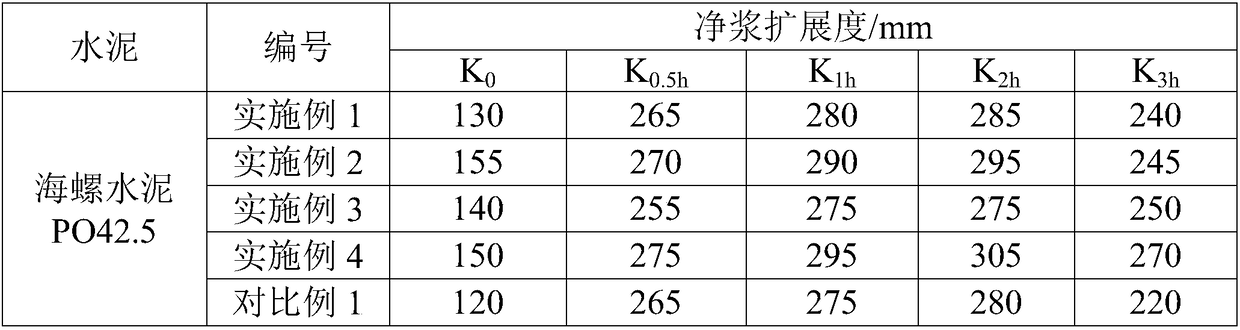

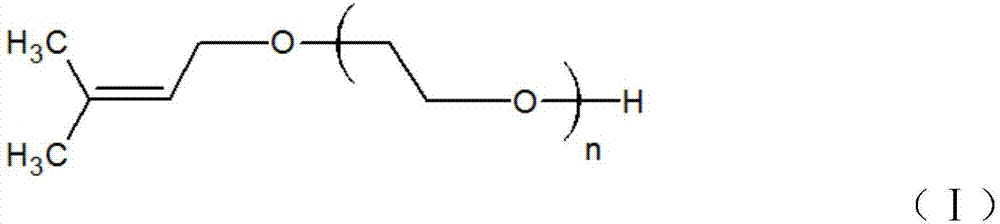

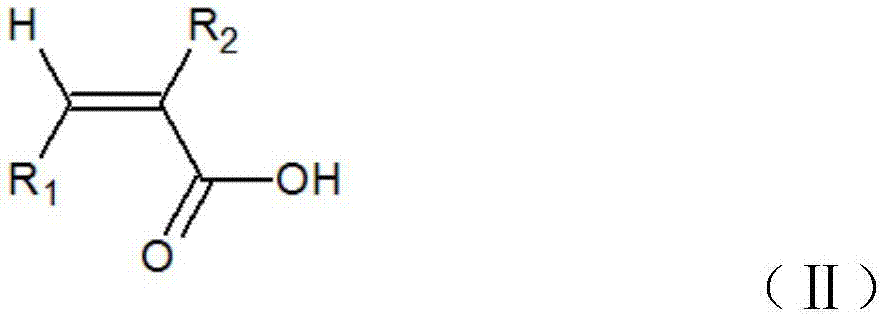

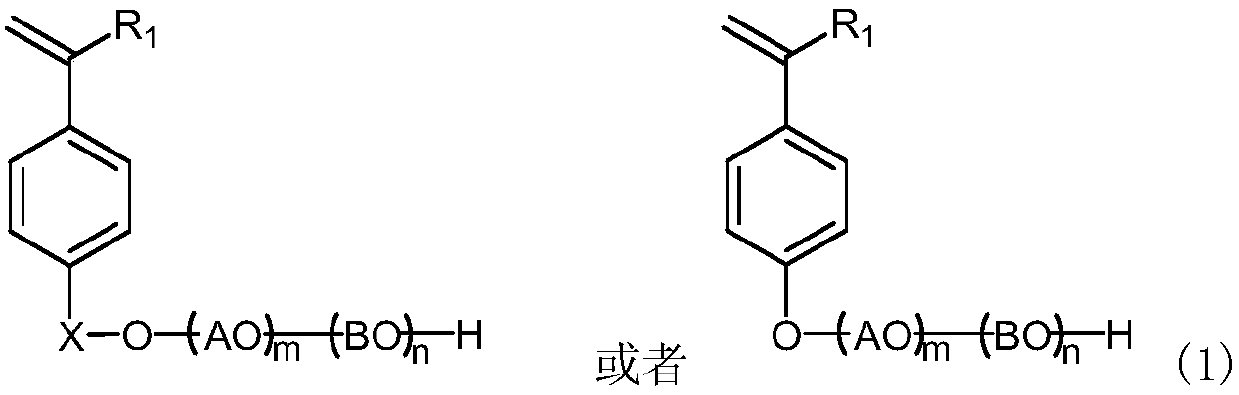

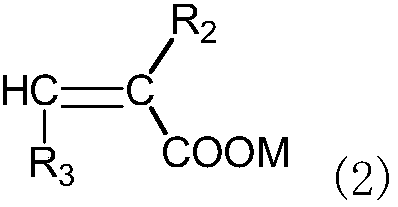

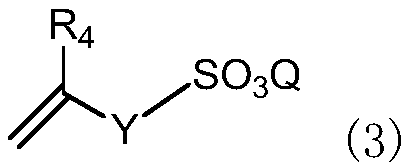

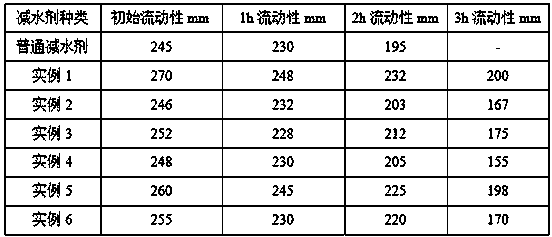

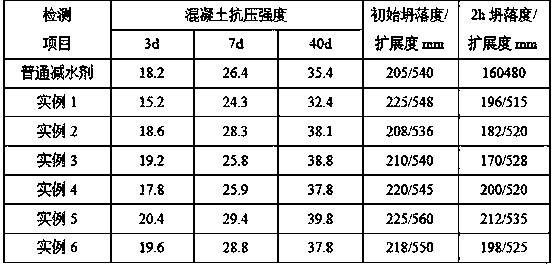

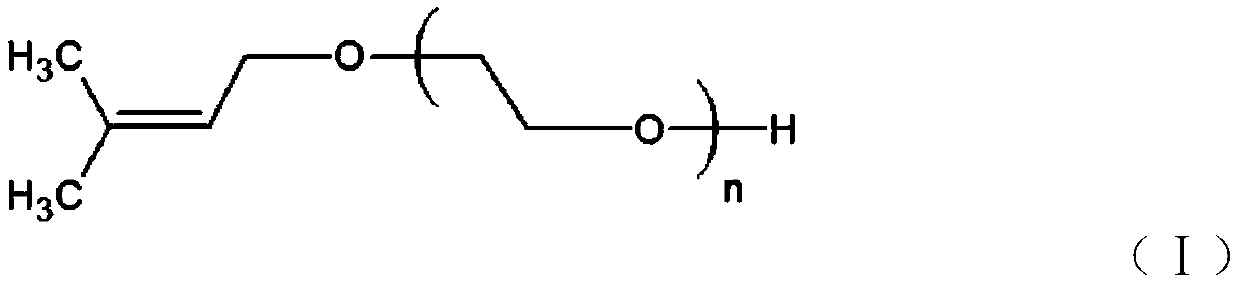

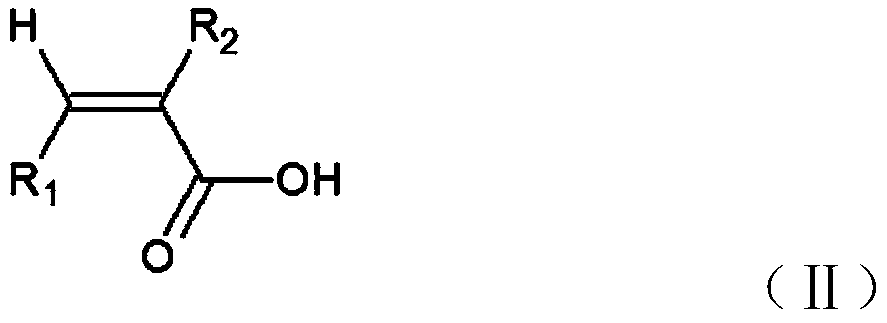

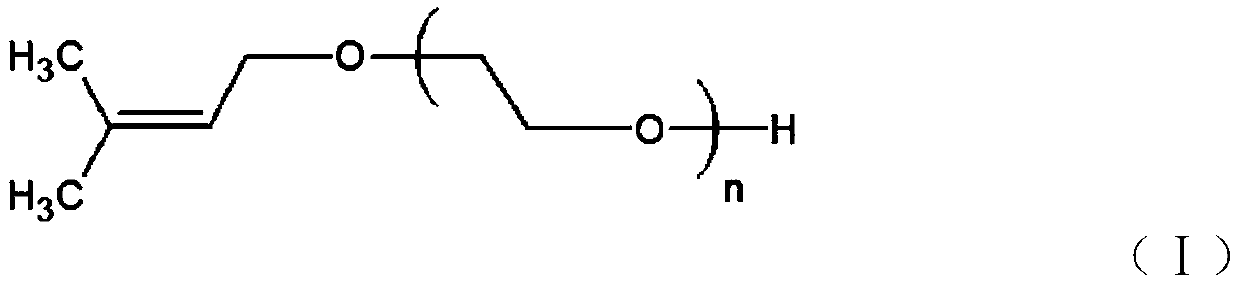

High-solid-content ether slump-retaining polycarboxylate superplasticizer preparation method

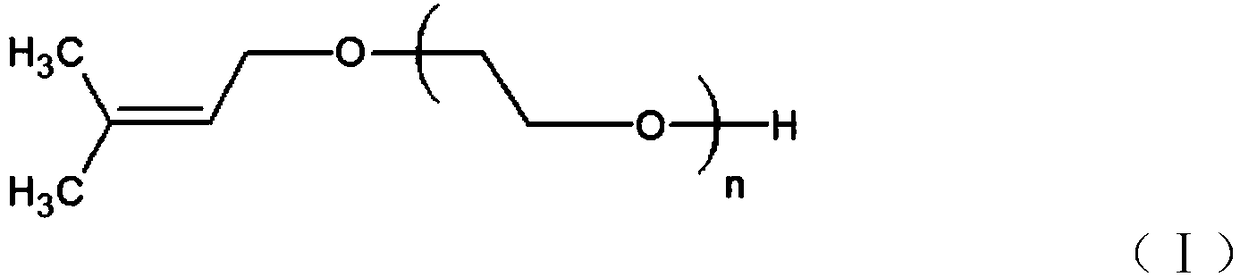

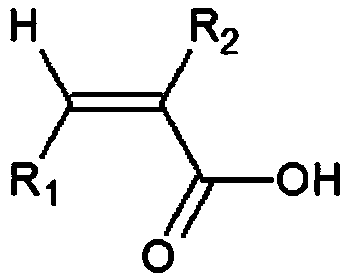

The invention discloses a high-solid-content ether slump-retaining polycarboxylate superplasticizer preparation method. The method includes steps: dissolving isopentenol polyoxyethylene ether into water, heating at 60-80 DEG C to melt, cooling to 20-30 DEG C, sequentially adding pre-prepared chain transfer agent solution and initiator A solution, adjusting stirring speed to 200-300r / min, dropwiseadding singly or doubly, wherein monomer-containing solution is subjected to dropwise adding for 2.5-3h, and initiator B solution is subjected to double dropwise adding for 3-3.5h, the first 1h reaction temperature rise in a reactor is controlled to be lower than 4 DEG C in a reaction process, and the whole reaction temperature does not exceed 40 DEG C; keeping the temperature for 1-2h after dropwise adding, and adopting caustic soda flakes to adjust product pH value to 7+ / -1 to obtain high-concentration ether slump-retaining polycarboxylate superplasticizer mother liquor in solid content of 80% and in state of thick liquid. Concrete mixed by adoption of the superplasticizer is great in slump retaining performance, and cost in production, transporting and storage processes is saved. In addition, products are green, environmentally friendly and free of formaldehyde, and discharging of waste gas, wastewater and industrial residues in the production process is avoided.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD +1

Cotton seedling substrate prepared from vinasse biogas residue and preparation method thereof

InactiveCN102229516ASolve the pollution of the environmentEconomical and effective useEnergy inputFertilizer mixturesClay mineralsFermentation

The invention relates to a cotton seedling substrate prepared from vinasse biogas residue and a preparation method thereof. The cotton seedling substrate comprises 7-9 cubes of vinasse biogas residue and 1-3 cubes of vermiculite, wherein the vinasse biogas residue is fresh mire which is generated after the vinasse is fermented in a biomass tank and biogas is generated, and the vermiculite is of clay mineral. The preparation method comprises the following steps of: sun-drying and dehydrating the vinasse biogas residue, carrying out first fermentation and secondary heterofermentation, air-drying leavening, mixing the leavening with the vermiculite, and then sieving to obtain the cotton seedling substrate. According to the invention, the problem that the vinasse biogas residue pollutes environments is solved, the vinasse biogas residue is used as the raw material of the seedling substrate, and the industrial chain of the circular economy for food processing is prolonged; the cost of the cotton seedling substrate per cubic meter is RMB 135 yuan; the cost of turf substrate raw material per cubic meter is RMB272 yuan; and therefore, the cost is reduced by more than 50%. The cotton seedling substrate has the following physicochemical indexes of: the grain sizes of 1-5mm of larger than or equal to 40%, organic matters with volume-weight of above 4.47 of 0.15-0.40g / m<3>, the total void of 60-70%, the pH value of 5.5-8.0, the conductivity of less than or equal to 80% us / cm, the total nutrient of 4.0%, and the moisture of less than or equal to 30% and reaches the optimal range of growth of seedling root systems.

Owner:ANHUI FENGTIAN AGRI TECH

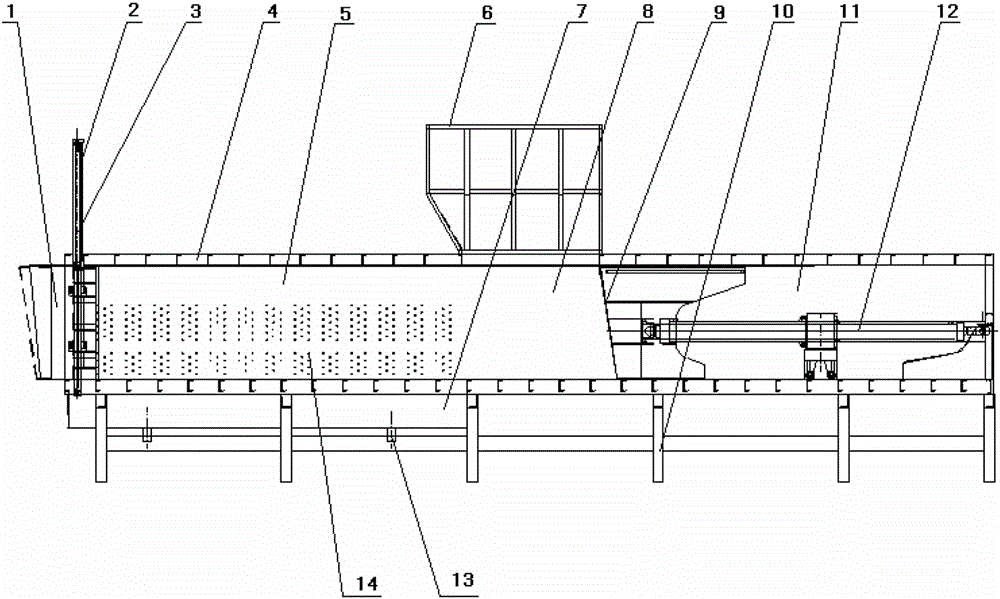

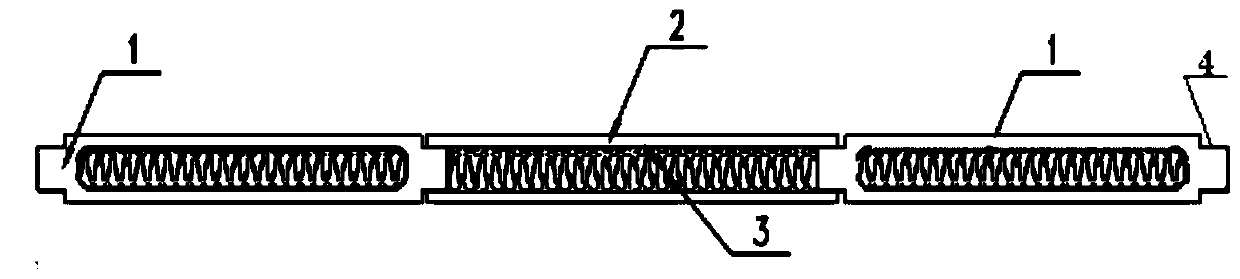

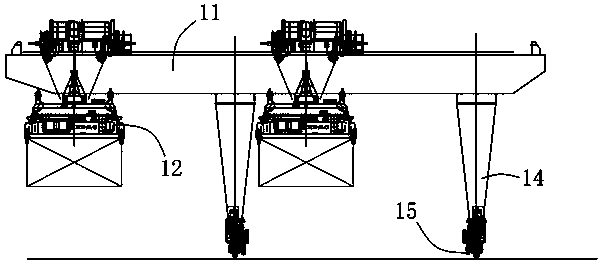

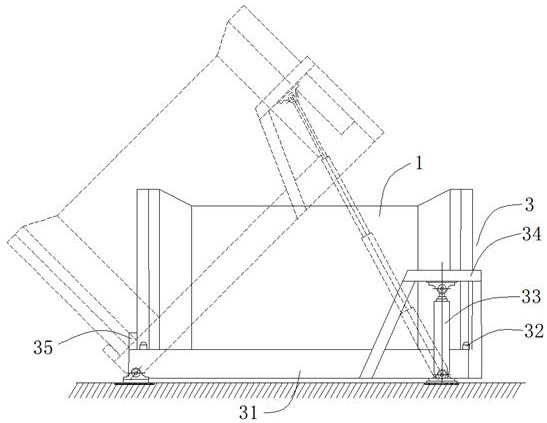

Garbage compressor, garbage compression processing method and garbage transfer station

InactiveCN104986484AReduce shipping costsReduce pollutionRefuse receptaclesRefuse transferringMachine partsButt joint

The invention relates to the technical field of garbage pretreatment, and specifically relates to a garbage compressor. The garbage compressor comprises a casing. The interior of the casing is sequentially provided with a butt joint chamber, a compression storage chamber, a feeding chamber and a machine part chamber, a gate is arranged between the butt joint chamber and the compression storage chamber, the compression storage chamber is provided with a draining system, a feeding funnel communicated with the feeding chamber is arranged on the feeding chamber, the machine part chamber is provided with a push head, and the gate and the push head are supplied with power through a hydraulic system. The invention also discloses a garbage compression processing method employing the above garbage compressor and a garbage transfer station employing the above garbage compressor. The garbage compressor is simple in structure, low in cost and high in automation degree, and is practical, simple, reliable and safe, the equipment failure rate is reduced, the operation cost is reduced, the labor intensity is reduced, and the labor efficiency is improved. The garbage transfer station can satisfy the tonnage of the transport vehicle, the long-distance transport cost is reduced, the equipment integration degree is high, the land is saved, and the capital construction cost is saved.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

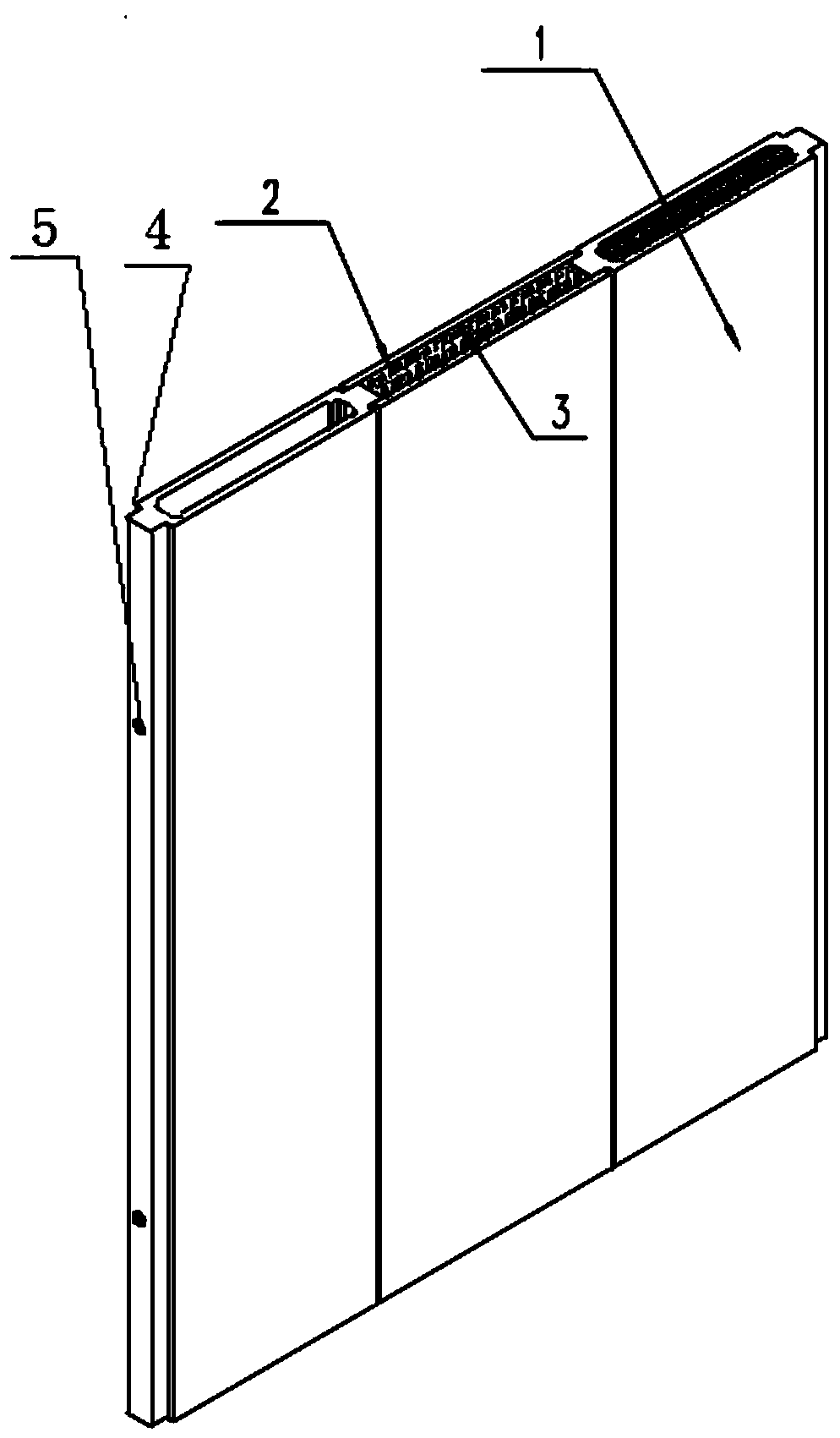

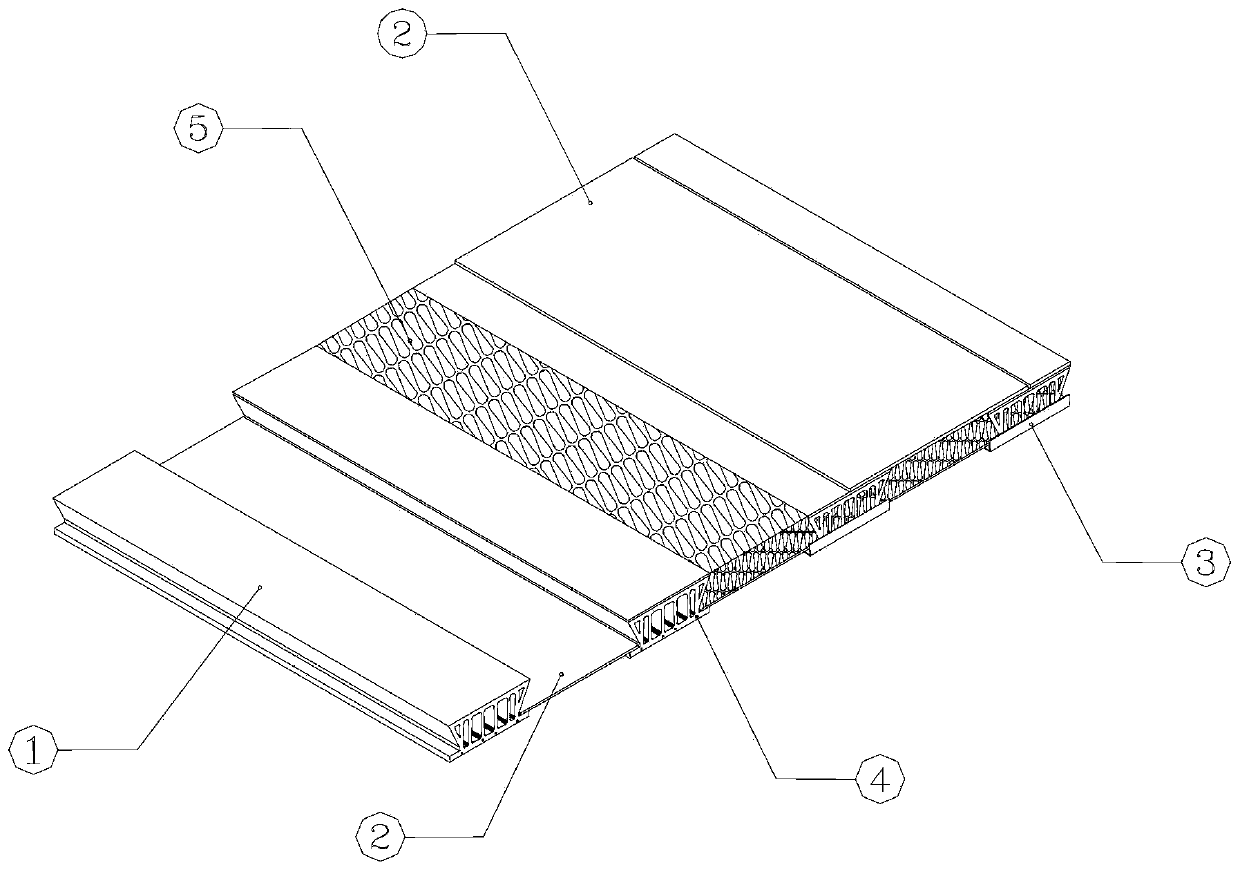

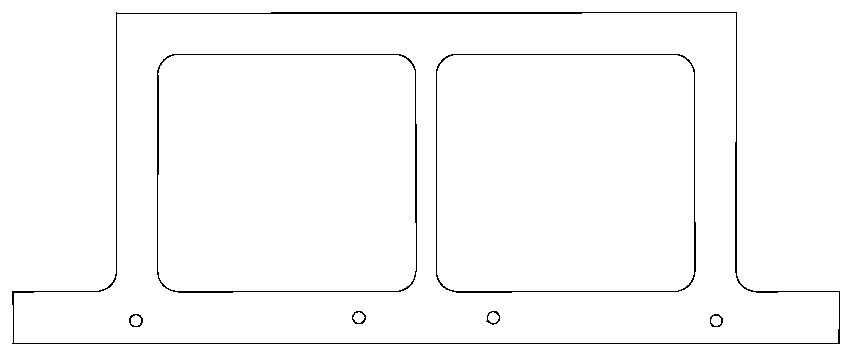

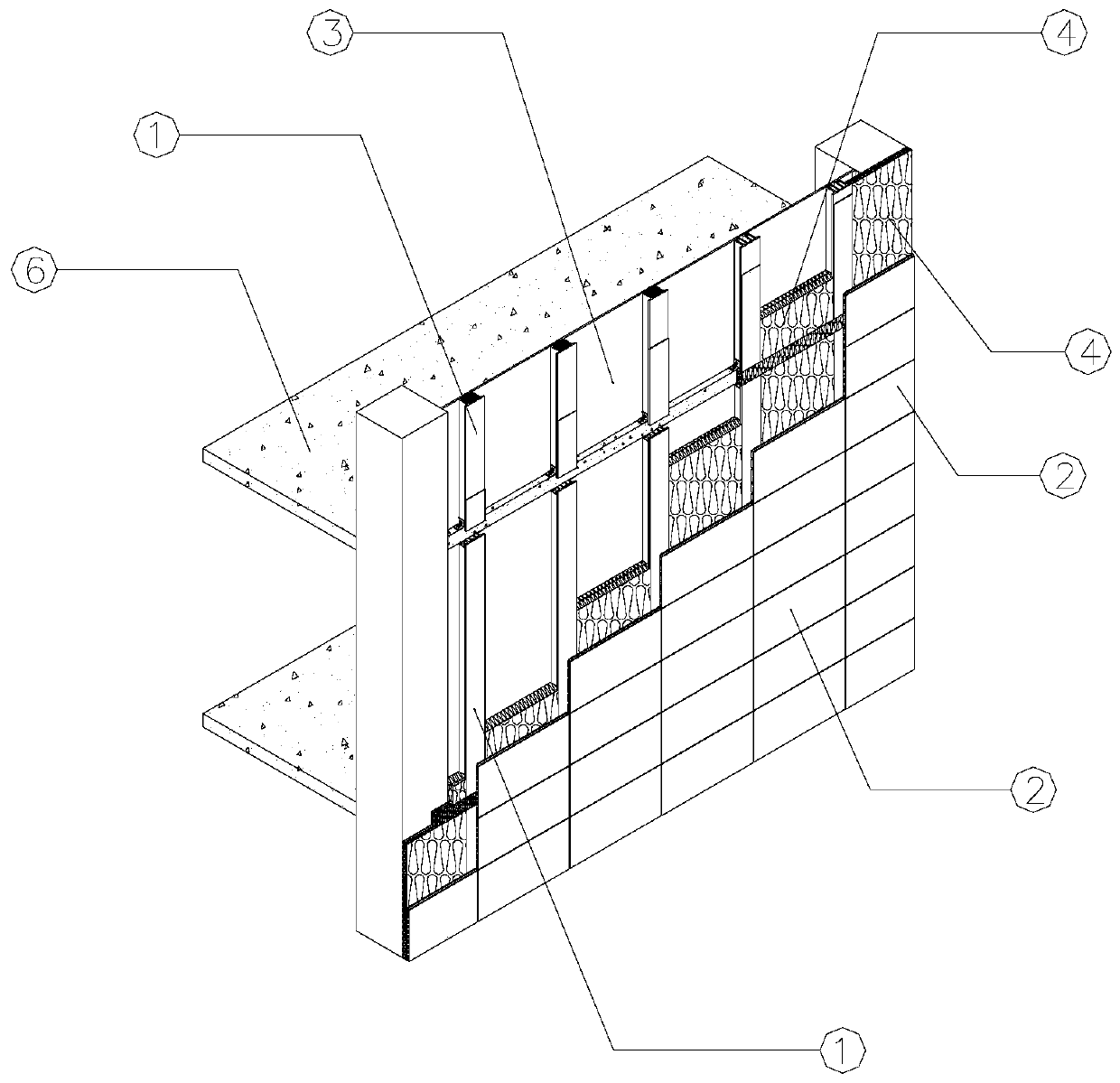

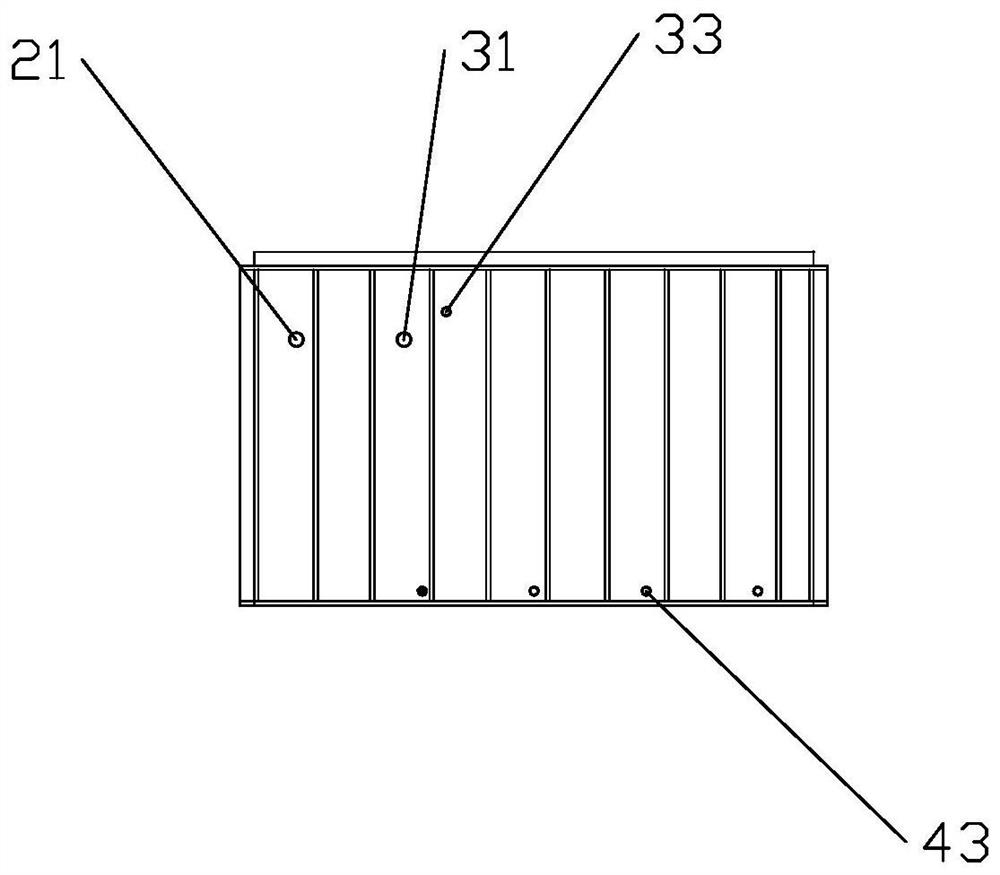

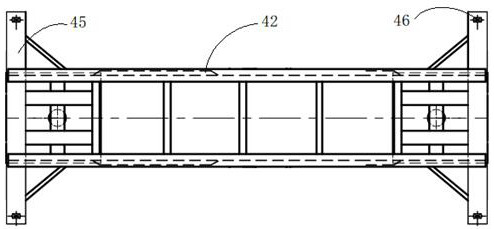

Assembled partition plate part, installation method and application

PendingCN110173071AEven by forceHigh strengthRoof covering using slabs/sheetsCovering/liningsThermal insulationKeel

The invention provides an assembled partition plate part, an installation method and application. The assembled partition plate part comprises sound insulation keel plates, the middles of the sound insulation keel plates are provided with cavities which are filled with a thermal insulation and / or sound absorption material, panels are arranged between the adjacent sound insulation keel plates, thetwo sides of the sound insulation keel plates are provided with grooves, and the panels are clamped into the grooves formed in the two sides of the adjacent sound insulation keel plates. According tothe installation method, plate type sound insulation keel plates are adopted, precise measurement of size installation is facilitated, installation procedures are decreased, the operation time per unit time is shortened, the construction installation progress is improved, and the installation manpower cost is reduced; in addition, the plate type sound insulation keel plates and the assembled partition plate part have the good thermal insulation performance, sound insulation performance and sound absorption performance, can serve as an inner wall, an outer wall and a roof partition plate part,and are low in weight and manufacturing cost and economical.

Owner:潘旭鹏

Method for preparing high-solid-content ether high-water-reducing polycarboxylic acid water reducer

The invention discloses a method for preparing a high-solid-content ether high-water-reducing polycarboxylic acid water reducer. The method comprises the following steps: adding solid isopentenol polyoxyethylene ether into a reactor, adding water, of which the mass is 10% to 15% that of the solid isopentenol polyoxyethylene ether, into the reactor, starting a stirrer to stir, heating the internal temperature of the reactor to 70 DEG C to 80 DEG C, and carrying out stirring for 30min until the isopentenol polyoxyethylene ether is completely dissolved; cooling the internal temperature of the reactor to 30 DEG C to 40 DEG C, sequentially adding a chain transfer agent solution and an initiator A solution into the reactor, carrying out uniform mixing, simultaneously dropwise adding a monomer solution for 1.5 to 3 hours and an initiator B solution for 2.5 to 3.5 hours, continuing to carry out heat preservation for 1 to 2 hours after dropwise adding ends, and neutralizing the pH value of the solution to 7+ / -1 with caustic soda flakes, thereby obtaining the high-solid-content ether high-water-reducing polycarboxylic acid water reducer with the solid content of 85%. According to the method, the product is environmentally friendly and is free of formaldehyde content, and the production process is free of emission of waste gases, waste water and waste residues; compared with industrial-produced low-solid-content (40% to 50%) products, the product has the advantages that the water-reducing rate is consistent, the concrete wrapping property is good, costs of production, transportation and storage processes are reduced, and the price of the product is lowered.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

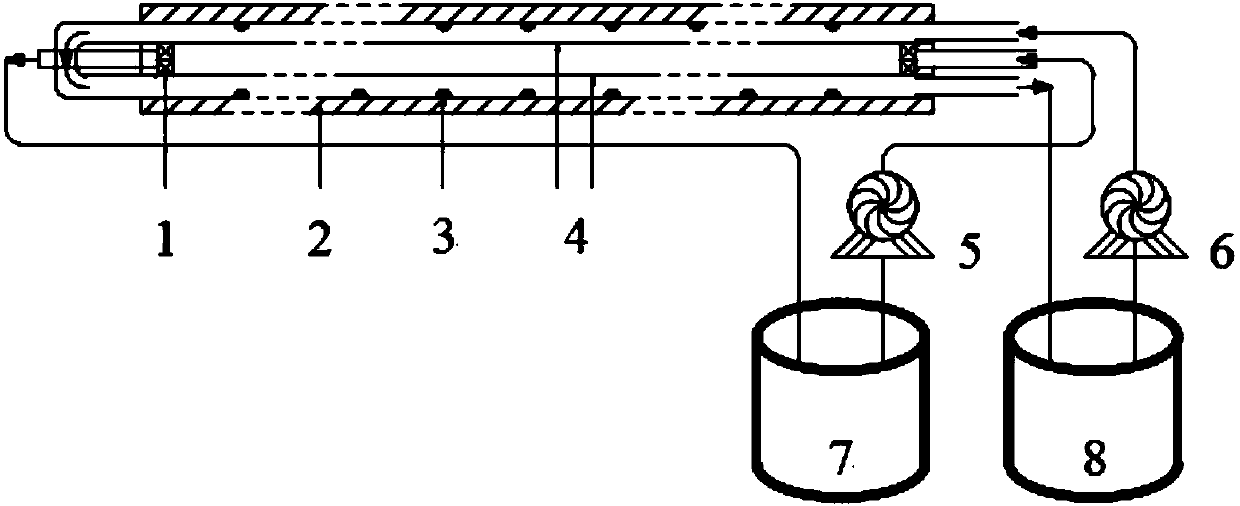

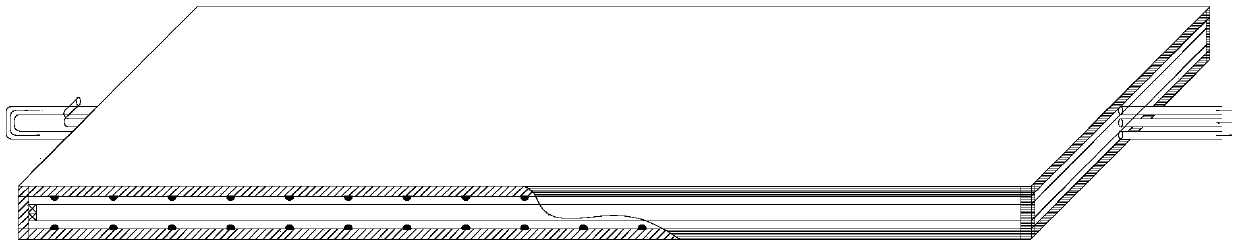

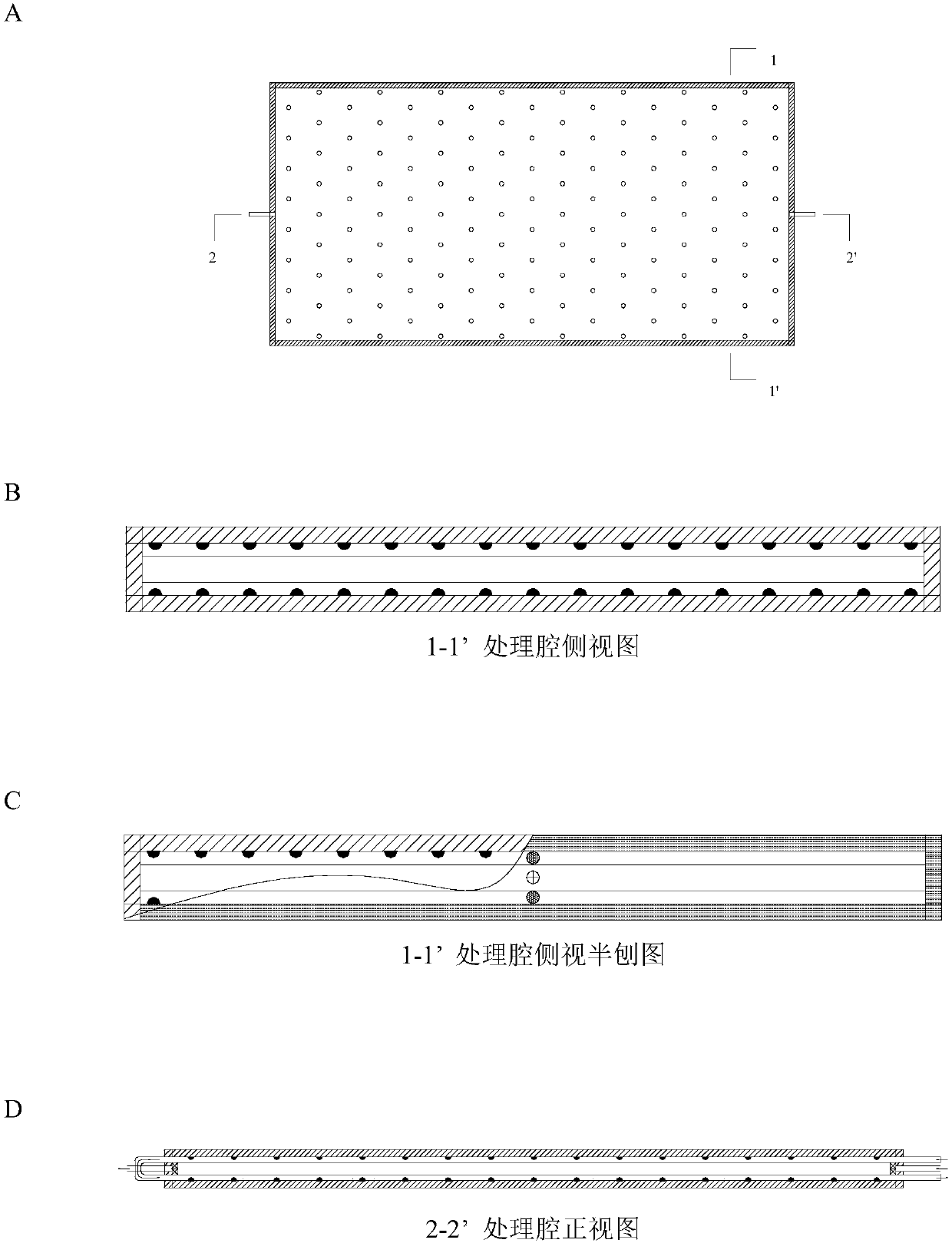

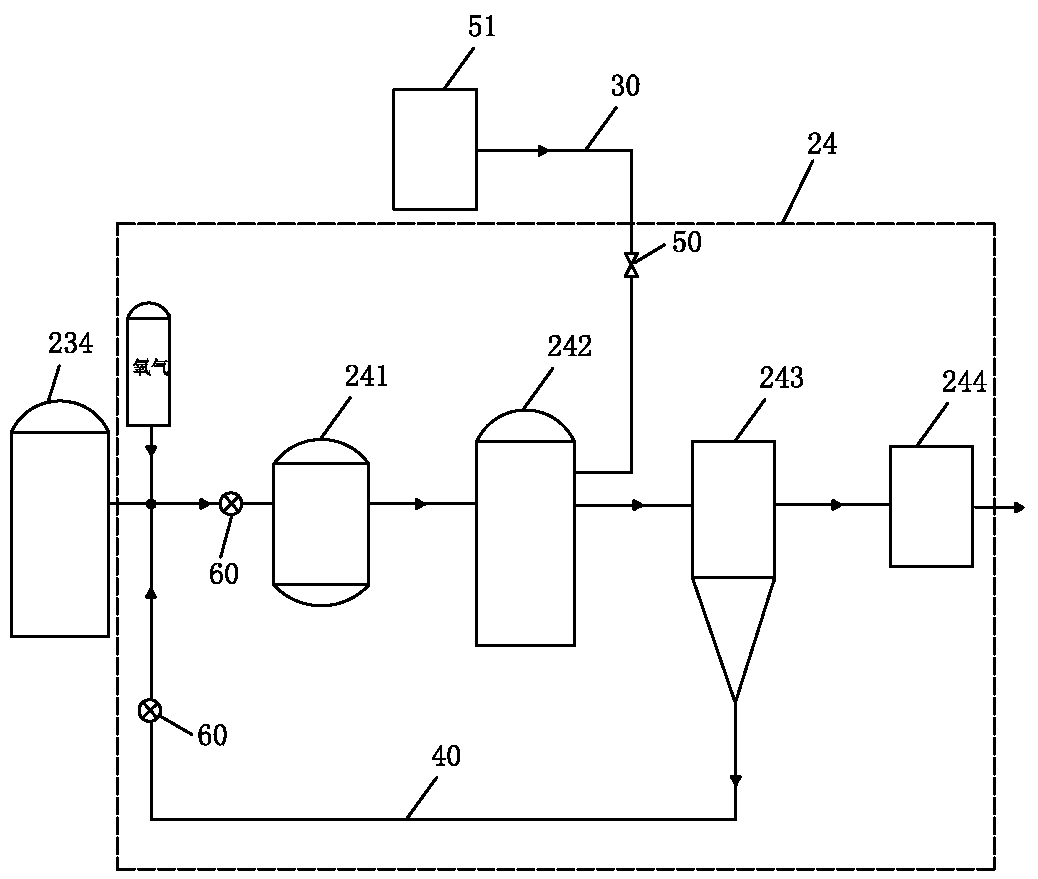

Device and method for concentrating and recycling anaerobic acid-producing kitchen waste fermentation solution

InactiveCN107619090AReduce long-distance transportation costsIncrease concentrationSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisResource utilizationNitrogen

The invention discloses a device and a method for concentrating and recycling an anaerobic acid-producing kitchen waste fermentation solution. The method comprises a treatment chamber, and two layersof positive osmosis membranes which are mounted inside the chamber and are parallel to the chamber wall, wherein a driving solution passage is formed between the two layers of positive osmosis membranes; a fermentation solution passage is formed between each of the positive osmosis membranes on the two sides and the chamber wall. Through a positive osmosis membrane principle and a unique design ofa membrane assembly, the concentration of the recycled and concentrated anaerobic acid-producing kitchen waste fermentation solution can be greatly increased and the long-distance transportation costof the anaerobic acid-producing fermentation solution can be reduced. Through the device and the method, the anaerobic acid-producing fermentation solution is recycled and concentrated as a good denitrifying and dephosphorizing organic carbon source for resource utilization, so that the purpose of ectopically applying the anaerobic acid-producing fermentation solution to a domestic sewage treatment plant, an industrial sewage station, a landfill leachate treatment station and the like is achieved.

Owner:ZHEJIANG NORMAL UNIVERSITY

Powdery early-strength type polycarboxylate water reducing agent and preparation method thereof

A powdery early-strength type polycarboxylate water reducing agent and a preparation method thereof are disclosed. Rigid groups and a polyether chain having a high molecular weight are introduced intoa polymerization system, and are hybridized with a calcium-silicon composite oxide to obtain a polymer; then a nanometer separating agent is introduced in a spray drying process to finally prepare the water reducing agent. The prepared water reducing agent has good fluidity, no agglomeration, good storage stability and low long-distance transportation cost, and is suitable for special mortar withan early-strength requirement, such as self-leveling mortar, grouting materials, grouting agents, waterproof mortar and external wall insulation mortar, and concrete prefabricated products such as beams, boards, pillars, tubular piles, duct pieces, and prestressed components.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

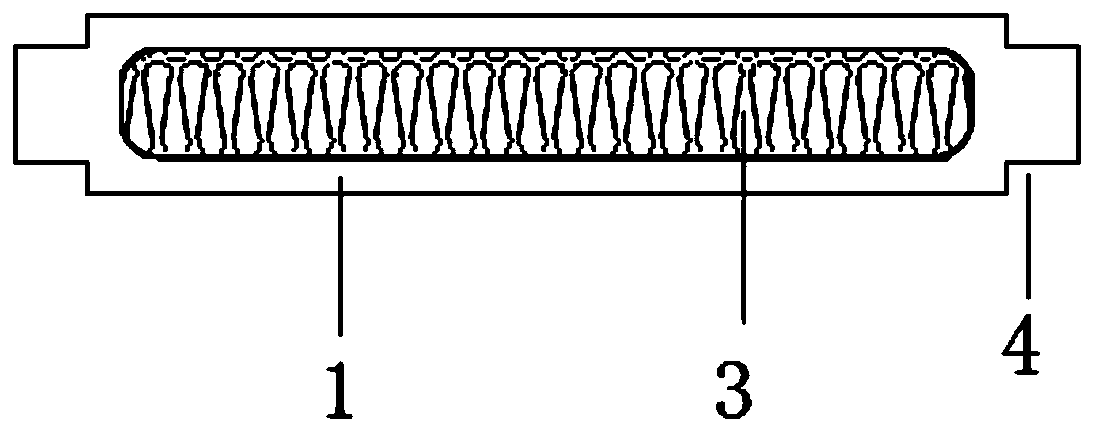

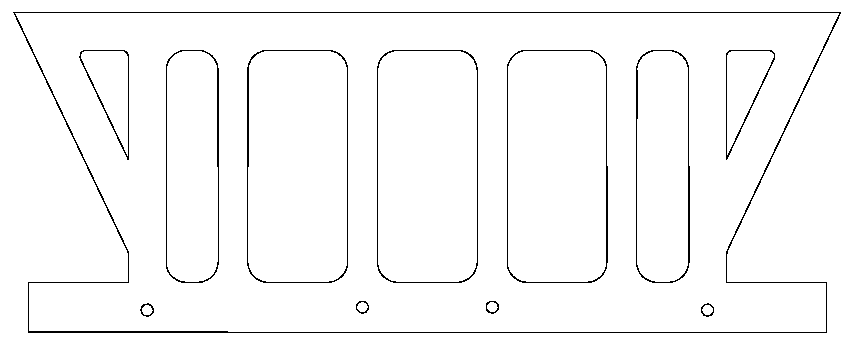

Inorganic bearing purline bearing built-up roof and floor

The invention relates to an inorganic bearing purline bearing built-up roof and floor. An inorganic material is employed by each of inorganic bearing purlines (1) to form a cavity mold body by vacuumextruding; when the purlines are extruded, steel bars or fiber tows (4) are evenly distributed at the middle position of the plane of a bottom end plate of each inorganic bearing purline (1); after the inorganic bearing purlines (1) are molded by curing and drying, a connecting steel plate (3) or section steel is fixed to the bottom end horizontally and / or the side end of the bottom end of each ofthe two ends of each inorganic bearing purline (1) by welding or bolted connection; the connecting steel plate (3) or section steel at the bottom end of each of the two ends of each inorganic bearingpurline (1) is effectively connected with a main bearing structure part into a whole; bearing plates (2) are arranged at the upper portion and the lower portion between every two adjacent inorganic bearing purlines (1); and thermal insulation or sound insulation materials (5) fill a position between every two adjacent inorganic bearing purlines (1) and a space between the corresponding two bearing plates (2). The built-up roof and floor has good thermal insulation performance, sound insulation performance and sound absorption performance.

Owner:潘旭鹏

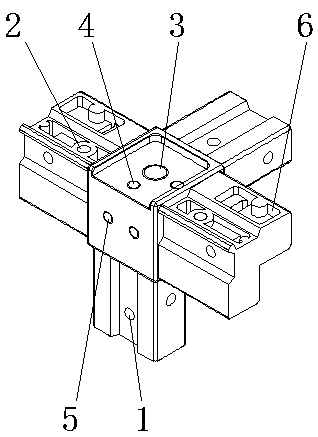

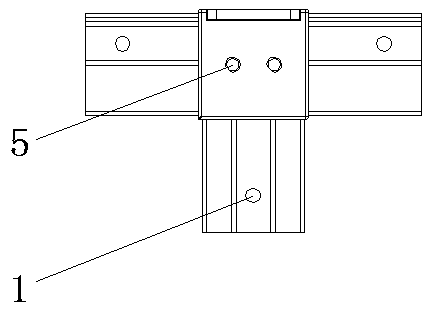

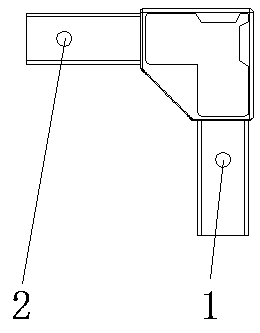

Three-dimensional cross and manufacturing process thereof

The invention discloses a three-dimensional cross and a manufacturing process thereof. The three-dimensional cross comprises a stand column fixing hole and a hinge fixing hole. Door fixing holes are arranged above the stand column fixing hole, inner column fixing holes are arranged behind the stand column fixing hole, a lifting ring fixing hole is arranged behind the hinge fixing hole, the hinge fixing hole is located above the door fixing holes, left and right cross beam fixing holes are arranged on the left side of the lifting ring fixing hole, and process grooves are arranged on the right side of the lifting ring fixing hole. Compared with an existing common three-dimensional cross, the three-dimensional cross achieves standardized design and production of cabinets, the product qualityis stable, welding is avoided in the whole process, products can be packaged and transported in a scattered manner, the long-distance transport cost is reduced, and an outer convex door and an inner concave door can be freely assembled; different cabinet requirements are met, the hinge function is achieved, cost hinges are omitted, and the cost is reduced; and although the cost of the three-dimensional cross is high, comprehensively-saved manpower and materials have larger advantages than the traditional manner.

Owner:青岛日建机电有限公司

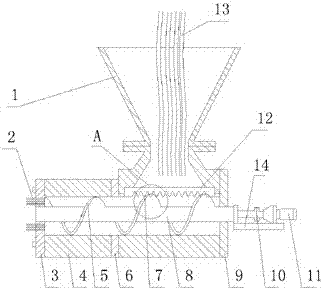

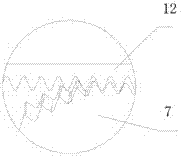

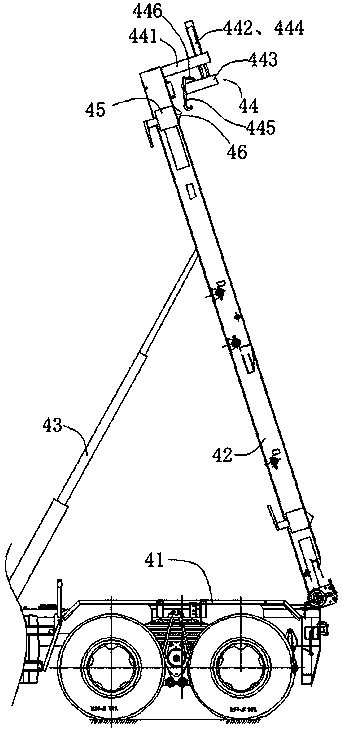

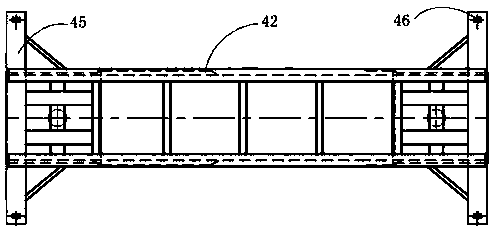

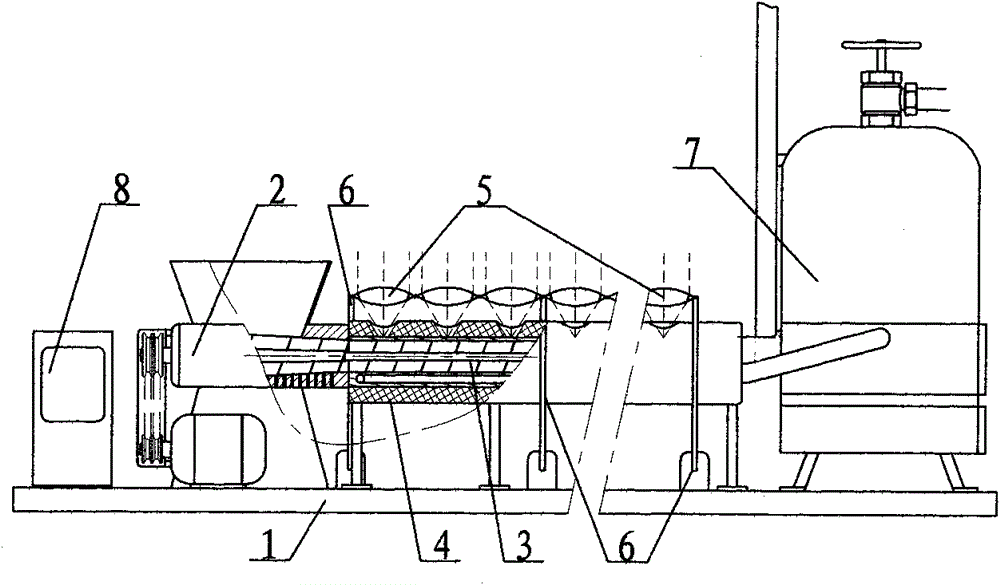

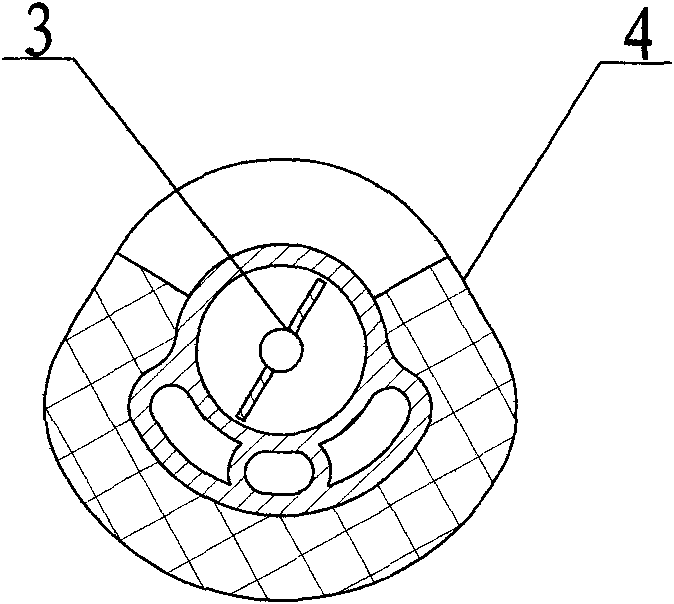

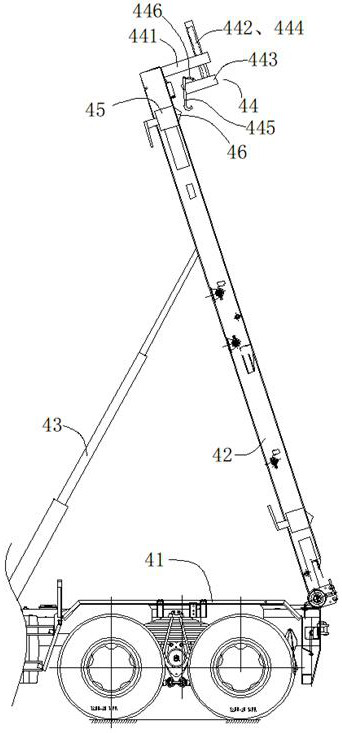

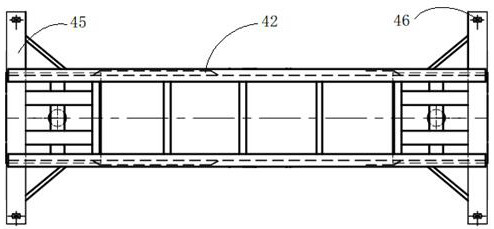

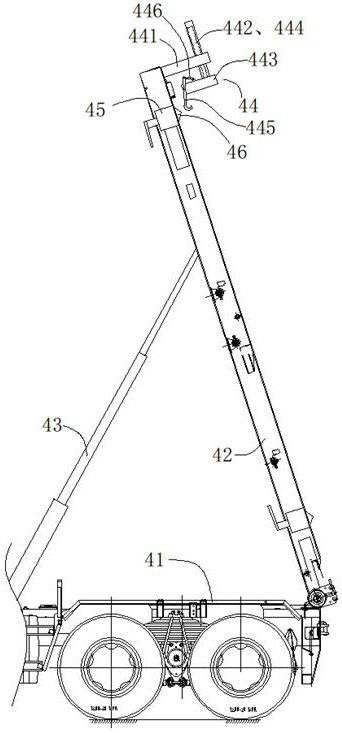

Straw smashing and rod making device for anaerobic fermentation biogas production

PendingCN107974396AReduced shipping volumeReduce long-distance transportation costsBiological substance pretreatmentsGas production bioreactorsSmooth surfaceEngineering

The invention relates to a straw smashing and rod making device for anaerobic fermentation biogas production. The straw smashing and rod making device for anaerobic fermentation biogas production is characterized by comprising an auger spindle (8), wherein the auger spindle (8) is coaxially arranged in a cavity body (4) of the device and is provided with a spiral auger; the spiral auger is formedby two sections of spiral augers used as an extruding section and a smashing section and continuously arranged front and back; an auger end cutting knife (7) with a toothed cutting edge is arranged onan outer contour of the spiral auger used as the smashing section located at a feed inlet position of the cavity (4); the toothed cutting edge on the auger end cutting knife (7) is matched with a toothed cutting edge of an upper cutting knife (12) arranged at the feed inlet position of the cavity (4) in a shearing-meshing way; an outer contour of the spiral auger section used as the extruding section (5) is a smooth surface, and is in movable fit to the cavity body (4) and an inner cavity of a baffle ring (6); a rod making hole plate mold (3) is arranged on the front end of the cavity body ofthe equipment; a plurality of straw rod forming holes are formed in the rod making hole plate mold (3).

Owner:安阳利浦筒仓工程有限公司

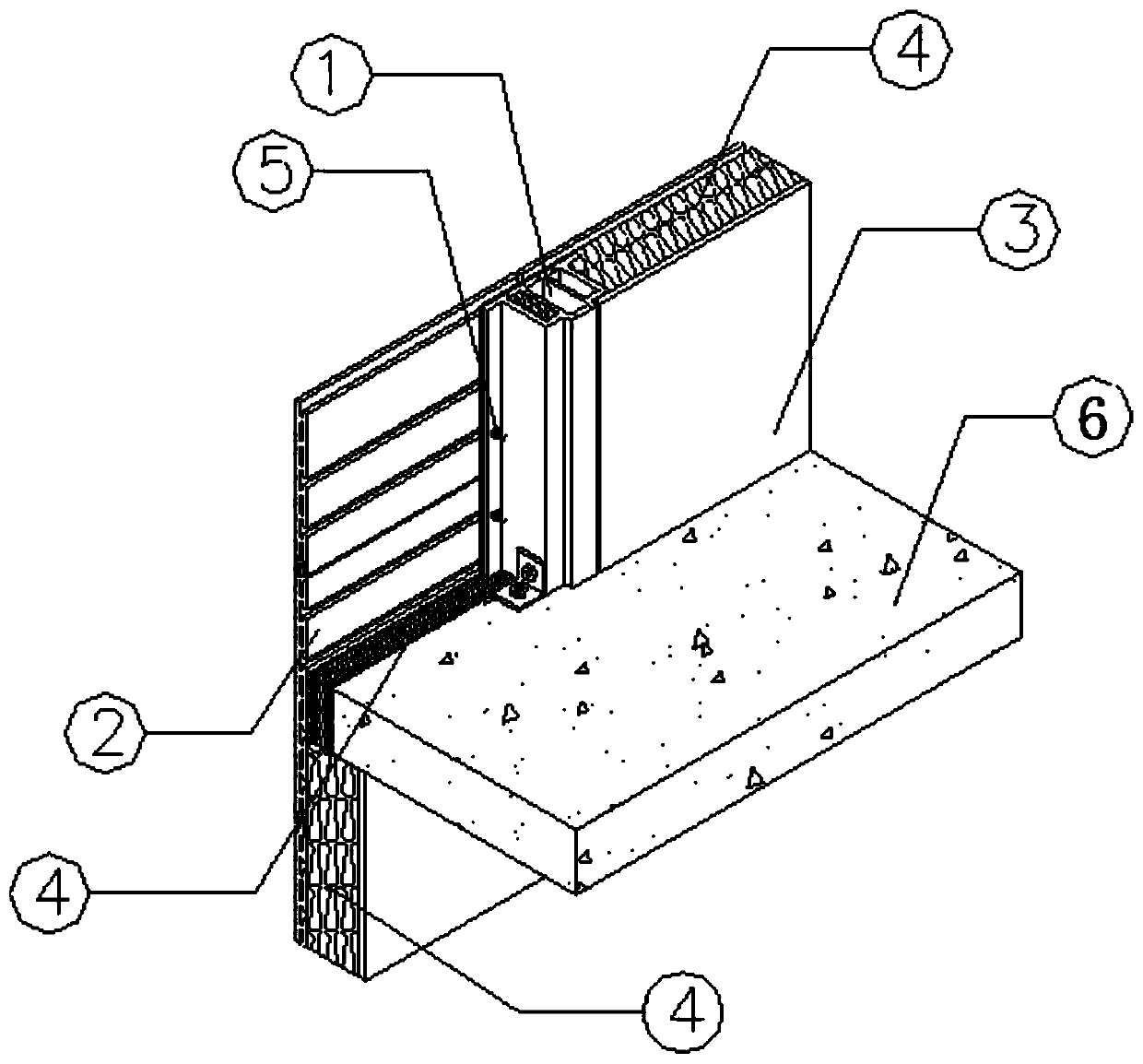

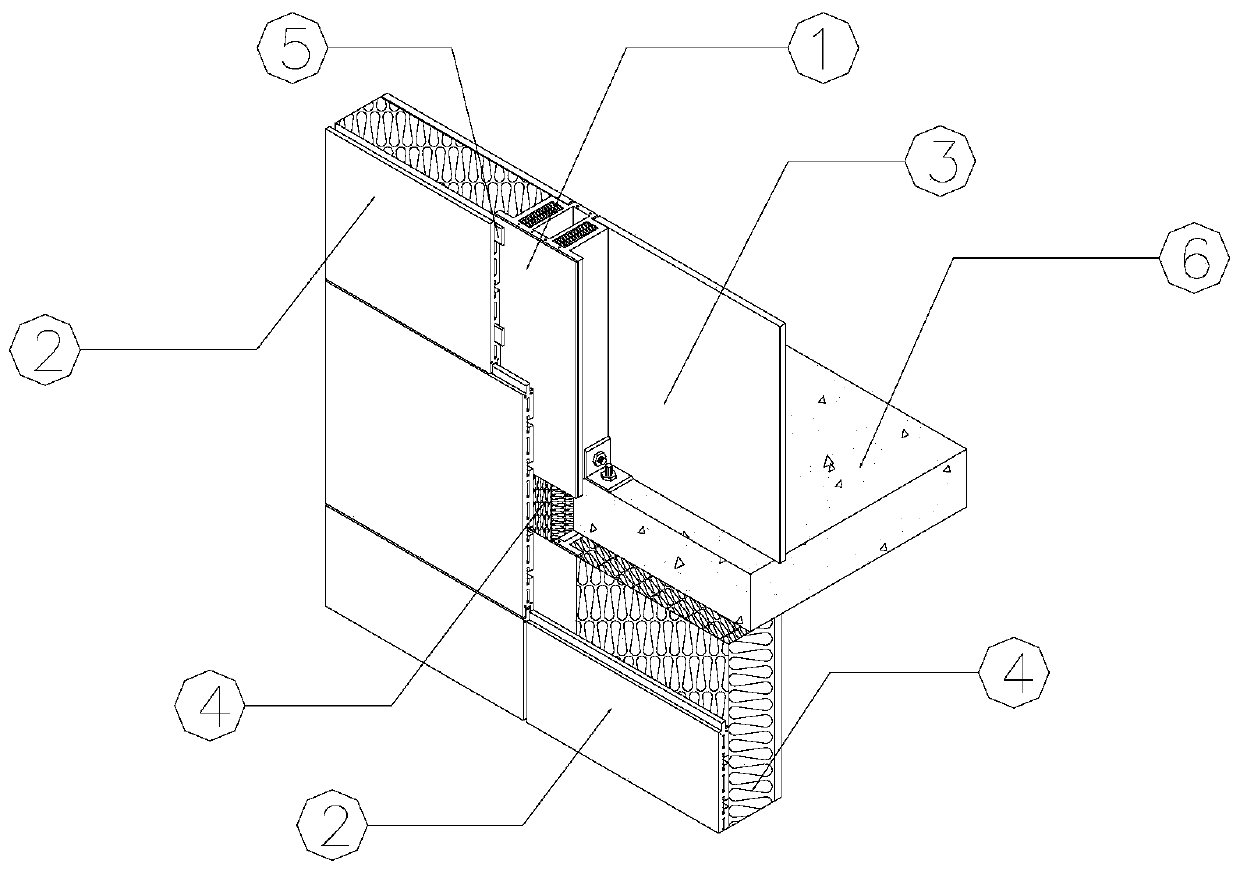

Inorganic keel purline assembly external wall and assembly method

ActiveCN110792194AIncrease stiffnessSmall load deformationWallsClimate change adaptationPurlinFloor slab

The invention relates to an inorganic keel purlin assembly external wall and an assembly method. The inorganic keel purlin assembly external wall comprises main structure floor slabs (6) and inorganickeel purlins (1), and interior cavities of the inorganic keel purlins (1) are filled with thermal insulation and sound insulation materials (4), the inorganic keel purlins (1) are vertically arrangedand fixed between the upper and lower main structural floor slabs (6), and arranged vertically inorganic material indoor side panels (3) are installed at the side end, in the indoor part, between thetwo inorganic keel purlins (1); and transversely arranged inorganic material outdoor side panels (2) are fixedly installed at the outer side ends of the inorganic keel purlins (1), and cold bridge insulation layers are sandwiched between the outdoor side panels (2) and the inorganic keel purlins (1). According to the inorganic keel purlin assembly external wall and the assembly method, assembledconstruction installation can be achieved, material, transportation and installation costs are reduced, the adaptability is high, the inorganic keel purlin assembly external wall can be provided withexterior decoration and provided with thermal insulation and sound insulation performance, and cold bridge and thermal bridge are eliminated.

Owner:包头市兼强轻型板业有限责任公司

Solid flaky polycarboxylate superplasticizer and method for preparing same by core-shell emulsion method

The invention provides a solid flaky polycarboxylate superplasticizer and a method for preparing the same by a core-shell emulsion method. The superplasticizer comprises the following components in parts by weight: 18-32 parts of a special methacrylate hydrophobic monomer for emulsification, 7-13 parts of a carboxylic hydrophilic monomer for emulsification, 0.33-0.68 parts of an emulsion initiator, 0.56-0.84 parts of a chain transfer agent for emulsification, 37-62 parts of a carboxyl small monomer, 53-76 parts of an unsaturated sulfonic small monomer, 790-830 parts of a polyether macromonomer, 4-9 parts of a weak chain transfer agent, 3.6-6.8 parts of an azo initiator, 4.2-7.6 parts of an initiator, 2.3-4.2 parts of a strong chain transfer agent, and 3.4-5.6 parts of a pH regulator. The method comprises the following steps: (1) preparing an emulsifier; (2) preparing a nuclear monomer emulsion; (3) preparing a shell monomer pre-emulsion; and (4) preparing the solid flaky polycarboxylate superplasticizer. The polycarboxylate superplasticizer prepared by the core-shell emulsion method has the advantages of single molecular weight, excellent performance, strong adaptability and easiness in storage, is prepared into solid sheets, and is lower in transportation cost and suitable for long-distance transportation.

Owner:HUBEI UNIV OF TECH

Construction method of composite consolidated soil pavement base course

InactiveCN100570059CHigh compressive strengthAvoid damageRoadwaysOrganic fertilisersAnti freezingRoad surface

A composite consolidated soil pavement base material and its construction method, the material is composed of the following components by weight percentage: 92-98% of sandy soil, 2-8% of cement, ZL-1 containing 85% of sulfonic acid Or EN-1 liquid curing agent is 0.1-0.3‰ of the total lime-soil mixture; or ZL-1 with 90-96% silty soil or clay soil, 4-10% lime, and 85% sulfonic acid EN-1 liquid curing agent, 0.1-0.3‰ of the total amount of lime-soil mixture. The material and construction method of this kind of composite consolidated soil pavement base uses widely distributed soil as the main material, which can use local materials, reduce the construction cost by 20-50%, have early strength, shorten the construction period, and resist frost. Areas can extend the effective construction period.

Owner:王涌

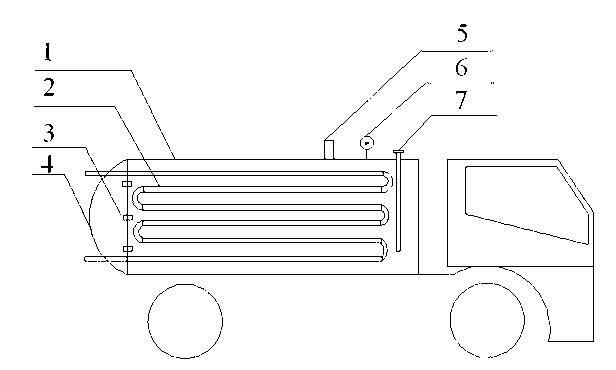

Transporting and use method for absorbing coal bed gas with coal serving as medium

InactiveCN102840443AEasy to fillReduce long-distance transportation costsInternal combustion piston enginesExhaust apparatusDesorptionProcess engineering

The invention provides a transporting and use method for absorbing coal bed gas with coal serving as a medium. The transporting and use method is characterized in that a large amount of coal bed gas is carried out and transported based on the absorbing property of the coal to the coal bed gas, and then supplied as the energy supply to a vehicle in the transporting process; and moreover, the heat in the burnt tail gas of a car is fully utilized to promote the desorption of the coal bed gas, so that the comprehensive utilization of the energy can be achieved to the greatest extent. According to the transporting and use method for absorbing coal absorbing bed gas with the coal serving as the medium, the properties of various energies such as coal, coal bed gas and tail gas of the car can be comprehensively utilized, so that the energy can be saved, and the cost of transporting is greatly reduced.

Owner:徐毅

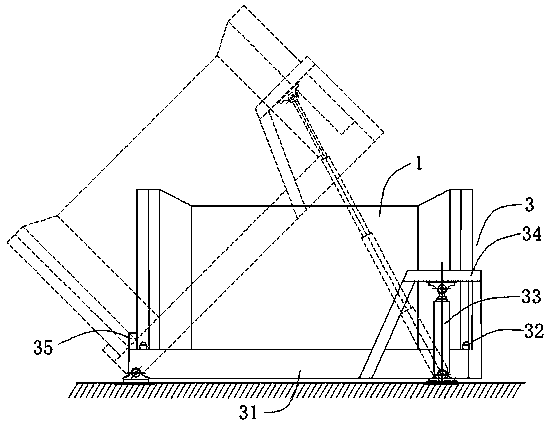

Garbage long-distance transport and transfer method

The invention discloses a garbage long-distance transport and transfer method. The garbage long-distance transport and transfer method is characterized by comprising the following steps that during transport, firstly, collected garbage is loaded into a cavity of a garbage carrier with a discharging port at the tail; then the garbage carrier is enabled to be connected with a transfer tractor used for providing transport power and is transported to a garbage treatment area; and the garbage carrier is separated from the transfer tractor, and a lifting and discharging device installed in the garbage treatment area is used for turning over the garbage carrier, so that the tail of the garbage carrier is inclined downwards to complete discharging. According to the garbage long-distance transportand transfer method, the advantages that assembly reduction of a garbage transfer truck can be realized, the garbage loading rate of the garbage transfer truck can be improved, the long-distance transport cost of the garbage can be reduced, and the transport and transfer efficiency can be improved are achieved.

Owner:CHONGQING ENVIRONMENT & SANITATION GRP CO LTD

Sunlight-accumulating garbage incineration device

ActiveCN103175206BReduce pollutionLess investmentSolar heating energySolar heat devicesCombustion chamberPropeller

Owner:QIDONG CHUANGLU NEW MATERIAL CO LTD

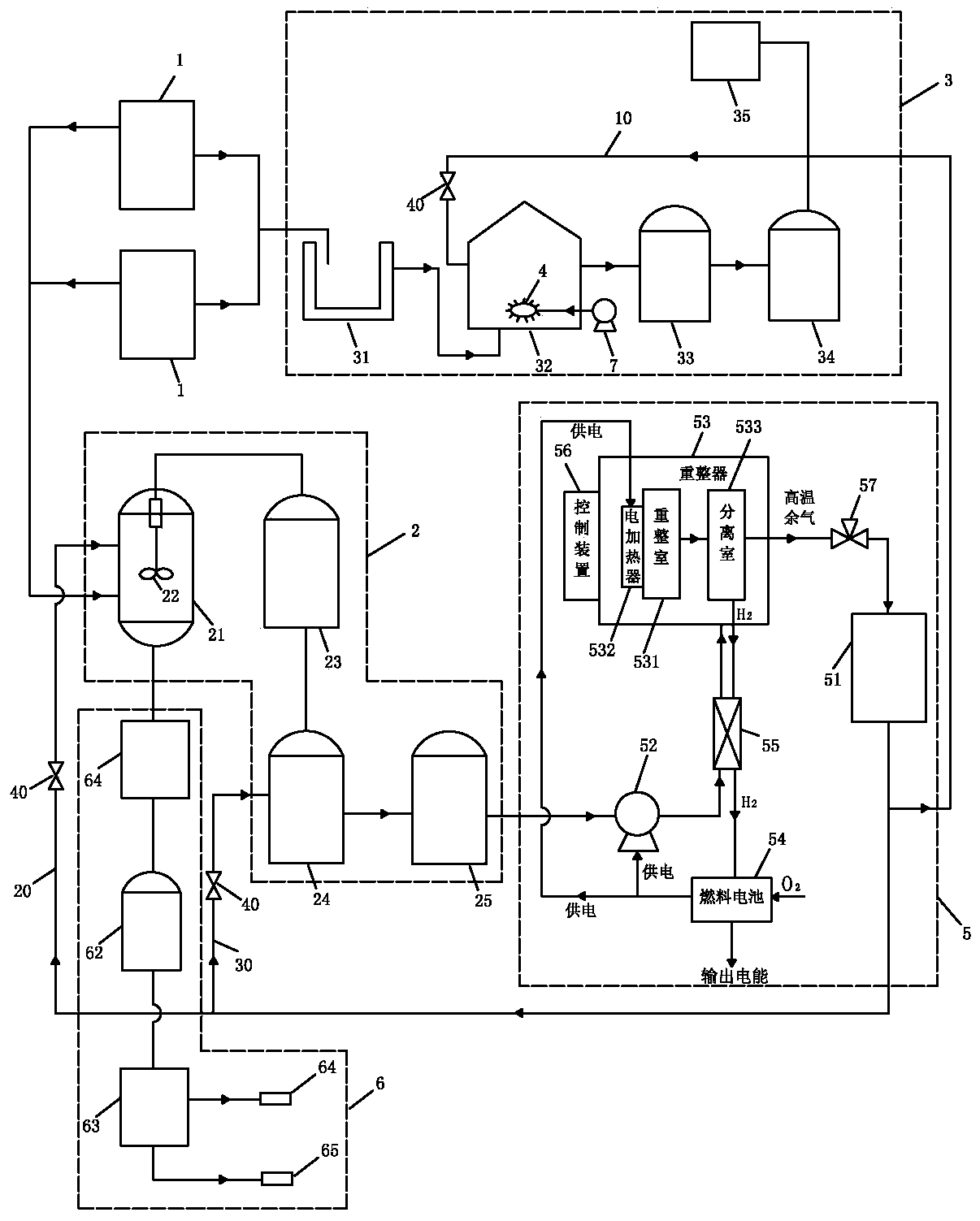

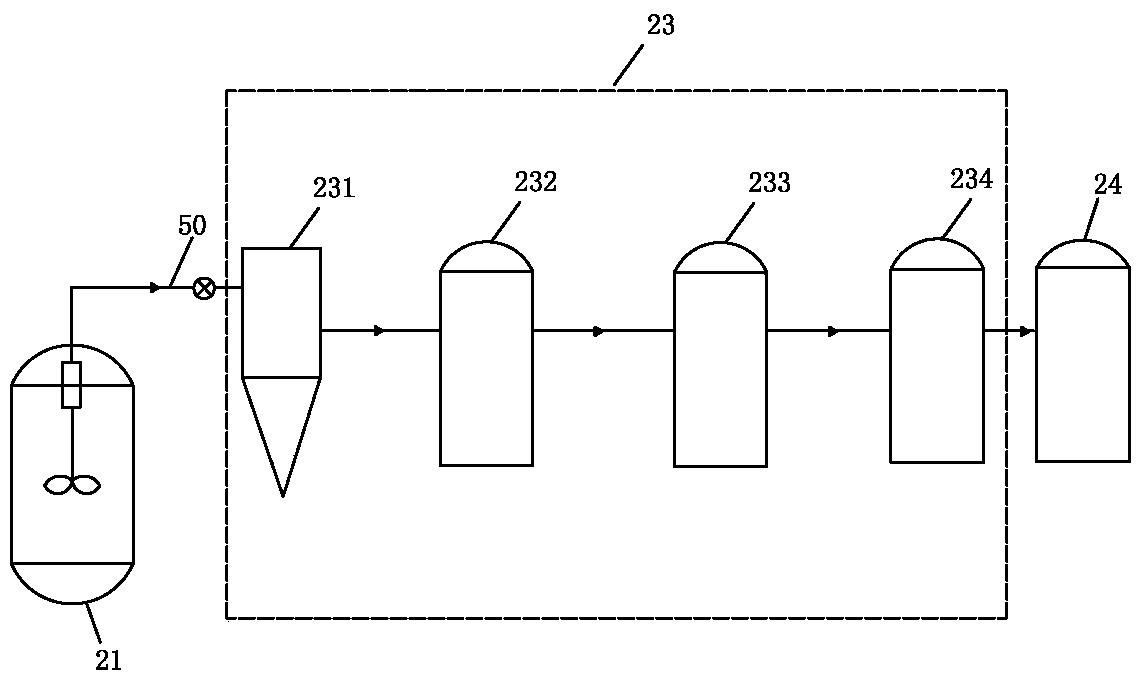

Urban community sewage treatment station with combined heat and power effect

InactiveCN108928991AEfficient conversionEfficient use ofTreatment involving filtrationPhotovoltaicsThermal energyFeces

The invention relates to the technical field of municipal sewage treatment, in particular to a municipal community sewage treatment station with a combined heat and power effect. The municipal community sewage treatment station comprises a sewage treatment module, a feces treatment module and a thermoelectric control module, wherein the sewage treatment module a grille tank, a MBR biofilm reactorand a clean water collection tank, the feces treatment module includes a CSTR anaerobic fermentation tank, a methane extraction device, and a methanol synthesis device, and the thermoelectric controlmodule includes a reformer for hydrogen production from methanol and water, a heat exchanger, a fuel cell, a high-temperature residual gas collection device and a control device. The municipal community sewage treatment station integrates power supply, heat supply and sewage treatment in the community, the sewage is treated in the neighborhood of the community, the efficient conversion and utilization of electric energy and heat energy are realized, the transportation cost and the burden of centralized treatment of urban sewage can be reduced, and the municipal community sewage treatment station is not limited by the site.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

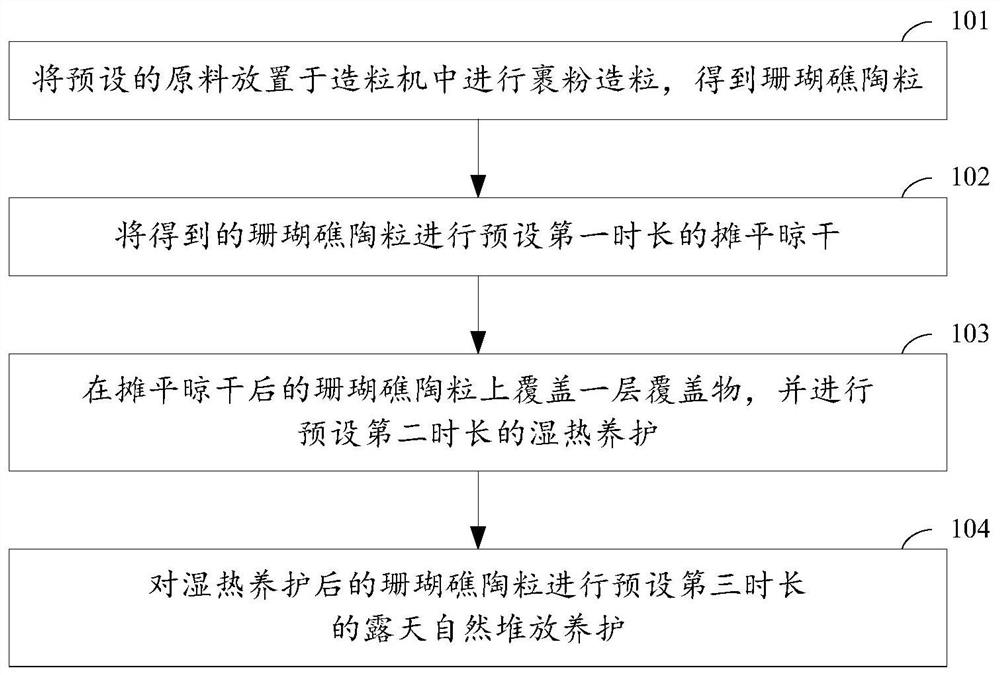

A kind of preparation method of coral reef ceramsite

ActiveCN108178572BLow costReduce energy consumptionClimate change adaptationGreen environmentEngineering

The invention provides a preparation method of coral reef ceramsite. The preparation method comprises the following steps: putting pre-set raw materials into a granulating machine and carrying out powder covering and granulation, so as to obtain the coral reef ceramsite; carrying out spreading and airing on the obtained coral reef ceramsite for a pre-set first duration; covering the spread and aired coral reef ceramsite with a layer of covering material, and carrying out wet and hot curing for a pre-set second duration; carrying out open-air natural stacking and curing on the coral reef ceramsite subjected to the wet and hot curing for a pre-set third duration. By adopting the preparation method of the coral reef ceramsite, provided by the invention, energy sources and clay resources can be saved and long-distance transportation cost of a large amount of clay is reduced, so that the prepared coral reef ceramsite has the characteristics of low cost, low energy consumption and greennessand environment friendliness.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

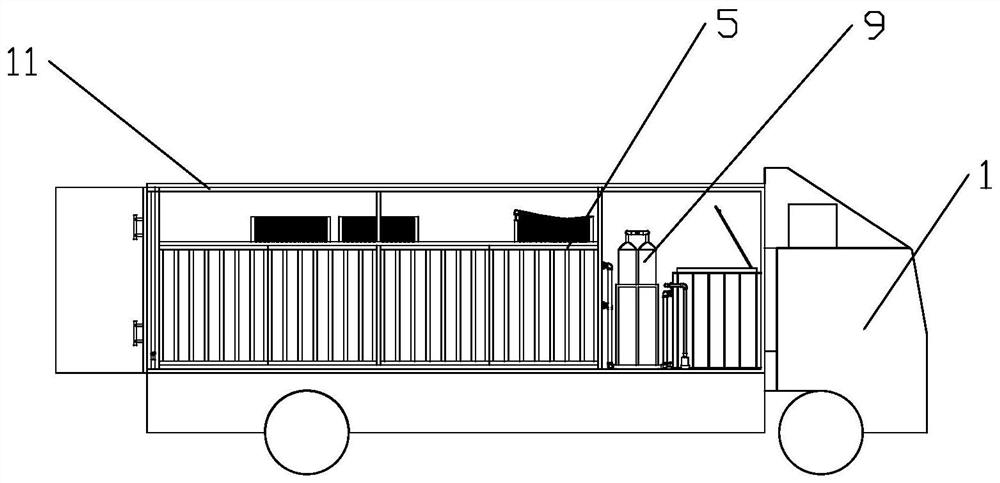

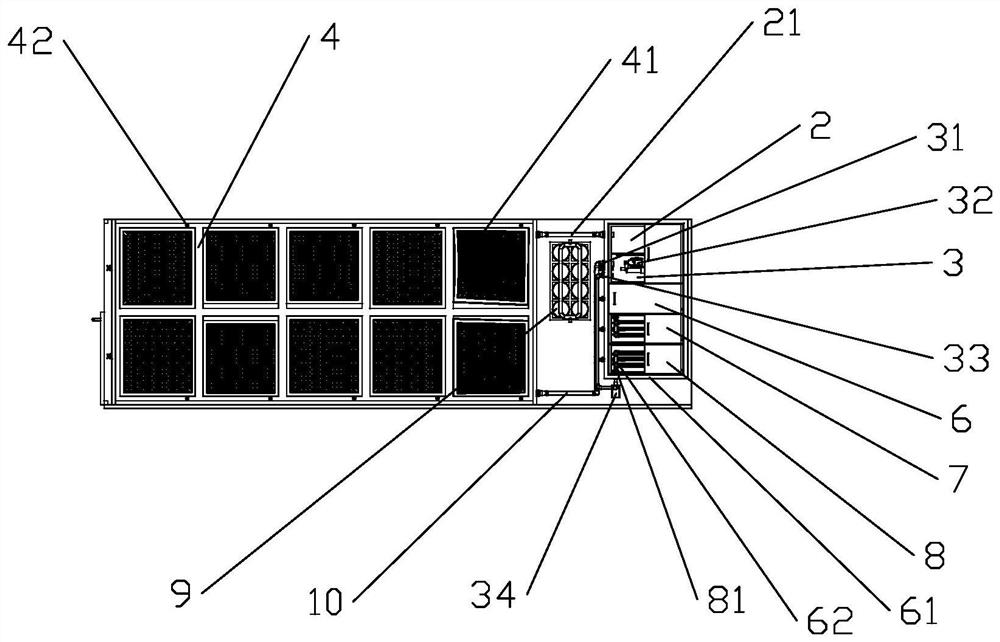

Multifunctional transport vehicle suitable for long-distance transport of live seafood

PendingCN112005952AImprove the living environmentImprove survival rateRefrigerated goods vehicleTreatment involving filtrationBiofilmEnvironmental engineering

The invention relates to a multifunctional transport vehicle suitable for long-distance transport of live seafood. The multifunctional transport vehicle comprises a transport vehicle body, the transport vehicle body is provided with a compartment, and a liquid bag, a sedimentation filter tank, a water purification tank, an anaerobic filter tank, an aerobic filter tank and a microalgae filter tankare arranged in the compartment. Water in the liquid bag automatically flows into the sedimentation filter tank and then enters the water purification tank, water in the water purification tank returns to the liquid bag under the action of a first water pump, and one-time water purification treatment circulation is completed. The water body in the water purification tank can further sequentially enter the anaerobic filter tank, the aerobic filter tank and the microalgae filter tank, nitrogen and phosphorus in the water body are effectively treated by anaerobic bacteria, aerobic bacteria and microalgae and then return to the water purification tank again through a biological membrane group, a filter water outlet and a water purification tank water return pipe under the action of a second water pump, and thus biological purification circulation treatment of the water is completed. By means of the mode, impurity dirt and nitrogen and phosphorus waste in the water body are well treated, the survival rate of the live seafood in the liquid bag is increased, and the problem that the inland live seafood is high in price is essentially solved.

Owner:青岛鲜达物流科技有限公司

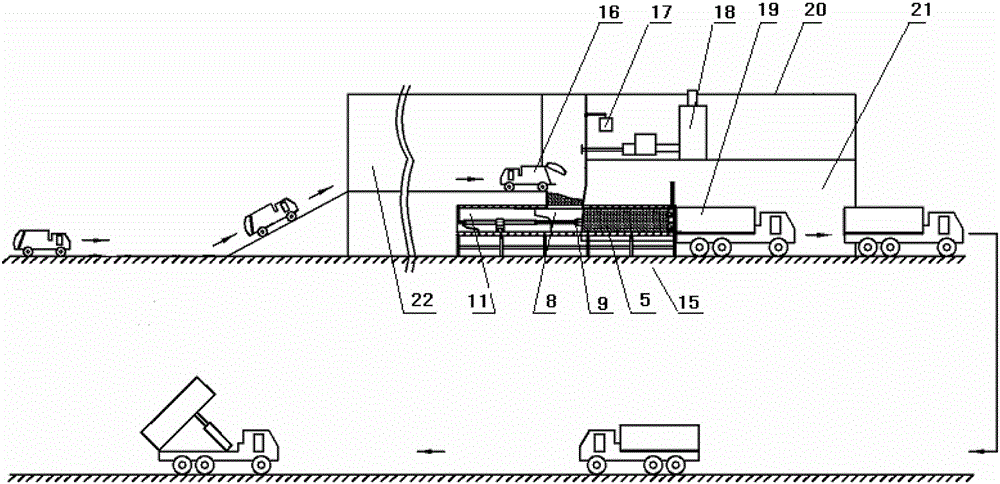

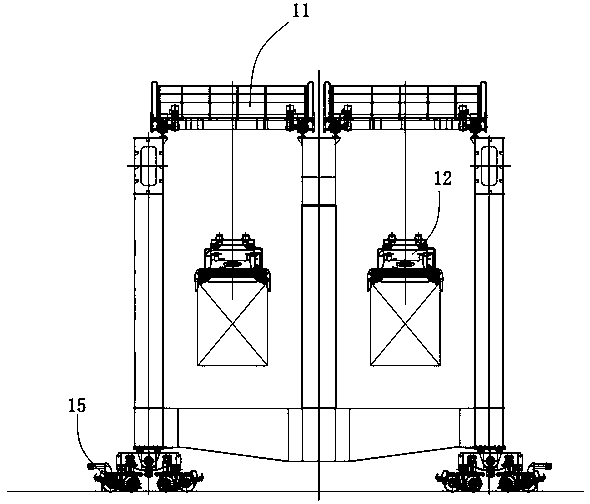

Garbage transferring method

InactiveCN108910547AIncrease loading capacityReduce long-distance transportation costsBottle emptyingLoading/unloadingLitterSelf weight

The invention discloses a garbage transferring method. The garbage transferring method is characterized in that firstly garbage is loaded into garbage transferring boxes with discharge ports at the tail parts, the four corners of the bottom and the four corners of the top of each garbage transferring box each are provided with a container corner piece, then, the two garbage transferring boxes which are loaded with the garbage are loaded and transported to a garbage unloading field through a container semitrailer at the same time, the garbage transferring boxes are lifted to lifting and discharging devices through a crane in the garbage unloading field, finally, the lifting and discharging devices are used for enabling the garbage transferring boxes to be inclined, so that the heads of thegarbage transferring boxes are higher than the tail parts, and unloading is completed. The garbage transferring method has the advantages that the garbage loading capacity for long-distance transportation can be increased, the ratio of the self-weight of a vehicle body is reduced, and the long-distance transportation cost of the garbage is reduced are achieved.

Owner:CHONGQING ENVIRONMENT & SANITATION GRP CO LTD

A clean production process for recovering molybdenum-rhenium from ion adsorption type molybdenum-rhenium ore

ActiveCN112853122BLow costReduce infrastructure costsProcess efficiency improvementRheniumPregnant leach solution

The invention relates to a clean production process for recovering molybdenum-rhenium from ion-adsorption type molybdenum-rhenium ore. The ore is leached for the first time, and then the mixed solution of the leaching agent and the leaching aid is used for the second leaching of the ion-adsorbed molybdenum-rhenium ore. Finally, the molybdenum and rhenium in the leaching solution are mixed and recovered. In the present invention, a leaching agent solution is used for the first leaching so that molybdenum ions and rhenium ions that are easy to be recovered in the ore are leached into the solution, and a mixed solution of a leaching agent and a leaching aid is used in the second leaching to make the molybdenum ions and rhenium ions that are difficult to recover in the ore leached. The rhenium ions are leached into the solution, thereby increasing the leaching rate of molybdenum and rhenium, while reducing the amount of leaching agent and leaching aid. The method has the characteristics of low cost, good environmental protection and simple process. In this process, the recovery rate of rhenium is greater than 70%, and the recovery rate of molybdenum is greater than 80%.

Owner:北京地科绿色资源科技有限公司

A kind of preparation method of high solid content ether type high water-reducing polycarboxylate water-reducer

The invention discloses a method for preparing a high-solid-content ether high-water-reducing polycarboxylic acid water reducer. The method comprises the following steps: adding solid isopentenol polyoxyethylene ether into a reactor, adding water, of which the mass is 10% to 15% that of the solid isopentenol polyoxyethylene ether, into the reactor, starting a stirrer to stir, heating the internal temperature of the reactor to 70 DEG C to 80 DEG C, and carrying out stirring for 30min until the isopentenol polyoxyethylene ether is completely dissolved; cooling the internal temperature of the reactor to 30 DEG C to 40 DEG C, sequentially adding a chain transfer agent solution and an initiator A solution into the reactor, carrying out uniform mixing, simultaneously dropwise adding a monomer solution for 1.5 to 3 hours and an initiator B solution for 2.5 to 3.5 hours, continuing to carry out heat preservation for 1 to 2 hours after dropwise adding ends, and neutralizing the pH value of the solution to 7+ / -1 with caustic soda flakes, thereby obtaining the high-solid-content ether high-water-reducing polycarboxylic acid water reducer with the solid content of 85%. According to the method, the product is environmentally friendly and is free of formaldehyde content, and the production process is free of emission of waste gases, waste water and waste residues; compared with industrial-produced low-solid-content (40% to 50%) products, the product has the advantages that the water-reducing rate is consistent, the concrete wrapping property is good, costs of production, transportation and storage processes are reduced, and the price of the product is lowered.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

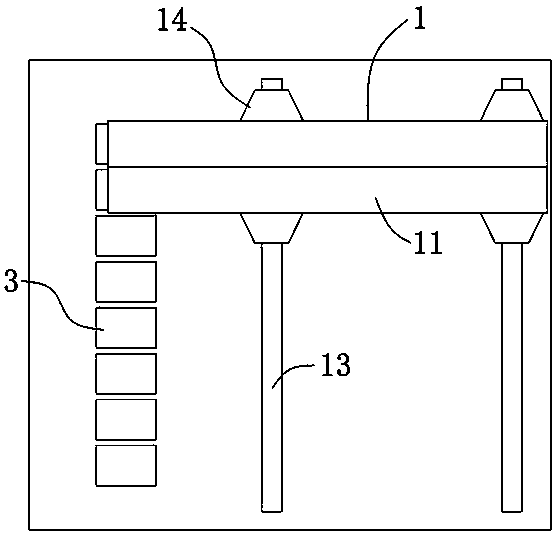

A comprehensive garbage operation system

ActiveCN108750499BIncrease loading capacityReduce long-distance transportation costsRefuse vehiclesUrban regionSemi-trailer

The invention discloses a garbage comprehensive operation system, which comprises an urban transfer vehicle and a garbage operation box matched with the urban transfer vehicle, and a container corner is respectively arranged at the bottom four corners and the top four corners of the garbage operation box It also includes a container semi-trailer and a tractor head. The length of the container semi-trailer is greater than the sum of the lengths of the two garbage operation boxes. The container corner fittings at the bottom of the garbage transfer box correspond to the trailer container twist locks; it also includes the container spreader for lifting the garbage transfer box in the garbage transfer station and the garbage treatment plant outside the urban area, and the container spreader installed in the garbage disposal station. The lifting and unloading device used in the factory for overall lifting and tilting unloading of the garbage operation box. The invention has the advantages of combining short-distance transportation and long-distance transportation, increasing the garbage load in long-distance transportation, reducing the cost of long-distance transportation of garbage, and the like.

Owner:CHONGQING ENVIRONMENT & SANITATION GRP CO LTD

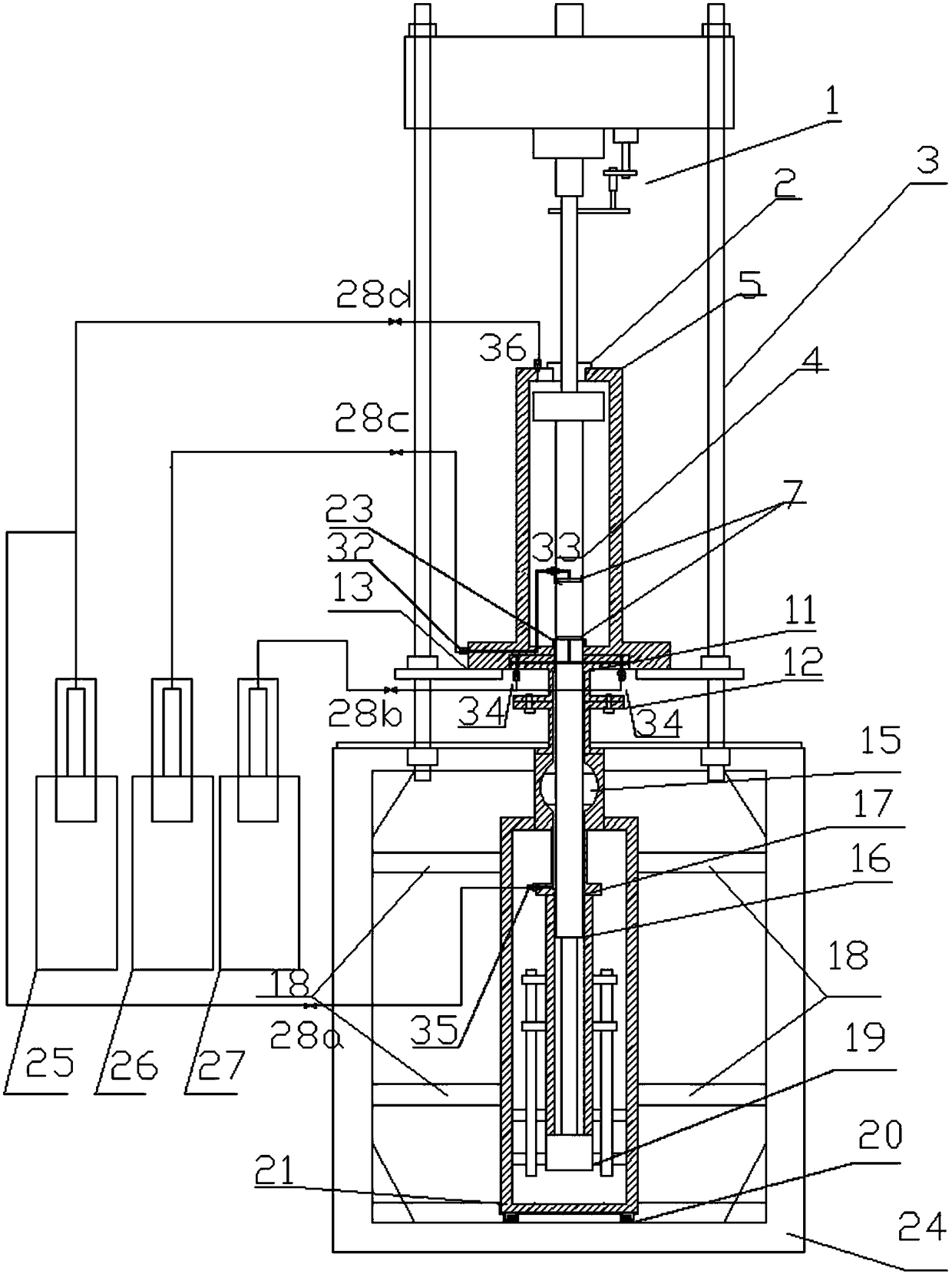

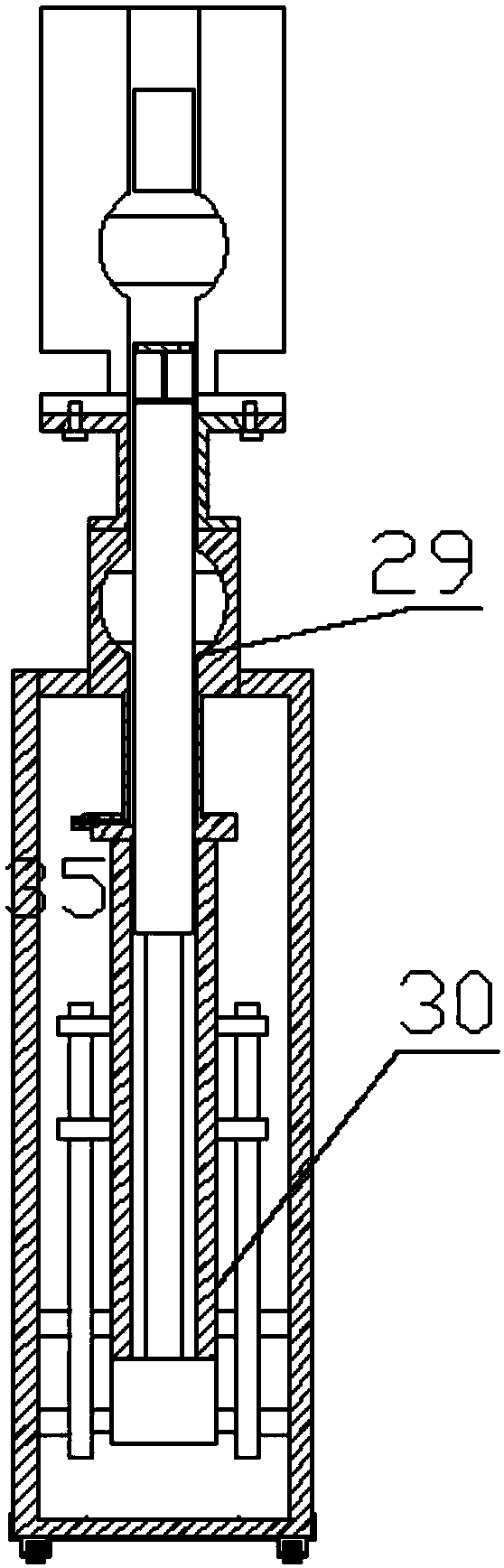

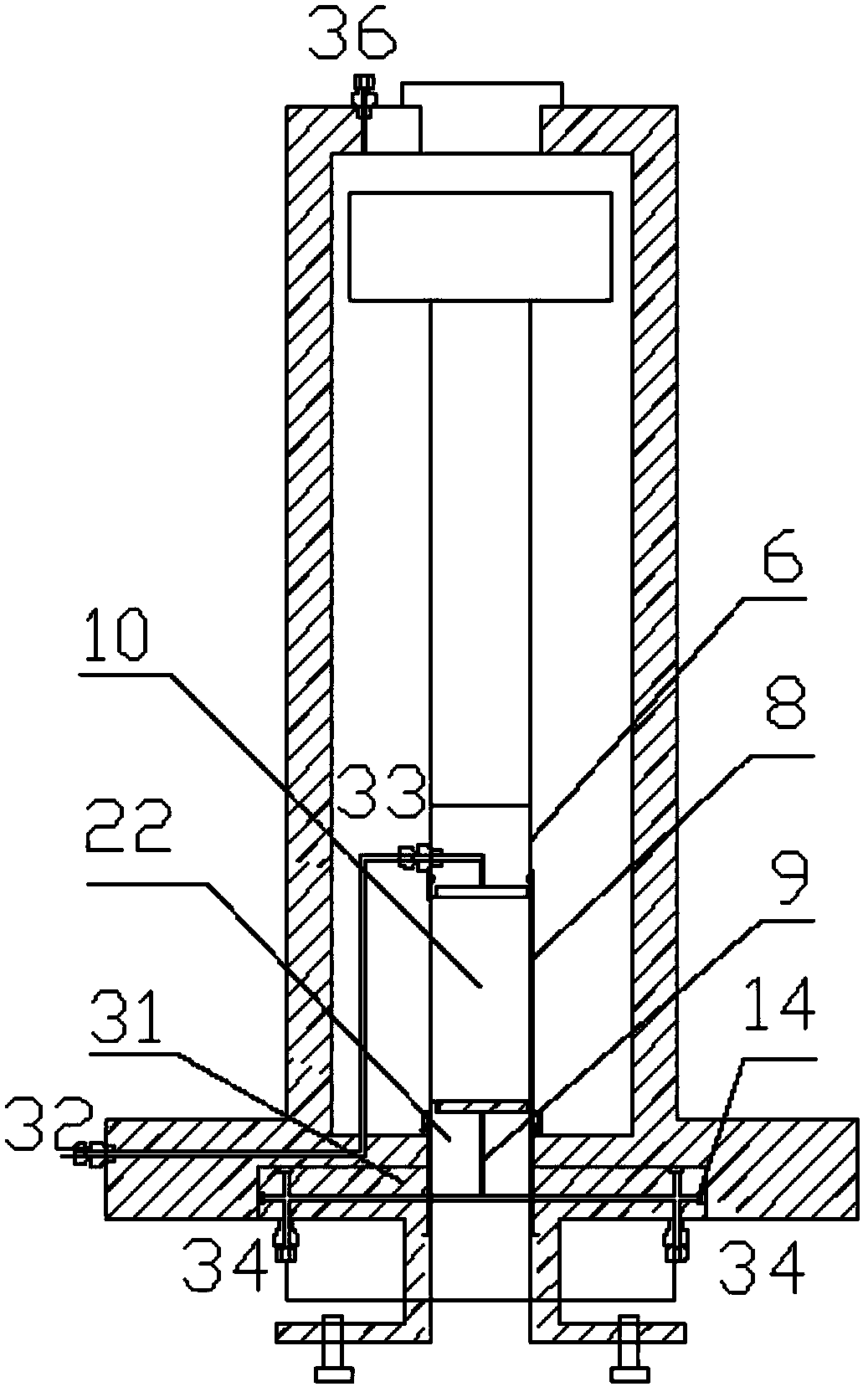

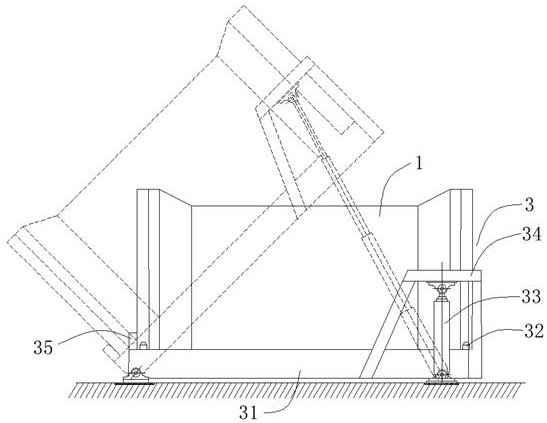

A kind of pressure-holding transfer type triaxial device and method for natural gas hydrate core sample

ActiveCN106092772BEasy to controlRapid positioningMaterial strength using steady shearing forcesRubber membraneData acquisition

The invention relates to a natural gas hydrate rock core sample dwell transfer-type triaxial apparatus and a method thereof, which belongs to the technical field of natural gas hydrate base physical property measurement. The apparatus comprises a rock core transfer apparatus, a triaxial apparatus host, a confining pressure and aperture pressure control system, a computer data acquisition and a control system. By using the triaxial apparatus, a rock core is transferred from a sample storage device to the rock core transfer apparatus; the rock core transfer apparatus and the triaxial apparatus host are subjected to abutting joint and locked; a dwell rock core is transferred to a triaxial pressure chamber by the dwell rock core, an original plastic sleeve of the rock core is removed, and the rock core is sleeved by a rubber membrane, and pressure control and motion control are required during whole course of a hydrate dwell rock core transfer process. The apparatus realizes transfer of the hydrate dwell rock core, and realizes deposit intensity measurement under original cementation structure condition and consolidating condition of the hydrate, mechanical property of a practical storage layer is obtained, and the method has important meaning for revealing the destroy mechanism of the practical storage layer and evaluating the risk of exploitation geology of the natural gas hydrate.

Owner:DALIAN UNIV OF TECH

A method for long-distance transportation of garbage

ActiveCN108706253BRealize allocation reductionIncrease load rateRefuse vehiclesProcess engineeringRefuse Disposals

The invention discloses a method for long-distance operation of garbage, which is characterized in that, during transportation, the collected garbage is first loaded into a chamber of a garbage carrier with a discharge port at the tail; The transfer tractor is connected and transported to the garbage disposal area; the garbage carrier is separated from the transfer tractor, and the garbage carrier is turned over by the lifting and unloading device installed in the garbage disposal area, so that the tail of the garbage carrier faces downwards. Unloading is completed in an inclined manner. The invention has the advantages of being able to reduce allocation of garbage transfer vehicles, increase the garbage loading rate of the garbage transfer vehicles, reduce long-distance transportation costs of garbage, and improve operating efficiency.

Owner:CHONGQING ENVIRONMENT & SANITATION GRP CO LTD

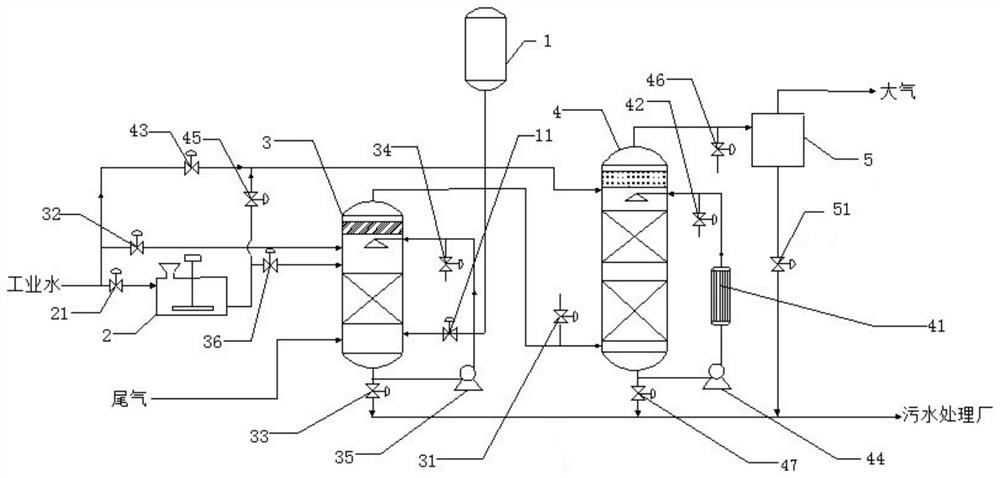

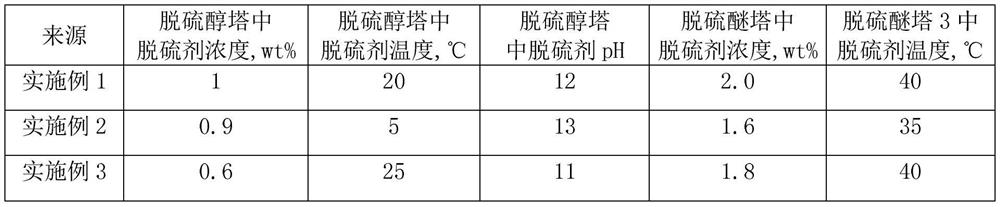

Device for treating tail gas containing mercaptan and thioether

PendingCN114425231ASimultaneous processingNo driftGas treatmentDispersed particle separationEtherMaterials science

The invention belongs to the technical field of gas separation through gas-liquid contact, and particularly relates to a device for treating tail gas containing mercaptan and thioether. The device for treating the tail gas containing the mercaptan and the thioether comprises a liquid caustic soda supply device; a desulfurizing agent supply device; an air inlet is formed in the bottom of the sweetening tower, and the top is communicated with a liquid caustic soda supply device and a desulfurizer supply device; the bottom of the desulfurization ether tower is communicated with the top of the mercaptan removal tower, the top of the desulfurization ether tower is communicated with a desulfurizer supply device, and the desulfurization ether tower is provided with a gas outlet. When the device is used for treating the tail gas containing mercaptan and thioether, equipment corrosion cannot be caused at the high temperature, meanwhile, the operation flexibility is high, closed operation can be achieved for replacement of a desulfurizing agent, and drifting of odor cannot be generated.

Owner:CHINA PETROLEUM & CHEM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com