Garbage compressor, garbage compression processing method and garbage transfer station

A garbage compressor and garbage technology, which can be used in trash cans, garbage conveying, garbage collection, etc., can solve the problems of high garbage transportation cost and environmental pollution, and achieve the effect of reducing garbage transportation cost, reducing environmental pollution, and high equipment integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

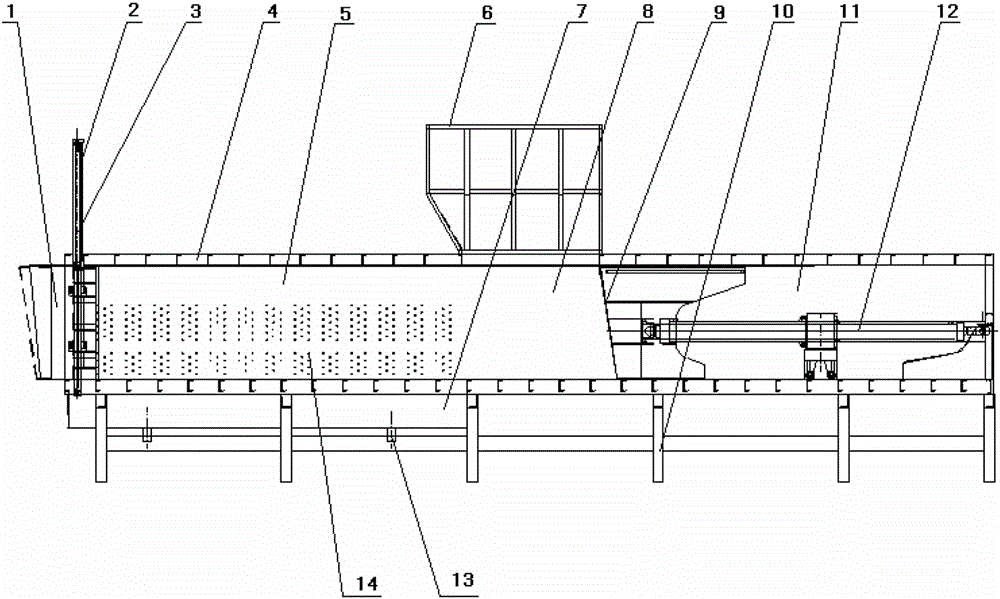

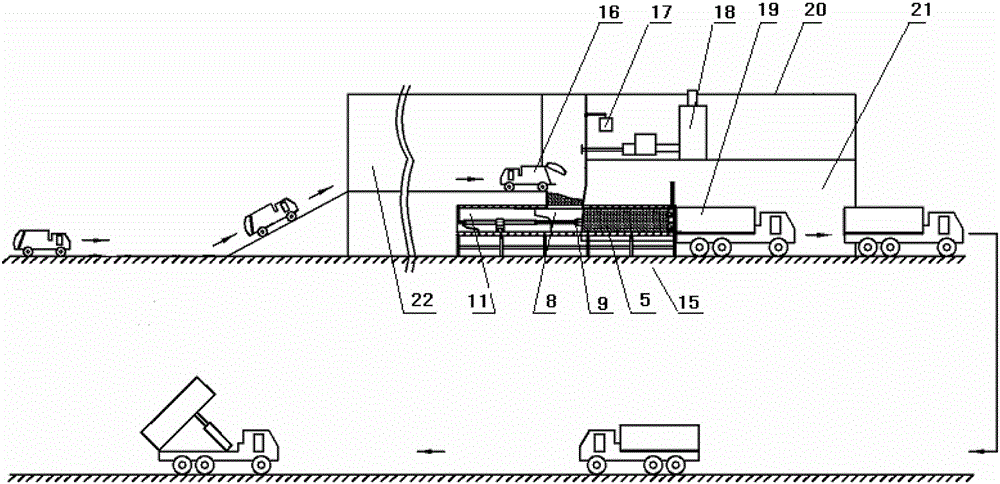

[0024] Such as figure 1 As shown, a garbage compressor 15 includes a casing 4, the compressor casing 4 is a cuboid steel structure, and the height of the casing is determined according to the height of the transport vehicle.

[0025] A docking bin 1, a compression storage bin 5, a feeding bin 8 and a machine parts bin 11 are sequentially arranged in the box body 4. The docking bin 1 is located at the front of the box body 4 and is composed of wall panels around the box body 4. Mainly interface with transfer vehicles. Compression storage bin 5 is made up of gate 2, gate opening and closing oil cylinder 3 and box body 4 surrounding wall plates. Loose garbage is compressed and stored in this area, which is the main working area of this machine. Feeding cabin 8 is positioned at the middle part of casing 4, is connected with upper hopper 6, is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com