Powdery early-strength type polycarboxylate water reducing agent and preparation method thereof

An early-strength type and water-reducing agent technology, applied in the field of concrete admixtures, can solve the problems of low cost of long-distance transportation and difficulty in powdering early-strength polycarboxylic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

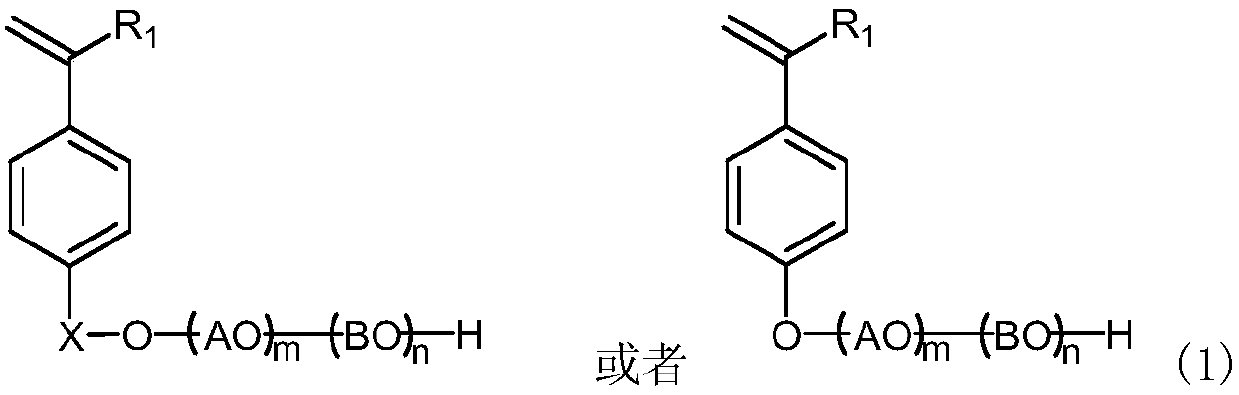

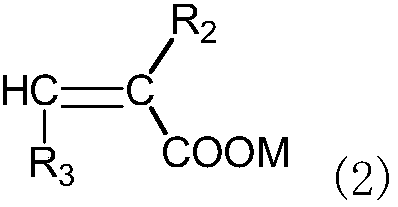

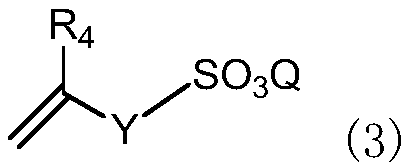

Method used

Image

Examples

preparation example Construction

[0070] Preparation of monomer a:

[0071] Put the substance of general formula (4) in a 2L dry stainless steel autoclave, add an appropriate amount of catalyst (such as metal sodium), stir and dissolve, seal the autoclave, replace the air in the autoclave with nitrogen for three times, and then evacuate the autoclave When it is below -0.09MPa, turn on the heating, raise the temperature to 120°C, and keep the reactor continuously vacuumed for 30 minutes, then stop, and then continue to slowly feed an appropriate amount of propylene oxide into the reactor to maintain the internal pressure of 0.15-0.2MPa, and the reaction temperature is 110 -150°C, when the propylene oxide feeding is completed, continue the constant temperature reaction until the pressure no longer drops, and after maintaining for 30 minutes, continue to feed an appropriate amount of ethylene oxide into the kettle to maintain the pressure in the kettle at 0.15-0.2MPa, and the reaction temperature is 110- 150°C, w...

preparation Embodiment 1

[0080] In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel, and a nitrogen inlet tube, add 60 g of water to make a base, and raise the temperature to 15° C., adjust the pH value of the system to 8.5, and then contain 531 g (a-1, 0.09mol), 32.4g (b-1, 0.45mol), 12.96g (c-1, 0.096mol), 6.39g (d-1, 0.09mol), 2.92g mercaptopropionic acid, 1.16g ascorbic acid and 200g aqueous phase Mix and stir to make uniform monomer aqueous solution I, fully dissolve 49.1g of water-soluble calcium salt e-1 in 50g of water as drop solution II, fully dissolve 29.4g of water-soluble silicate f-1 in 80g of water as Add solution III dropwise, and start the reaction. After adding 2.91g of hydrogen peroxide to the bottoming water, start adding solutions I, II and III dropwise for about 2.0 hours at the same time. The concentration is 60%, the weight average molecular weight is 31500, and it is used for spray drying.

[0081] Dilute the above polymer solution to 38%, and then us...

preparation Embodiment 2

[0083] In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel, and a nitrogen inlet tube, add 100 g of water to make a base, and raise the temperature to 35° C., adjust the pH value of the system to 9.5, and then add 390 g of (a-2, 0.06mol), 36.12g (b-2, 0.42mol), 12.42g (c-2, 0.06mol), 20.4g (d-2, 0.24mol), 7.34g mercaptopropionic acid, 2.29g ascorbic acid and 200g aqueous phase Mix and stir to make uniform monomer aqueous solution I, fully dissolve 28.52g of water-soluble calcium salt e-2 in 80g of water as drop solution II, fully dissolve 57.05g of water-soluble silicate f-2 in 80g of water as Add solution III dropwise, and start the reaction. After adding 6.88g of hydrogen peroxide in the bottoming water, start adding solutions I, II and III dropwise for about 6.0 hours at the same time. The concentration is 50%, the weight average molecular weight is 49500, and it is used for spray drying.

[0084] Dilute the above polymer solution to 35%, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com