Method for preparing high-solid-content ether high-water-reducing polycarboxylic acid water reducer

A high-solid content, water-reducing technology, applied in the field of concrete admixtures, can solve the problems of hindered rearrangement of functional groups, high viscosity, etc., and achieve the effects of no three wastes, low price, and good packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

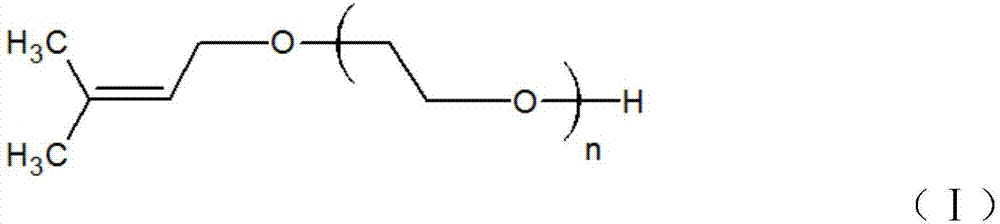

[0028] A preparation method of high solid content ether type high water-reducing polycarboxylate water-reducer, comprising the following steps:

[0029] (1) Add 800g of isopentenol polyoxyethylene ether with a molecular weight of 2400 and 80g of distilled water into a 2000mL reaction kettle, turn on the stirrer at a stirring speed of 240r / min, and heat to 70°C with an electric heating mantle until the bottom material dissolves into a homogeneous transparent solution.

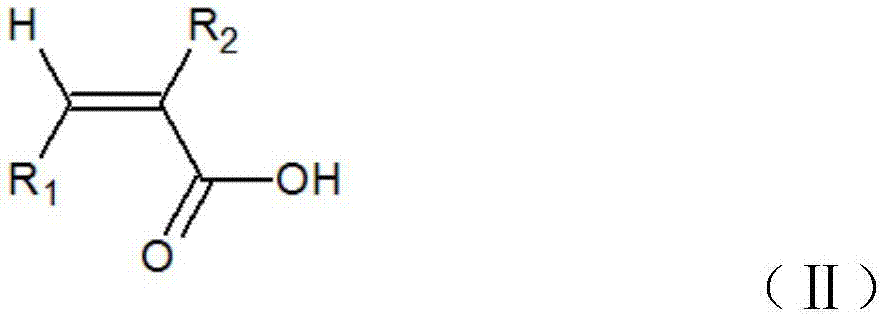

[0030] (2) Take out the electric heating mantle, cool the material at the bottom of the kettle to 35°C with an ice-water bath, add 20g of chain transfer agent solution to the bottom of the kettle, a mixed solution prepared by 10g of sodium hypophosphite and 10g of water; Add 14g of initiator A solution, a mixed solution prepared by 4g of ammonium persulfate and 10g of water; after stirring for 5min, add dropwise the monomer solution for 3h and the initiator B solution for 3.5h; wherein the monomer solution consi...

Embodiment 2

[0032] A preparation method of high solid content ether type high water-reducing polycarboxylate water-reducer, comprising the following steps:

[0033] (1) Add 800g of isopentenol polyoxyethylene ether with a molecular weight of 3000 and 120g of distilled water to a 2000mL reaction kettle, turn on the agitator at a stirring speed of 260r / min, and heat to 65°C with an electric heating mantle until the material at the bottom of the kettle is dissolved into a homogeneous transparent solution.

[0034] (2) Take out the electric heating mantle, cool the material at the bottom of the kettle to 30°C with an ice-water bath, add 23.33g of chain transfer agent solution to the bottom of the kettle, a mixed solution prepared by 13.33g of sodium hypophosphite and 10g of water; Add 15.5g of initiator A solution to the bottom of the kettle, a mixed solution prepared from 5.5g of ammonium persulfate and 10g of water; after stirring for 5min, add dropwise monomer solution for 2.5h and initiat...

Embodiment 3

[0036] A preparation method of high solid content ether type high water-reducing polycarboxylate water-reducer, comprising the following steps:

[0037] (1) Add 800g of isopentenol polyoxyethylene ether with a molecular weight of 2400 and 100g of distilled water to 2000mL, turn on the stirrer, stir at a speed of 200r / min, and heat it to 80°C with an electric heating mantle until the bottom material dissolves into a uniform transparent solution.

[0038] (2) Take out the electric heating mantle, cool the material at the bottom of the kettle to 40°C with an ice-water bath, add 14.3g of chain transfer agent solution to the bottom of the kettle, a mixed solution prepared by 4.3g of sodium methacrylate and 10g of water; after 10min , add 16g of initiator A solution to the bottom of the kettle, a mixed solution prepared by 6g of potassium persulfate and 10g of water; after stirring for 5min, dropwise add the monomer solution for 1.5h, and the initiator B solution for 3h10min; wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com