Straw smashing and rod making device for anaerobic fermentation biogas production

A straw crushing and anaerobic fermentation technology, applied in biochemical equipment and methods, gas production bioreactors, biochemical instruments, etc., can solve the problems of increasing transportation costs and storage space, reducing gas production rate, and strengthening transportation costs, etc. Achieve the effects of reducing long-distance transportation costs, reducing transportation volume, and increasing inventory capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with embodiment (accompanying drawing):

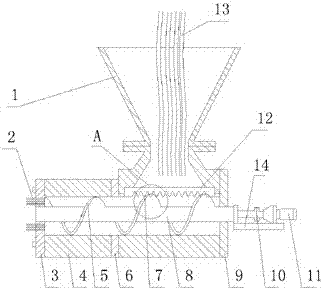

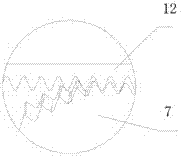

[0021] like figure 1 , figure 2 As shown, the straw crushing and rod making equipment of the present invention includes an auger mandrel 8 provided with a screw auger installed in the cavity 4 coaxially with the cavity of the equipment, and the auger is formed as an extrusion The front and back of the crushing section and the crushing section are composed of two sections of spiral augers; the outer contour of the spiral auger as the crushing section at the position of the feeding port of the cavity 4 is provided with an auger end cutting knife 7 with a toothed edge. , the toothed edge on the auger end cutting knife 7 and the toothed edge of the upper cutter 12 installed at the position of the feed port of the cavity 4 are in a shearing engagement relationship; as the extruding section 5 The outer contour of the spiral auger section is a smooth surface and has a dy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com