Folding working lamp

A technology for working lamps and folding poles, applied in lighting and heating equipment, portable lighting devices, with built-in batteries, etc., to achieve the effects of cost control, compact structure, and reduced packaging and transportation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

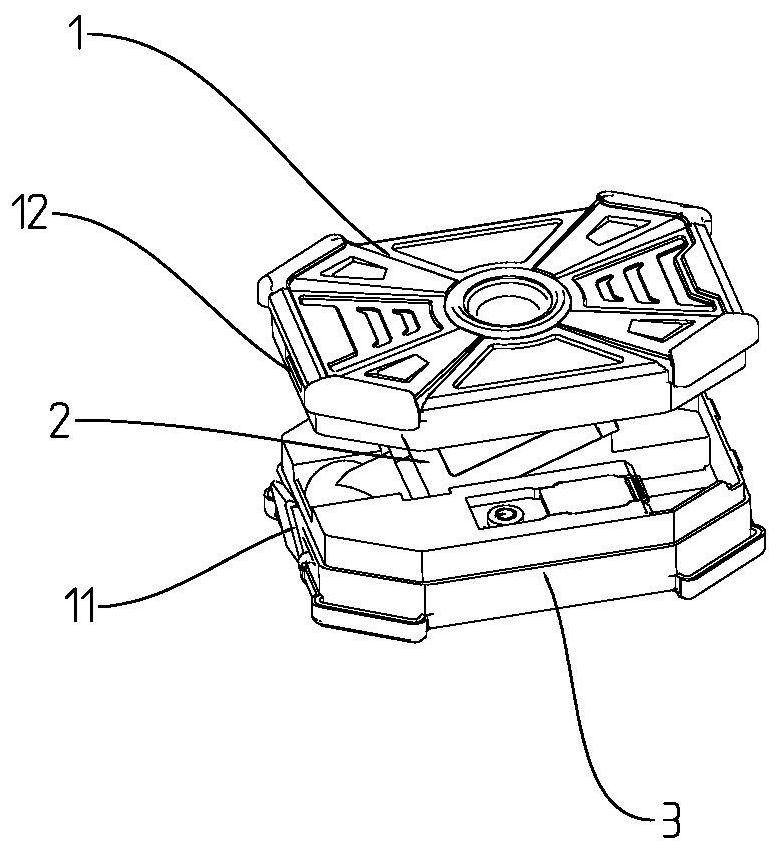

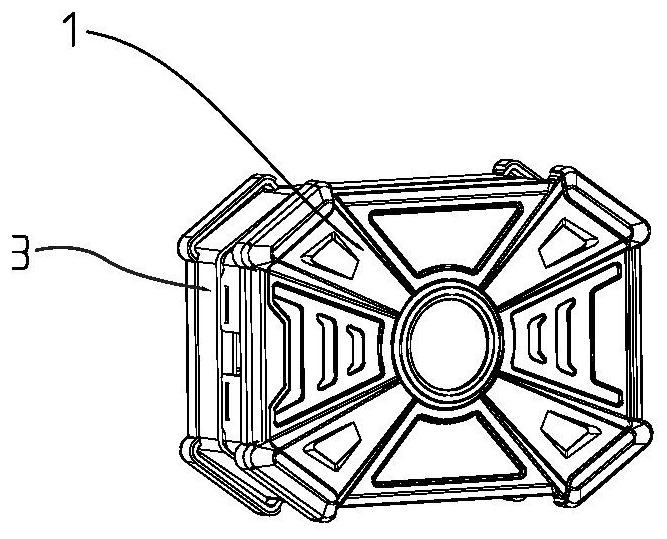

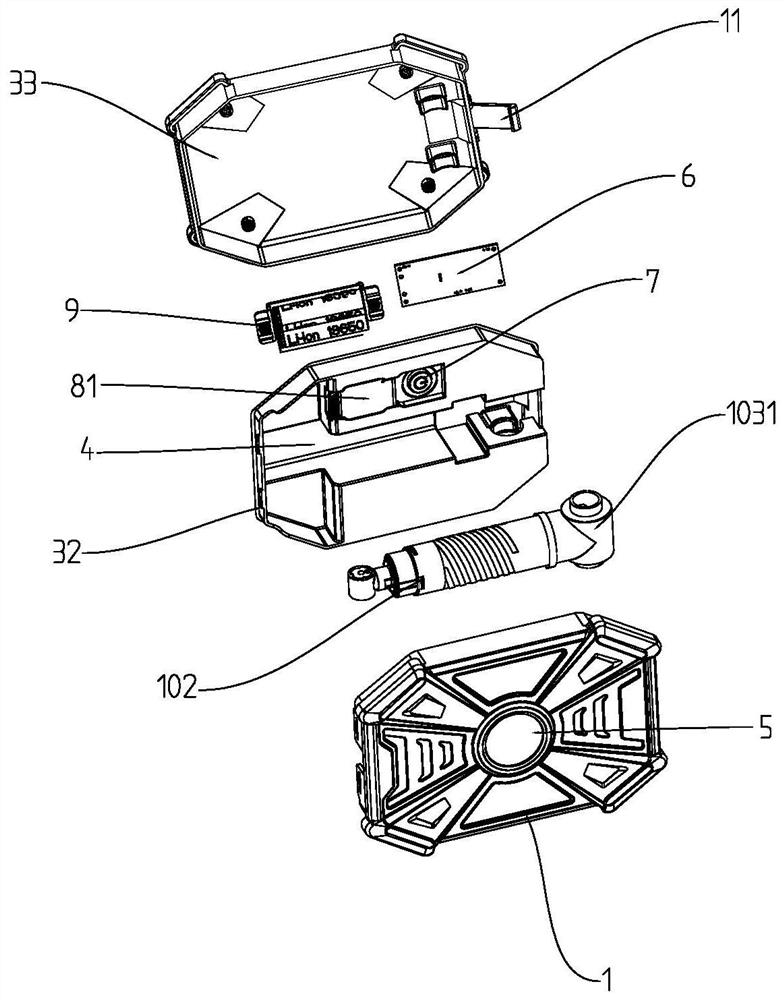

[0032] Such as Figure 1 to Figure 7 As shown, a foldable work light includes a lamp body and a bracket 2, the lamp body includes a lighting part 1 and a support part 3, and the support part 3 of the lamp body is provided with an accommodating space 4 for accommodating the bracket 2, accommodating The space 4 is in the shape of a groove. One end of the bracket 2 is connected to the lighting unit 1 , and the other end is connected to the support unit 3 . The bracket 2 is an adjustable part. In this embodiment, the bracket 2 is a telescopic rod, including a seven-section sleeve. The sleeve is in the shape of a truncated cone. Decreasing and nested connections, that is, the diameter of the sleeve connected to one end of the support part 3 is the largest, and the diameter of the sleeve connected to the end of the lighting part 1 is the smallest. The bracket 2 is rotatably connected with the lighting part 1, so that the lighting part 1 can be adjusted 360° relative to the bracket...

Embodiment 2

[0035] The support 2 includes four sleeve pipes, and the sleeve pipes are screwed together. The support 2 in the form of a telescopic rod can be adjusted to any length within the telescopic range. All the other are with embodiment 1.

[0036]If the length of the support 2 needs to be adjusted, each segment of the casing can be rotated separately to convert the rotation of the casing into the variation of the axial position. When the support 2 reaches the required length, the rotation can be stopped, and each joint sleeve pipe stays on the position adjusted to at last.

Embodiment 3

[0038] Such as Figure 8 , Figure 9 As shown, the bracket 2 is a foldable rod, including five tubular rods, and each tubular rod is hinged sequentially through hinges, that is, the head end of the tubular rod is connected to the tail end of the previous tubular rod, and all the tubular rods pass through the tension rope inside the tubular rod. 13 in series, the head end of the tension rope 13 is connected to the lighting part 1, the end of the tension rope 13 is wound on a rope shaft located at the support part 3, and the rope winding shaft is connected to the support part 3 in rotation and positioned by the ratchet ratchet structure . The included angle between adjacent tubular rods changes between 0-180°, and when it reaches 180°, it is limited by the hinge and does not change anymore. The hinge constrains the rear end of the connecting part of the adjacent tubular rod, and the connecting part of the adjacent tubular rod is provided with a tenon-tenon hole matching struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com