Assembled partition plate part, installation method and application

A partition board and assembled technology, which is applied to building components, roofs using flat/curved panels, roofs, etc., can solve the problems of complex installation procedures, high strength requirements of inorganic keels, and easy breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

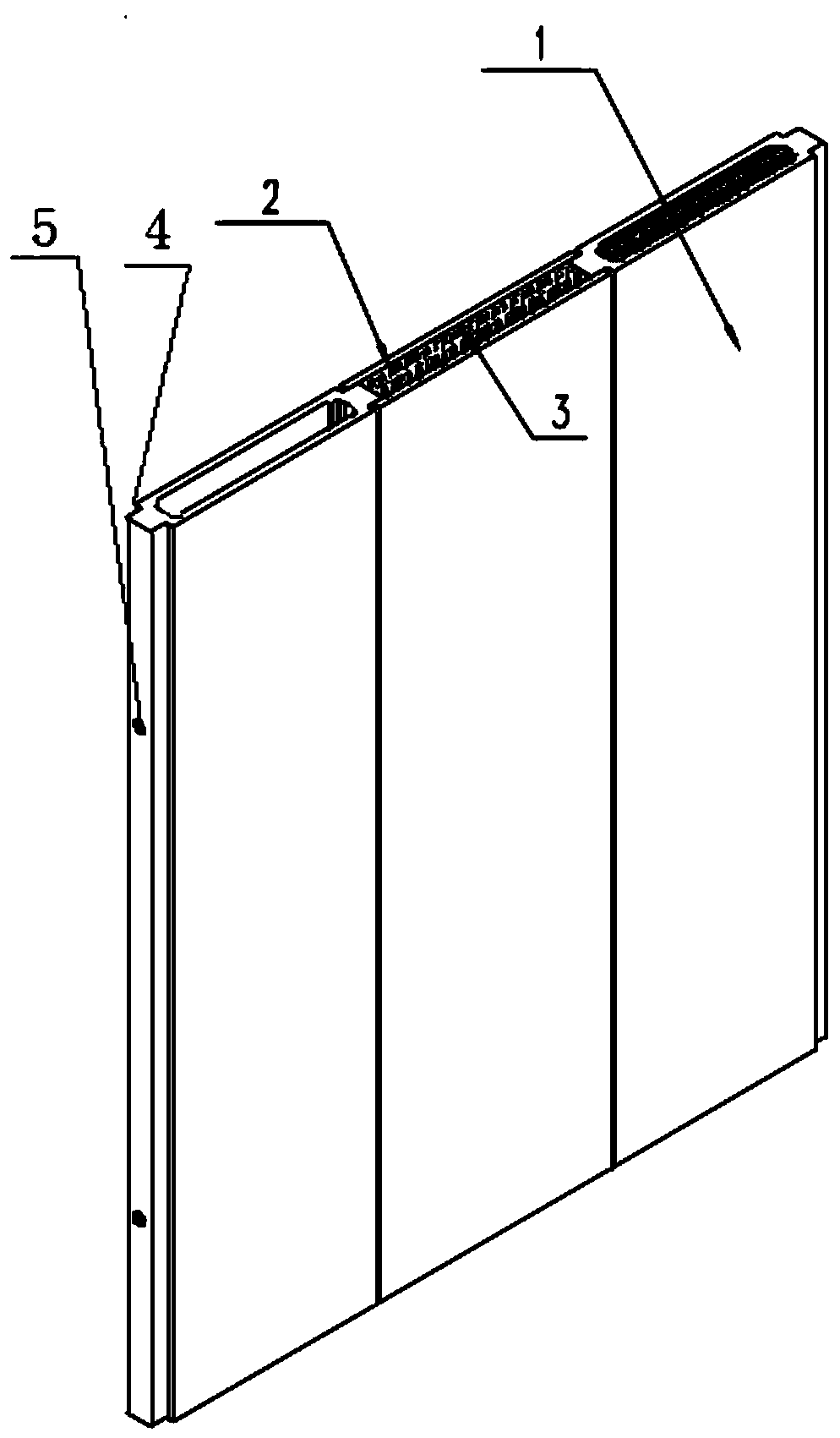

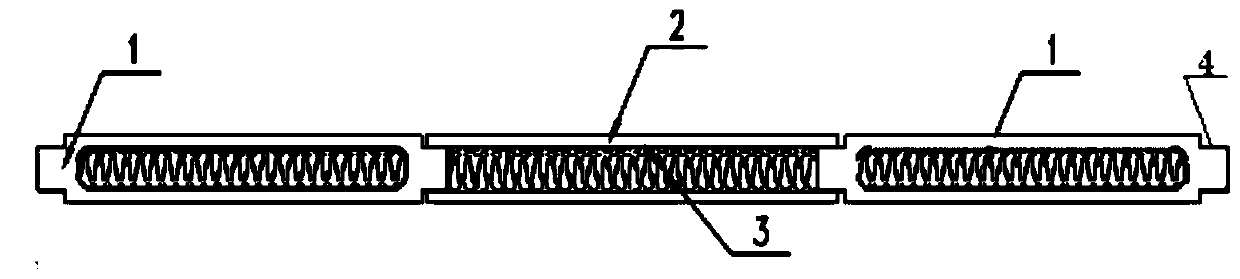

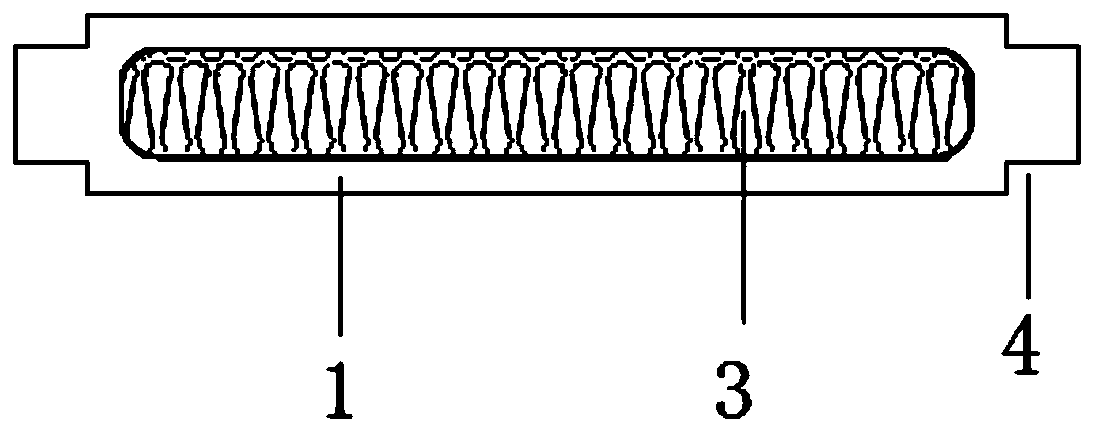

[0099] Such as Figure 1-Figure 3 As shown, the present invention provides an assembled partition panel component, which includes a sound-insulating keel plate 1, and the sound-insulating keel plate 1 is a plate-type sound-insulating keel plate. A cavity is provided in the middle of the sound-insulating keel board 1 , and the cavity is filled with heat-insulating and / or sound-absorbing materials 3 , and panels 2 are provided between adjacent sound-insulating keel boards 1 . Grooves 4 are provided on both sides of the sound insulation keel board 1, and the panel 2 is stuck in the grooves 4 on both sides of the adjacent sound insulation keel board.

[0100] The width of the sound insulation keel board is 200-600mm, the thickness is 90-250mm, the length is determined according to the specific size of the project, there is no limit, and the length can be spliced. The panel width is generally 600mm, and the thickness is 10-30mm. There is no limit to the panel length and can be spl...

Embodiment 2

[0111] The assembled partition panel part of this embodiment is the same as that of Embodiment 1, the difference is that the end of the sound insulation keel plate 1 or inside or in the cavity is provided with or buried or interspersed with structural columns, and the structural columns can be arranged horizontally or vertically, so that Improve the overall strength of the sound insulation keel board and the assembled partition board, such as Figure 4-Figure 11 shown.

Embodiment 3

[0113] The assembled partition plate part of this embodiment is the same as that of Embodiment 1, the difference is that the groove 4 is a concave double groove, such as Figure 14 As shown, the panel 2 is fixed by grooves 4 on both sides. The concave double grooves are set in the thickness direction of the side end surface of the sound insulation keel board, which can be one or a group. The concave grooves on both sides can be set asymmetrically. The thickness of the concave grooves on both sides is the same or different. At the same time, it is convenient to install panels 2 with different thicknesses.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com