Process and device for quickly preparing powdered active coke for desulfurization by utilizing pulverized coal

A preparation process, active coke technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of high production cost of active coke, complex manufacturing process, complex preparation process, etc., to save transportation The effect of cost, simple furnace type and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

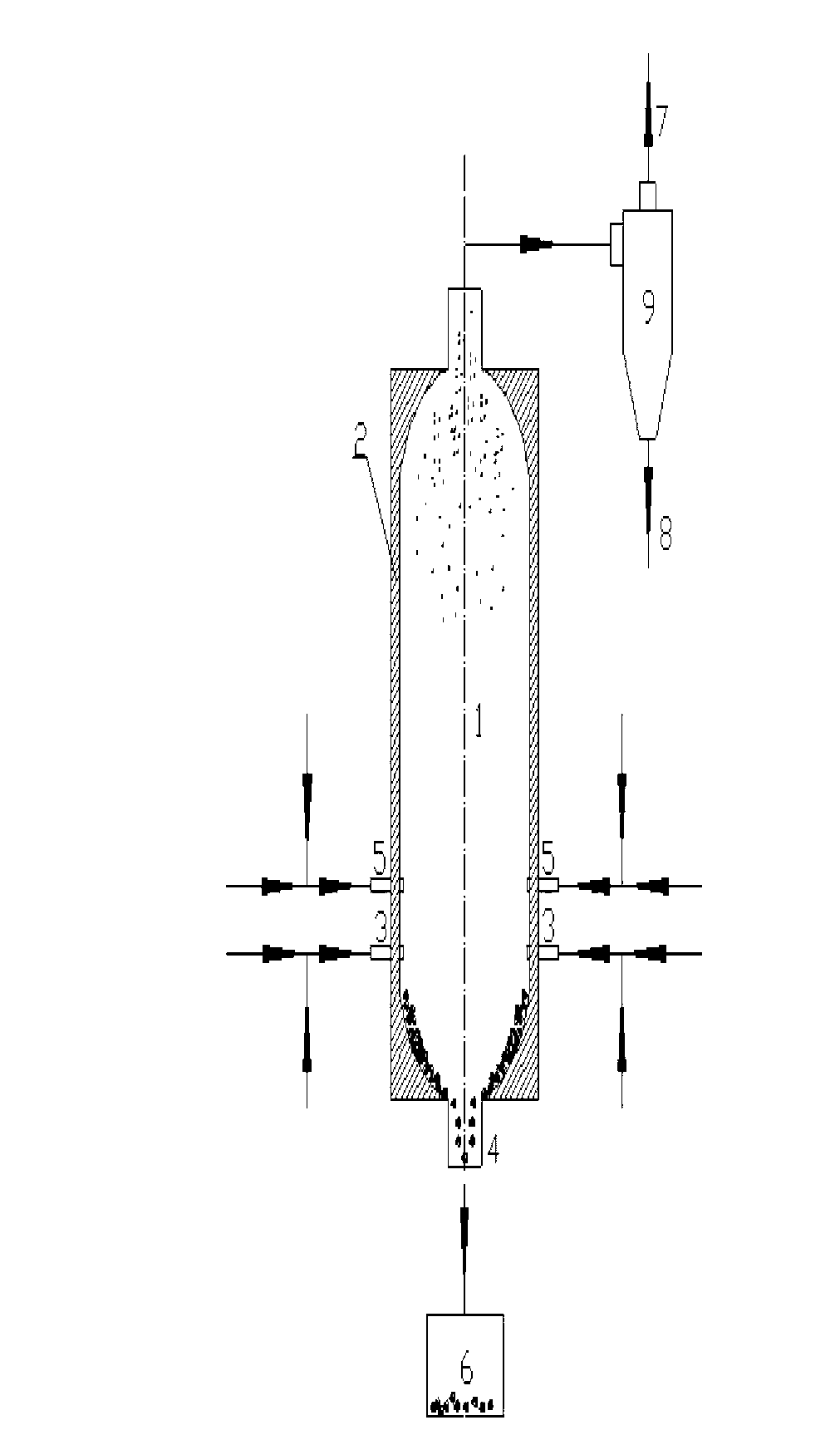

[0031] combined with figure 1 , In this implementation example, the raw coal used is Longde bituminous coal, and the average particle size of pulverized coal is 75 μm. The furnace inner layer of the entrained-bed rapid reaction furnace 1 used is a refractory insulation layer 2, and the reaction pressure is normal pressure. The specific steps are:

[0032] 1. From the tail flue of the entrained-bed rapid reaction furnace 1, the low-temperature flue gas with a temperature of 300 ° C is extracted by the fan, and the coal powder flowing out of the coal powder bin is sent into the entrained-bed rapid reaction furnace 1 through the feeding air nozzle 3, and the coal is The powder completes the low-temperature oxidation during the conveying process.

[0033] 2. The reaction gas is a mixture of flue gas extracted from the boiler with a temperature of 900°C and hot air at the outlet of the air preheater at 200°C, and the temperature of the mixture is 800°C. The reaction gas is sent ...

Embodiment 2

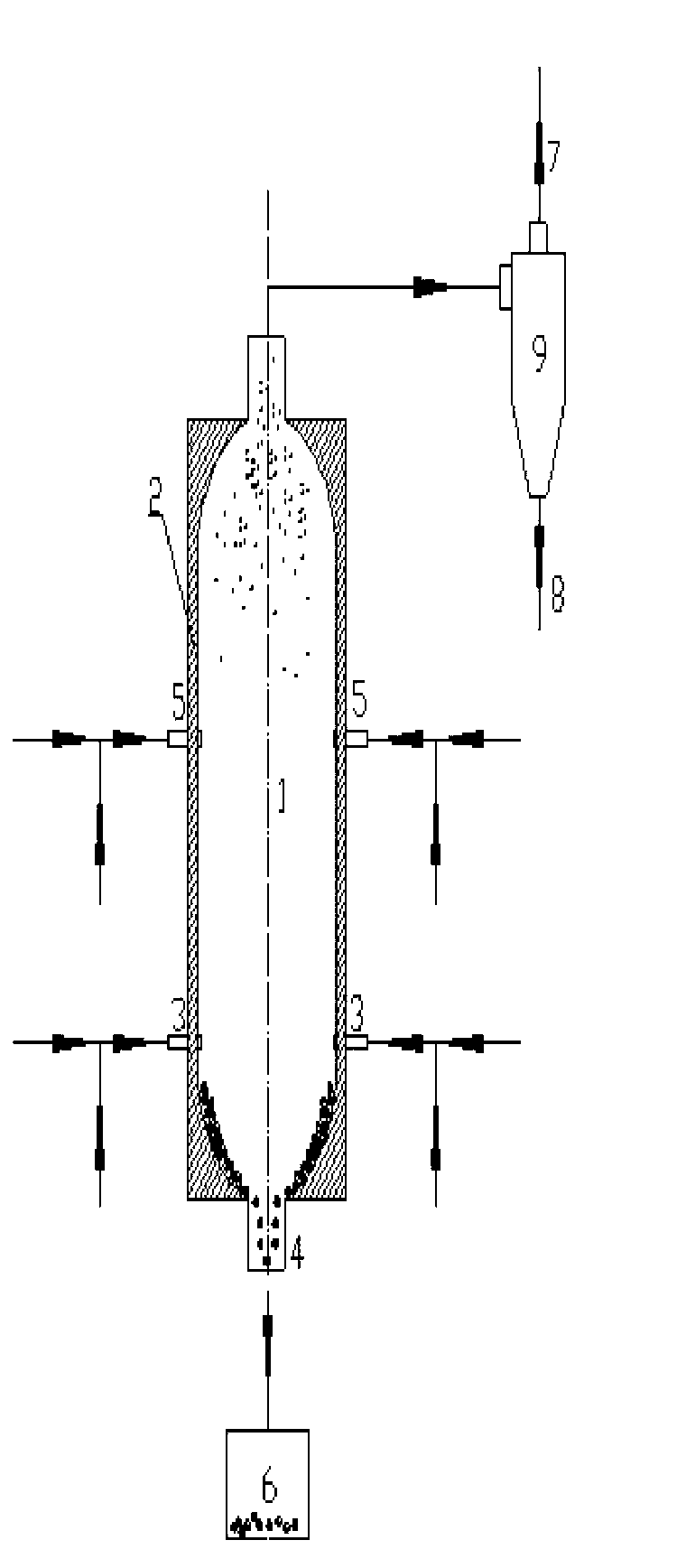

[0037] combined with figure 2 , In this implementation example, the raw coal used is Longde bituminous coal, and the average particle size of pulverized coal is 75 μm. The furnace inner layer of the entrained-bed rapid reaction furnace 1 used is a refractory insulation layer 2, and the reaction pressure is normal pressure. The specific steps are:

[0038] 1. From the flue of the entrained-bed rapid reaction furnace 1, the low-temperature flue gas with a temperature of 700 ° C is extracted by the fan, and the coal powder flowing out of the coal powder bin is sent into the entrained-bed rapid reaction furnace 1 through the feeding air nozzle 3, and the pulverized coal is Low temperature oxidation is completed during the transportation process.

[0039] 2. The reaction gas is a mixture of flue gas extracted from the boiler at a temperature of 1000°C, superheated steam and hot air, and the temperature of the mixture is 850°C. The reaction gas is sent into the reaction chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com