A kind of preparation method of coral reef ceramsite

A technology for coral reefs and coral reef stones, which is applied to the field of preparation of coral reef ceramsite, can solve the problems of reduced survival rate of newly planted green plants, declining growth of existing green plants, and high cost of fresh water, so as to save freshwater resources of islands and reefs and save transportation. Cost, energy saving and effect of clay resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

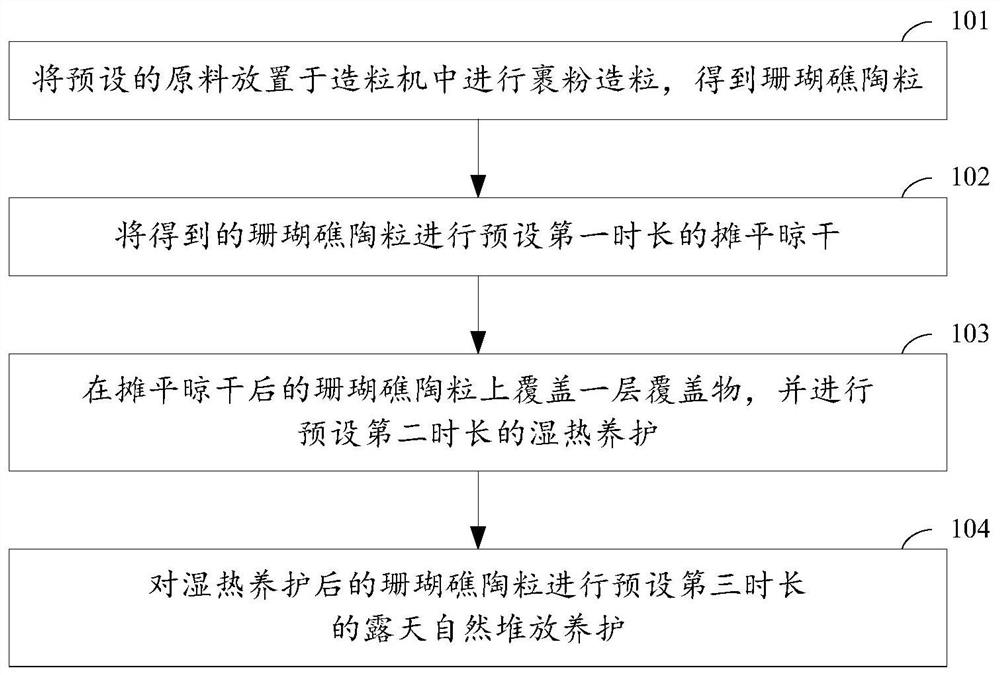

[0046] Such as figure 1 Shown, the preparation method of the coral reef ceramsite in the embodiment of the present invention comprises the following steps:

[0047] Step 101, placing preset raw materials in a granulator for powder coating and granulation to obtain coral reef ceramsite.

[0048] Wherein, the preset raw materials include: 10-30mm coral reef, Portland cement, functional additives and seawater;

[0049] The weight ratio of the preset raw materials is: 75-88 parts by weight of 10-30mm coral reef, 7-14 parts by weight of Portland cement, 3-9 parts by weight of functional additives, and 2-6 parts by weight of fresh sea water.

[0050] In the technical scheme of the present invention, the above-mentioned coral reefs can directly use the 10-30mm coral reefs on the islands and reefs of tropical oceans, so materials can be obtained locally, and the loose and porous coral reefs that are naturally screened or mechanically broken can be used as granulated Tao nuclear. Si...

Embodiment 1

[0084] In this embodiment, the preset raw materials include: 10-20 mm coral reef, Portland cement, functional additives and seawater;

[0085] The weight ratio of the preset raw materials is: 82-86 parts by weight of 10-20mm coral reef, 9-12 parts by weight of Portland cement, 2-2.5 parts by weight of functional additives, and 3-5 parts by weight of fresh sea water.

[0086] In addition, preferably, in a specific embodiment of the present invention, the main chemical composition of the 10-20mm coral reef is 95% CaCO 3 , the porosity is 30% to 34%, the saturated water absorption is 14% to 16%, the cylinder compressive strength is 5.8 to 7.0MPa, and the crushing index is 29% to 32%; the openings in the 10 to 20mm coral reef are connected pores The proportion of the pores is greater than 60%, and the diameter of more than 95% of the main pores is greater than 700nm.

[0087] In addition, preferably, in a specific embodiment of the present invention, the local natural water conte...

Embodiment 2

[0099] In this embodiment, the preset raw materials include: 10-30mm coral reef, Portland cement, functional additives and seawater;

[0100] The weight ratio of the preset raw materials is: 83.5 parts by weight of 10-30 mm coral reef, 9 parts by weight of Portland cement, 5.0 parts by weight of functional additives, and 2.5 parts by weight of seawater.

[0101] In addition, preferably, in a specific embodiment of the present invention, the main chemical composition of the 10-30mm coral reef is 95% CaCO 3 , The porosity is 31%, the saturated water absorption is 14.7%, the cylinder compressive strength is 6.5MPa, and the crushing index is 28%.

[0102] In addition, preferably, in a specific embodiment of the present invention, the local natural water content of the 10-30mm coral reefs in the South China Sea is 13%.

[0103] In addition, preferably, in a specific embodiment of the present invention, the functional auxiliary agent includes: ground steel slag powder, emulsified a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cylinder compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com