Slow-release grouting material for steel shell immersed tube grouting and construction method of slow-release grouting material

A slow-release, grouting material technology, applied in the field of building materials, can solve the problems of affecting the setting time, drying shrinkage cannot achieve the construction purpose, and cannot achieve super-long slump preservation, so as to facilitate secondary refilling and strong slump retention , The effect of small loss over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

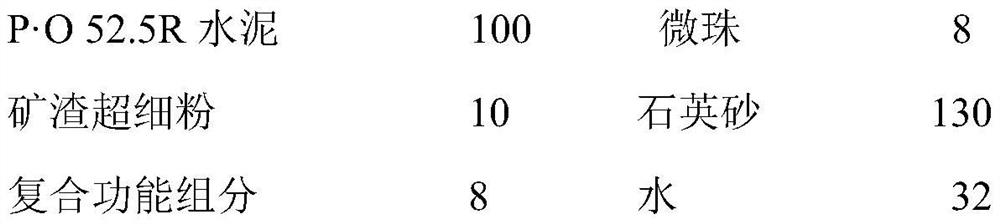

[0021] The raw material of a slow-release grouting material for grouting of a steel shell immersed tube, calculated in parts by weight, is composed of the following components:

[0022]

[0023] Among them, the composite functional components are composed of expansion agent, sustained-release water reducing agent, early strength agent, quick-acting defoamer, rheology agent, plastic expansion agent, and slump retention agent according to 100:35:12:10:5:2:6 The slump retention agent is composed of sodium gluconate and boric acid in a weight ratio of 1:2, the early strength agent adopts sodium sulfate, and the expansion agent adopts calcium oxide expansion agent.

[0024] The construction method of the slow-release grouting material for grouting of the steel shell immersed tube is as follows: all components of the grouting material (except water) are fully pre-mixed into a uniform dry powder in a professional factory, and the dry powder of the grouting material is mixed and sti...

Embodiment 2

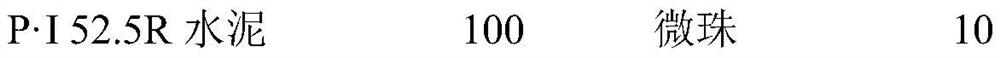

[0026] The raw material of a slow-release grouting material for grouting of a steel shell immersed tube, calculated in parts by weight, is composed of the following components:

[0027]

[0028]

[0029] Among them, the composite functional components are composed of expansion agent, sustained-release water reducing agent, early strength agent, quick-acting defoamer, rheology agent, plastic expansion agent, and slump retention agent according to 100:40:20:15:5:2.5:5 The slump retention agent is composed of sodium gluconate and boric acid in a weight ratio of 1:4, calcium formate is used as the early strength agent, and magnesium oxide is used as the expansion agent.

[0030]The construction method of the slow-release grouting material for grouting of the steel shell immersed tube is as follows: all components of the grouting material (except water) are fully pre-mixed into a uniform dry powder in a professional factory, and the dry powder of the grouting material is mixed...

Embodiment 3

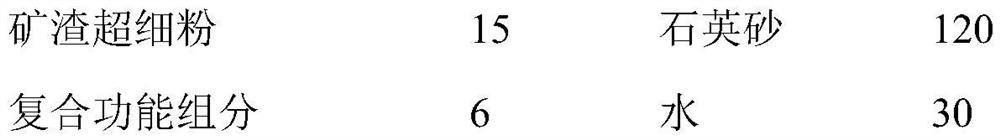

[0032] The raw material of a slow-release grouting material for grouting of a steel shell immersed tube, calculated in parts by weight, is composed of the following components:

[0033]

[0034] Among them, the composite functional components are composed of expansion agent, sustained-release water reducing agent, early strength agent, quick-acting defoamer, rheology agent, plastic expansion agent, and slump retention agent according to 100:32:15:12:4:3:5 The slump retention agent is composed of sodium gluconate and borax in a weight ratio of 2:3, calcium formate is used as the early strength agent, and anhydrite is used as the expansion agent.

[0035] The construction method of the slow-release grouting material for grouting of the steel shell immersed tube is as follows: all components of the grouting material (except water) are fully pre-mixed into a uniform dry powder in a professional factory, and the dry powder of the grouting material is mixed and stirred at the cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com