a p 2 o 5 Method and application for preparing phosphate ester functional monomer by dispersion method

A technology of functional monomer and phosphate ester, applied in the chemical industry, can solve the problems of difficult separation and recovery of toxic organic solvents, environmental pollution, etc., and achieve the effects of easy industrial production, simple synthesis method and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

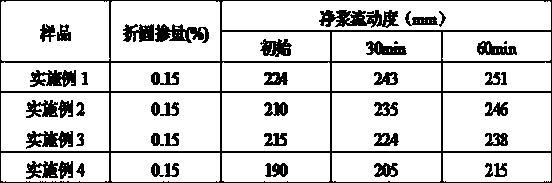

Embodiment 1

[0018] (1) 213g P 2 O 5 Put it in 426g methyl acrylate and stir it evenly as a phosphorylation reagent; (2) Add 6.2g hydroquinone and 348g hydroxyethyl acrylate into a 1500mL four-neck flask equipped with a stirrer and a thermometer, and place it at 0~ 8 o In the ice-water bath of C, under high-speed stirring, slowly disperse the above-mentioned dispersed P with methyl acrylate 2 O 5 Put in 5 times, keep the temperature at 8~45 o C, the temperature rises quickly to 65 after feeding o C, heat preservation and esterification for 4 hours, add 28g deionized water and heat to 70 o C, heat preservation for 2.5 hours to obtain a brown-yellow liquid that is a phosphate functional monomer solution with methyl acrylate as a solvent.

Embodiment 2

[0020] (1) 213g P 2 O 5 Put it in 426g methyl methacrylate and stir it evenly as a phosphorylation reagent; (2) Add 7.1g p-hydroxyanisole and 468g hydroxyethyl methacrylate into a 1500mL four-neck flask equipped with a stirrer and a thermometer , Placed at 0~8 o In the ice water bath of C, under high-speed stirring, slowly disperse the above-mentioned P well dispersed with methyl methacrylate 2 O 5 Put in 5 times, keep the temperature at 8~45 o C, the temperature rises to 70 quickly after feeding o C, heat preservation and esterification for 4 hours, add 34g deionized water and heat to 85 o C, heat preservation for 2 hours to obtain a brown-yellow liquid that is a phosphate functional monomer solution with methyl methacrylate as a solvent.

Embodiment 3

[0022] (1) Add 142g P 2 O 5 Put it in 426g ethyl acrylate, stir evenly and use it as a phosphorylation reagent; (2) Add 5.5g hydroquinone and 260g hydroxypropyl acrylate to a 1500mL four-neck flask equipped with a stirrer and thermometer, and place it at 0~ 8 o In the ice water bath of C, under high-speed stirring, slowly disperse the above-mentioned P well dispersed with ethyl acrylate 2 O 5 Put in 3 times, keep the temperature at 8~45 o C, the temperature rises to 70 quickly after feeding o C, heat preservation and esterification for 4 hours, add 20g deionized water and heat to 85 o C, heat preservation for 1.5 hours to obtain a brown-yellow liquid that is a phosphate functional monomer solution with ethyl acrylate as a solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com