A kind of method of low temperature esterification synthetic comb type carboxylic acid polymer

A carboxylic acid polymer, chemical synthesis technology, applied in the field of concrete admixtures, can solve the problems of high degree of side reaction, high esterification reaction temperature, difficult esterification reaction, etc. in the esterification process, and achieves strong slump retention ability, The effect of fast esterification rate and easy maintenance of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] With the PAA 50wt% aqueous solution of the about 2000 of number average molecular weight, MPEG-1200 is raw material, the method for synthesizing carboxylic acid polymer is as follows:

[0032] Melt 120.0g of MPEG-1200 at 70 degrees Celsius and add it to the reactor, add 36.0g of PAA 50wt% aqueous solution under stirring, the acid-ether ratio is 2.5:1, and add 0.5wt% of the total mass of the solidified reactants to Toluenesulfonic acid, through nitrogen.

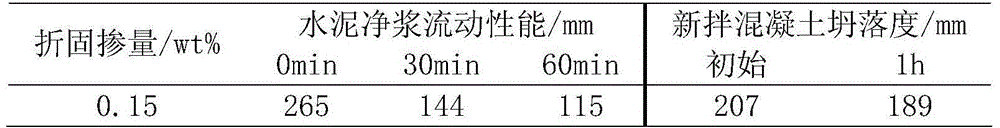

[0033] Under the protection of nitrogen, start the vacuum device and adjust the pressure in the reactor to about 4kPa. Remove the water in the reaction system by carrying water with nitrogen until the water in the water separator no longer increases, or after the temperature of the reaction system is stabilized at 70 degrees Celsius for half an hour, add 0.1wt% of the total mass of the reactant from a constant pressure feeder SF catalyst, heat preservation at 70 degrees Celsius, esterification for 6 hours. Stop the h...

Embodiment 2

[0036] With the PAA 50wt% aqueous solution of the about 4000 of number average molecular weight, MPEG-700 is raw material, the method for synthesizing carboxylic acid polymer is as follows:

[0037] Melt 70.0g of MPEG-700 at 60 degrees Celsius and add to the reactor, add 28.8g of PAA 50wt% aqueous solution under stirring conditions, the acid-ether ratio is 2:1, and add 0.5wt% p-toluene of the total mass of the solidified reaction product Sulfonic acid, pass into nitrogen.

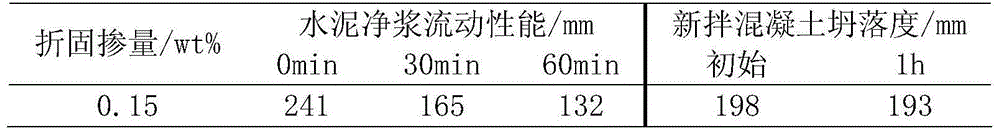

[0038] Under the protection of nitrogen, start the vacuum device and adjust the pressure in the reactor to about 8kPa. Remove the water in the reaction system by carrying water with nitrogen until the water in the water separator no longer increases, or after the temperature of the reaction system is stable at 70 degrees Celsius for half an hour, add 0.2wt% of the total mass of the reactant from a constant pressure feeder SF catalyst, heat preservation at 60 degrees Celsius, esterification for 7 hours. St...

Embodiment 3

[0041] With the PAA 50wt% aqueous solution of the about 2000 of number average molecular weight, MPEG-2400 is raw material, the method for synthesizing carboxylic acid polymer is as follows:

[0042] Melt 120.0g of MPEG-2400 at 80 degrees Celsius and add to the reactor, add 21.6g of PAA 50wt% aqueous solution under stirring conditions, the acid-ether ratio is 3:1, and add 0.5wt% p-toluene of the total mass of the solidified reaction product Sulfonic acid, pass into nitrogen.

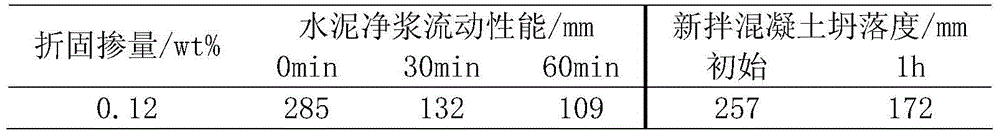

[0043] Under the protection of nitrogen, start the vacuum device and adjust the pressure in the reactor to about 6kPa. Remove the water in the reaction system by carrying water with nitrogen until the water in the water separator no longer increases, or after the temperature of the reaction system is stabilized at 70 degrees Celsius for half an hour, add 0.1wt% of the total mass of the reactant from a constant pressure feeder SF catalyst, heat preservation at 80 degrees Celsius, esterification for 5 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com