A kind of amphiphilic polycarboxylate cement dispersant and preparation method thereof

A technology of cement dispersant and polycarboxylate, which is applied in the field of amphiphilic polycarboxylate cement dispersant and its preparation, to achieve the effects of improving compressive strength, strong slump retention, and high water-reducing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

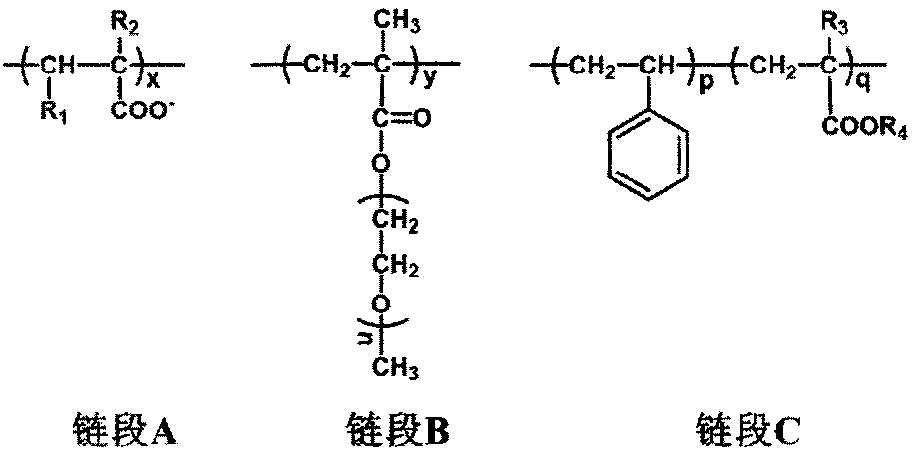

Method used

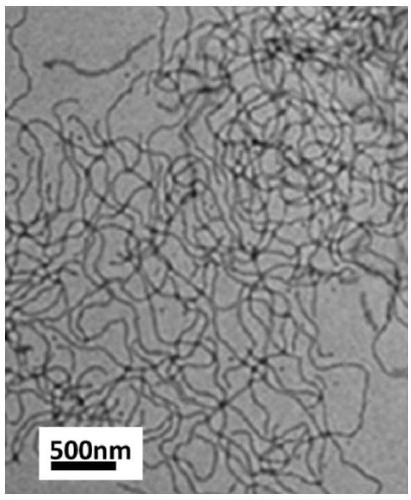

Image

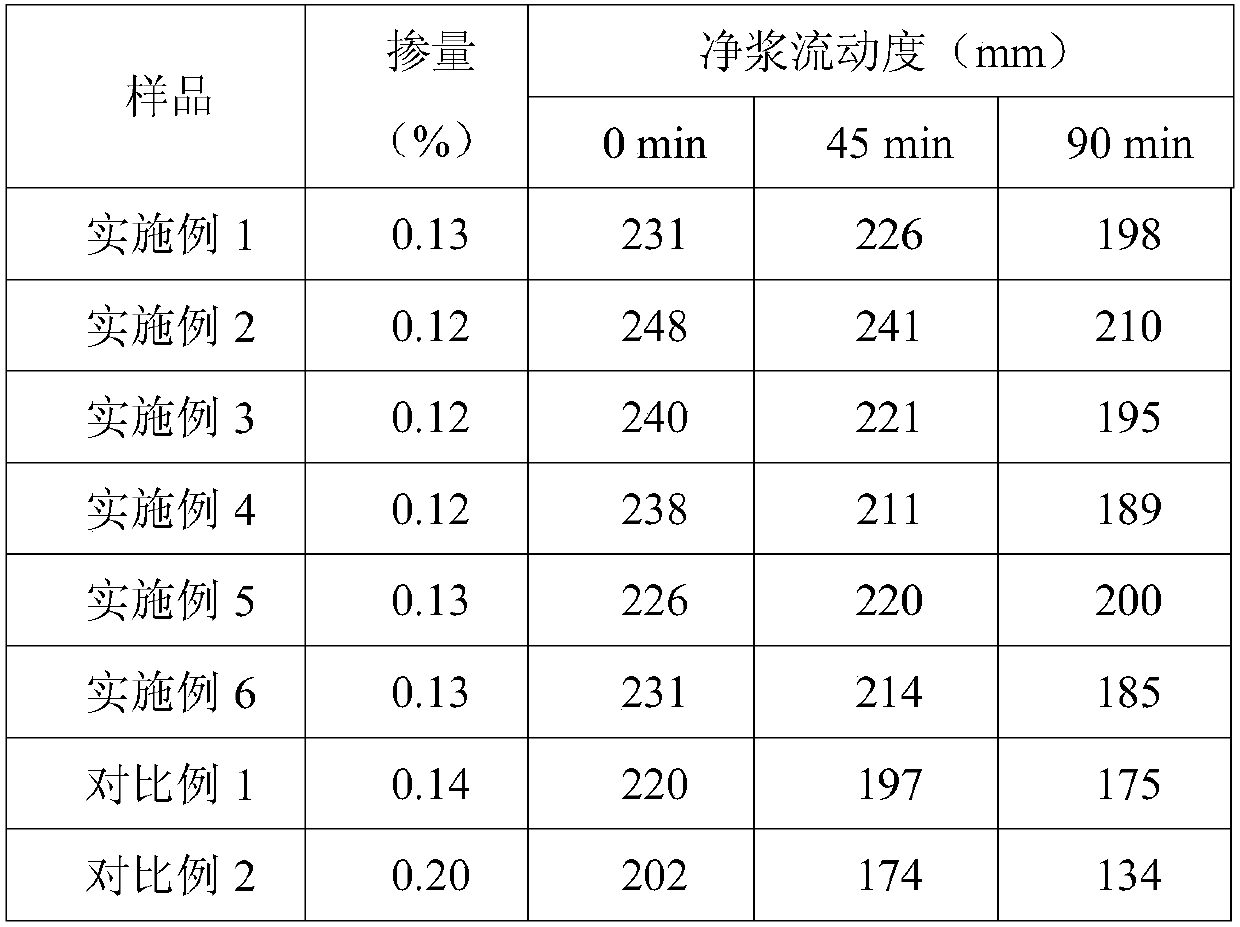

Examples

Embodiment 1

[0056] Add 9.33g of RAFT reagent EMP, 30g of acrylic acid, 2.26g of V-50 initiator (the molar ratio of raw materials is 5:50:1) and 27.7g of water into the flask equipped with a stirrer, and mix well. At this time, the polymerization concentration is 60 % in N 2 Under the atmosphere, the temperature was raised to 60°C, and after 1 hour of reaction, the polymer A-1 solution containing RAFT functional ends was obtained, and the monomer conversion rate was 99.2% as measured by HPLC;

[0057] In the flask that stirrer is housed, add RAFT reagent EMP4.03g, polyethylene glycol monomethyl ether methacrylate macromonomer (M w =600) 180g, V-501 initiator 1.67g (the molar ratio of the raw materials is 3:50:1) and fully mixed. At this time, the polymerization concentration is 100%. 2 Under the atmosphere, the temperature was raised to 60°C, and after 3 hours of reaction, the polymer B-1 containing RAFT functional terminal was obtained, and the monomer conversion rate was 98.6% as measur...

Embodiment 2

[0060] Add 6.11g of RAFT reagent CETPA, 20g of acrylic acid + 5.97g of methacrylic acid, 1.25g of V-50 initiator (the molar ratio of raw materials is 5:60+15:1) and 33.4g of water into the flask equipped with a stirrer, and mix well , when the polymerization concentration is 50%, at N 2 Under the atmosphere, the temperature was raised to 70°C, and after 1 hour of reaction, the polymer A-2 solution containing RAFT functional ends was obtained, and the monomer conversion rate was 98.9% as measured by HPLC;

[0061] In the flask that stirrer is housed, add RAFT reagent BDMAT3.38g, polyethylene glycol monomethyl ether methacrylate macromonomer (M w =1000) 180g, 1.29g of VA-044 initiator (the molar ratio of raw materials is 3:45:1) and 46.2g of water are fully mixed. At this time, the polymerization concentration is 80%. 2 Under the atmosphere, the temperature was raised to 70°C, and after 2 hours of reaction, the polymer B-2 solution containing RAFT functional ends was obtained, ...

Embodiment 3

[0064] Add 4.61g of RAFT reagent BDMAT, 23.5g of acrylic acid + 8.01g of maleic anhydride, 1.06g of VA-044 initiator (the molar ratio of raw materials is 5:100+25:1) and 37.2g of water to the flask equipped with a stirrer. Mixing, at this time the polymerization concentration is 50%, in N 2 Under the atmosphere, the temperature was raised to 70°C, and after 2 hours of reaction, the polymer A-3 solution containing RAFT functional ends was obtained, and the monomer conversion rate was 98.7% as measured by HPLC;

[0065] In the flask that stirrer is housed, add RAFT reagent CETPA4.22g, polyethylene glycol monomethyl ether methacrylate macromonomer (M w =1200) 240g, ammonium persulfate initiator 1.21g (the molar ratio of raw materials is 3:37.5:1) and water 163g are fully mixed, and the polymerization concentration is 60% at this moment, in N 2 Under the atmosphere, the temperature was raised to 70°C, and after 2 hours of reaction, the polymer B-3 solution containing RAFT functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com