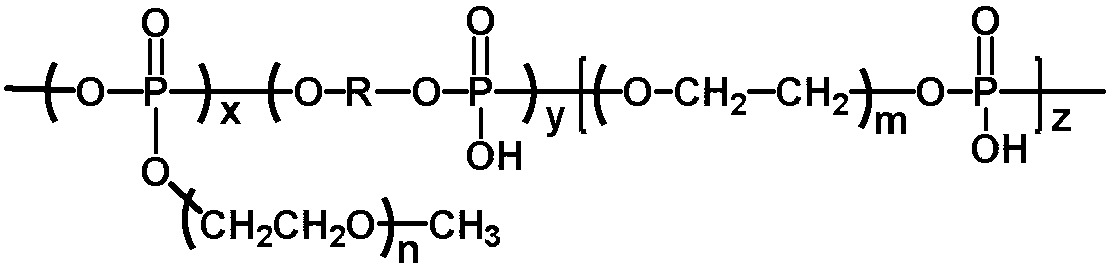

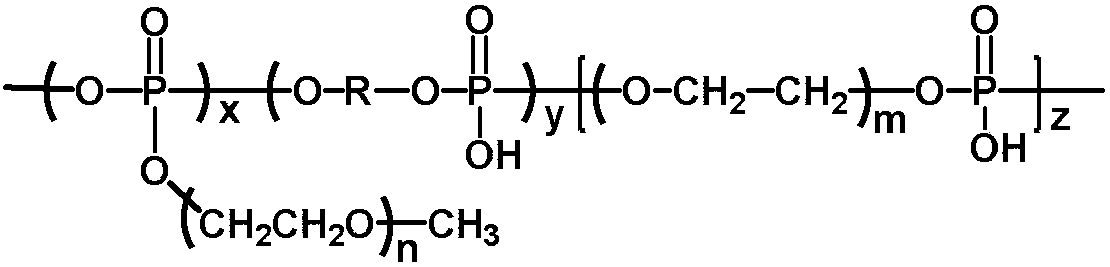

Polyphosphoric acid water reducing agent and preparation method thereof

A technology of water reducing agent and polyphosphoric acid, which is applied in the field of concrete admixtures, can solve the problems of insufficient water reducing and slump retention capabilities, large differences in material performance, and difficulty in adapting, so as to save transportation costs, strengthen tolerance, improve The effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

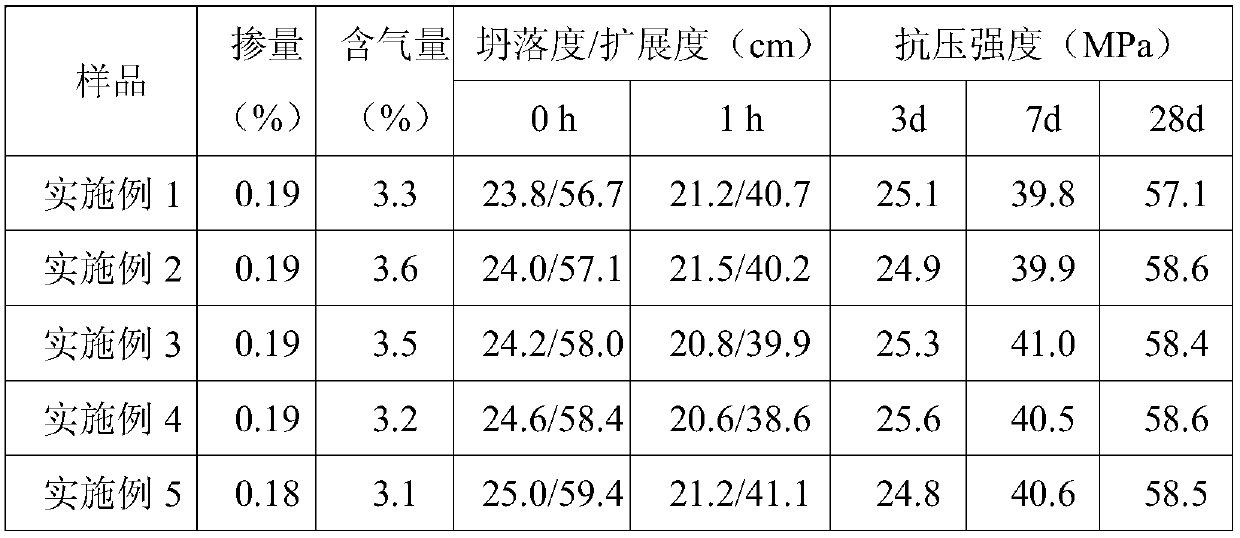

Examples

Embodiment 1

[0039] (1) Synthesis of phosphoric acid polyether:

[0040] Add 500g of MPEG500 (numbers indicate molecular weight, the same below) and 205.8g of phosphoric acid into the reaction flask equipped with a thermometer and agitator, raise the temperature to 80°C, and react for 6 hours to obtain polyether phosphate;

[0041] (2) Preparation of polyphosphoric acid superplasticizer:

[0042] Add 300g PEG200, 12.4g ethylene glycol, 115.3g phosphoric acid and 1110g cyclohexane to the phosphoric acid polyether prepared above, and reflux at 90°C for 12 hours. 35wt% NaOH solution and 1430g water were neutralized and diluted to obtain the finished polyphosphoric acid superplasticizer with a solid content of 40.2%, a pH of 7.2, a weight average molecular weight of 11400, and a molecular weight distribution of 2.09.

Embodiment 2

[0044] (1) Synthesis of phosphoric acid polyether:

[0045] Add 600g of MPEG750 and 141.9g of polyphosphoric acid into a reaction flask equipped with a thermometer and a stirrer, raise the temperature to 100°C, and react for 6 hours to obtain polyether phosphate;

[0046] (2) Preparation of polyphosphoric acid superplasticizer:

[0047] Add 240g PEG200, 24.3g 1,3-propylene glycol, 110.7g phosphoric acid and 1124g cyclohexane to the phosphoric acid polyether prepared above, and reflux at 90°C for 12 hours. Add 205g of 35wt% NaOH solution and 1590g of water for neutralization and dilution to obtain the finished polyphosphoric acid superplasticizer with a solid content of 40.4%, a pH of 6.8, a weight average molecular weight of 17600, and a molecular weight distribution of 2.17.

Embodiment 3

[0049] (1) Synthesis of phosphoric acid polyether:

[0050] Add 500g of MPEG1000 and 93.4g of pyrophosphoric acid into a reaction flask equipped with a thermometer and a stirrer, raise the temperature to 120°C, and react for 10 hours to obtain polyether phosphate;

[0051] (2) Preparation of polyphosphoric acid superplasticizer:

[0052] Add 180g PEG200, 18g 1,4-butanediol, 86.5g phosphoric acid and 865g cyclohexane to the phosphoric acid polyether prepared above, and reflux at 100°C for 12 hours. , adding 145g of 35wt% NaOH solution and 1244g of water for neutralization and dilution, the finished product of polyphosphoric acid superplasticizer can be obtained, the solid content is 40.1%, the pH is 6.5, the weight average molecular weight is 20600, and the molecular weight distribution is 1.96.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com