Preparing method for nano-copper powder

A technology of nano-copper powder and copper nitrate, which is applied in the field of nano-material preparation, can solve the problems of uneven particle size, wide particle size distribution range, and low yield, and achieve good dispersion, narrow particle size distribution range, and high yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

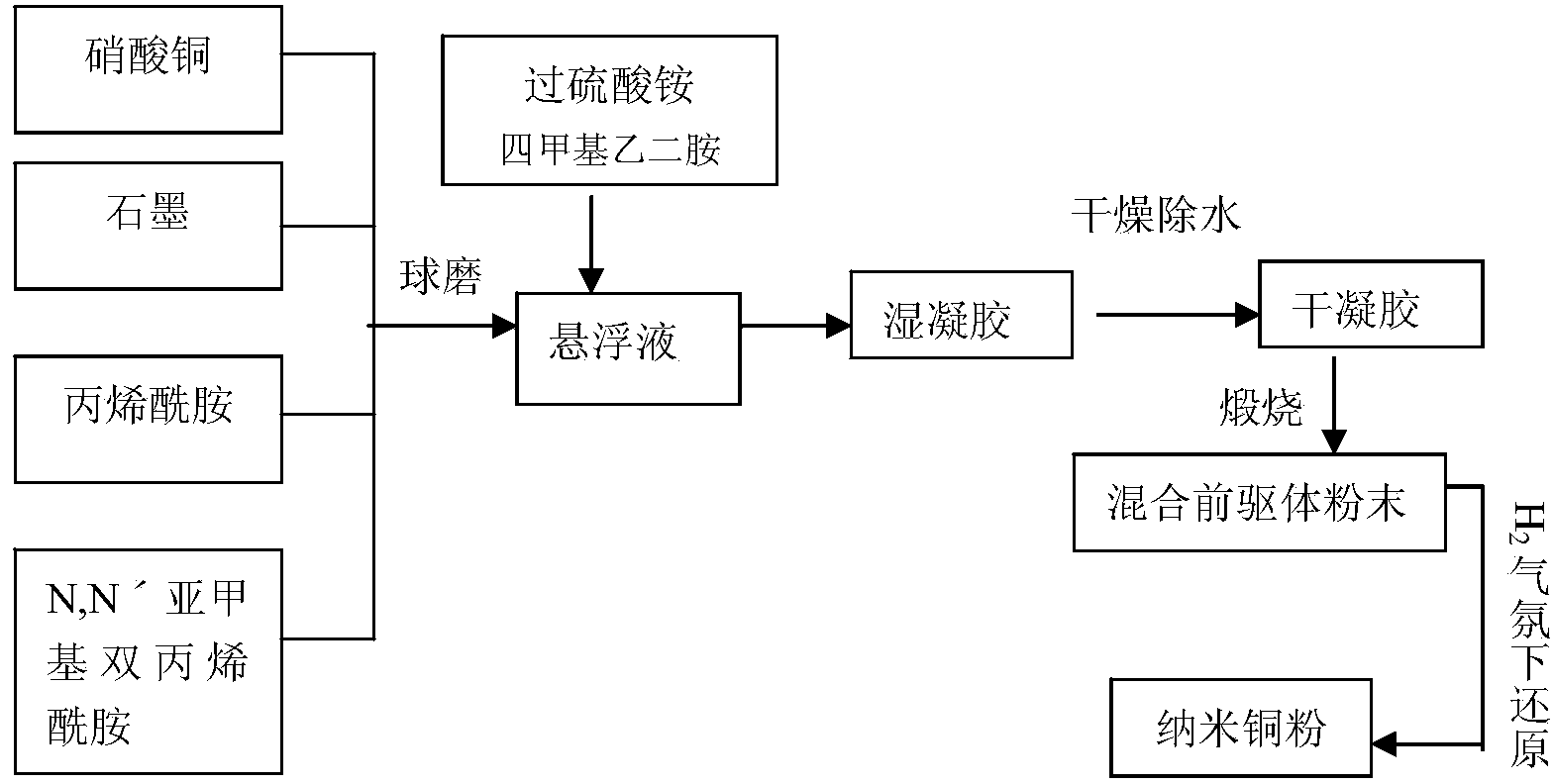

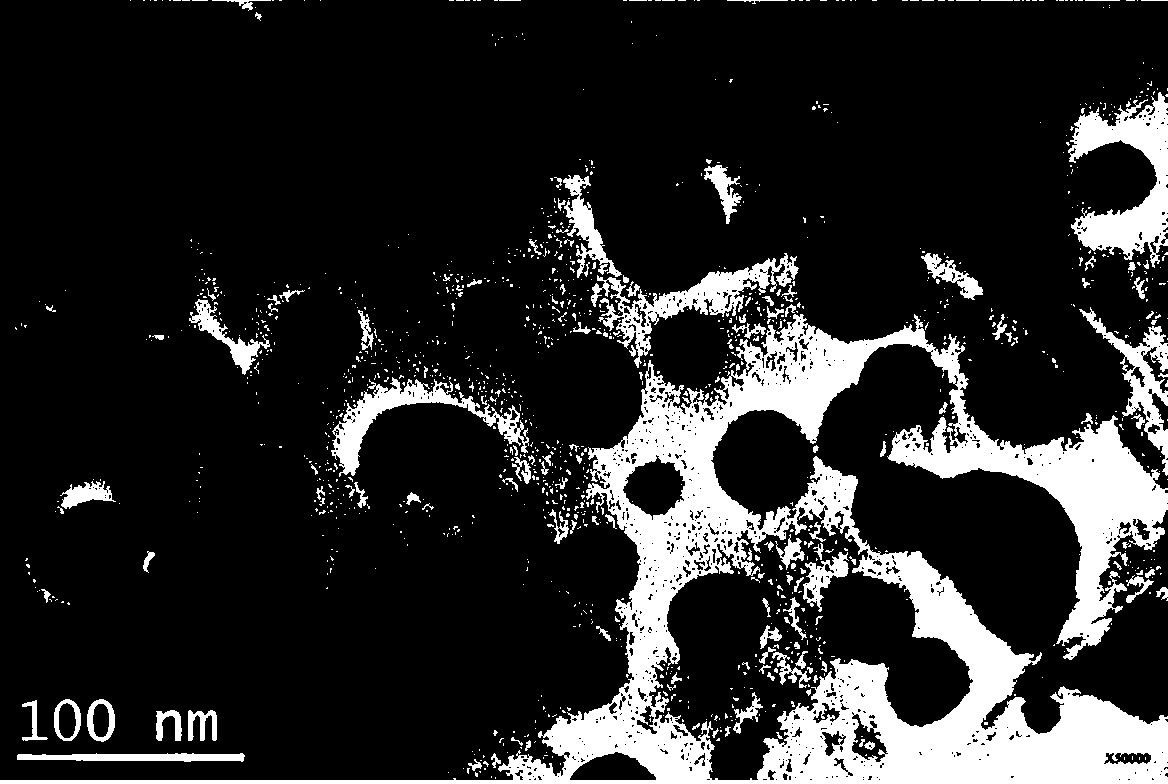

[0028] Such as figure 1 As shown, this example prepares nano-copper powder according to the following steps: a mixture of copper nitrate and graphite with a molar ratio of 1:1 is used as a raw material; 50 g of the above raw material is added to 100 ml of acrylamide (AM) with a concentration of 20 wt. Organic monomer and N,N-methylenebisacrylamide (MBAM) crosslinking agent (wherein the mass ratio of organic monomer to crosslinking agent is m (AM) :m (MBAM) =20:1) in the organic monomer solution, after 24h ball milling and mixing to obtain a suspension; add 2.5ml catalyst tetramethylethylenediamine and 1ml initiator ammonium persulfate saturated solution (1.5wt%) to the suspension, and placed in a constant temperature water bath at 80°C for 1 hour to obtain a wet gel; place the wet gel in a blast oven at 120°C to dry and dehydrate for 3 hours to obtain a xerogel; calcinate the xerogel at a temperature of 300°C 3h, obtained by CuO 2 Precursor powder formed by mixing with Cu; ...

Embodiment 2

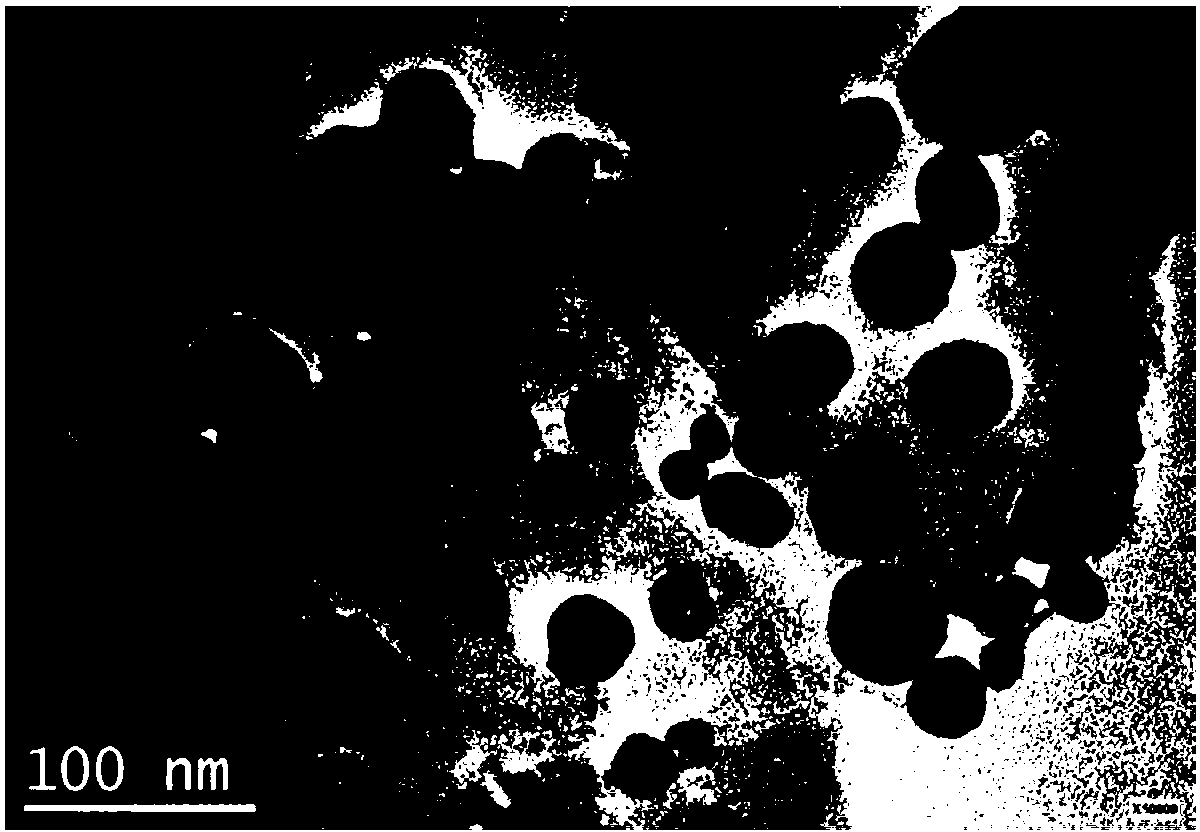

[0031] Such as figure 1 As shown, this example prepares nano-copper powder according to the following steps: a mixture of copper nitrate and graphite with a molar ratio of 3:1 is used as a raw material; 50g of the above-mentioned raw material is added to 150ml of acrylamide (AM) with a concentration of 20wt.%. Organic monomer and N,N-methylenebisacrylamide (MBAM) crosslinking agent (wherein the mass ratio of organic monomer to crosslinking agent is m (AM) :m (MBAM) =25:1) in the organic monomer solution, mixed by ball milling for 24 hours to obtain a suspension; add 1.25ml catalyst tetramethylethylenediamine and 0.5ml initiator ammonium persulfate saturated solution (1.5wt%) to the suspension , and placed in a constant temperature water bath at 60°C for 2 hours to obtain a wet gel; place the wet gel in a blast oven at 105°C to dry and dehydrate for 5 hours to obtain a dry gel; dry the dry gel at a temperature of 350°C Calcined for 2h, obtained by CuO 2 Precursor powder form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com