Preparation method and application of concrete plasticizer with improved clay adaptability

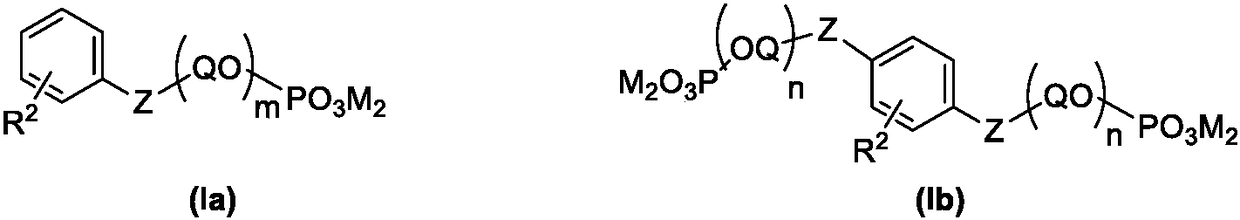

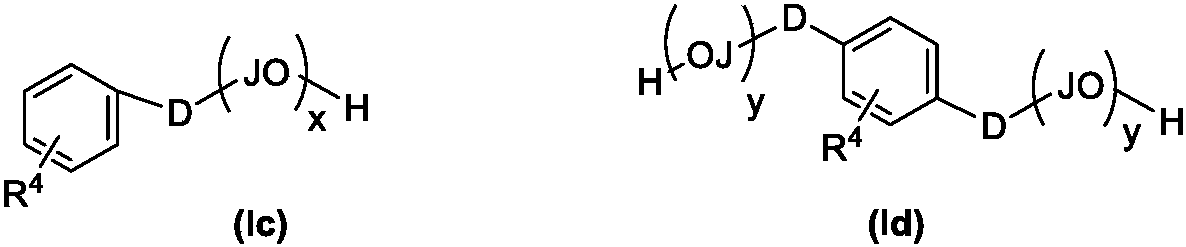

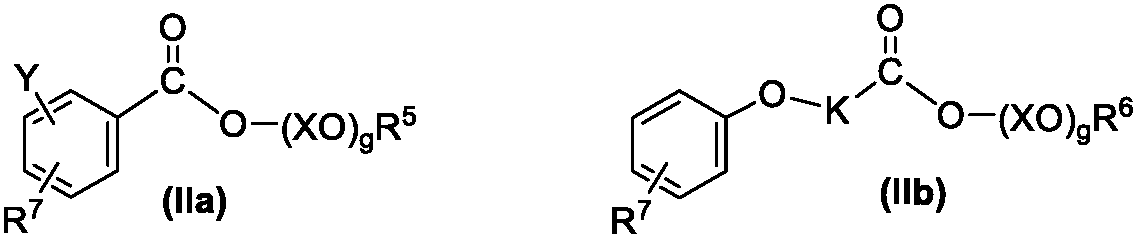

A concrete and plasticizer technology, applied in the field of concrete admixtures, can solve problems such as weak adsorption of phosphate ester, water reduction and poor slump retention ability of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Preparation of monomer a-2, Mw=2000, starter phenol (monomer A2-1): the preparation method is ethoxylation method, here is the preparation of phenoxy polyethylene glycol (Mw=2000) Take the description as an example. Starter phenol, catalyst sodium hydroxide. Weigh 94 g of phenol and 3 g of sodium hydroxide, add the above materials into the reaction kettle, and evacuate the reaction kettle to -0.1 MPa at room temperature. Then the reactor was heated to 100°C, and 50 g of ethylene oxide was introduced into the reactor. When the pressure in the reactor dropped and the temperature rose, the polymerization reaction started. Continue to feed 1856g of ethylene oxide into the reactor. During the feeding process, maintain the temperature of the reactor at 100~120℃ and the pressure at 0.2~0.4MPa. After the ethylene oxide feed is finished, keep the temperature at 100℃ for about 1h. . When the pressure of the reactor no longer decreases, reduce the temperature of the reactor to a...

Embodiment 1

[0069] In this embodiment, a-1%=50%, a / b=1:2, (a+b) / d=1:1.0, e-2 / e-1=10%, e / a=0.55, c / b=0.15.

[0070] In a 1000ml four-necked flask equipped with electromechanical stirring and constant temperature heating oil bath, add monomer A1-1260g (0.125mol), monomer A2-3250g (0.125mol), monomer B-1 112g (0.50mol) , Concentrated sulfuric acid 12.5g (98% concentration) (0.125mol), FeCl 3 2.03g (0.0125mol), monomer C-510.35g (0.075mol), heat and stir until it is a homogeneous phase. Then, 60.75 g (0.75 mol) of 37% aqueous formaldehyde solution was slowly added dropwise. After the dropwise addition, the reaction was carried out at 115°C for 5 hours. After the reaction, it is diluted with 30% lye until the pH is about 10, and the reaction is continued at 105°C for 0.5-1 hour to remove unreacted formaldehyde. The reaction is cooled to room temperature and diluted with water to about 30%-40%.

Embodiment 2

[0072] In this embodiment, a-1%=50%, a / b=1:2, (a+b) / d=1:1.0, e-2 / e-1=10%, e / a=0.55, c / b=0.15.

[0073] In a 1000ml four-necked flask equipped with electric mechanical stirring and constant temperature heating oil bath, add monomer A1-2135g (0.125mol), monomer A2-2 125g (0.125mol), monomer B-1 112g (0.50mol) ), concentrated sulfuric acid (concentration 98%) 12.5g (0.125mol), Cu(NO 3 ) 2 2.33g (0.0125mol), monomer C-510.35g (0.075mol), heat and stir until it is a homogeneous phase. Then, 60.75 g (0.75 mol) of 37% aqueous formaldehyde solution was slowly added dropwise. After the dropwise addition, the reaction was carried out at 115°C for 5 hours. After the reaction, it is diluted with 30% lye until the pH is about 10, and the reaction is continued at 105°C for 0.5-1 hour to remove unreacted formaldehyde. The reaction is cooled to room temperature and diluted with water to about 30%-40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com