Slow-release high-efficiency polycarboxylate water reducer and preparation method thereof

A polycarboxylic acid, slow-release technology, applied to concrete admixtures, slow-release high-efficiency polycarboxylate water reducers, the preparation of said polycarboxylate water reducers, and the field of polycarboxylate water reducers can solve the problem of Issues such as no guidance plan are given to achieve high water reduction efficiency, prevent agglomeration, and effective electrostatic adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

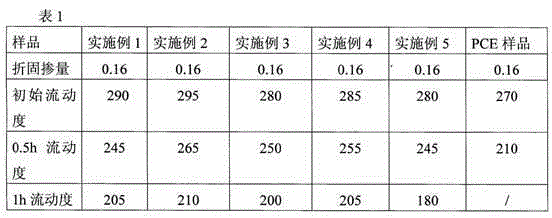

Examples

Embodiment 1

[0017] Example 1: The slow-release high-efficiency polycarboxylate water reducer is made of the following mass ratio (weight ratio) of raw materials: 6.7 parts of acrylic acid, 1.8 parts of maleic anhydride, polyoxyethylene ether macromonomer 38.7 parts, 4.6 parts of polymer template agent, 1.8 parts of sodium hydroxide, 59.5 parts of deionized water, 0.6 part of peroxide initiator, and 0.5 part of chain transfer agent. The above-mentioned polyoxyethylene ether macromonomer is a combination of isobutenol polyoxyethylene ether HPEG-2400 and isopentenol polyoxyethylene ether TPEG-2400. In 38.7 parts of polyoxyethylene ether macromonomer, isobutenol Polyoxyethylene ether HPEG-2400 accounts for 20 parts, isopentenol polyoxyethylene ether TPEG-2400 accounts for 18.7 parts; the above polymer template is a combination of poly N-vinylpyrrolidone and polyallylamine. In 4.6 parts of polymer templates, poly-N-vinylpyrrolidone accounts for 3 parts, and polyallylamine accounts for 1.6 part...

Embodiment 2

[0020] Example 2: The slow-release high-efficiency polycarboxylate superplasticizer is made of the following mass ratio (weight ratio) of raw materials: 1.5 parts of acrylic acid, 0.5 parts of maleic anhydride, polyoxyethylene ether macromonomer 30.5 parts, 2.5 parts of polymer template, 1.4 parts of sodium hydroxide, 55.3 parts of deionized water, 0.4 parts of peroxide initiator, and 0.2 parts of chain transfer agent.

[0021] The above-mentioned polyoxyethylene ether macromonomer is one or a combination of isobutenol polyoxyethylene ether HPEG-2400, isobutenol polyoxyethylene ether HPEG-3000, isopentenol polyoxyethylene ether TPEG-2400 (the mass ratio can be arbitrary when combined). In this embodiment, the polyoxyethylene ether macromonomer is selected from the combination of isobutenyl alcohol polyoxyethylene ether HPEG-2400 and isobutenyl alcohol polyoxyethylene ether HPEG-3000. In 30.5 parts of polyoxyethylene ether macromonomer, isobutylene Alcohol polyoxyethylene ethe...

Embodiment 3

[0023] Example 3: The slow-release high-efficiency polycarboxylate superplasticizer is made of the following mass ratio (weight ratio): 4.1 parts of acrylic acid, 1.1 parts of maleic anhydride, polyoxyethylene ether macromonomer 34.6 parts, 3.5 parts of polymer template, 1.6 parts of sodium hydroxide, 57.4 parts of deionized water, 0.5 parts of peroxide initiator, and 0.35 parts of chain transfer agent.

[0024] The above-mentioned polyoxyethylene ether macromonomer is one or a combination of isobutenol polyoxyethylene ether HPEG-2400, isobutenol polyoxyethylene ether HPEG-3000, isopentenol polyoxyethylene ether TPEG-2400 (the mass ratio can be arbitrary when combined). In this embodiment, the polyoxyethylene ether macromonomer is selected from isopentenol polyoxyethylene ether TPEG-2400. The above-mentioned polymer template agent is one or a combination of polycarboxylic acid, poly-N-vinylpyrrolidone, poly-2-vinylpyridine, and polyallylamine (the mass ratio of the combinatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com