Water-plastic retaining polycarboxylic acid water reducer and method for preparing same

A technology of polycarboxylate and water reducing agent, which is applied in the field of cement dispersants, can solve the problems of rapid loss, bleeding and segregation slump, etc., and achieve the effects of reducing operating intensity, ensuring safety, and enhancing controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

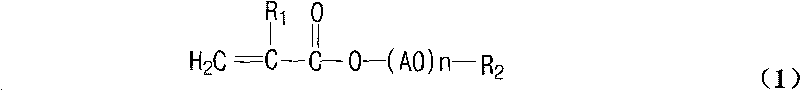

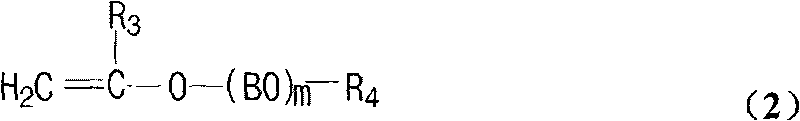

Method used

Image

Examples

example example 1

[0033] The molar ratio of macromonomer (a-1) to macromonomer (b-1) is 1: 4, BBEG: AA: NMA=1: 2.5: 0.1 (molar ratio), and the initiation system is (NH 4 ) 2 S 2 o 8 : NaHSO 3 =1:0.4 (weight ratio), (NH 4 ) 2 S 2 o 8 The dosage is 0.8% of the total mass of the monomers, which is formulated into a 1.0% aqueous solution (mass concentration), and the dosage of SA is 0.6% of the monomers.

[0034] Combine BBEG and NaHSO 3 Put it into the bottom water in advance and start to heat up. Make AA, NMA, SA and a certain amount of water into a 55% aqueous solution as material A, and the initiator (NH 4 ) 2 S 2 o 8 The solution is material B. When the temperature of the bottom liquid rises to 70-85°C, start to add material A and material B with a metering pump, and the material A will drop in 2.5 hours, and the material B will be added in 3.0 hours. After adding material A, keep it at this temperature for 1 hour, lower it to 40-50°C, neutralize it with 30% NaOH to pH=6-8, and o...

example example 2

[0036] The molar ratio of macromonomer (a-2) to macromonomer (b-1) is 1:6, BBEG:MAA:NMA=1:3:0.3 (molar ratio). The initiator system is (NH 4 ) 2 S 2 o 8 : NaHSO 3 =1:0.6 (weight ratio), NH4S 2 o 8 The dosage is 1.2% of the total mass of the monomers, which is formulated into a 1.0% aqueous solution (mass concentration), and the dosage of SA is 0.6% of the monomers.

[0037] Combine BBEG with NaHSO 3 Put it into the bottom water in advance and start to heat up. MAA, NMA, SA and a certain amount of water are made into 55% aqueous solution (mass concentration) as A material, and initiator ammonium persulfate solution is used as B material. When the bottom water rises to 70-85°C, start feeding material A and material B with a metering pump. Add material A in 2.5 hours, add material B in 3.0 hours, and keep warm at the temperature for 1 hour after adding material B. Lower the temperature to 40-50°C, neutralize with 30% NaOH to pH = 6-8, and obtain the polycarboxylate wate...

example example 3

[0039] The molar ratio of macromonomer (a-3) to macromonomer (b-2) is 1:8, BBEG:MAA:AA:NMA=1:2:1:1 (molar ratio). The initiator system is (NH 4 ) 2 S 2 o 8 : NaHSO 3 =1:0.4 (weight ratio), (NH 4 ) 2 S 2 o 8 The dosage is 1.5% of the total mass of the monomer, and it is made into a 1.0% aqueous solution; the dosage of SA is 0.3% of the monomer dosage.

[0040] Combine BBEG with NaHSO 3 Put it into the bottom water in advance and start to heat up. Make MAA, NMA, SA and a certain amount of water into a 55% aqueous solution as A material, and use the initiator ammonium persulfate solution as B material. When the bottom water rises to 70-85°C, start feeding material A and material B with a metering pump. Add material A in 2.5 hours, add material B in 3.0 hours, and keep warm at the temperature for 1 hour after adding material B. Lower the temperature to 40-50°C, neutralize with 30% NaOH to pH=6-8, and obtain the polycarboxylate water reducer product. The weight ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com