Polycarboxylic acid water reducer prepared from running water and preparation method of polycarboxylic acid water reducer

A technology of tap water and polycarboxylic acid, which is applied in the field of concrete admixtures, can solve the problems of too sensitive sand and gravel, complicated reaction process, and low reaction success rate, and achieve the effect of extending shelf life, prolonging storage time, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

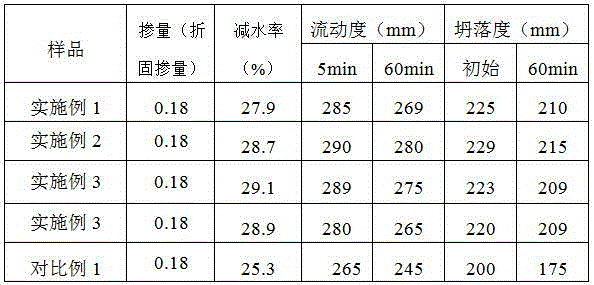

Examples

Embodiment 1

[0026] A polycarboxylate water reducer prepared from tap water is prepared by copolymerization of the following raw materials in parts by weight:

[0027] Base material: methallyl polyoxyethylene ether: 310, 30%H 2 o 2 : 2.8, hexamethylenetetramine: 0.5, tap water: 200;

[0028] Liquid A: acrylic acid (AA): 40, mercaptopropionic acid: 1.4, tap water: 95;

[0029] Liquid B: potassium persulfate: 3.0, tap water: 180.

[0030] The preparation method of the present invention is as follows: under room temperature conditions, drop A liquid and B liquid into the base material simultaneously, A liquid is added dropwise after 1 hour, B liquid is added dropwise after 1.5 hours, heat preservation and aging for 0.5 hour, and the polymerization is completed React to obtain a polymer solution; add 32% mass concentration of sodium hydroxide solution to the above polymer solution for neutralization, adjust the pH value to 6.5, and continue stirring for 20 minutes to obtain a polycarboxylat...

Embodiment 2

[0032] A polycarboxylate water reducer prepared from tap water is prepared by copolymerization of the following raw materials in parts by weight:

[0033] Base material: methallyl polyoxyethylene ether: 330, 30%H 2 o 2 : 3.2, hexamethylenetetramine: 1.2, tap water: 230;

[0034] Liquid A: acrylic acid (AA): 45, mercaptopropionic acid: 1.75, tap water: 100;

[0035] Liquid B: potassium persulfate: 4.0, tap water: 200.

[0036] The preparation method of the present invention is as follows: under room temperature conditions, drop A liquid and B liquid into the base material simultaneously, A liquid is added dropwise after 1 hour, B liquid is added dropwise after 1.5 hours, heat preservation and aging for 0.5 hour, and the polymerization is completed React to obtain a polymer solution; add 32% mass concentration of sodium hydroxide solution to the above polymer solution for neutralization, adjust the pH value to 7, and continue stirring for 20 minutes to obtain a polycarboxylat...

Embodiment 3

[0038] A polycarboxylate water reducer prepared from tap water is prepared by copolymerization of the following raw materials in parts by weight:

[0039] Base material: methallyl polyoxyethylene ether: 348, 30%H 2 o 2 : 3.8, hexamethylenetetramine: 1.3, tap water: 245;

[0040] Liquid A: acrylic acid (AA): 46.3, mercaptopropionic acid: 1.85, tap water: 110;

[0041] Liquid B: potassium persulfate: 4.1, tap water: 215.

[0042] The preparation method of the present invention is as follows: under room temperature conditions, drop A liquid and B liquid into the base material simultaneously, A liquid is added dropwise after 1 hour, B liquid is added dropwise after 1.5 hours, heat preservation and aging for 0.5 hour, and the polymerization is completed React to obtain a polymer solution; add 32% mass concentration of potassium hydroxide solution to the above polymer solution for neutralization, adjust the pH value to 7, and continue stirring for 20 minutes to obtain a polycarbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com