Preparation method of air entraining agent applied to preparation of modified cassava starch-polycarboxylic acid composite water reducing agent

A composite water reducing agent and tapioca starch technology, applied in the field of building materials, can solve the problems of unreasonable bubble structure, uneven distribution, inappropriate size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

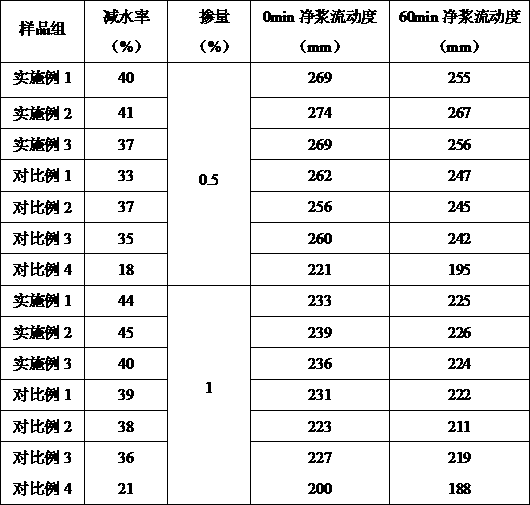

Examples

preparation example Construction

[0032] A preparation method of an air-entraining agent, comprising the following steps:

[0033] S1: Put rosin powder, p-toluenesulfonic acid and sodium hydroxide into the reaction kettle to obtain mixture A, add water with 50% of the total mass of mixture A, mix and stir for 30min, heat to 80°C, keep warm for 50min, and heat up to 80°C , keep warm for 45min to obtain mixed solution A;

[0034] S2: Heat the mixture A to 85°C, slowly add pentaerythritol and tall oil, keep it warm for 35 minutes, then raise the temperature to 70-85°C, slowly add petroleum sulfonate, keep it warm for 1 hour, to obtain the air-entraining agent.

[0035] The air-entraining agent includes the following components in parts by weight: 48-60 parts of rosin powder, 38-55 parts of p-toluenesulfonic acid, 25-37 parts of sodium hydroxide, 18-22 parts of pentaerythritol, tall oil 7-14 parts and 5-9 parts of petroleum sulfonate.

[0036] The modified tapioca starch-polycarboxylic acid composite water reducer...

Embodiment 1

[0048] A preparation method of an air-entraining agent, comprising the following steps:

[0049] S1: Put rosin powder, p-toluenesulfonic acid and sodium hydroxide into the reaction kettle to obtain mixture A, add water with 50% of the total mass of mixture A, mix and stir for 30min, heat to 80°C, keep warm for 50min, and heat up to 80°C , keep warm for 45min to obtain mixed solution A;

[0050] S2: Heat the mixture A to 85°C, slowly add pentaerythritol and tall oil, keep it warm for 35 minutes, then raise the temperature to 70°C, slowly add petroleum sulfonate, keep it warm for 1 hour, to obtain the air-entraining agent.

[0051] The air-entraining agent includes the following components in parts by weight: 48 parts of rosin powder, 55 parts of p-toluenesulfonic acid, 37 parts of sodium hydroxide, 18 parts of pentaerythritol, 7 parts of tall oil and 9 parts of petroleum sulfonate share.

[0052] The modified tapioca-polycarboxylic acid composite water reducer includes the fo...

Embodiment 2

[0062] A preparation method of an air-entraining agent, comprising the following steps:

[0063] S1: Put rosin powder, p-toluenesulfonic acid and sodium hydroxide into the reaction kettle to obtain mixture A, add water with 50% of the total mass of mixture A, mix and stir for 30min, heat to 80°C, keep warm for 50min, and heat up to 80°C , keep warm for 45min to obtain mixed solution A;

[0064] S2: Raise the temperature of the mixture A to 85°C, slowly add pentaerythritol and tall oil, keep it warm for 35 minutes, then raise the temperature to 85°C, slowly add petroleum sulfonate, keep it warm for 1 hour, to obtain the air-entraining agent.

[0065] The air-entraining agent includes the following components in parts by weight: 52 parts of rosin powder, 44 parts of p-toluenesulfonic acid, 32 parts of sodium hydroxide, 20.5 parts of pentaerythritol, 11 parts of tall oil and 7 parts of petroleum sulfonate share.

[0066] The modified tapioca starch-polycarboxylic acid composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com