High-efficiency concrete water reducer and preparation method thereof

A concrete water reducing agent and water reducing agent technology, applied in the field of concrete processing, can solve the problems of low water reducing rate, fresh concrete slump loss, affecting concrete setting hardening and durability, and not fully reflecting water reducing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

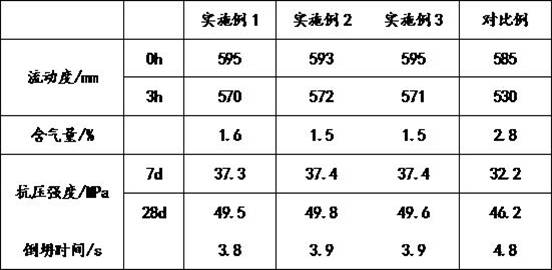

Examples

preparation example Construction

[0053] The preparation method of high-efficiency concrete water reducing agent comprises the steps:

[0054] Step S1, preparation of polycarboxylate water reducer:

[0055] In a four-necked flask equipped with a thermometer, a stirrer, a reflux condenser, and a heating device, add diglycolamine, deionized water, concentrated sulfuric acid, and sodium sulfate in sequence;

[0056] When the temperature reaches 90°C, maleic anhydride is added in batches in small amounts and reacted for 3 hours to obtain an active intermediate; wherein, n(maleic anhydride):n(diethylene glycol amine)=1.1:1, and the monomer concentration is 10%, the amount of concentrated sulfuric acid and sodium sulfate is 1.2% and 1% of the monomer mass respectively, and the concentrated sulfuric acid is sulfuric acid with a mass fraction of 98%; (active intermediates introduce ester groups and amino groups during aqueous radical polymerization )

[0057] In a glass reaction vessel equipped with a water bath, a ...

Embodiment 1

[0063] High-efficiency concrete water reducer, made of the following raw materials in parts by weight: 80 parts of polycarboxylate water reducer, 0.16 parts of defoamer, 1 part of viscosity regulator, and 0.8 parts of modified lignin;

[0064] The preparation method of high-efficiency concrete water reducing agent comprises the steps:

[0065] Step S1, preparation of polycarboxylate water reducer:

[0066] 1) Add diglycolamine, deionized water, concentrated sulfuric acid and sodium sulfate in sequence into a four-necked flask equipped with a thermometer, agitator, reflux condenser and heating device;

[0067] 2) When the temperature reaches 90°C, add maleic anhydride in batches in small amounts and react for 3 hours to obtain an active intermediate; among them, n(maleic anhydride):n(diethylene glycol amine)=1.1:1, monomer Concentration is 10%, the consumption of concentrated sulfuric acid and sodium sulfate is respectively 1.2% and 1% of monomer mass, and concentrated sulfuri...

Embodiment 2

[0072] High-efficiency concrete water reducer, made of the following raw materials in parts by weight: 85 parts of polycarboxylate water reducer, 0.17 parts of defoamer, 1.1 parts of viscosity regulator, and 0.85 parts of modified lignin;

[0073] The preparation method of high-efficiency concrete water reducing agent comprises the steps:

[0074] Step S1, preparation of polycarboxylate water reducer:

[0075] 1) Add diglycolamine, deionized water, concentrated sulfuric acid and sodium sulfate in sequence into a four-necked flask equipped with a thermometer, agitator, reflux condenser and heating device;

[0076] 2) When the temperature reaches 90°C, add maleic anhydride in batches in small amounts and react for 3 hours to obtain an active intermediate; among them, n(maleic anhydride):n(diethylene glycol amine)=1.1:1, monomer Concentration is 10%, the consumption of concentrated sulfuric acid and sodium sulfate is respectively 1.2% and 1% of monomer mass, and concentrated sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com