Modified polyether macromonomer as well as preparation method and use method thereof

A polyether macromonomer and modification technology, which is applied in the field of modified polyether macromonomer and its preparation, can solve problems affecting the fluidity and durability of concrete, poor cohesion of machine-made sand concrete, synthesis and application troubles, etc. , to achieve good economic benefits, good air-entraining effect, improved workability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of a modified polyether macromonomer, which comprises the following steps: adding 0.1 parts of Tributyl phosphate, 0.3 part of polydimethylsiloxane, 0.05 part of polyoxyethylene polyoxypropylene alcohol amine ether, 0.01 part of polyoxyethylene polyoxypropylene glyceryl ether, 0.1 part of sodium dodecylsulfonate, 0.2 part Triterpene saponins, 0.5 part of fumaric acid, 0.5 part of itaconic acid, and 1 part of citric acid were stirred for 30 minutes until they were evenly mixed, and the pH value of the obtained modified polyether macromonomer was 4.0.

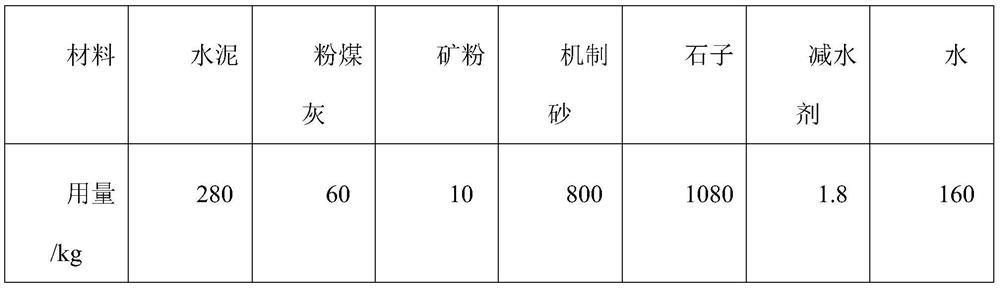

[0022] The prepared modified polyether macromonomer is polymerized to obtain a polycarboxylate water reducer, which is applied to C30 concrete. Among them, the mix ratio of C30 concrete is shown in Table 1: the concrete test refers to GB 8076-2008 " Concrete Admixtures" and GB / T 50082-2009 "Standards for Test Methods of Long-term Performance and Durability of Ordinary Concrete".

[0023] Table 1

[0...

Embodiment 2~5

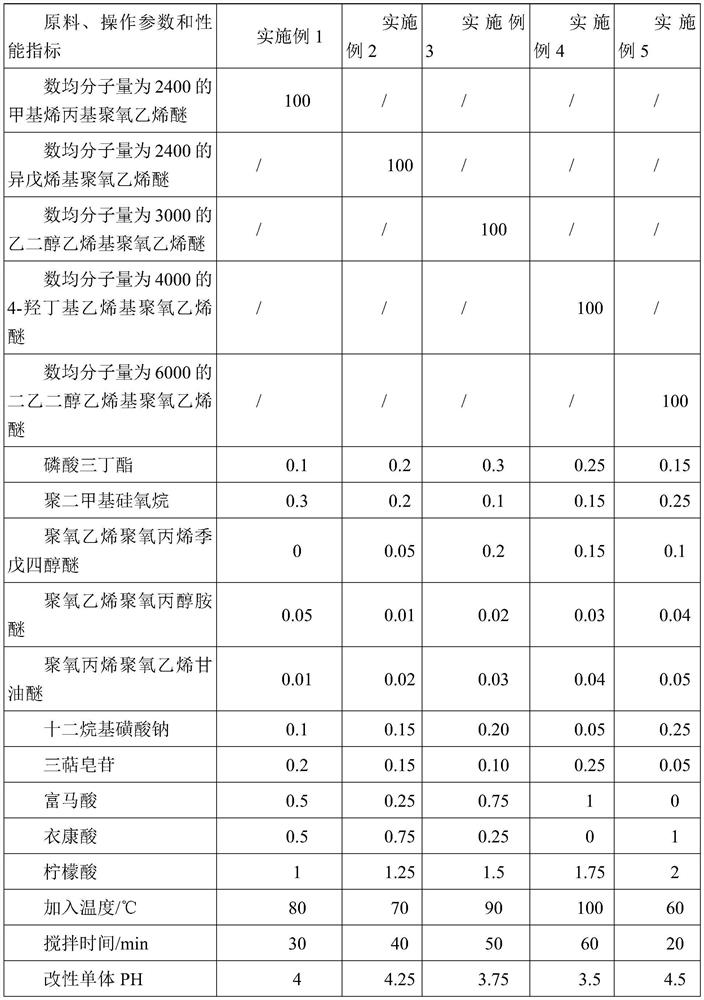

[0027] According to the method and steps of Example 1, the modified polyether macromonomer was prepared according to the formula and operating parameters in Table 1.

[0028] Table 2

[0029]

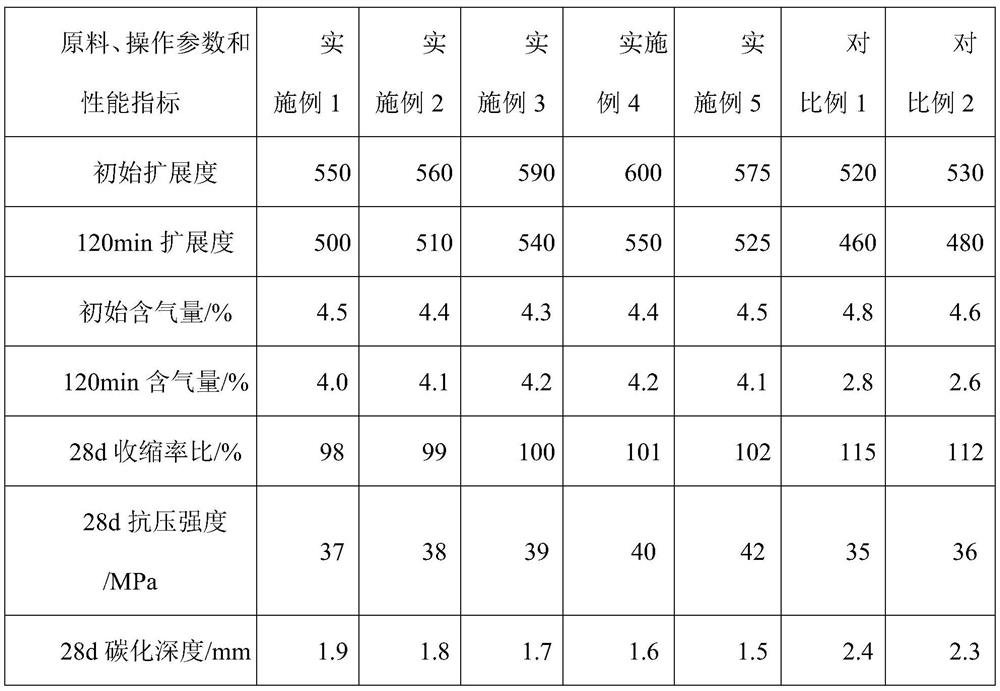

[0030] The modified polyether macromonomer obtained in the above-mentioned Examples 1-5 was prepared by a conventional synthesis process in the field to obtain a polycarboxylate water-reducer, which was applied to the above-mentioned C30 mix ratio concrete summary, and its performance was tested, as shown in Table 3 below .

[0031]

[0032] Among them, comparative example 1 is a polycarboxylate water reducer prepared by using commercially available data molecular weight of 2400 methallyl polyoxyethylene ether according to the conventional synthesis process in this field, and comparative example 2 is using commercially available data molecular weight of 2400. Isopentenyl polyoxyethylene ether is a polycarboxylate water reducer prepared according to the conventional synthesis proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com