Grouting agent and preparation method thereof

A technology of grouting agent and powder, which is applied in the field of concrete admixture and its preparation, and can solve problems affecting the durability of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

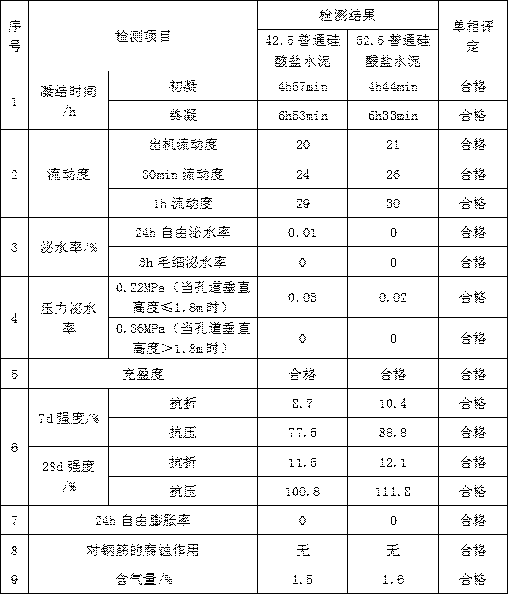

Embodiment 1

[0034] The grouting agent of the present invention and its preparation method, the grouting agent described in this embodiment is mainly designed to compare with 42.5 Portland cement and 52.5 Portland cement, and the specific preparation of this grouting agent Methods as below:

[0035] 1. Preparation method of grouting agent

[0036] (1) The cement used is ordinary Portland 42.5 cement

[0037] Step 1: Preparation of primary product of grouting agent

[0038] 1. Add 10 parts of silica fume, 3 parts of fly ash, 3 parts of polycarboxylic acid, 1 part of magnesium oxide, 0.3 parts of sodium sulfate, 0.2 parts of β-naphthalenesulfonic acid formaldehyde condensate, 0.01 parts of organic Silicon, 0.1 part of rosin saponification, 0.3 part of sodium carbonate.

[0039] 2. Turn on the powder agitator, and control the halving speed of the agitator for the first 10 minutes to 30 rpm.

[0040] 3. When all the powder is basically stirred evenly, adjust the stirring speed of the powde...

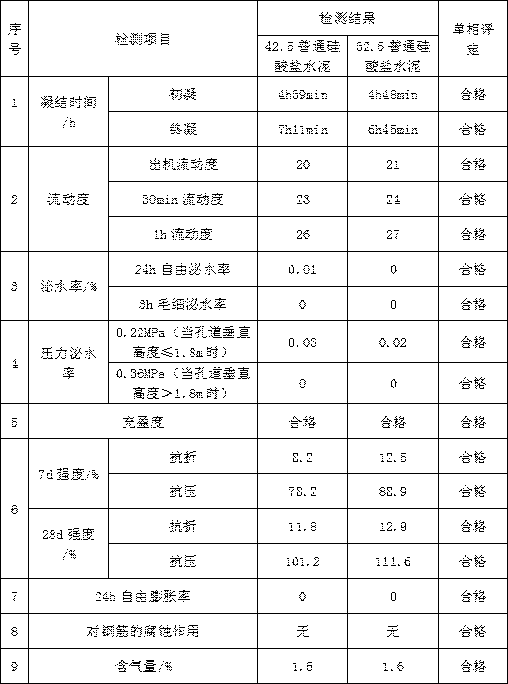

Embodiment 2

[0046] (1) The cement used is ordinary Portland 52.5 cement

[0047] Step 1: Preparation of primary product of grouting agent

[0048] 1. Add 10 parts of silica fume, 3 parts of fly ash, 5 parts of polycarboxylic acid, 1 part of magnesium oxide, 0.15 parts of sodium sulfate, 0.1 part of β-naphthalenesulfonic acid formaldehyde condensate, 0.01 part of organic Silicon, 0.1 part of rosin saponification, 0.3 part of sodium carbonate.

[0049] 2. Turn on the powder agitator, and control the halving speed of the agitator for the first 10 minutes to 30 rpm.

[0050] 3. When all the powder is basically stirred evenly, adjust the stirring speed of the powder agitator, adjust the stirring speed to 40 rpm, and continue stirring for 30 minutes.

[0051] 4. After stirring all the reaction raw materials evenly, move the initial product of the grouting agent to the storage tank for storage for later use.

[0052] Step 2: Compounding of grouting agent

[0053] 1. Take out part of the prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com