Concrete air-entraining agent

A concrete and catalyst technology, applied in the field of concrete air-entraining agent, can solve problems such as unreasonable bubble size, large loss of air content, insufficient air-entrainment, etc., achieve good air-entrainment effect, maintain high air content, and good foam stabilization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

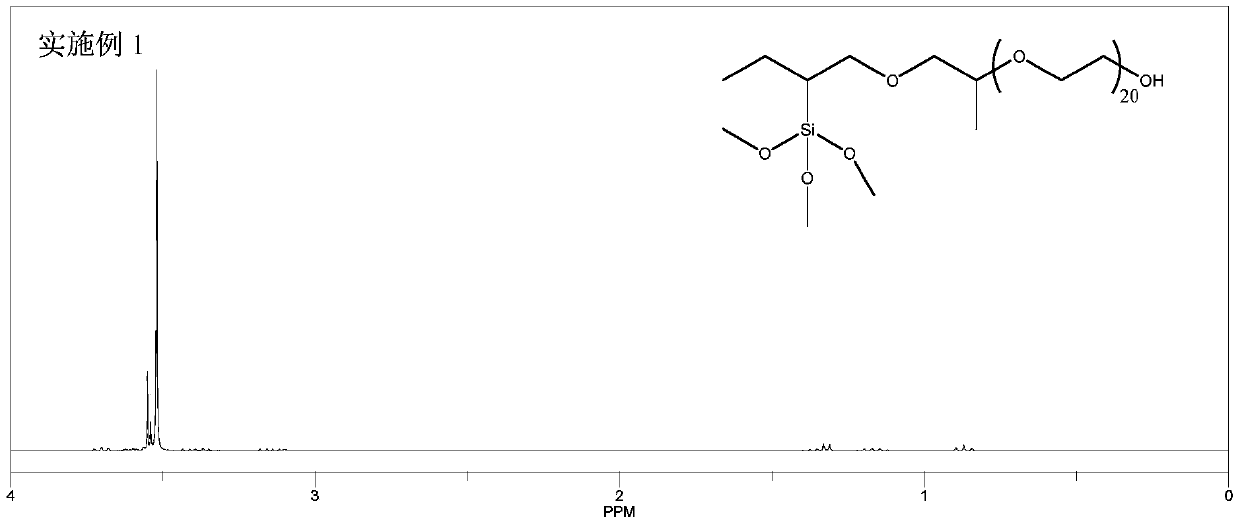

Embodiment 1

[0036] Step 1: Add 1.0mol of 2-butenol and 0.7g of sodium methoxide (1.0wt% of butenol) into the cleaned and dried reactor, seal it, and exchange it with nitrogen for 3 to 4 times to remove the reactor the air inside. Raise the temperature to 100°C, and under the condition that the reaction pressure is below 0.6Mpa, slowly feed 1mol of propylene oxide into the reaction kettle. After the feeding is completed, mature for 1h, and then continue to feed 20mol of ethylene oxide. After the feeding is completed, Aging for 2h, then cooling and degassing to discharge.

[0037] Step 2: Add 1.0 mol of the unsaturated alcohol polyether obtained in Step 1 and 1.0 mol of HSi(OCH3)3 into a dry flask equipped with a thermometer, a condenser and a stirrer. Heat up under stirring, when the temperature reaches 50°C, add 0.3ml of 0.01mol / L isopropanol solution of chloroplatinic acid (amount of 1ppm) dropwise, and control the temperature at 50-80°C during the dropwise addition. After the dropwise...

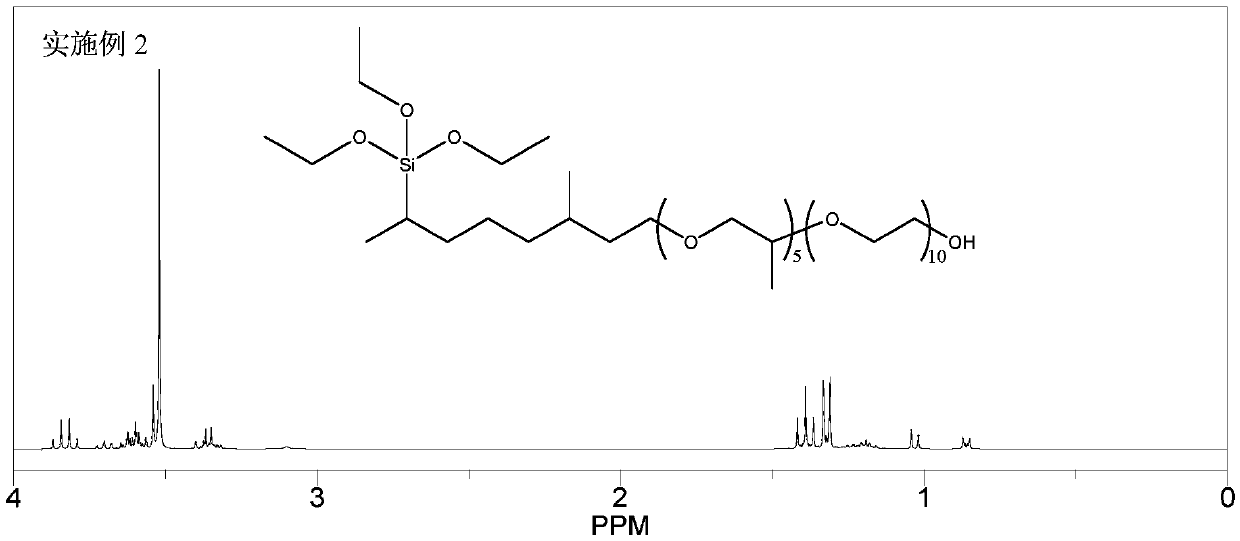

Embodiment 2

[0041]Step 1: Add 1.0mol of 3-methyl-7-heptenol and 2.0g of potassium hydroxide (1.5wt% of 3-methyl-7-heptenol) into the cleaned and dried reactor, Seal it, and exchange it with nitrogen for 3 to 4 times to remove the air in the kettle. Raise the temperature to 80°C, and under the condition that the reaction pressure is below 0.7Mpa, slowly feed 5 mol of propylene oxide into the reaction kettle. After the feeding is completed, mature for 1 hour, and then continue to feed 10 mol of ethylene oxide. After the feeding is completed, Aging for 1h, then cooling down and degassing to discharge.

[0042] Step 2: In a dry flask equipped with a thermometer, condenser and stirrer, add 1.0mol of the unsaturated alcohol polyether obtained in step 1 and 1.2mol of HSi(OCH 2 CH 3 ) 3 . The temperature was raised under stirring, and when the temperature reached 60°C, 4.0ml of 0.01mol / L isopropanol solution of chloroplatinic acid (amount of 15ppm) was added dropwise, and the temperature was ...

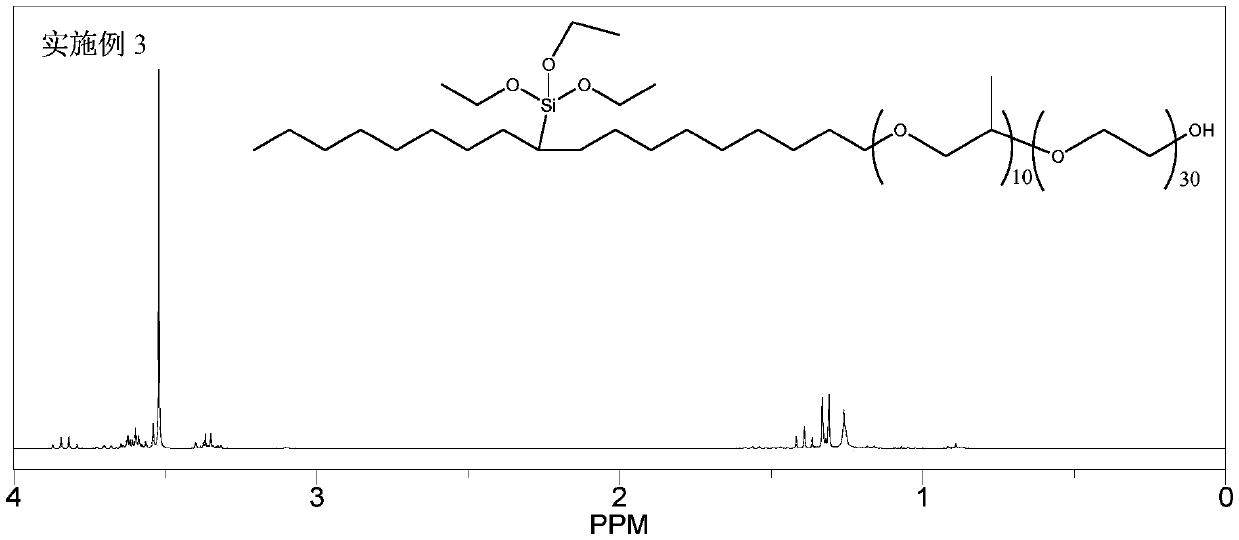

Embodiment 3

[0046] Step 1: Add 1.0mol of cis-9-octadecenol, 2.2g of sodium hydroxide and 3.2g of sodium methoxide (the sum of both mass is 2.0wt% of cis-9-octadecenol) and wash , In the dried reaction kettle, seal it, and exchange it with nitrogen for 3 to 4 times to remove the air in the kettle. Raise the temperature to 140°C, and under the condition that the reaction pressure is below 0.5Mpa, slowly feed 10mol of propylene oxide into the reaction kettle. After the feeding is completed, mature for 2 hours, and then continue to feed 30mol of ethylene oxide. After the feeding is completed, Aging for 2h, then cooling and degassing to discharge.

[0047] Step 2: In a dry flask equipped with a thermometer, condenser and stirrer, add 1.0mol of the unsaturated alcohol polyether obtained in step 1 and 1.5mol of HSi(OCH 2 CH 3 ) 3 . Heat up under stirring, when the temperature reaches 70°C, add 58.9ml of 0.01mol / L isopropanol solution of chloroplatinic acid (amount of 100ppm) dropwise, during...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com