R-T-B based permanent magnet

A R-T-B, permanent magnet technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of controllability, difficult control of magnetic force, reduced efficiency of variable flux motors, etc., and achieve low coercivity. , The effect of high residual magnetic flux density and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8、 comparative example 1~2

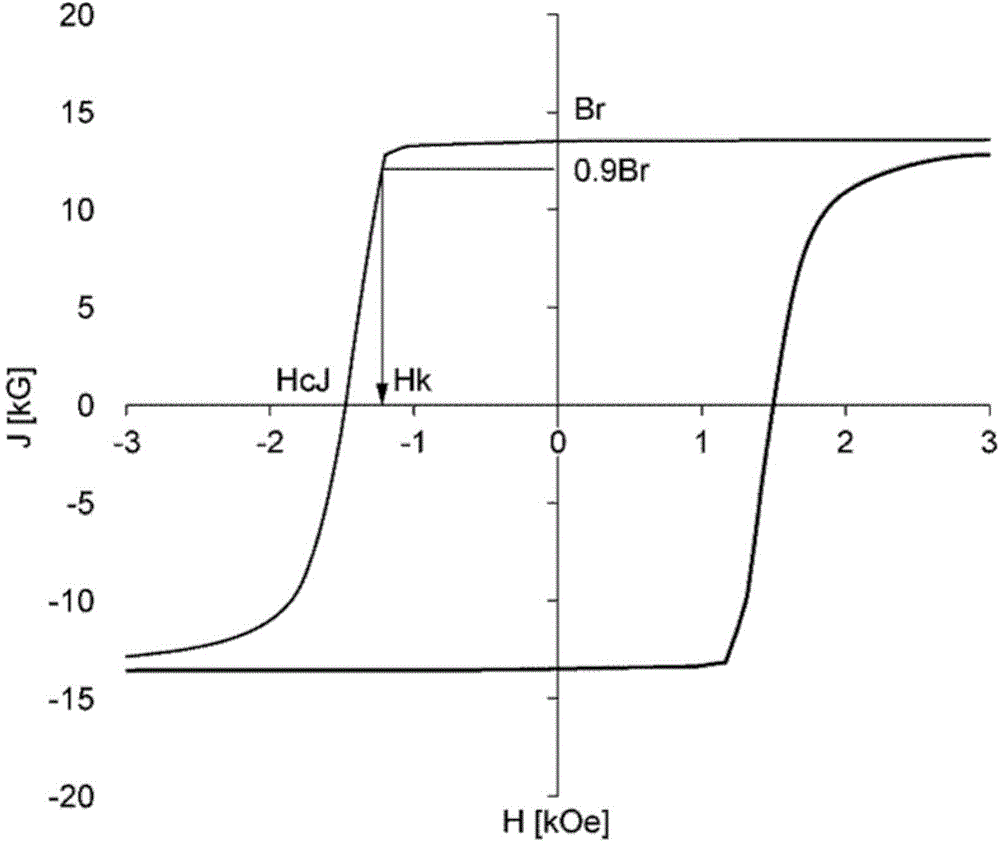

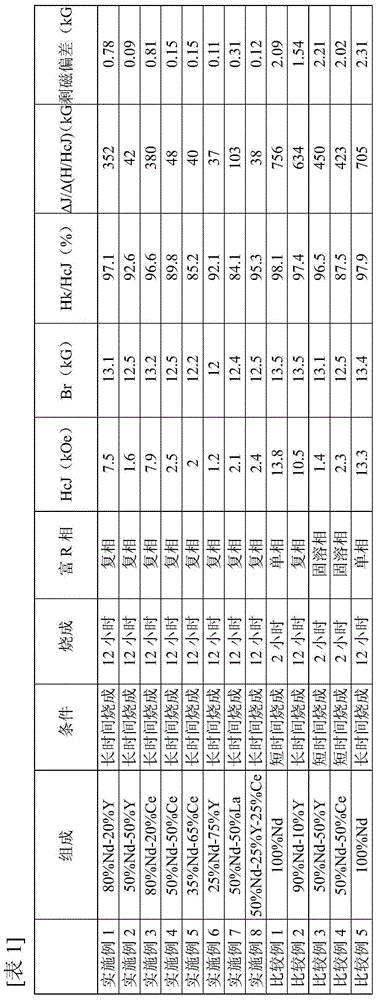

[0052] With 14.2 mol% R-5.8 mol% B-balance Fe as a basic component, 0.5 mass % Co, 0.18 mass % Al, and 0.1 mass % Cu were added thereto. A sintered body of this composition was produced. The composition (atomic %) and firing time of R are shown in Table 1. Their magnetic properties, residual magnetism deviation and demagnetization were measured. The results are shown in Table 1.

[0053] The absolute value of the coercive force HcJ decreases by adding Y, Ce, and La compared to 100% Nd. In addition, a low ΔJ / Δ(H / HcJ) was shown. As a result, the variation in residual magnetization is small, and the controllability of magnetization is good. Since the squareness ratio (HK / HcJ) was high, no demagnetization was found either. In Comparative Examples 1 and 2, the coercivity HcJ was high, and the variation in remanence was large. Example 6 showed low ΔJ / Δ(H / HcJ), and the residual magnetism deviation became small. However, if the coercive force HcJ is significantly lowered to 1.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com