Patents

Literature

108results about How to "Solve molding difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

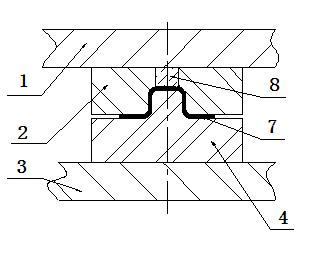

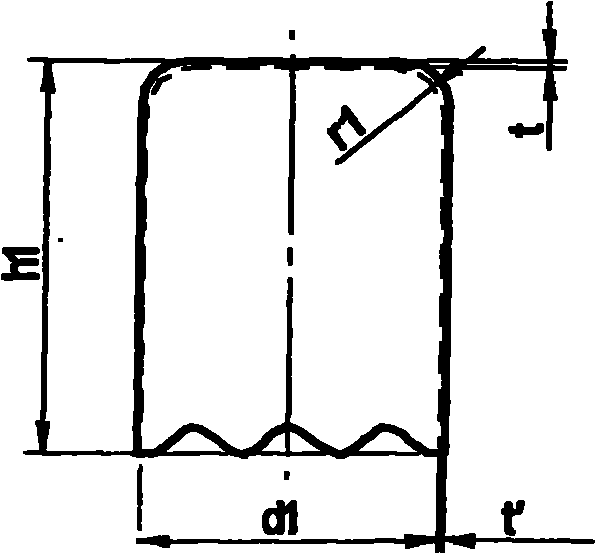

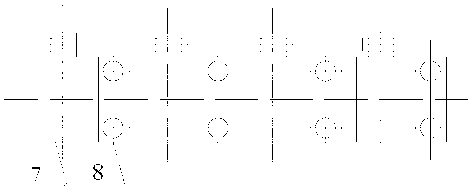

Molding die for processing high-tension plate parts

ActiveCN102310147ASolve molding difficultiesSolve insufficient plastic deformation during moldingShaping toolsEngineeringNitrogen gas

The invention relates to a molding die for processing high-tension plate parts, which comprises an upper die seat (11), a material press core (13), an upper die fixing plate (14), a lower die seat (15), a convex die (17), a material press plate (18) and an upper die knife block (19), wherein the upper die fixing plate (14) is arranged between the upper die seat (11) and the upper die knife block (19), at least one nitrogen spring (12) is arranged between the material press core (3) and the upper die seat (11), at least two nitrogen springs (16) are arranged between the material press plate (18) and the lower die seat (15), a locking unit (21) is manufactured on the material press plate (18) and the upper die knife block (19), a material plate (20) locked between the material press core (13) and the locking unit (21) in molding can be fully stretched for plastic deformation, and the large springback amount after molding is overcome.

Owner:CHERY AUTOMOBILE CO LTD

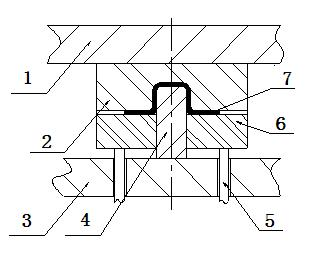

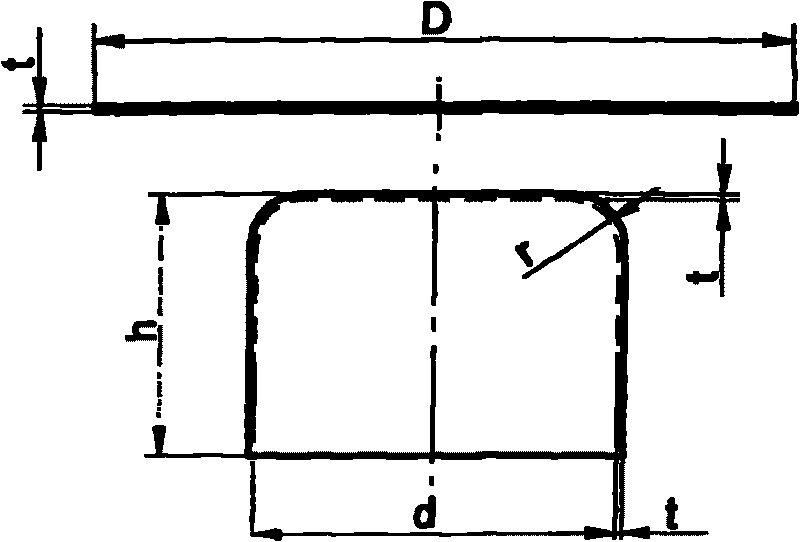

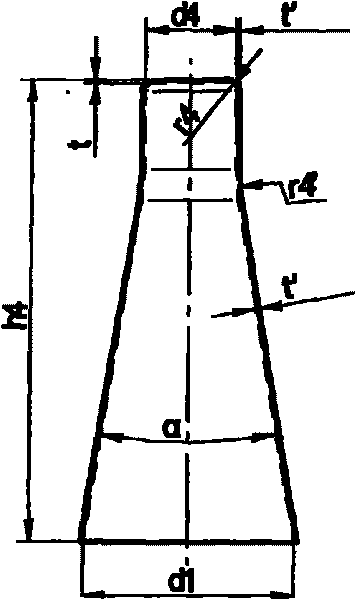

Forming technology of ultra-deep taper thin-wall part

InactiveCN101733338AIncrease productivitySolve molding difficultiesHollow articlesForm processingThin walled

The invention provides a forming technology of an ultra-deep taper thin-wall part, comprising the following technological steps of: cupping blanks; attenuating and deeply drawing; cutting; continuously tapering for three times; anaerobically annealing; and continuously tapering to finally obtain the products with the specified shapes, sizes, and the like. The forming technology is characterized by solving the problem of difficult forming of the ultra-deep taper thin-wall part by firstly forming a large-end taper hole and gradually contracting a small-end cylindrical aperture through tapering and combining with anaerobic annealing processing and effectively solving the problem of non-uniform wall thickness of the integral ultra-deep taper thin-wall part due to the partial attenuation of a bottom long filleted corner of a workpiece in the tapering process of the taper thin-wall parts. The invention can complete the forming processing of the ultra-deep taper thin-wall part on a mechanical punching machine, has the production efficiency far higher that that of a common hydraulic press (the production takt time of the mechanical punching machine is more than 25 times per minute, and the production takt time of the common hydraulic press is 2-3 times per minute) and is suitable for match production.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

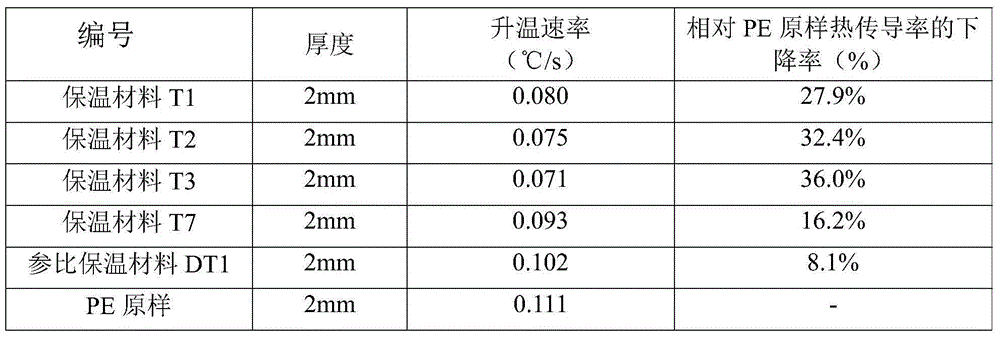

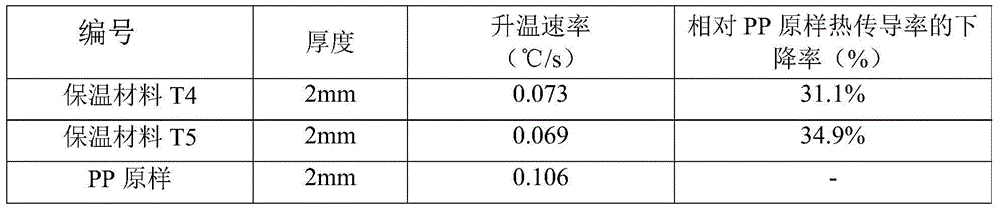

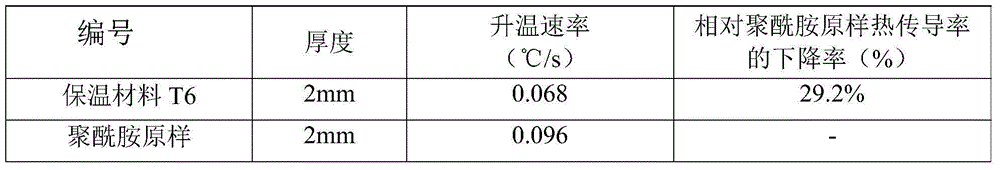

Thermal insulation raw material, thermal insulation material and multilayered composite material

InactiveCN104558745AOvercome the defect of low thermal insulation performanceImprove insulation effectSynthetic resin layered productsThermal insulationThermosetting polymer

The invention provides a thermal insulation raw material, a thermal insulation material and a multilayered composite material. The thermal insulation raw material comprises aerogel and thermoplastic polymer, by taking the total weight of the thermal raw insulation material as a reference, the content of the aerogel is not smaller than 10 percent, and the content of the thermoplastic polymer is not greater than 90 percent. The thermal insulation material provided by the invention has an excellent thermal insulation property, and the multilayered composite material comprising a thermal insulation formed by the thermal insulation material further has good mechanical property.

Owner:CHINA PETROLEUM & CHEM CORP +1

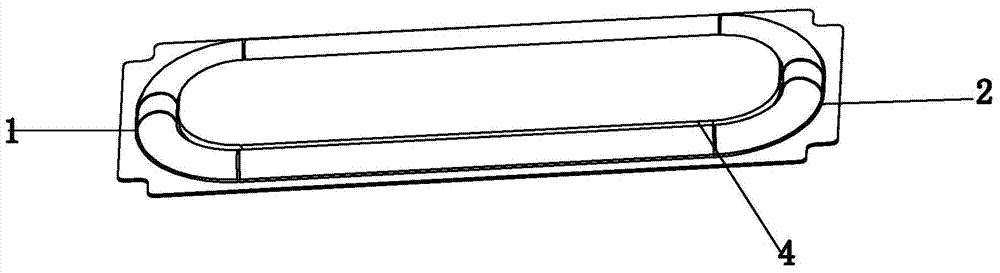

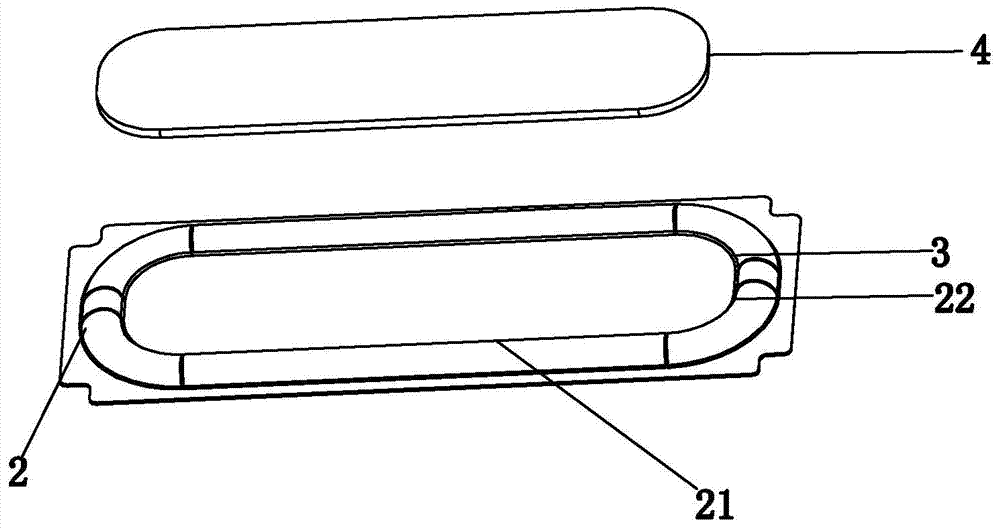

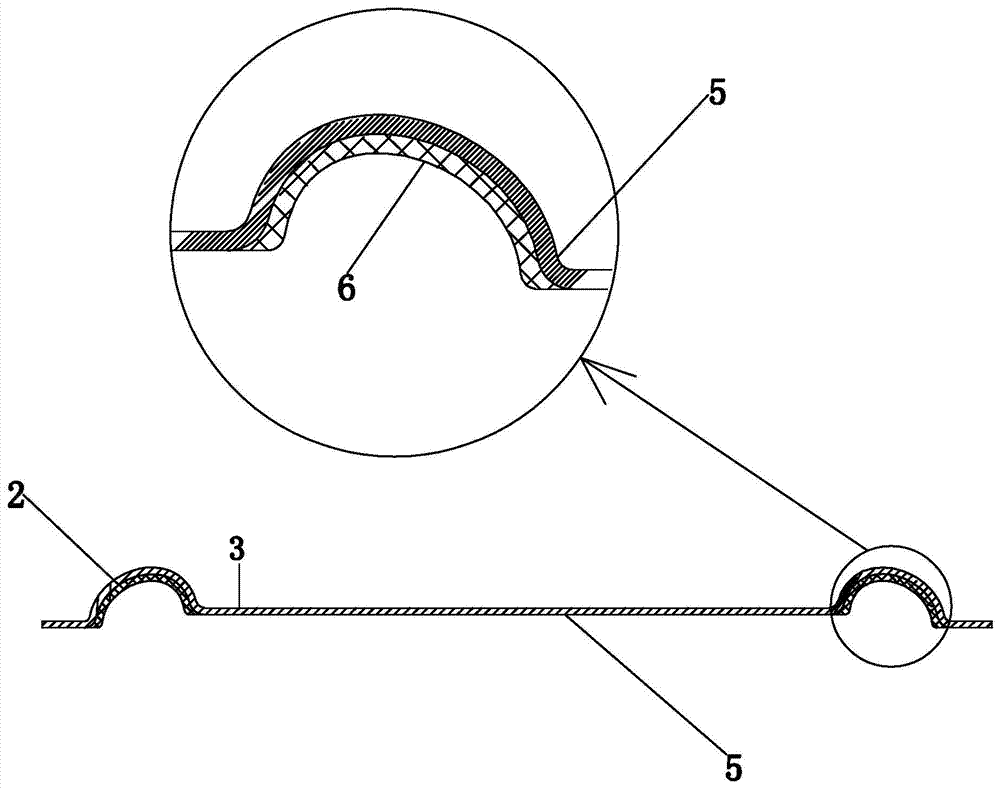

Vibration film component

InactiveCN104754472AStrong mechanical propertiesIncrease vibration amplitudePolymeric diaphragmsSynthetic resin layered productsFilm baseInjection moulding

The invention discloses a vibration film component, and relates to the technical field of electro acoustical products. The vibration film component comprises a vibration film, wherein the vibration film comprises a middle portion and a fold ring portion which wraps around the periphery of the middle portion. The vibration film furthermore comprises a vibration film base layer and a silica gel layer, wherein the silica gel layer is integrated in the vibration film base layer at least partially, the vibration film base layer is a polymer material layer, the silica gel layer is integrated in the surface of the fold ring portion, and the silica gel layer and the polymer material layer are injection molded. The vibrating film component achieves recombination of the silica gel layer and the polymer material layer by arranging the silica gel layer in the surface of the fold ring portion, and thereby improves compliance of the vibration film, enhances chemical stability and adaptability to temperature of the vibration film, optimizes acoustic performances, and improves products yield rate.

Owner:GOERTEK INC

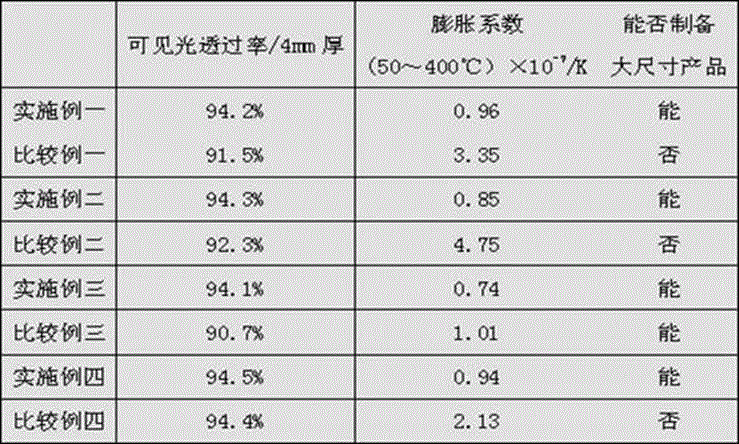

Ultralow-expansion-coefficient high-transparency microcrystalline glass and preparation method thereof

The invention discloses an ultralow-expansion-coefficient high-transparency microcrystalline glass which comprises the following components in percentage by weight: 65-69% of SiO2, 19-20% of Al2O3, 3.1-4.2% of Li2O, 3-4.5% of B2O3, 0.1-0.4% of Na2O, 0.1-0.4% of K2O, 0.3-0.5% of MgO, 0.6-1.4% of BaO, 0.6-1.4% of ZnO, 1.0-1.7% of TiO2, 1.0-1.3% of ZrO2, 0.4-0.8% of P2O5, 0.3-0.8% of F and 0.02-0.3% of CeO2. The preparation method comprises the following steps: melting glass raw materials, cooling, molding, annealing, crystallizing, and carrying out after treatment to obtain the microcrystalline glass finished product. The microcrystalline glass has the advantages of high transparency and ultralow expansion coefficient, and can be used for manufacturing large-size or complex-structure products.

Owner:虎石新材料(宜兴)有限公司

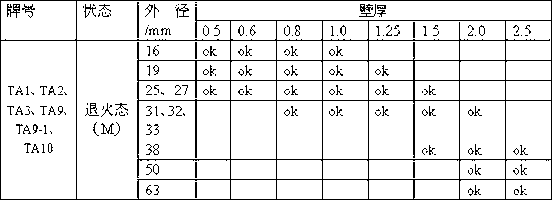

Preparation method of thickness-diameter ratio longitudinal titanium and titanium alloy welded pipe

InactiveCN103008386ARealize mass productionSolve molding difficultiesArc welding apparatusFurnace typesTungstenDiameter ratio

The invention discloses a preparation method of a thickness-diameter ratio longitudinal titanium and titanium alloy welded pipe The preparation method is characterized by comprising the following processes of: (1) by online continuous cold-bending and forming of a titanium tape, preparing a pipe material which is formed as a cylindrical structure from a plate-shaped structure; (2) feeding into a welding box body, implementing argon tungsten-arc welding, thereby welding the un-sealed cylindrical structure into a sealed pipe-shaped structure; (3) implementing online conductive stress removing annealing on the welded pipe material; (4) sizing and straightening; and (5) implementing eddy loss-less flaw detection, ultrasonic loss-less flaw detection and airtightness detection, and obtaining a qualified pipe material in the circumstances of no alarm and no pressure relief. According to the thickness-diameter ratio titanium welded pipe which is produced by the method disclosed by the invention, the size and specification, mechanical performance, chemical component, surface quality and the like can meet the demands of the titanium welded pipe applied to the seawater desalination engineering; and the unconventional titanium welded pipe production process is broken through, to manufacture the unconventional titanium welded pipe applied to the seawater desalination engineering with the thickness-diameter ratio ranging from 0.015 to 0.020.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Environmental-friendly permeable ceramic brick and preparation method thereof

InactiveCN106892675ASolve the problem of accumulating and polluting the environmentRealize recyclingCeramic materials productionCeramicwareEnvironmental resistanceFrost

The invention belongs to the technical field of ceramic flooring tiles and in particular relates to an environmental-friendly permeable ceramic brick and a preparation method thereof. The permeable ceramic brick comprises the following components in percentage by mass: 60-80% of waste ceramic chip granules of the ceramic brick, 5-10% of a high-temperature inorganic adhesive, 5-10% of a fluxing agent, 10-20% of a pore forming agent and a low-temperature organic adhesive accounting for 1-1.5% of the mass sum of the previous four basic materials. The preparation method comprises the following steps: mixing all the materials, molding, drying and roasting, thereby obtaining the permeable ceramic brick. The permeable ceramic brick has excellent water permeability, strength and anti-frost property.

Owner:辽宁法库陶瓷工程技术研究中心

Method for forming slender bent irregularly-shaped hole in aluminum alloy casting

ActiveCN103949588AHigh dimensional accuracyImprove surface roughnessFoundry mouldsFoundry coresSurface roughnessMetal mold

The invention belongs to the field of precision casting of fired molds, in particular relates to a precision casting forming method for an aluminum alloy casting with a slender irregularly-shaped bent hole, and aims to solve the problems of difficulty in extracting a metal mold core, difficulty in manufacturing a shell, even incapability of manufacturing the shell and the like in a conventional process for forming a slender bent hole in the metal mold core as well as the problem of severe corrosion of the casting during core stripping in a process for forming a slender bent hole through a ceramic mold core. By adopting the method provided by the invention, the qualified molding of the slender bent irregularly-shaped hole in the aluminum casting can be ensured, and the size accuracy, surface roughness, wear resistance, erosion resistance and use strength of the slender bent irregularly-shaped hole in the aluminum casting can be enhanced.

Owner:西安钢研高纳航空部件有限公司

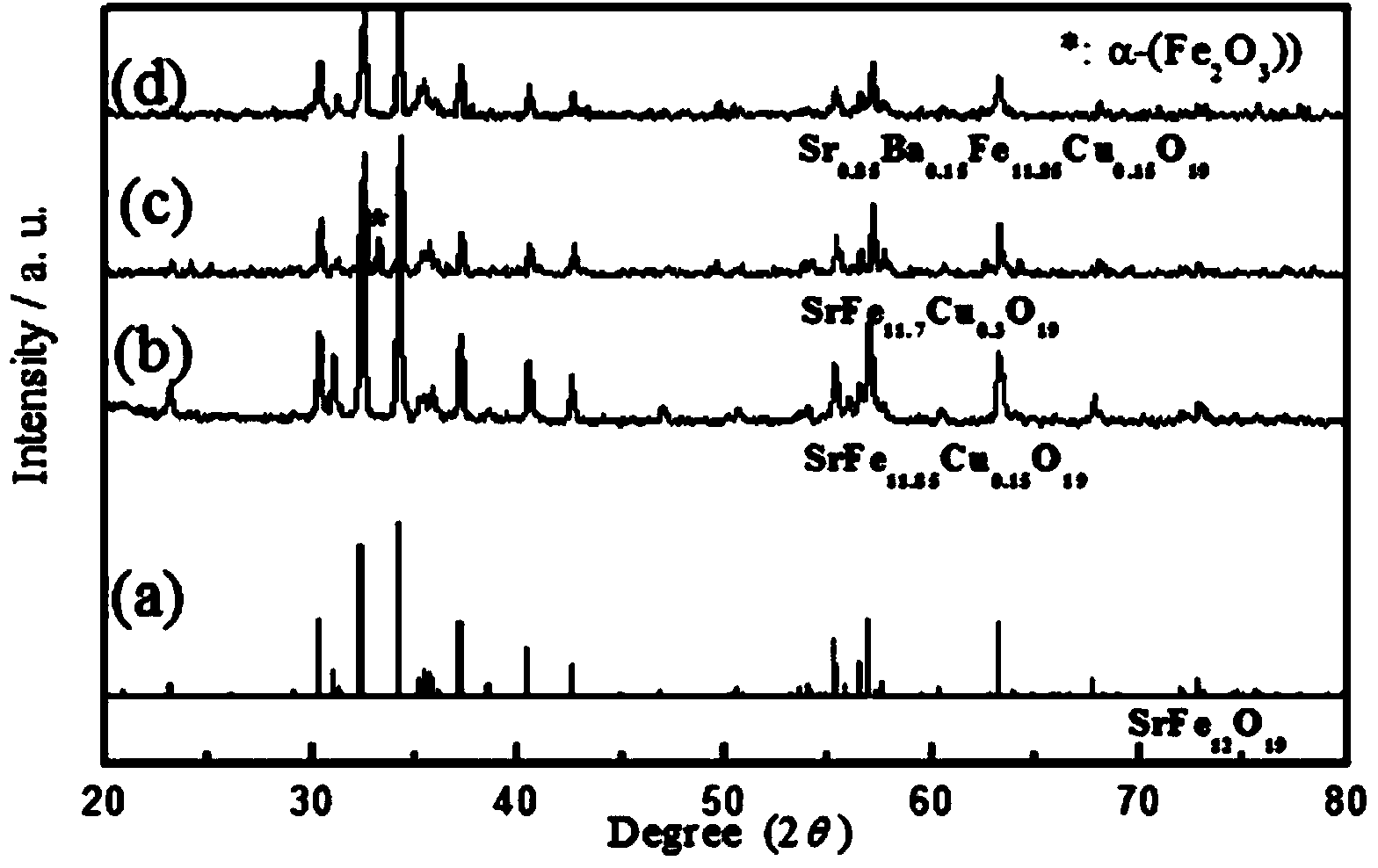

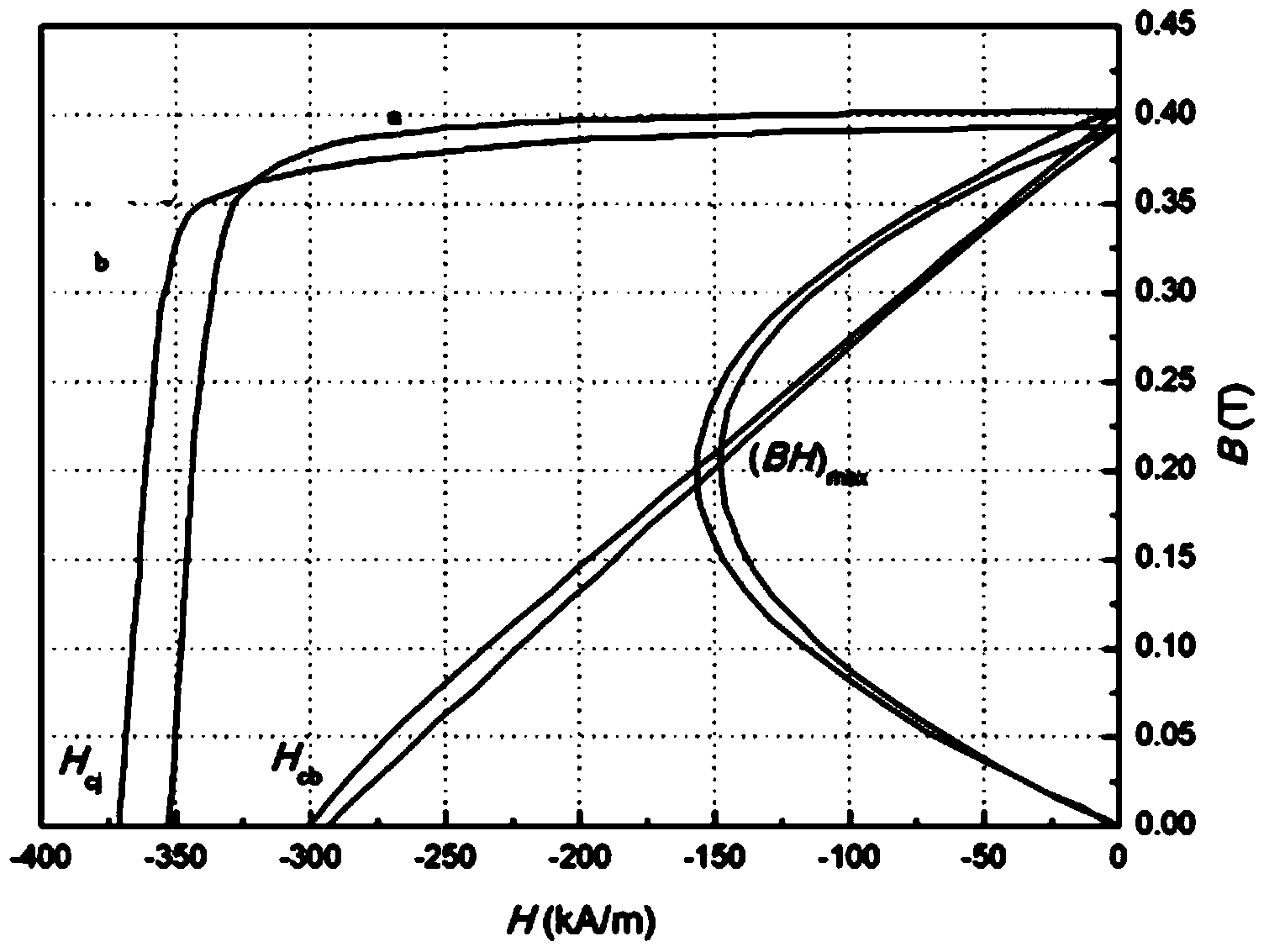

Plumbite type yttrium permanent magnetic ferrite material and preparation method thereof

The invention discloses a plumbite type yttrium permanent magnetic ferrite material and a preparation method thereof. The plumbite type yttrium permanent magnetic ferrite material is a hexagonal system, the chemical structural formula of which is R1-x-yYxLayO.nFe(12-z) / nCoz / nO3, wherein x is less than or equal to 0.5 but greater than or equal to 0.01, y is less than or equal to 0.75 but greater than or equal to 0.1, z is less than or equal to 0.082 but greater than or equal to 0.07, n is less than or equal to 6.5 but greater than or equal to 5.0, and (1-x-y) is less than or equal to 0.5 but greater than or equal to 0. R is Ca, Ba, Sr or one, two and three of Ce, Pr and Nd and Sm in lanthanide series exclusive of La. Compared with the conventional permanent magnetic ferrite, for the plumbite type yttrium permanent magnetic ferrite material, at the sintering temperature of 1150-1300 DEG C, the remanence Br value reaches 4.2-4.8kGs, the magnetic induction coercive force Hcb value reaches 4.2-5.2kOe, the intrinsic coercive force Hcj value reaches 4.5-6.0kOe, and the magnetic energy product value reaches 5.2-5.7MGOe. The plumbite type yttrium permanent magnetic ferrite material provided by the invention is high in remanence and intrinsic coercive force. When the sintered magnet becomes smaller and thinner, the high residual magnetic flux density is still maintained.

Owner:ANHUI UNIVERSITY

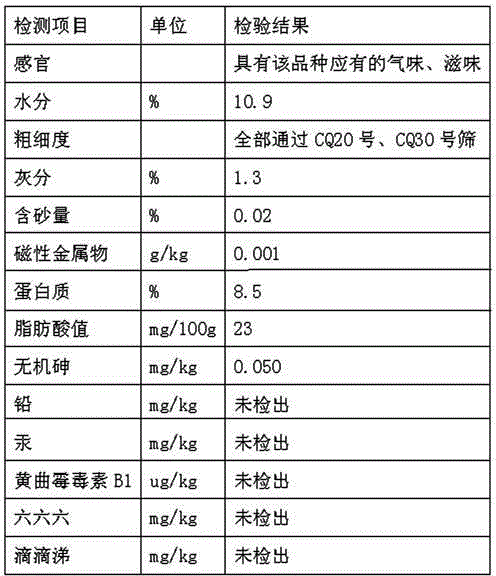

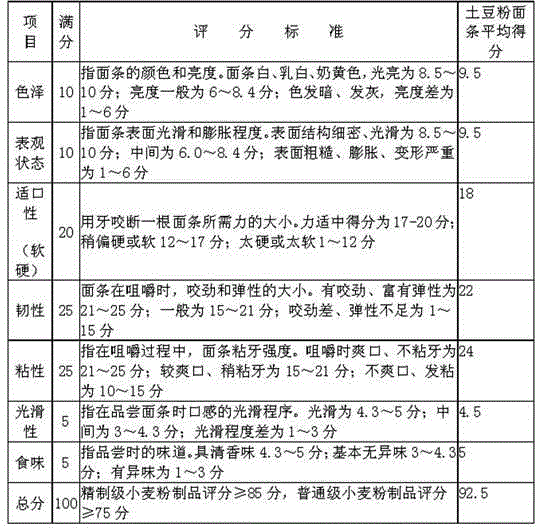

Potato whole flour and staple food prepared by employing same

InactiveCN104886504AReasonable retention of nutrientsKeep the quality reasonablyFood preparationPotato starchHardness

The invention belongs to the technical field of food processing. In order to solve the problems that the existing potato whole flour is relatively high in processing cost and relatively complex in processing step while the existing potato whole flour which is used for manufacturing staple food products is hard to mold, is great in hardness and is not resistant to cooking, the potato whole flour is low in content, the cost for manufacturing a potato food made of flour is high and the like, the invention provides potato whole flour and staple food prepared by employing the potato whole flour. The preparation method of the potato whole flour comprises the following steps: choosing raw materials; cleaning and peeling the raw materials; selecting the raw materials; cutting the raw materials into slices; blanching the raw materials; cooling and drying the raw materials; and pulverizing the raw materials. The potato whole flour is mixed with oat flour to prepare steam buns; the potato whole flour is mixed with wheat flour and potato starch to prepare noodles; the potato whole flour is mixed with wheat flour to prepare cakes; the potato whole flour is mixed with potato starch to prepare dough and dumpling wrappers; and the potato whole flour is mixed with oat flour and potato starch to prepare Helaomian (a kind of noodles). The staple food preparation process is time-saving, simple and convenient and the prepared food is suitable for the public to eat, the popularization is facilitated, and the potato flour is industrially produced and is stable in quality; the staple food is easy to mold, is tenacious, is complete in nutrition and is good in taste.

Owner:SHANXI SHUYAN FOOD

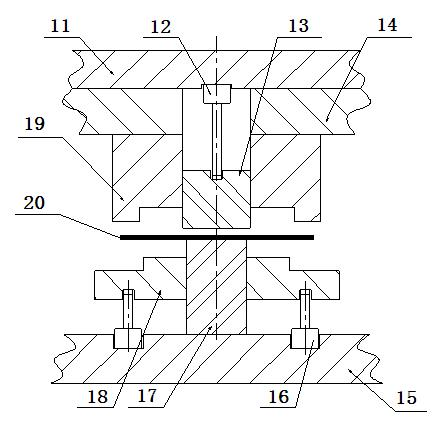

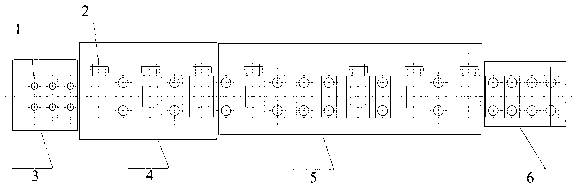

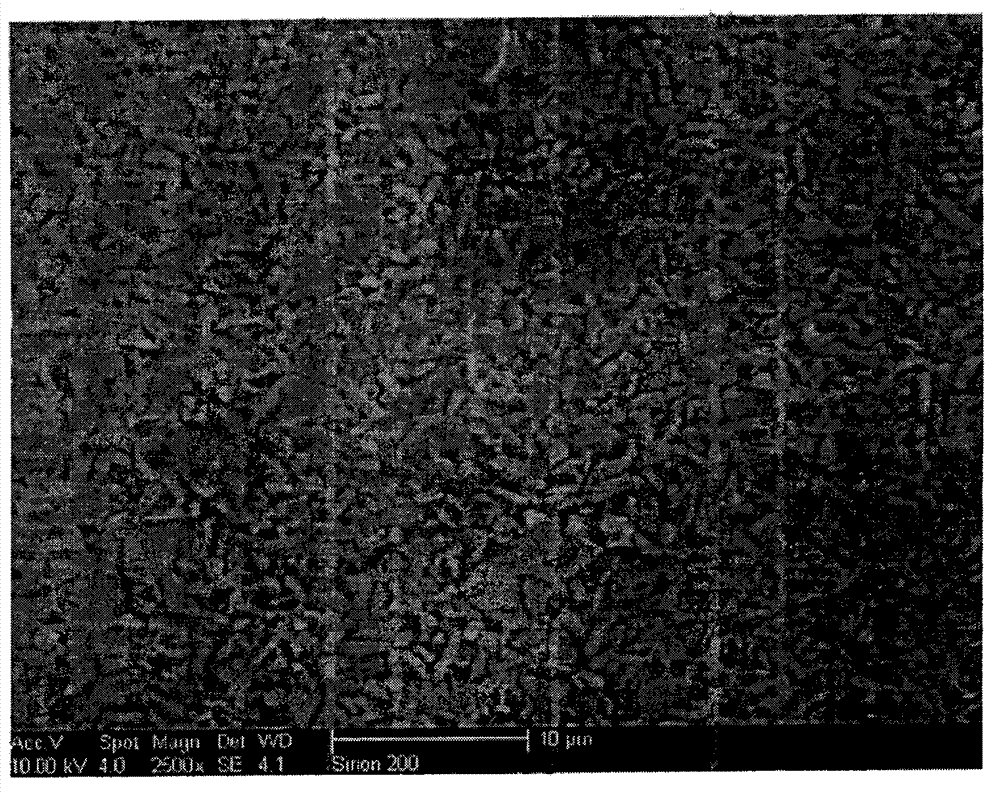

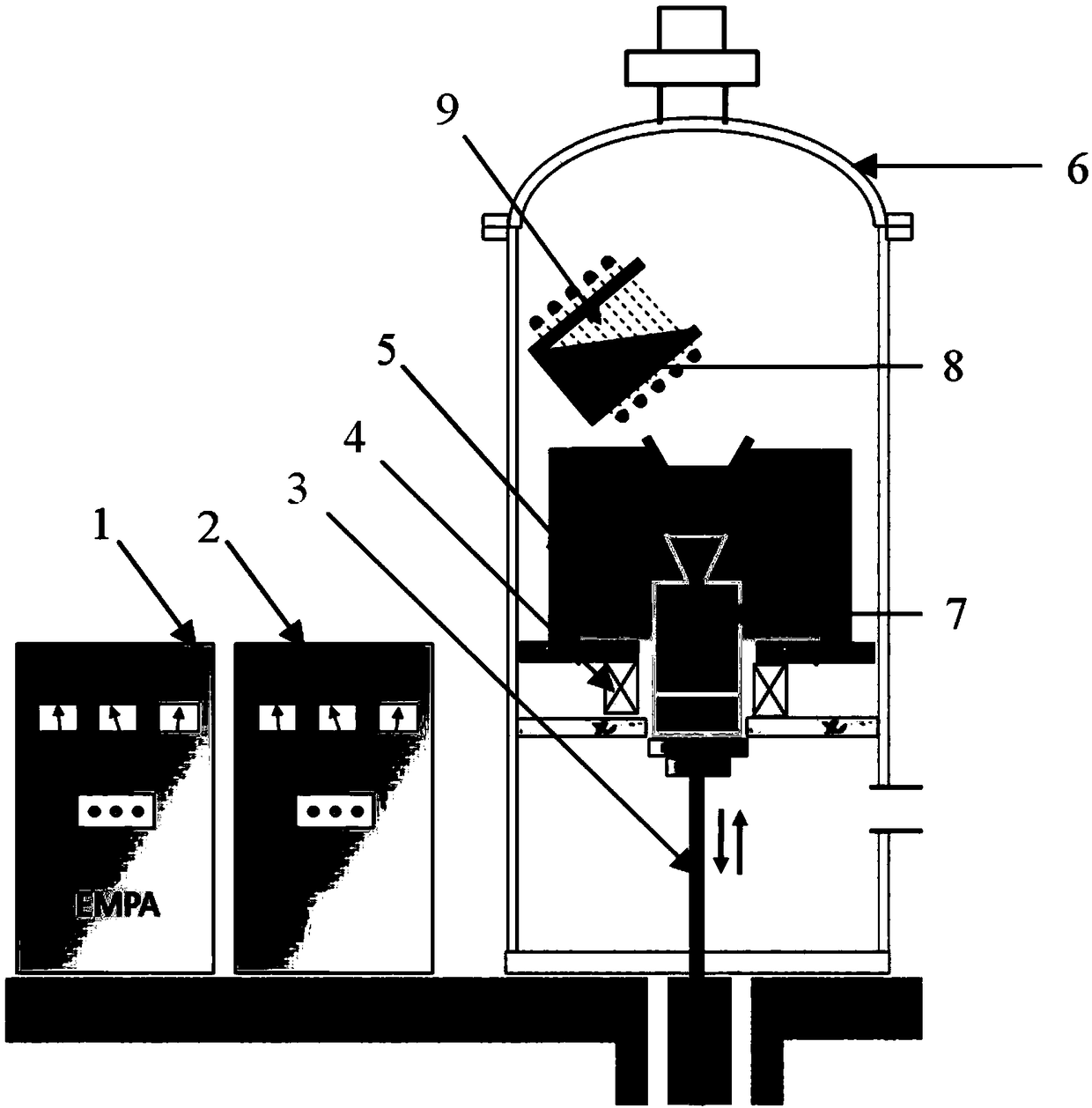

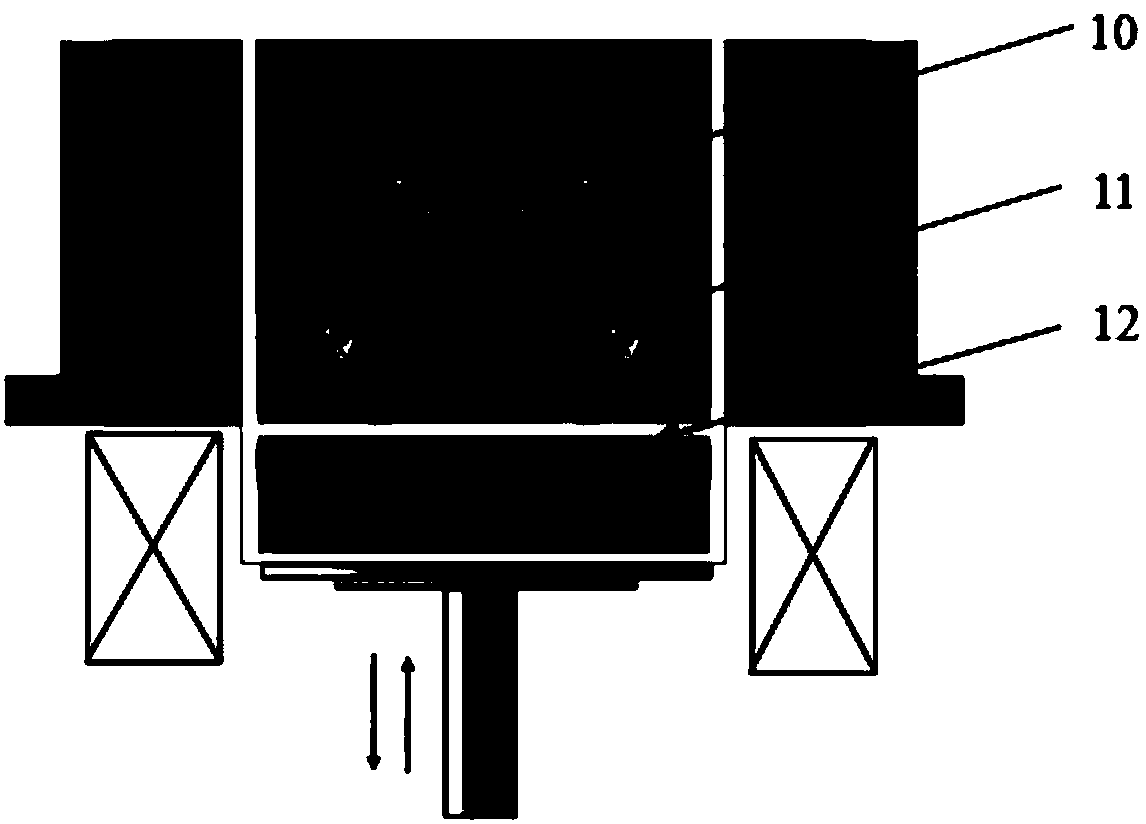

Integrated forming method and integrated forming device for large complex thin-walled fine grain casting

ActiveCN109396400ASolve molding difficultiesSolve the coarse grainCasting parameters measurement/indication devicesTemperature controlHigh energy

The invention relates to an integrated forming method and an integrated forming device for a large complex thin-walled fine grain casting. The device is composed of four systems such as a mold temperature control system, a mold ingot withdrawing system, a magnetic pulse disturbing system and a monitoring and controlling system. The method comprises the following steps: generating a temperature gradient from top to bottom in a mold shell melt by means of the multi-area heating precise mold temperature control system; and withdrawing a melt, close to a liquid phase line temperature, at the bottom of the casting out of an insulating area by matching a proper withdrawing speed to achieve progressive solidification of the melt from bottom to top, so that the solidification defects such as looseness are eliminated and the compactness of the casting is improved. On this basis, intense electromagnetic solidification is generated at the front edge of a solid / liquid interface under the instant high energy electromagnetic action at the solidification front of an electromagnetic field to play roles of hindering crystal growth and refining crystal grains intensively as well as refining the solidification structures of the casting. The integrally refined solidification structure is obtained, and in particular, tissues on thick and large parts of the casting are refined. Therefore, cooperative control of integral forming, crystal grain refining and defect control of the large complex thin-walled fine grain casting can be achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

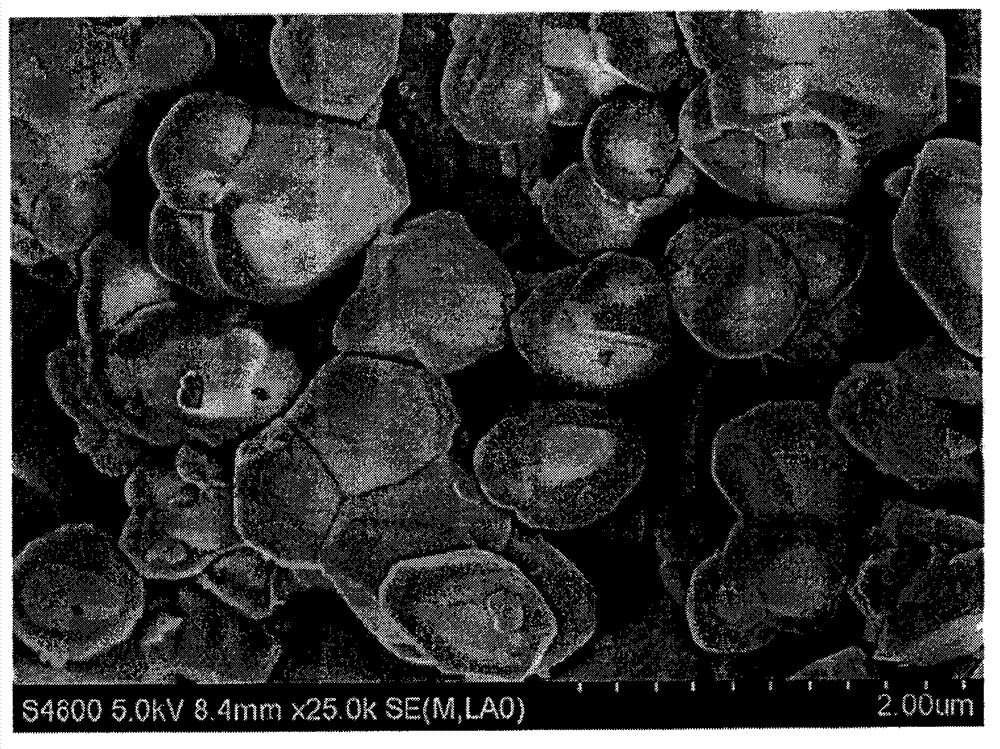

Preparation method of high-performance permanent magnet ferrite magnet and magnet

InactiveCN107382303AImprove performanceInhibit growthInorganic material magnetismInductances/transformers/magnets manufactureRemanenceStrontium

The invention discloses a preparation method of a high-performance permanent magnet ferrite magnet and the magnet, belonging to the technical field of magnetic materials. The method comprises the steps of mixing and grinding a strontium ferrite pre-sintered material and an La-Ca-Sr-Co ferrite pre-sintered material in a certain weight proportion, wherein the La-Ca-Sr-Co ferrite material is prepared from the following components: La0.6Ca0.4-xSrxOn (Fe1-yCoy)2O3, wherein the x is more than or equal to 0.1 and is less than or equal to 0.4, the y is more than or equal to 0.2 and is less than or equal to 0.3, the n is more than or equal to 5.0 and is less than or equal to 6.0, the strontium ferrite material is prepared from the component of SrO.6(Fe2O3). When the strontium ferrite pre-sintered material is mixed with the La-Ca-Sr-Co ferrite pre-sintered material, the minimum remanence Br of the prepared permanent magnet ferrite is 418.7mT, and the maximum is 429.1mT; the minimum intrinsic coercivity is 350.3kA / m, and the maximum is 388.6kA / m, which fully meets the requirements of current use: the remanence Br is 415mT to 430mT, and the intrinsic coercivity is 350kA / m to 380kA / m.

Owner:MAANSHAN GAOKE MAGNETIC MATERIAL

Low pressure casting process of preparing in-situ aluminium-base composite material

InactiveCN1739887ASolve molding problemsSolve the problem of serious oxidationPressure castingCrucible

The low pressure casting process of preparing in-situ aluminum-base composite material includes the following steps: melting and stirring the composite material under the protection of inert gas; sealing liquid metal inside sealing crucible with middle partition and installing the cast mold on the middle partition; deairing the composite material in vacuum environment; pressurizing the sealed crucible to pressurize liquid composite material into mold cavity in the antigravity direction; maintaining the pressure after crusting for some period; raising the pressure inside the crucible to certain high pressure and maintaining the high pressure until complete solidification of the casting; eliminating pressure and taking out the casting. The present invention applies low pressure casting method in preparing in-situ aluminum-base composite material and can form high performance aluminum-base composite material.

Owner:SHANGHAI JIAO TONG UNIV

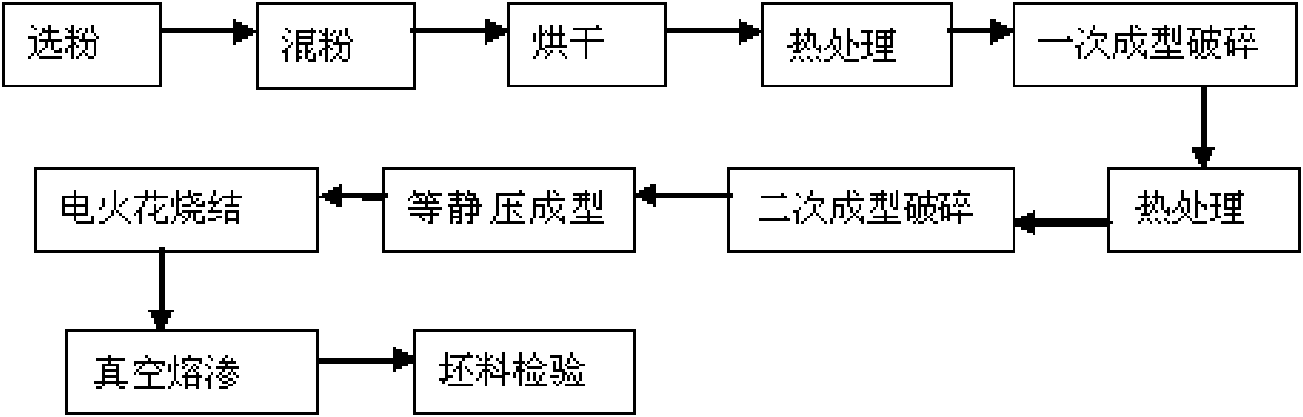

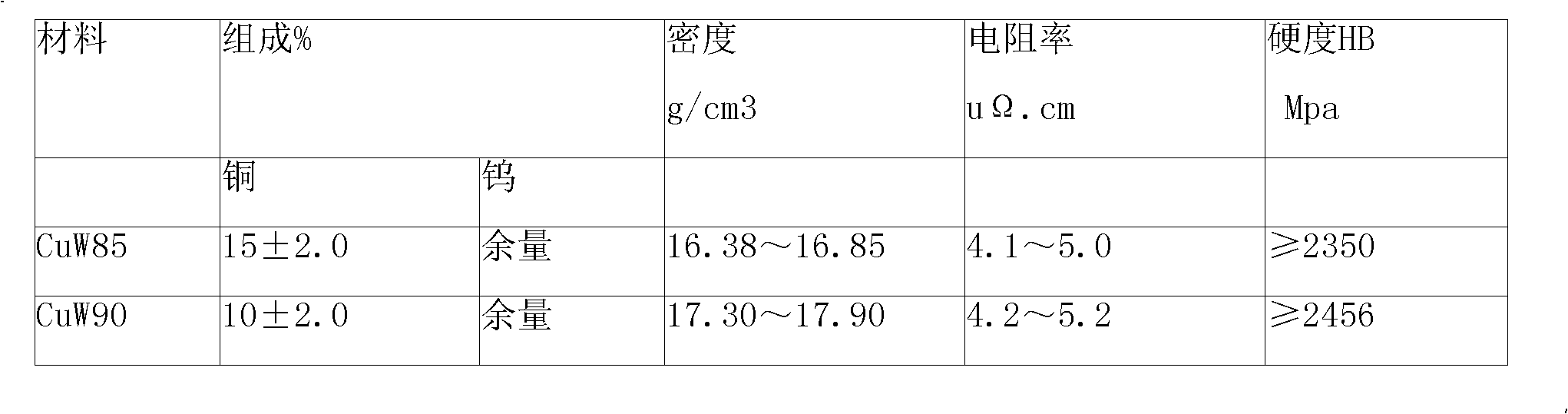

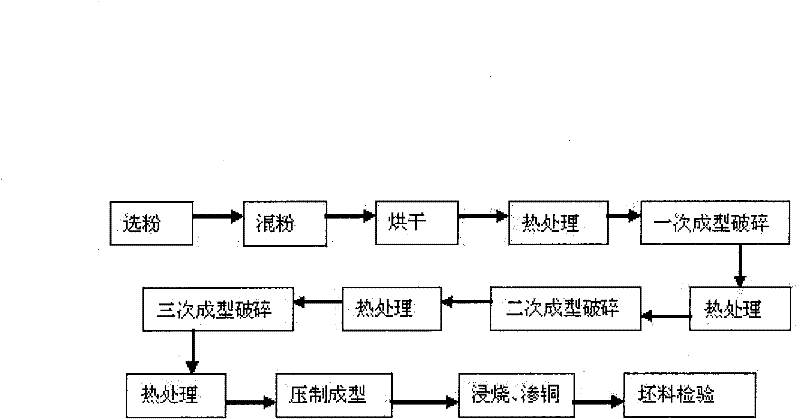

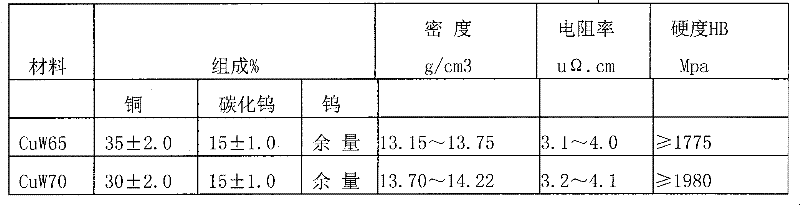

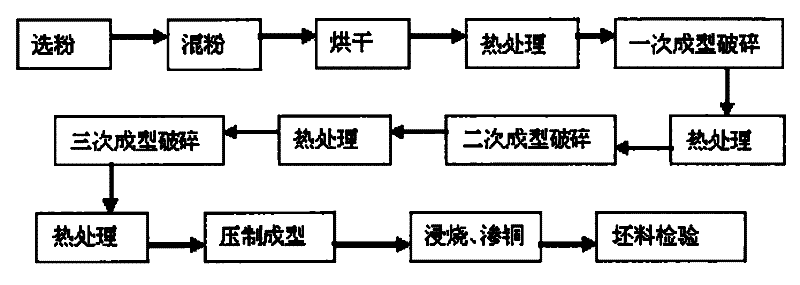

Profiled high conductivity copper-tungsten electrical contact material and processing technique thereof

The invention discloses a profiled high conductivity copper-tungsten electrical contact material and a processing technique thereof. the processing technique is characterized by firstly choosing copper powder and tungsten powder with suitable granularity and mixing the powders according to a certain proportion; carrying out to-and-fro heat treatment, press forming and smashing on the mixed raw powder, then isostatically pressing a required shape and sintering the shape with electric sparks into copper tungsten blanks; lastly, carrying out vacuum infiltration on the prepared copper and the sintered blanks to ensure that copper can be totally infiltrated into the body during material production to produce the profiled high conductivity copper-tungsten electrical contact material with the porosity of less than 0.15%. The electrical contact produced by the contact material simplifies construction of electric switches, eliminates the dispersivity of the springs in the switches and greatly improves the reliability of components. The material is widely used in high temperature materials, electrical alloys for high voltage switches, electromachining electrodes, microelectronic materials and the like.

Owner:刘爱芬

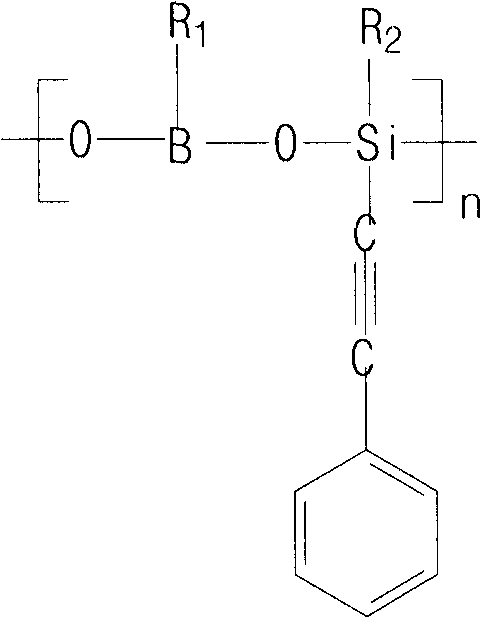

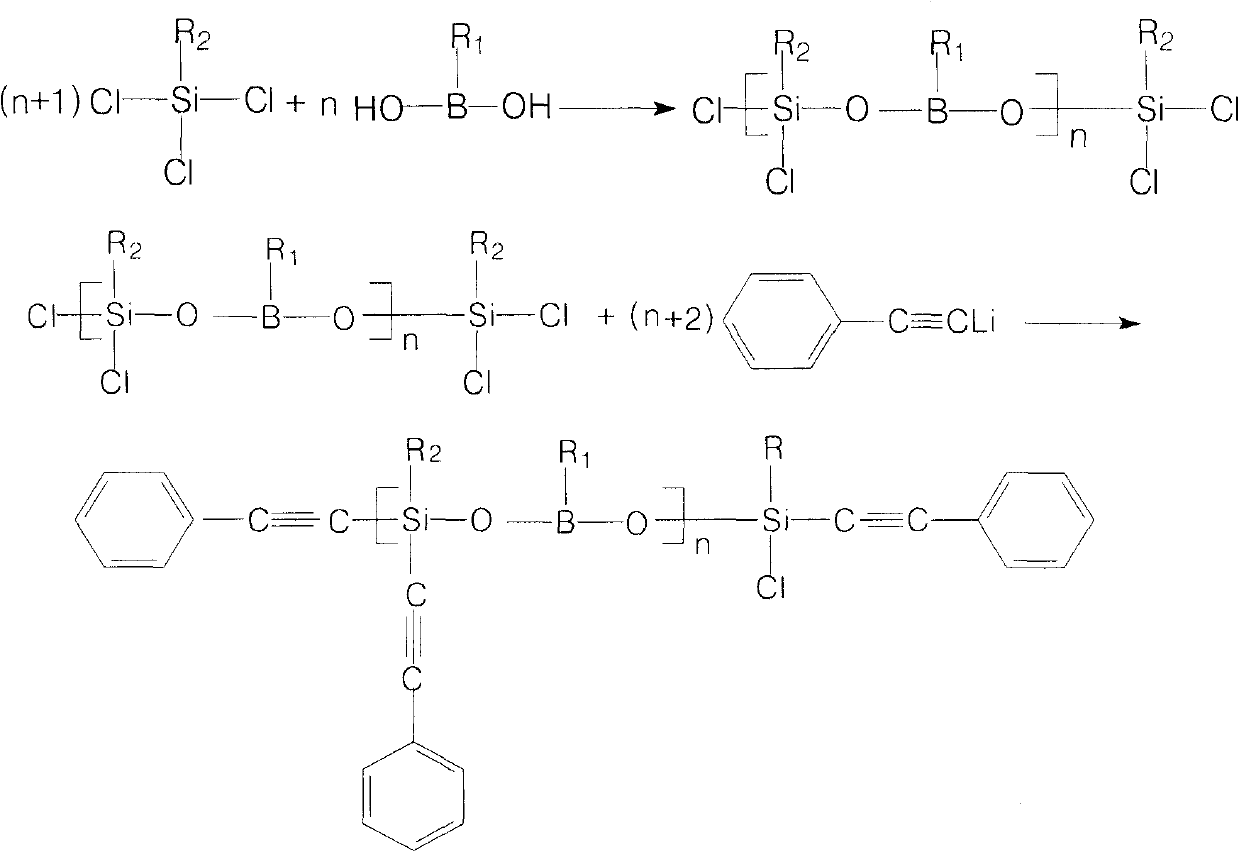

Polyphenylacetylene silicon oxide borane and preparation method thereof

ActiveCN102234375ADoes not affect crosslink densitySolve molding difficultiesBoron carbideSilicon oxide

The invention discloses polyphenylacetylene silicon oxide borane and a preparation method thereof. The structure of the prepared polyphenylacetylene silicon oxide borane is shown as a formula I, wherein R1 and R2 refer to CH3, C6H5, and n is 1-100. The preparation method comprises the following steps of: performing hydrogen chloride removal reaction on trichlorosilane and alkyl boric acid to obtain polychlorosilicon oxide borane; and reacting the polychlorosilicon oxide borane with phenylacetylenelithium to obtain the polyphenylacetylene silicon oxide borane. In the polymer, a repeat unit contains polyphenylacetylene, so the magnitude of the polymerization degree cannot influence the crosslinking density of the polymer. The molecular weight of the polymer can be controlled by proportioning raw materials. In high temperature environment, the surface of a material is vitrified, and a ceramic layer such as a silicon carbide layer or a boron carbide layer is formed, so that the inner material is isolated from heat and oxygen; therefore, the thermal oxidation performance of the structural material is improved. The polyphenylacetylene silicon oxide borane is applied to preparing ceramic precursors, high-performance composite material matrixes, ablation resistant materials, high temperature resistant coatings and the like. The formula I is shown in the specifications.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Preparation method of chalcogenide glass element based on 3D printing technology

ActiveCN105541108ASolve molding difficultiesSolve the accuracy problemGlass making apparatusGlass productionChalcogenide glassMaterials science

The invention relates to a preparation method of a chalcogenide glass element based on 3D printing technology. The preparation method comprises: wiredrawing basic chalcogenide glass consumables, winding the obtained filaments onto a reel of a 3D-printing machine, and performing laser sintering, layer-by-layer filament paving, and post-treatment to obtain the chalcogenide glass element with a required shape. In the preparation method, a die is not required, and the dimensional precision is controllable, so that the method is suitable for fast and low-cost manufacture of chalcogenide glass elements with miniature and complex shapes. Problems of glass material transportation and feeding, high-temperature melting, and moulding in the prior art of glass 3D-printing moulding are overcome, and 3D printing of a chalcogenide glass element can be efficiently completed.

Owner:CHINA BUILDING MATERIALS ACAD

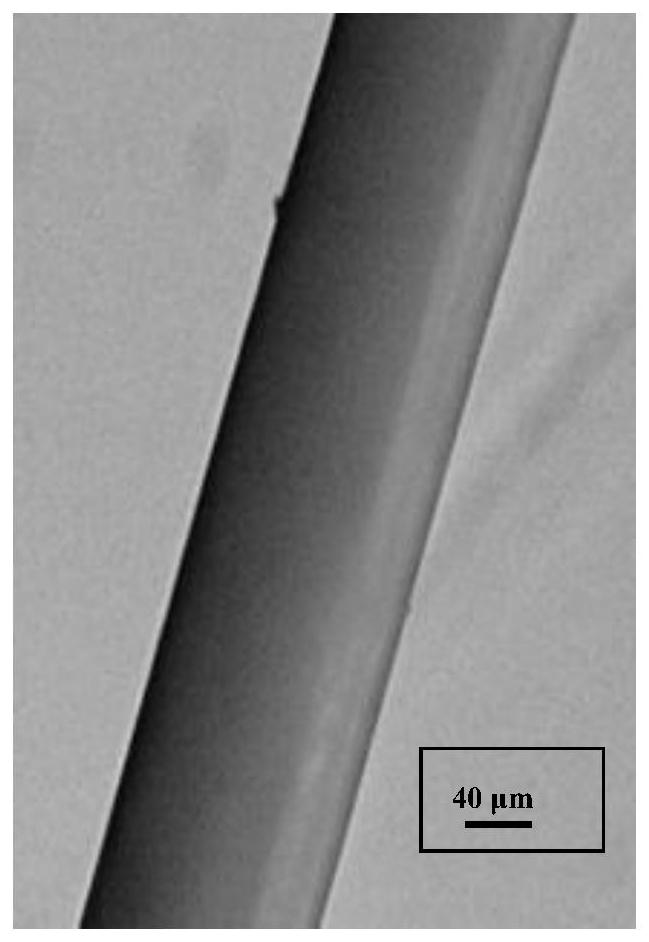

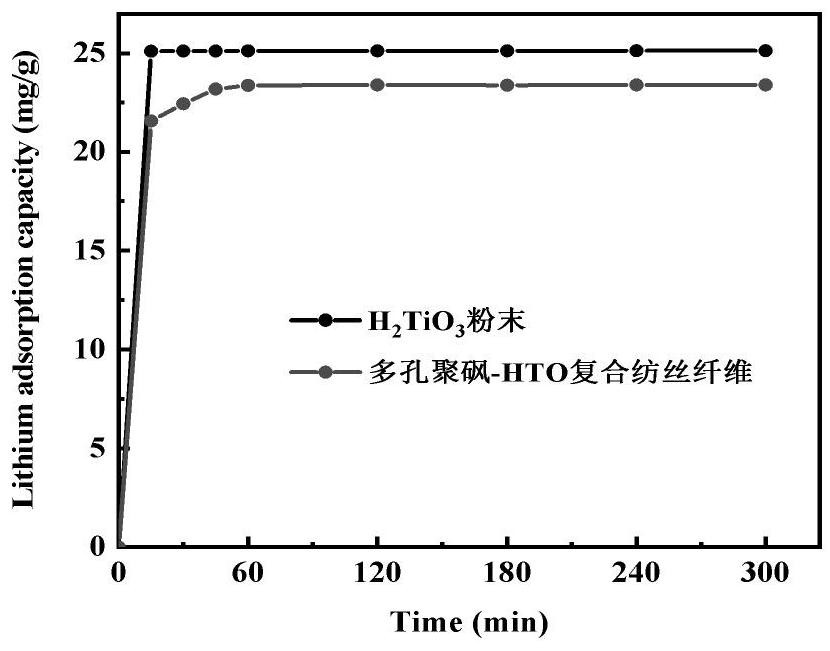

Preparation method of porous spinning composite material and lithium extraction application thereof

ActiveCN112619621ASimple preparation processLow costOther chemical processesProcess efficiency improvementSpinningFoaming agent

The invention discloses a method for preparing a porous spinning composite material and lithium extraction application of the porous spinning composite material, and the method comprises the following steps: (1) mixing, heating and stirring a high-molecular polymer and an organic solvent to fully dissolve the high-molecular polymer, and standing for defoaming; (2) adding lithium ion sieve powder and a water-soluble pore-foaming agent into the mixed solution, and fully stirring and uniformly mixing; (3) spraying the mixed solution into a coagulating bath by using wet spinning equipment, and carrying out phase inversion molding; and (4) drawing, washing, drying and curing to obtain the porous spinning composite adsorbing material. The obtained porous spinning composite adsorbing material is applied to extraction of lithium in liquid lithium ore. The method effectively solves the problems of poor fluidity and cycle stability of the powder material, and greatly enhances the adsorption rate and adsorption capacity compared with granular or rod-like adsorption materials, thereby having favorable application prospects in the development and utilization of lithium resources in salt lake brine, underground brine, geothermal water and the like.

Owner:TIANJIN UNIV OF SCI & TECH +1

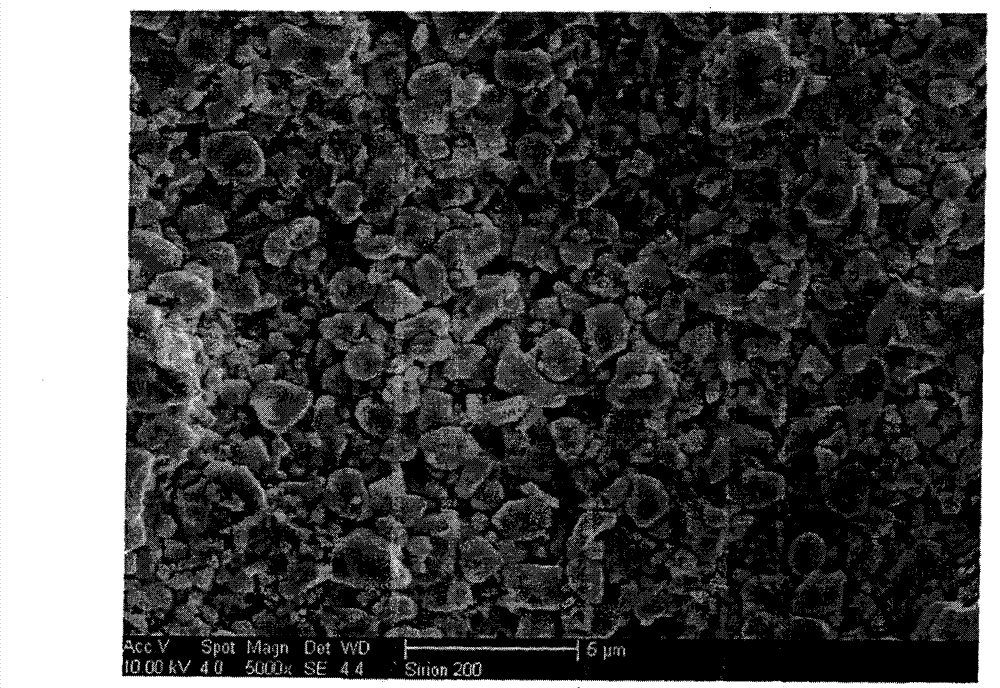

Preparation and sintering of single-aperture blank of oxygen self-supported permanent magnetic ferrite pre-sintering material

The invention relates to preparation and sintering of a single-aperture blank of an oxygen self-supported permanent magnetic ferrite pre-sintering material and belongs to the technical field of preparation of magnetic functional materials. The technical scheme is carried out according to a main-phase molecular formula: Srl-xBaxO.nFe (12-y) / nRy / nO3, wherein x is not less than 0 and is not greater than 0.998, and n is not less than 5.75 and not greater than 6.15, 0 & 1t; y is not greater than 0.6, and R is Mn and is secondarily added with one or more than two of industrial pure oxides CeO2, GeO2 and MnO2. To the prepared pre-sintering material and a high-performance permanent magnetic ferrite material prepared from auxiliary secondary adding, the residual magnetism Br value is at least 392 mT, the Hcj value is at least 343.1 kA / m, and the BHmax value is at least 27.9 kJ / m<3>. The preparation and sintering have the advantages that a certain amount of K2MnO4 is added to a raw material of the ferrite pre-sintering material prepared by one-time sintering and meanwhile MnO2 is added into a secondary adding auxiliary material, so that the uniformity of performance of the same batch of products is improved, and the grain refinement is facilitated at the same time; the problem of the restriction of residual magnetic flux density Br and Hcj is effectively solved, and the prepared permanent magnetic ferrite has high Br and Hcj.

Owner:宿州学院

Special potato noodle type powder for using potatoes as staple food

InactiveCN104905180ARealize large-scale factory productionGreat tasteFood preparationFood additivePotato starch

The invention belongs to the technical field of food processing. In order to solve the problems that the processing cost of conventional potato whole flour is higher, the processing procedures are complex, during making staple food products with the conventional potato whole flour, the forming is difficult, the hardness is high, the staple food products are not resistant to boiling, the content of the potato whole flour is low, the cost of making cooked potato food is high and the like, the invention provides special potato noodle type powder for using potatoes as staple food. A preparation method of the potato whole flour comprises the following steps: choosing raw materials, cleaning the chosen raw materials, removing skins of the potatoes, selecting the potatoes of which the skins are removed, cutting the selected potatoes into slices, blanching the potato slices, cooling the blanched potato slices, drying the cooled potato slices and milling the dried cooled potato slices; mixing the potato whole flour, wheat flour and potato starch to be made into noodles. The preparation process is time-saving, simple and convenient, the noodles are popular and suitable for people to eat, the popularization is facilitated, and the quality is steady; the noodles are easy to form, tenacious, comprehensive in nutrition and good in taste; the content of the potato whole flour is more than 50%, any food additive is not added, safe, healthy environment-friendly food is ensured, the situation that the potatoes are consumed as the staple food is facilitated, the sustainable development of agriculture of China is facilitated, and the special potato noodle type powder is good for nutrition and health of people.

Owner:SHANXI SHUYAN FOOD

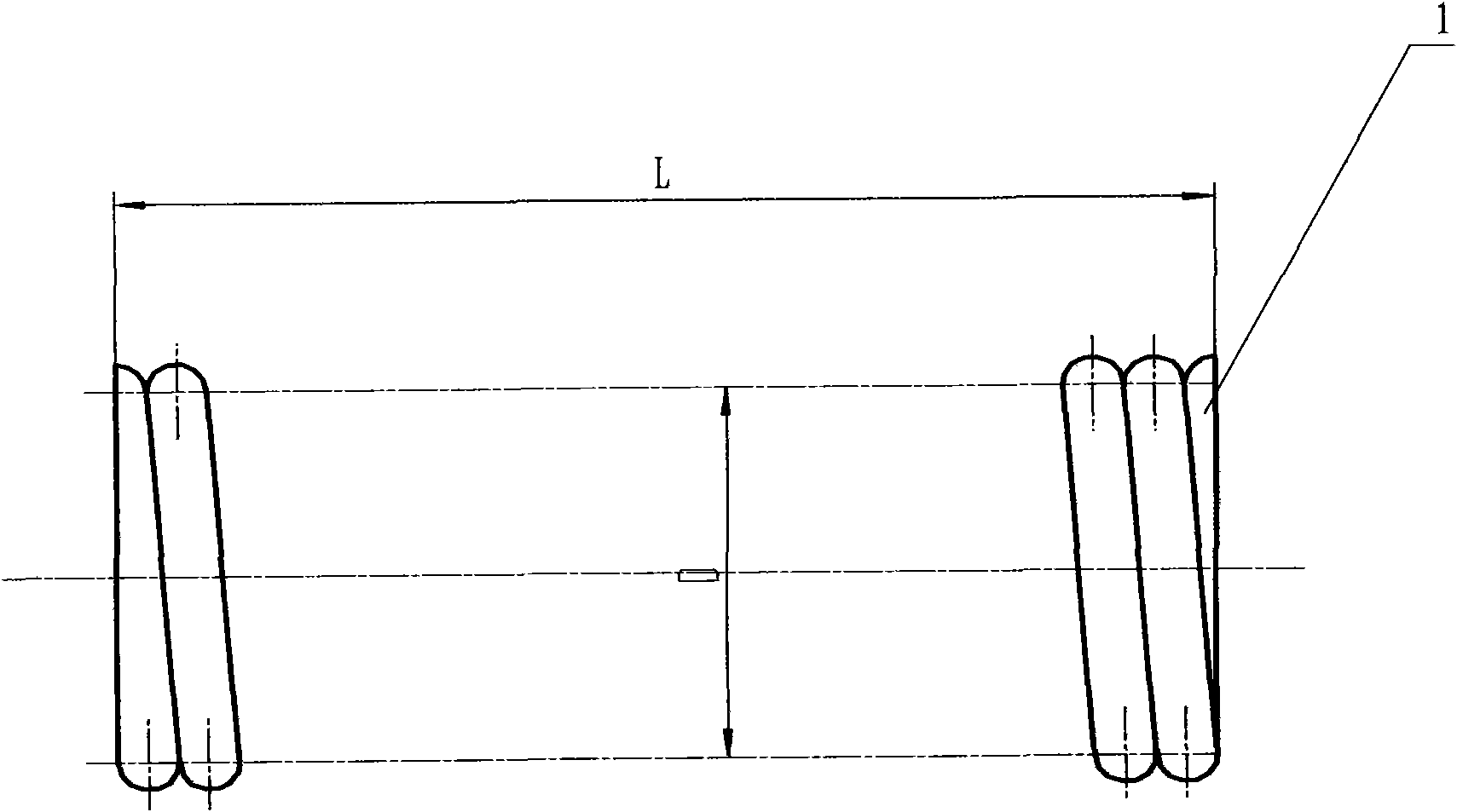

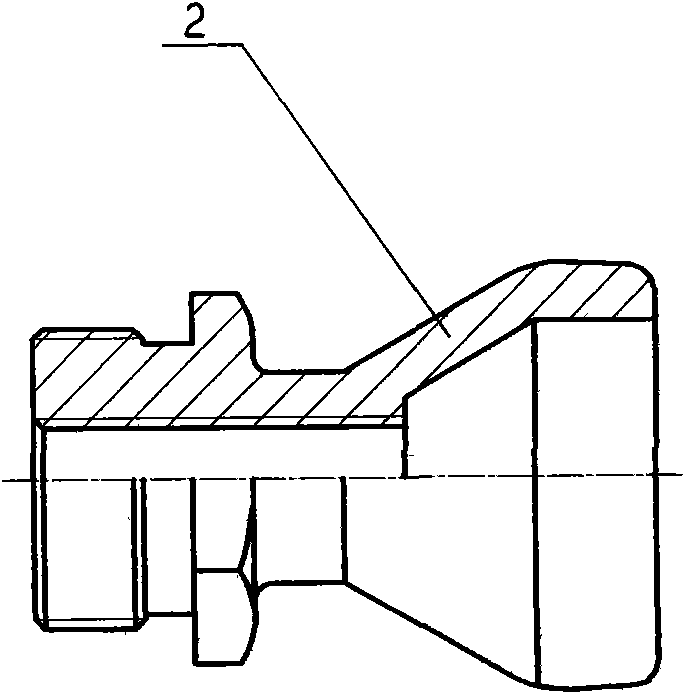

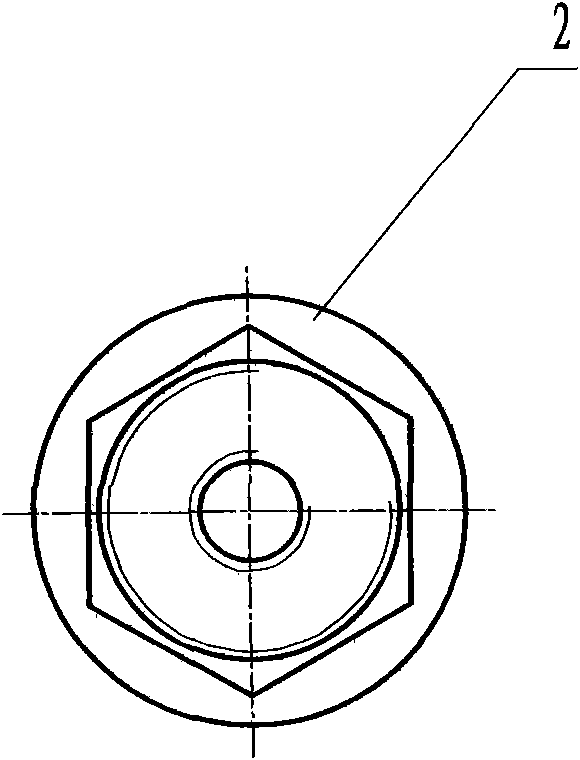

Method for manufacturing two-way threaded-insert type tension spring

InactiveCN101869956ASolve the initial tension problemSolve molding difficultiesEngineeringSpring steel

The invention discloses a method for manufacturing a two-way threaded-insert type tension spring. The method comprises the following steps of: selecting a spring steel wire; winding the spring steel wire to make a cylindrical spiral spring; embedding a threaded insert into the cylindrical spiral spring; performing sizing and tempering treatment; detecting the load of the obtained product on a spring tester according to the quality requirements of the product; immersing the two-way threaded-insert type tension spring which is tested and qualified into oil; and packaging the two-way threaded-insert type tension spring. The qualification rate of the two-way threaded-insert type tension spring produced by the method reaches 100 percent; compared with the traditional process, the method has the advantages that: the process procedures are simplified, the produced two-way threaded-insert type tension spring avoids quenching and surface treatment and the like, and the cost is reduced; and the two-way threaded-insert type tension spring is reliable in use.

Owner:CHONGQING WANGJIANG IND

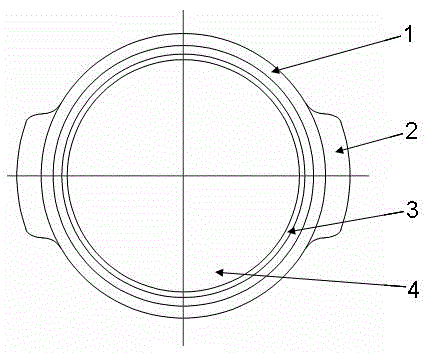

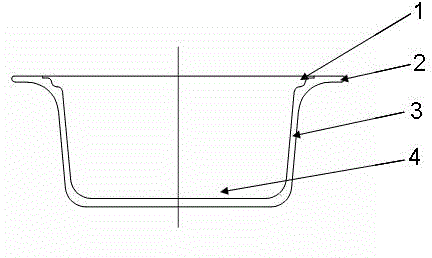

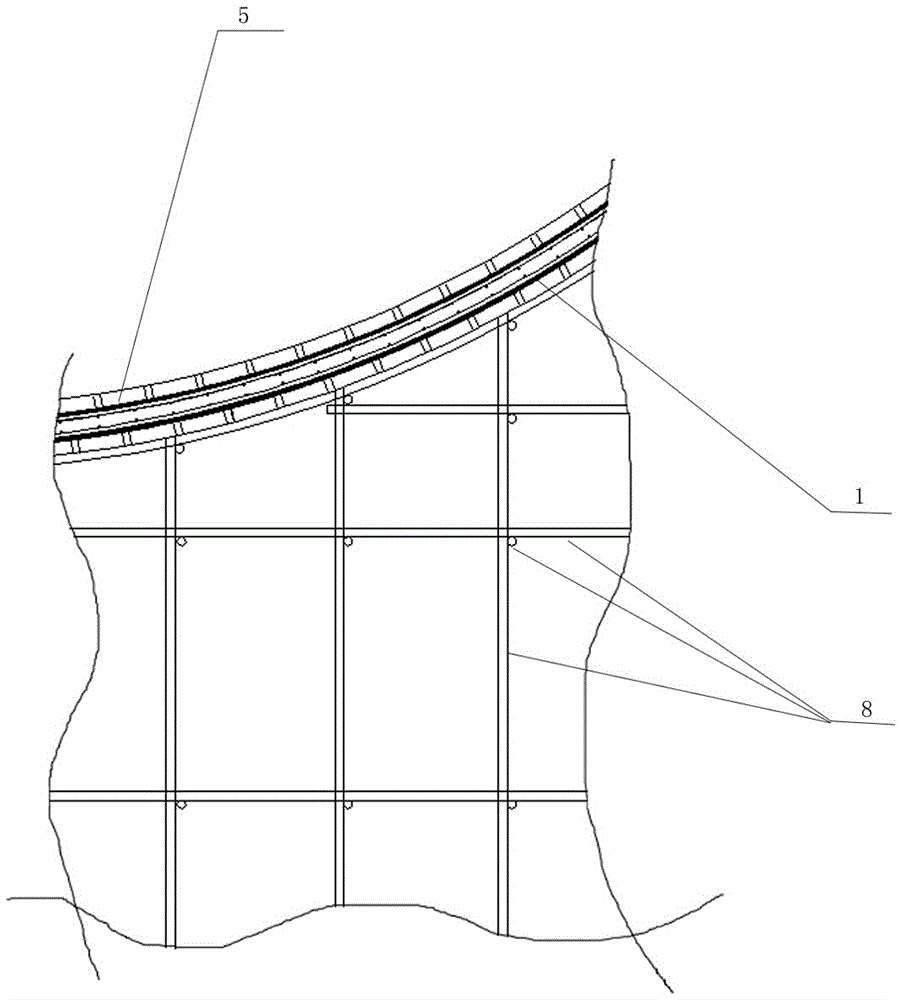

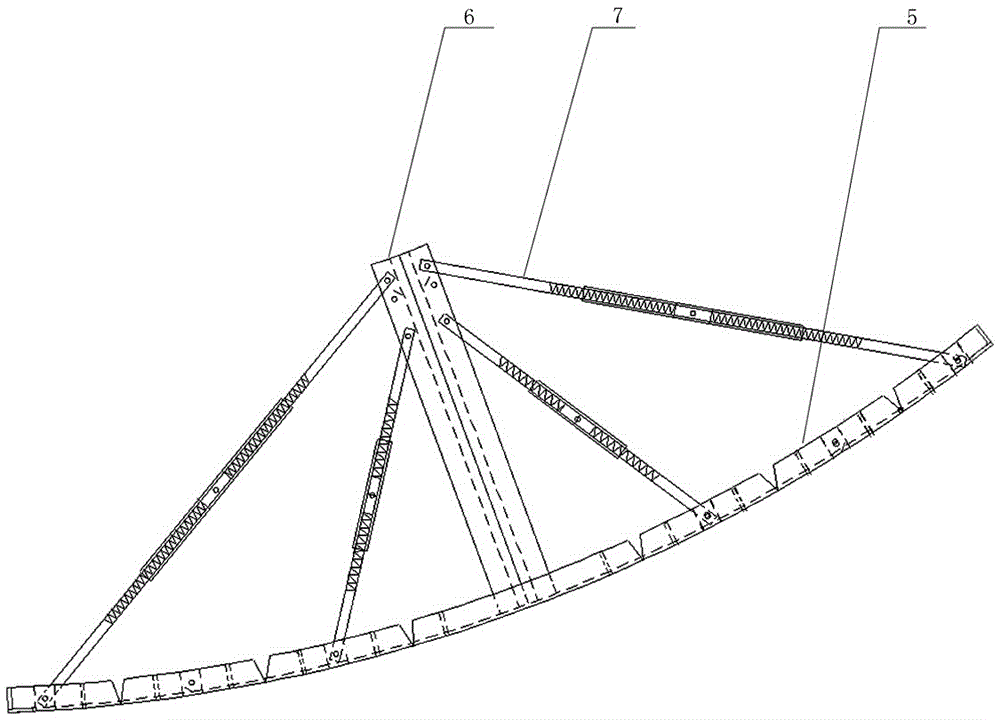

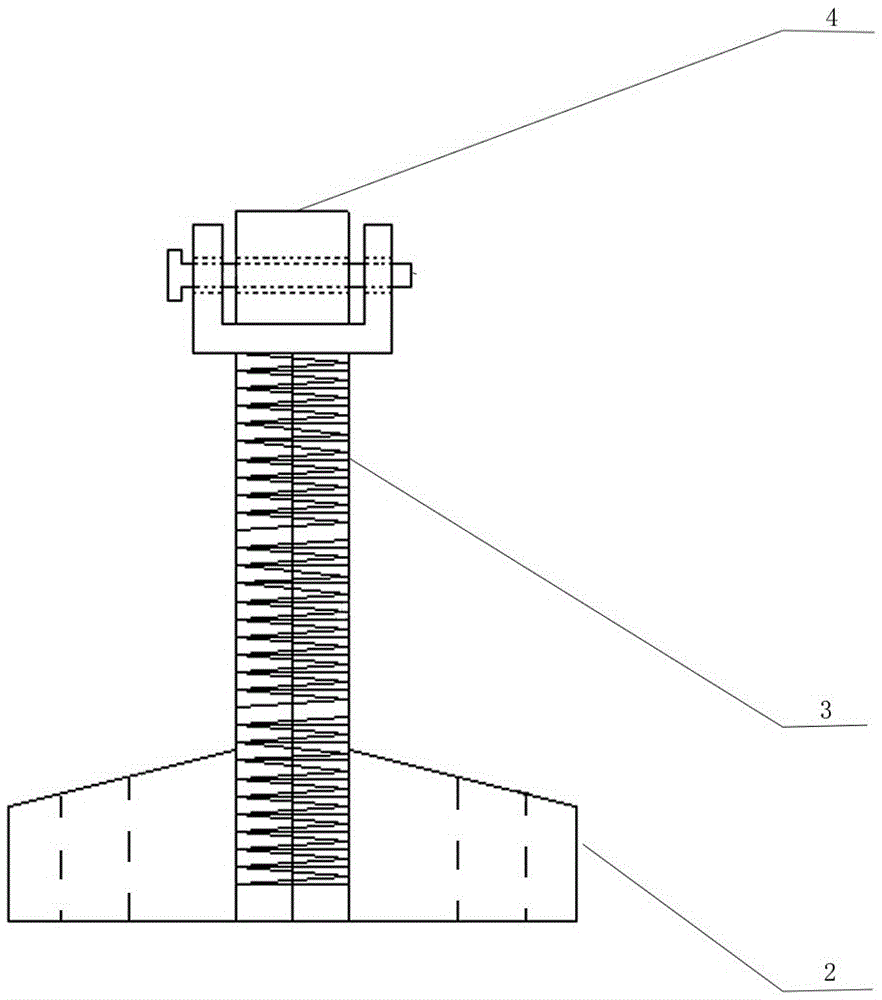

Vehicle laminated glass multi-section hinge baking-bending mold and application thereof

ActiveCN103964678AImprove fullyShorten the hanging distanceGlass reforming apparatusGlass productionEngineeringSelf weight

The present invention relates to a vehicle laminated glass multi-section hinge baking-bending mold and an application thereof. The vehicle laminated glass multi-section hinge baking-bending mold comprises a base, a fixed molding ring, an inner section molding ring, an outer section molding ring, an inner section balance force arm and an outer section balance force arm, wherein the fixed molding ring is fixed on the base, both sides of the fixed molding ring and the inner side of the inner section molding ring form hinged connections, the outer side of the inner section molding ring and the outer section molding ring form a hinged connection, the inner section molding ring is arranged on the inner section balance force arm, and the outer section molding ring is arranged on the outer section balance force arm. According to the present invention, during baking-bending molding, the inner section molding ring and the outer section molding ring completely unfold, softened glass is subjected to mold adhering and bending under a combined effect of gravity of the outer section balance force arm and the inner section balance force arm, and the glass self-weight, the outer section adjustment screw and the inner section adjustment screw respectively and slowly fall onto the outer section molding ring movement position limitation block and the inner section molding ring movement position limitation block, and the glass is baked and bends into the continuous and complete shape. Compared with the mold in the prior art, the mold of the present invention has characteristics of convenient operation, high efficiency and good quality.

Owner:FUJIAN WANDA AUTOMOBILE GLASS IND

Environmentally friendly water permeable brick

InactiveCN106518009AAchieve recyclingReduce pollutionCeramic materials productionClaywaresBrickSludge

The invention discloses an environmentally friendly water permeable brick. The environmentally friendly water permeable brick is prepared from 50 to 65 parts by weight of ceramic wastes, 15 to 20 parts by weight of sewage plant sludge powder, 10 to 20 parts by weight of waste bricks, 8 to 13 parts by weight of clay, 1 to 2 parts by weight of rosin resin and 10 to 15 parts by weight of water. A preparation method of the environmentally friendly water permeable brick comprises ingredient blending, stirring, blank making, drying and sintering. The environmentally friendly water permeable brick has the advantages of good water permeability, wide raw material source, low cost, simple production process, environmental protection and energy saving.

Owner:唐健发 +1

Concrete construction method for curved roof

ActiveCN106836662AHigh reuse rateHigh surface precisionBuilding roofsRoof covering using sealantsTower craneUltimate tensile strength

The invention provides a concrete construction method for a curved roof, the concrete construction method for the curved roof comprises the following steps of a, installing a slide rail; b, assembling and installing a steel framework; c, adjusting the radian of the steel framework; d, installing a framework moving mechanism on the steel framework; e, installing a plate vibrator on an assembled steel framework; f, checking the framework moving mechanism; g, pouring concrete on roof after finishing the framework moving mechanism; h, lifting the steel framework integrally to the next pouring area through a tower crane, and repeating steps F and G for concrete pouring until the entire roof is poured; and removing the steel framework after the entire roof is poured and the concrete reaches certain strength. The concrete construction method of the curved roof solves the problems of forming difficulty in concrete pouring of the curved roof, the construction quality and curve surface accuracy of curved roof concrete slabs are improved, and it is effectively guaranteed that the design thickness of the curved roof concrete and the compactness of the concrete meet the design requirements.

Owner:CHINA MCC20 GRP CORP +1

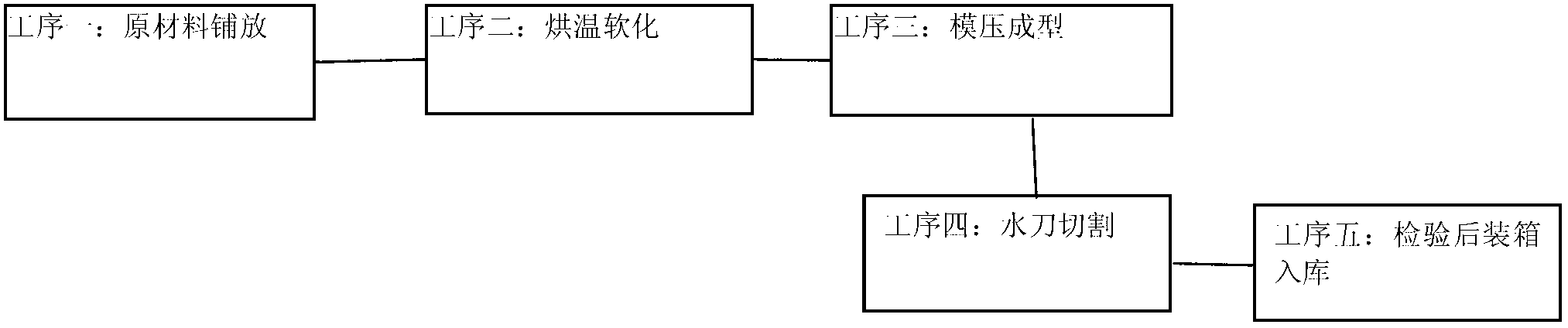

Production method of fibrilia automobile ceiling

ActiveCN102795170ASolve molding difficultiesAddress process complexityLaminationLamination apparatusFiberWrinkle skin

The invention relates to a production method of fibrilia automobile upholstery, and in particular relates to a production method of a fibrilia automobile ceiling, belonging to the technical field of manufacture of automobile upholstery. The production method comprises the following steps of: carrying out drying and heating treatment on a film-attached fibrilia board; then, conveying the film-attached fibrilia board to the center of an upper die and a lower die through a chain; carrying out cold press molding on the put fabric by using a product die; coldly standing for a period of time after molding; and finally, cutting by using a water jet cutter to obtain the ceiling, then, checking, casing and storing. By using the production method, the problems of difficulty in molding, complex process, low toughness, no environment friendliness and the like of the automobile ceiling are solved; the produced product is unique in machining process, low in energy source loss, light in weight, low in water content, high in bending strength, high in modulus, resistant to high temperature, low temperature, impact and wrinkles, strong in rigidity, free of acute-angle sections generated after the automobile ceiling is crushed as well as safer and more reliable; and materials belong to regenerative resources, and discarded products can be recycled and are also easy to realize natural degradation, and therefore, remarkable environment-friendly performance is achieved, and the production method accords with the low-carbon trend.

Owner:WUXI GISSING AUTO PARTS CO LTD

V-cut light guide plate forming method and V-cut light guide plate forming mold

The invention discloses a V-cut light guide plate forming method and a V-cut light guide plate forming mold. The method comprises the steps that glue is injected to the mold through an injection molding machine, glue injected by a glue injector flows into glue inlet runners on the two sides of a glue inlet through the glue inlet, the glue enters a light guide plate forming cavity through a short side of the light guide plate forming cavity, the glue flows along a groove in the light guide plate forming cavity until glue in the light guide plate forming cavity and a reserved space is enough toform a light guide plate; finally, die assembly is carried out, the light guide plate forming cavity is filled with glue, and the light guide plate forming step is executed. According to the V-cut light guide plate forming method, at least one part of groove does not need to receive glue coming through transverse cutting type flowing, use of the transverse cutting type glue flowing manner is reduced, and the problems that in the prior art, all grooves have to receive cutting type flowing glue, glue flowing is not facilitated, and forming is difficult are solved.

Owner:SHENZHEN SOUTH POLE OPTOELECTRONICS TECH

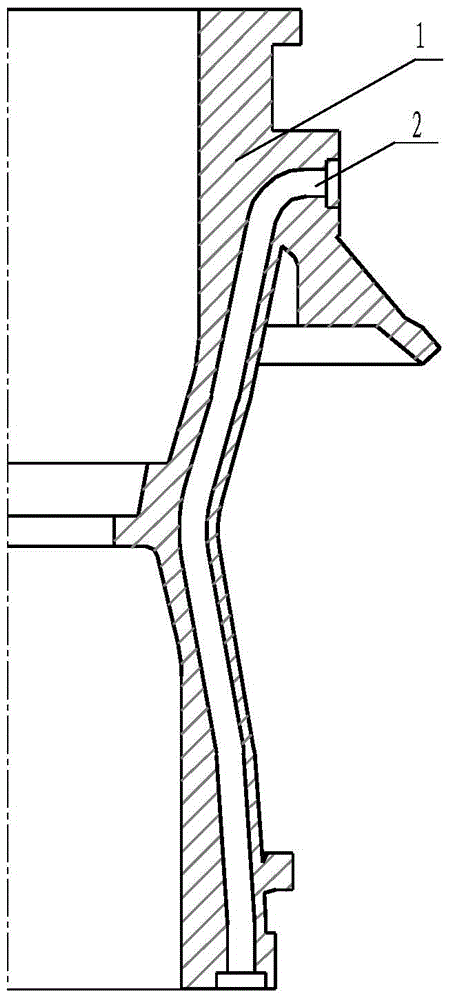

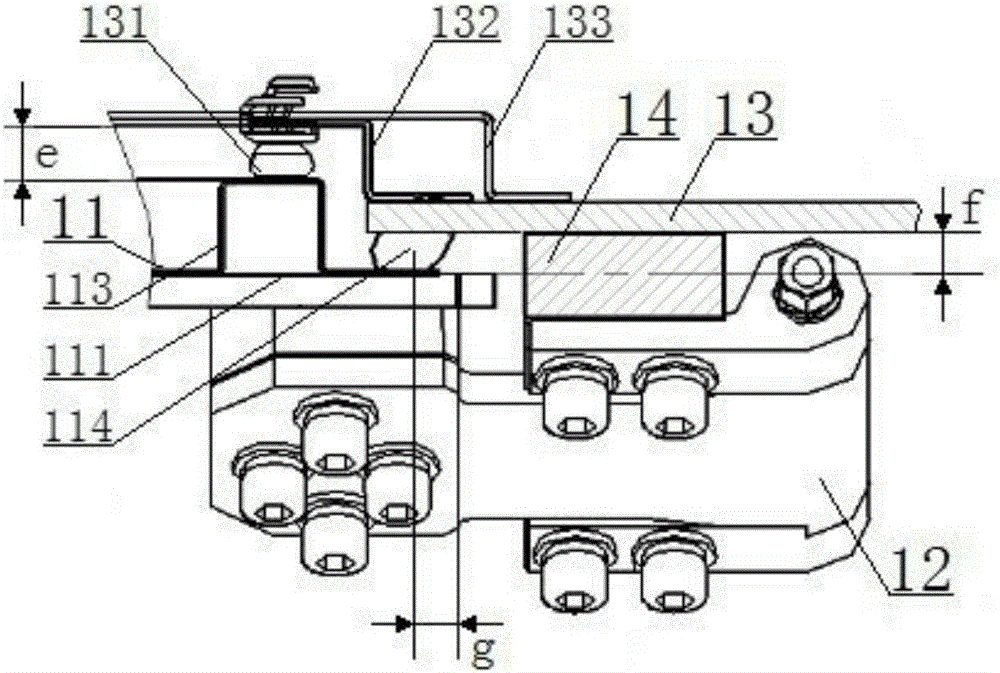

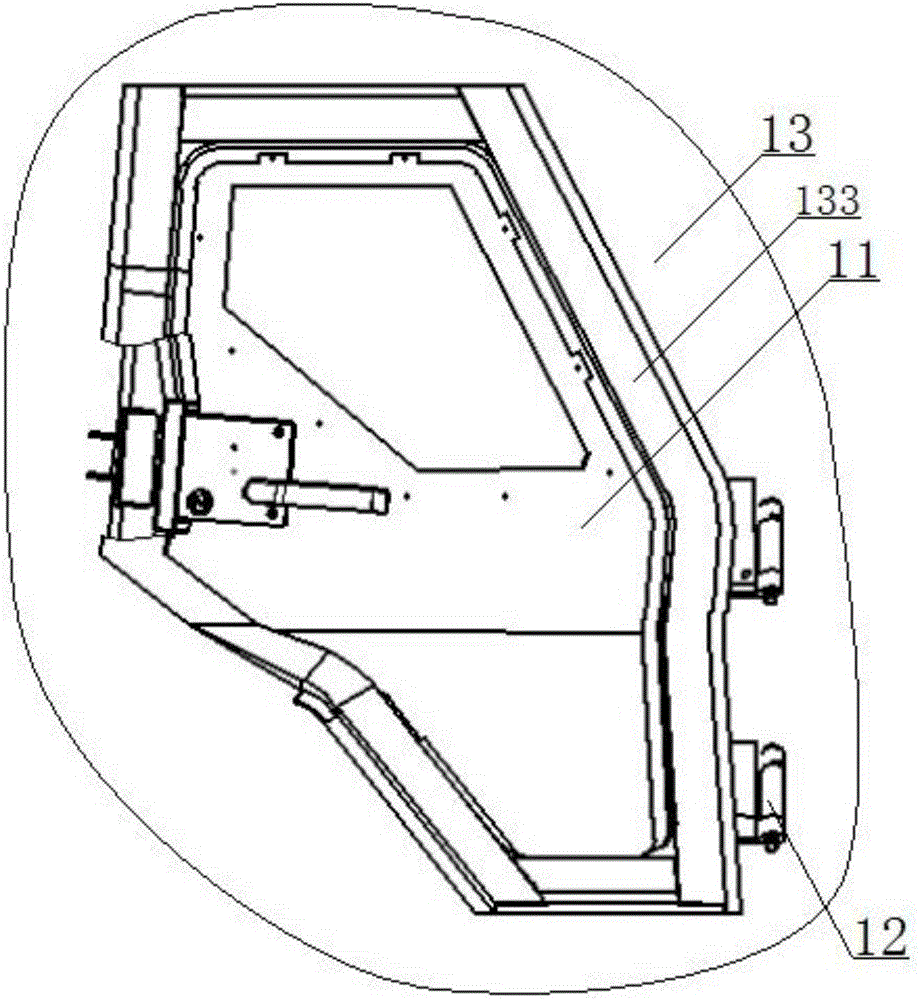

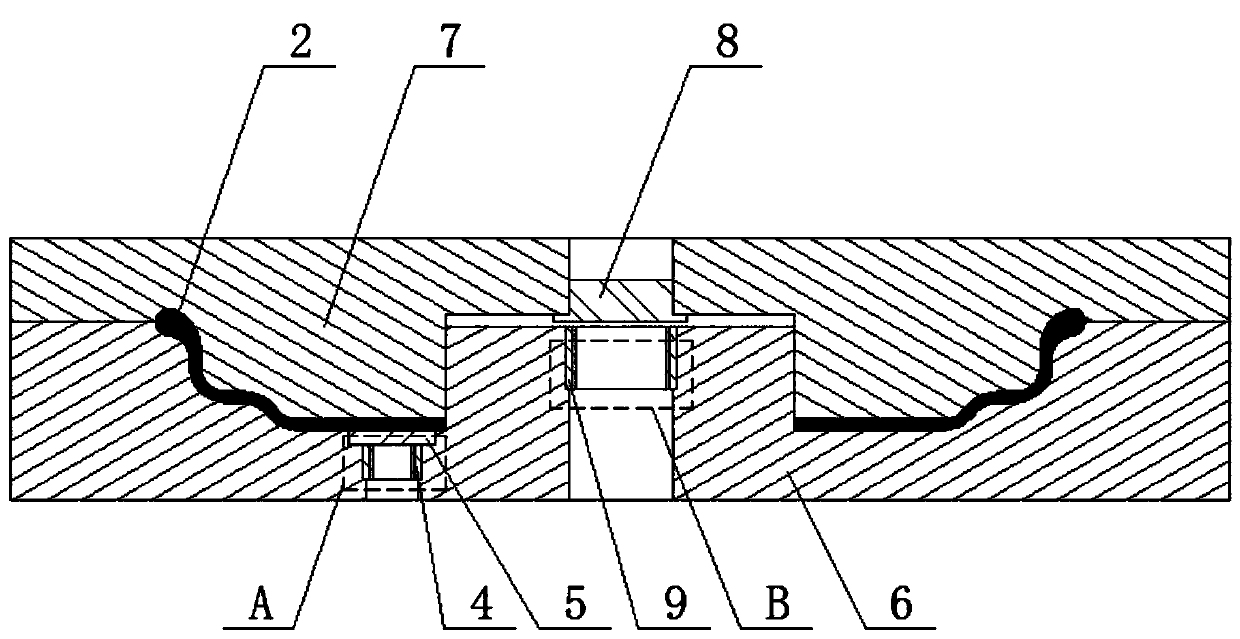

Double-layer sealing structure for armored car door and welding method

ActiveCN106541811ASolve molding difficultiesReduce welding distortionEngine sealsVehicle sealing arrangementsWelding deformationWater seepage

The invention relates to a double-layer sealing structure for an armored car door. The structure comprises a car door body, a car body and a car door hinge. It is characterized in that the car door body is formed by a door board, a door lock reinforcing board and an annular reinforcement. an external sealing strip is fit with the outboard of the annular reinforcement and the external sealing strip is clung to the car body to form a first layer sealing structure; the car body is provided with a doorframe and a lock box reinforcing board, wherein an internal sealing strip is fit with the doorframe and the internal sealing strip is clung to the annular reinforcement to form a second layer sealing structure. The invention also relates to a welding method for the double-layer sealing structure for an armored car door. The method comprises following steps: making members; welding the car door body; welding the doorframe; assembling the car door body; assembling the sealing strip; adjusting and calibrating the car door; testing the sealing performance. By means of the structure and method of the invention, good sealing effect of armored car doors can be ensured to avoid water seepage. The problems of difficult formation of annular reinforcement, doorframes and door plates can be solved; the welding deformation of car door body is reduced; the welding and assembling accuracy and consistency of armored car doors are increased so that the quality of armored cars is guaranteed; the assembly efficiency is increased.

Owner:重庆大江智防特种装备有限公司

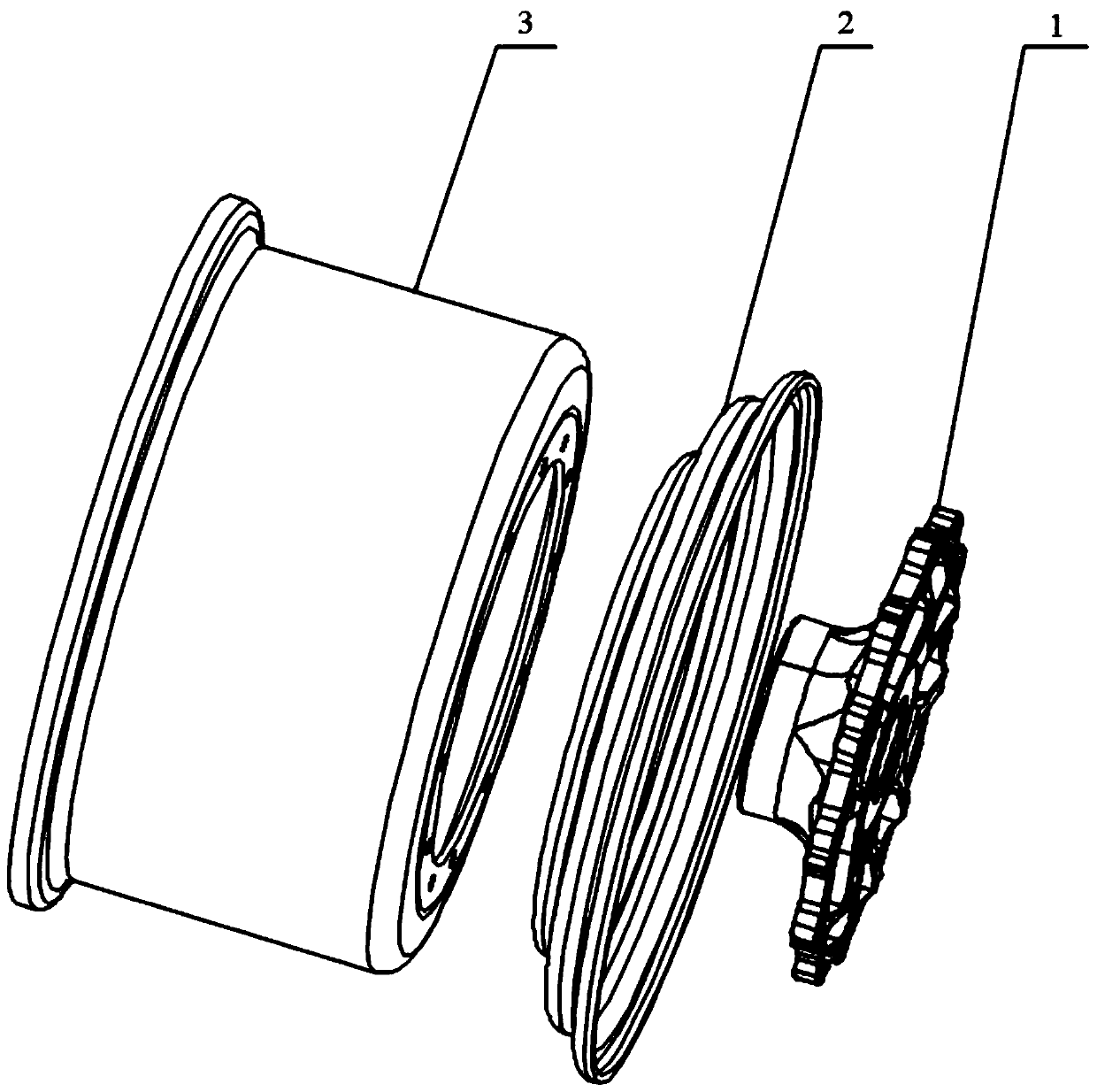

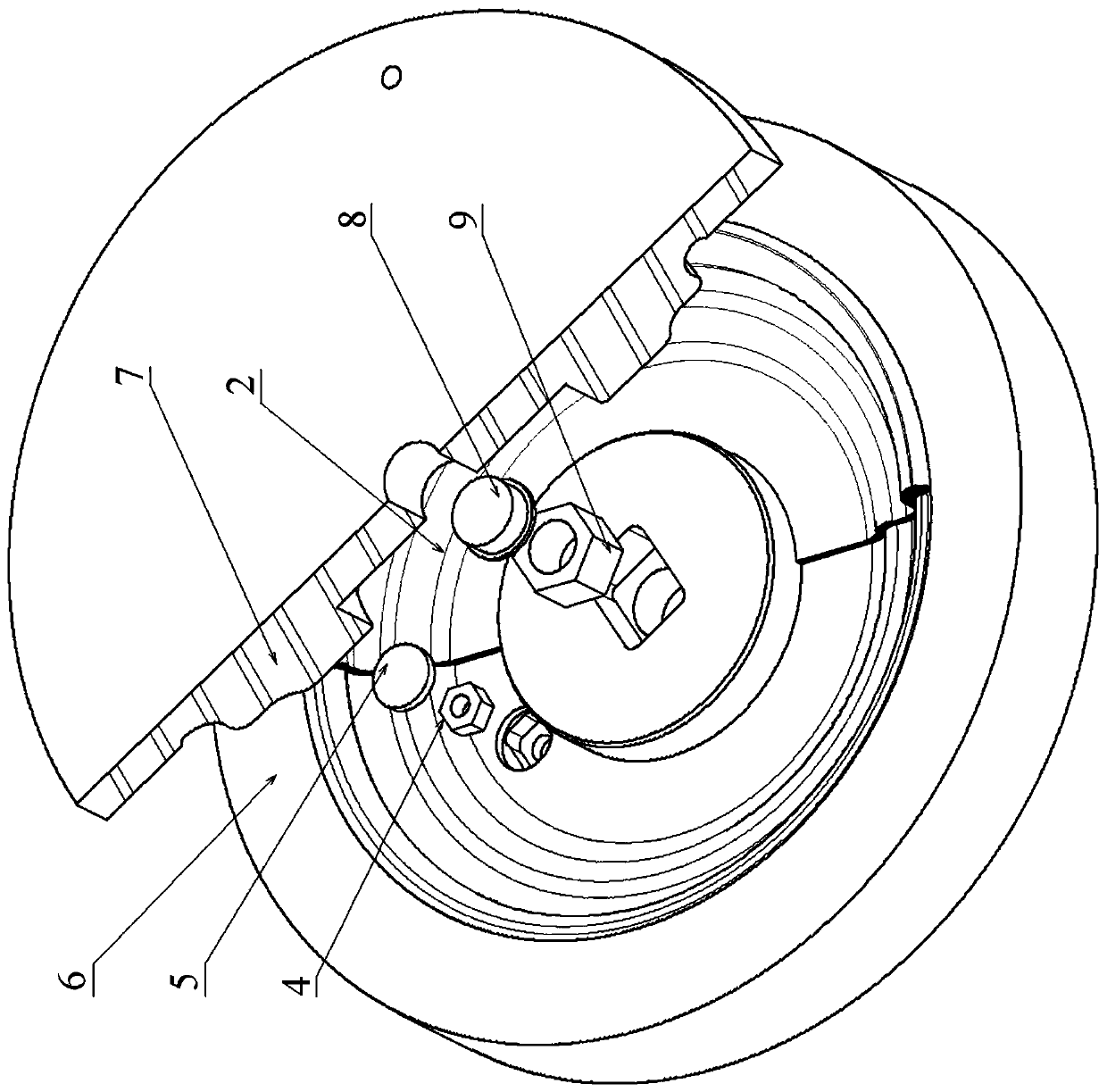

Carbon fiber three-piece combined rim and forming die thereof

The invention relates to a carbon fiber three-piece combined rim and a forming die thereof, and relates to the field of rims and forming dies thereof. The carbon fiber three-piece combined rim is characterized in that the inner end surface of an outer rim and the outer end surface of an inner rim are fixedly connected through high-strength adhesive to form a rim body, a central boss is arranged at the inner end of a spoke, the central boss of the spoke is arranged in a central cavity of the rim body, and the spoke is connected with the rim body in a locking mode. The forming die comprises an outer rim die set and an inner rim die set, when an upper die and a lower die of the outer rim die set are compounded, a cavity which is consistent with the contour shape of the outer rim to be manufactured is formed between the top surface of an annular boss of the upper die and the groove bottom surface of an annular inner groove of the lower die, and is used for forming the contour of the outer rim; and an inner core of a round pipe of the inner rim die set is arranged coaxial with a die cover and the inner core of the round cake, and carries out mutual insertion for positioning operation, and a round pipe outer die is arranged coaxial with the mold cover, and carries out mutual insertion for positioning operation. The forming die is used for forming the carbon fiber rim.

Owner:HARBIN INST OF TECH AT WEIHAI

Composite electrical contact processing technology

The invention discloses a composite electrical contact processing technology which comprises the following steps of: firstly selecting copper powder, tungsten carbide powder and tungsten powder of suitable particle size for mixing in proportion; heat-treating mixed raw material powder, compressing for molding and then preheating to obtain copper tungsten alloy blank; and finally sintering and infiltrating pure copper, iron co-alloy and preheated blank together to obtain a high-power rigid copper tungsten iron composite electrical contact material. Because iron co-alloy is adopted as a base material, the high-power rigid copper tungsten iron composite electrical contact material has the characteristics of high hardness and good wearability. Because the material adopts a copper material, combination properties of current breaking capacity, conductivity, current intermittent characteristic, and the like of the prepared electrical contact are improved. The property uniformity of the material is high in service life circle. With the adoption of the contact material, the electrical switch structure is simplified, dispersivity of a spring in a switch is eliminated, and the reliability of a part is greatly improved. The material is widely used in production of the electrical contact of various vacuum circuit breakers.

Owner:蔡玉凤

Making process for completely mashed potato steamed breads

InactiveCN106173923AIncrease contentFull of nutritionSugar food ingredientsYeast food ingredientsPotato starchSteamed bread

The invention discloses a making process for completely mashed potato steamed breads. Mashed potatoes made from cooked potatoes are proportionally mixed with flour, accessories such as konjac flour, sodium alginate and eggs are added, and the completely mashed potato steamed breads are processed by the procedures of making of the mashed potatoes, dough kneading, fermentation, cooking and the like, so that the shortcomings of severe pollution of a flour making process, serious loss of nutritional components and undiversified accessories and nutrients due to the fact that potato starch and whole flour are taken as main raw materials for conventional potato steamed breads are overcome, and the steamed breads are rich in more than 10 trace elements, such as potassium, icon, copper, selenium and calcium, linoleic acid and multiple amino acids, such as methionine, cystine, phenylalanine, tyrosine and threonine, with the content of various nutrients higher than that of the conventional potato steamed breads and other steamed breads, and are nutrient-richer and favorable for nutrition balance of a human body; the making process for the potato steamed breads is simple, the potato steamed breads can be conveniently produced by small and micro enterprises, and the problems of difficulties in forming and fermentation, high cracking rate, poor taste and the like of the potato steamed breads are solved.

Owner:QINGHAI HONGEN TECH

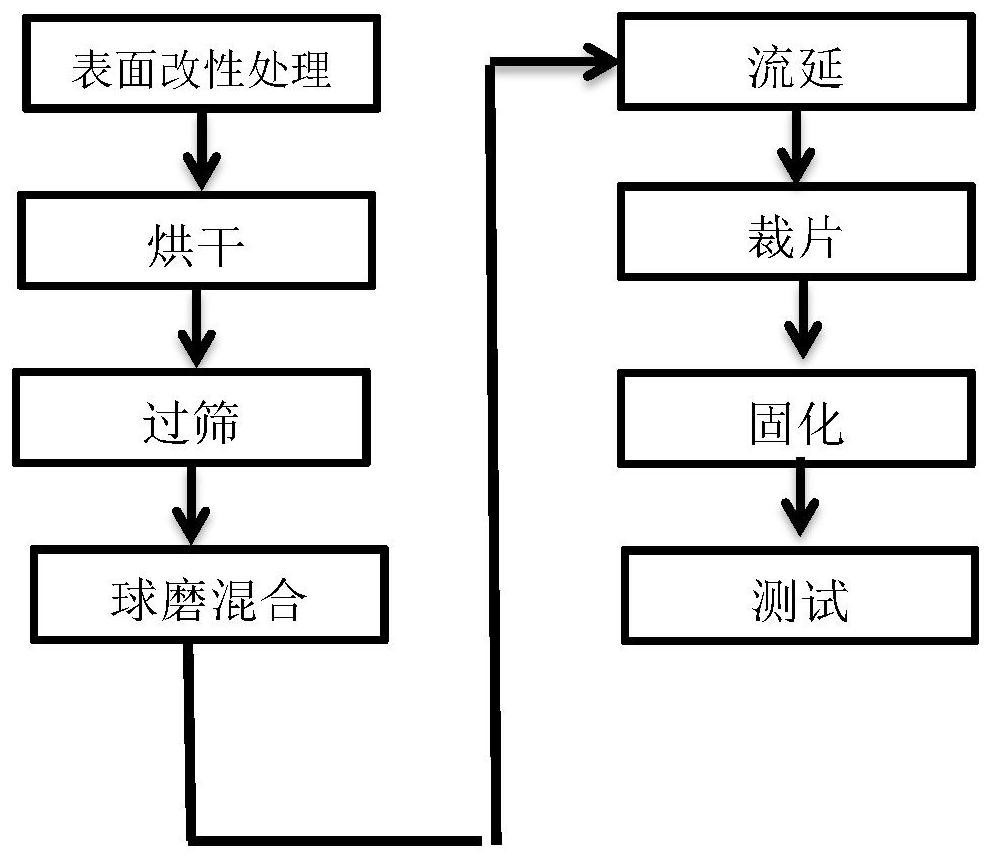

Hydrocarbon resin ceramic bonding sheet and batch production process thereof

The invention relates to a hydrocarbon resin ceramic bonding sheet and a batch production process thereof. The hydrocarbon resin ceramic bonding sheet comprises the following components: an inorganic filler, a silane coupling agent, hydrocarbon resin, a curing agent and a solvent. The mass production process comprises the following steps: carrying out surface modification treatment on an inorganic filler by using a silane coupling agent; mixing the surface-modified porcelain powder with a curing agent, hydrocarbon resin, a solvent and other materials, and carrying out planetary ball milling; carrying out tape casting on the mixed solution subjected to planetary ball milling to prepare a raw ceramic tape; and semi-curing and demolding the green tape in a vacuum high-temperature oven to prepare the bonding sheet. The problems that an existing ceramic filled hydrocarbon resin type bonding sheet is poor in thickness uniformity, long in production period and not suitable for batch production are solved. The hydrocarbon resin ceramic bonding sheet is widely applied to modern microwave electronic communication fields such as spaceflight electronic equipment, communication, a Beidou system, a wireless local area network and the Internet of Things.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com