Hydrocarbon resin ceramic bonding sheet and batch production process thereof

A hydrocarbon resin and production process technology, applied in the fields of microwave electronic components ceramic materials and electronic components, can solve the problems of poor thickness uniformity, long production cycle, difficult molding of high ceramic filled hydrocarbon resins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

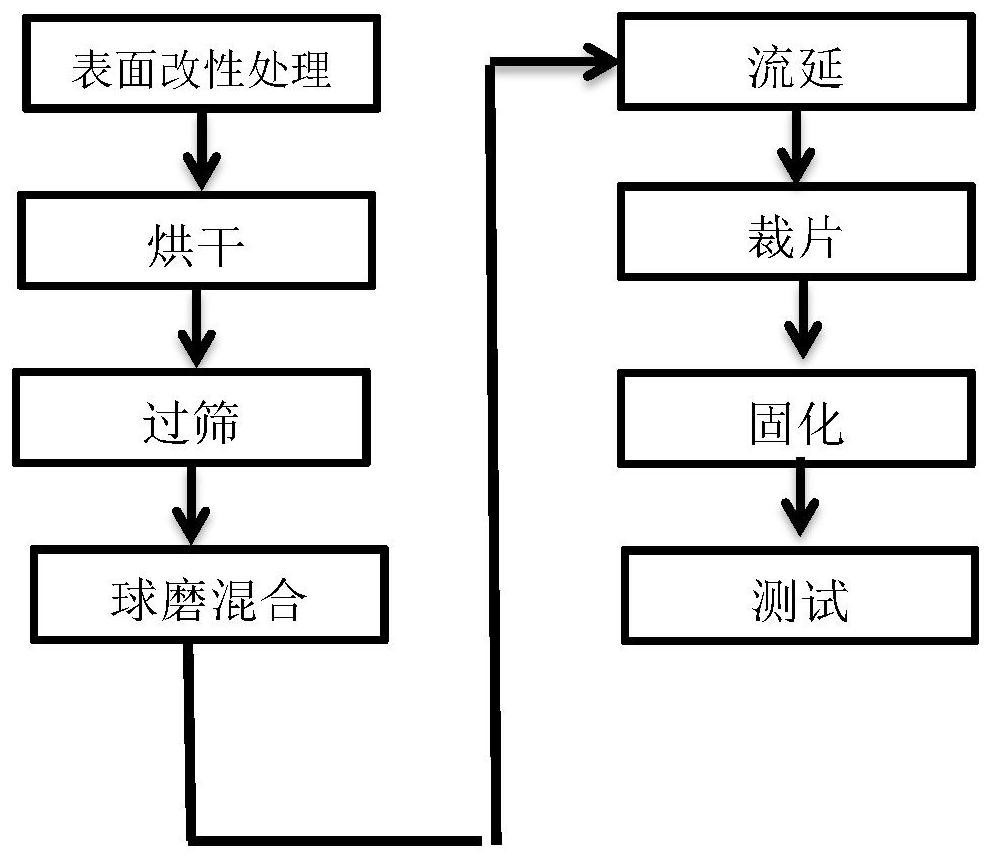

[0030] A production process of a hydrocarbon resin ceramic bonding sheet, comprising the following steps:

[0031] (1) The ceramic powder is surface-modified by a silane coupling agent, and the amount of the silane coupling agent is 1wt% to 3wt%;

[0032] (2) drying and sieving the porcelain powder after the surface modification treatment;

[0033] (3) Bake oven dry, sieved porcelain powder, hydrocarbon resin, and curing agent in a certain proportion, carry out batching by 78wt% silicon dioxide, 20wt% hydrocarbon resin, and 2wt% curing agent, add toluene as a dispersion solvent, The amount of solvent used is 70wt% of the mass fraction of silica, planetary ball milling is carried out, the ball milling time is 4h-6h, and the rotational speed is 325r / min;

[0034] (4) The ball-milled mixture was cast using a casting machine at a casting speed of 1 m / min; the casting drying temperature was 60° C.;

[0035] (5) Cutting the cast film into pieces, and cutting it to the required siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com