Double-layer sealing structure for armored car door and welding method

A double-layer sealing, armored vehicle technology, applied in sealing devices, engine sealing, motor vehicles, etc., can solve problems such as difficulty in forming, and achieve the effect of improving assembly efficiency, ensuring quality, and reducing welding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

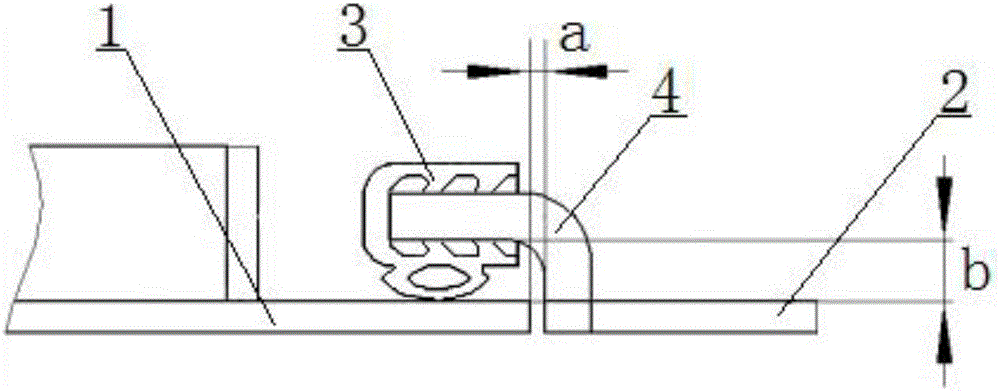

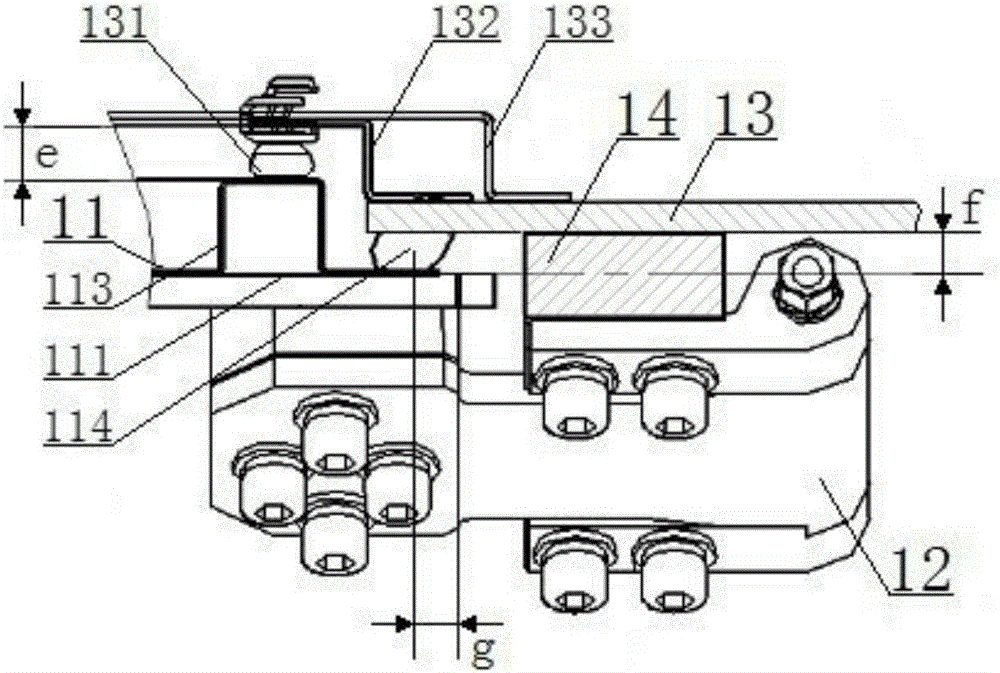

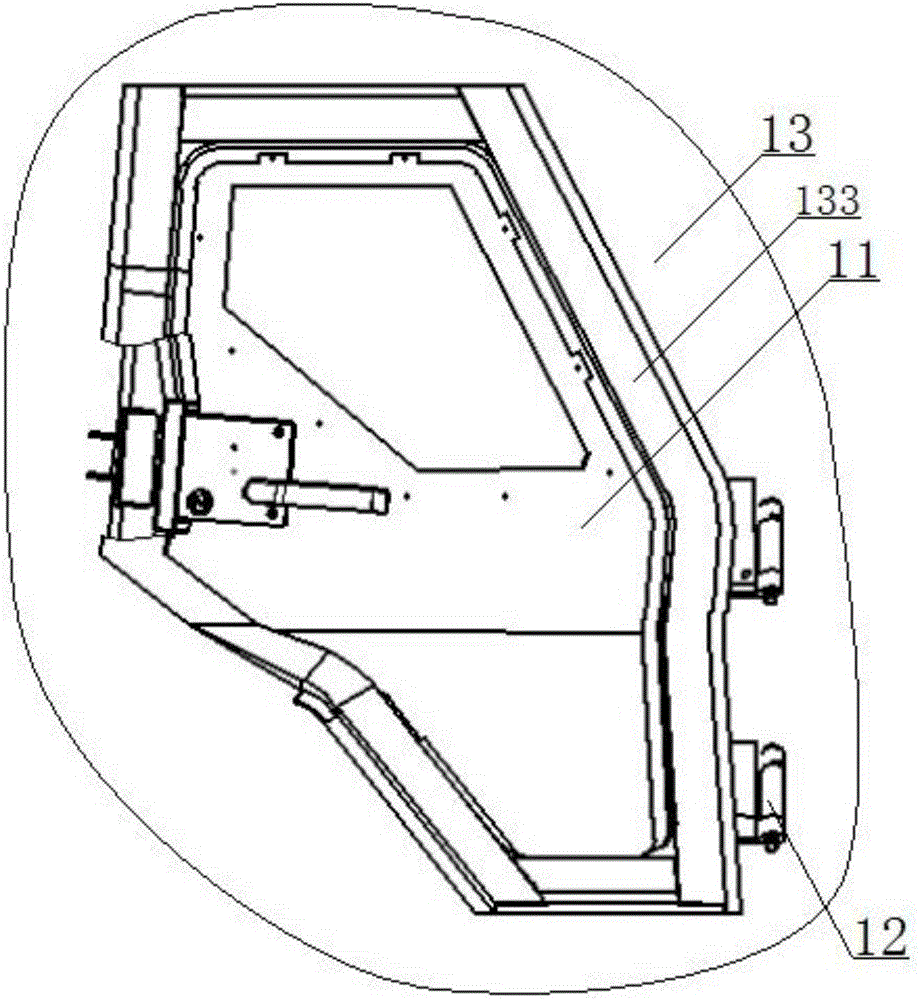

[0049] see Figure 2 to Figure 14 The shown double-layer sealing structure of an armored vehicle door includes a door body 11 and a vehicle body 13. The vehicle body 13 is provided with a door opening. The edge of the door opening on the vehicle body 13 is connected; its prominent substantive feature is: the door body 11 is composed of a door panel 111, a door lock rib 112 arranged on the inner surface middle edge of the door panel 111 and a door lock rib 112 arranged on the door panel 111 The ring rib 113 around the inner surface of the inner surface is formed. The ring rib 113 is made of "π" steel, and an outer sealing strip 114 is connected to the outer side of the ring rib 113. The outer sealing strip 114 is connected to the body 13 close to form the first layer of sealing structure; the edge of the door opening of the vehicle body 13 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com