Composite electrical contact processing technology

A processing technology and technology of electrical contacts, applied in the direction of circuits, electrical switches, electrical components, etc., can solve problems such as unsatisfactory current breaking capacity, high gas content of contact materials, unsatisfactory current intermittent characteristics, etc., to solve the problem of forming Difficulty and infiltration difficulty, high performance uniformity, improved conductivity and current intermittent characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

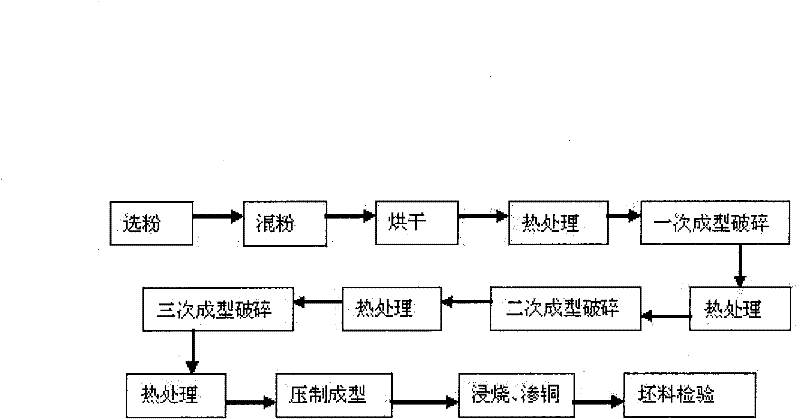

[0022] From figure 1 It can be seen that the processing technology of a high-power hard copper-tungsten-iron composite electrical contact material is as follows:

[0023] First select copper powder to pass through a 400 mesh sieve, and mix the powder particles of tungsten carbide and tungsten between 3-6 μm in proportion, and the content of copper powder weight in the mixed powder is 8-12%;

[0024] The mixed raw material powder is heat-treated at 580--620°C for 2--4 hours, and pressed at a pressure of 4.5-8.5 tons / square centimeter, crushed after the first pressing, and again at 630 --Heat treatment at 670°C for 1.5-4 hours, and press for the second time at a pressure of 5.5-6.5 tons / square centimeter;

[0025] Crushing after the second compression molding, heat treatment at 670-710°C for 1.5-4 hours again, and pressing for the third time under the pressure of 5.5-6.5 tons / square centimeter;

[0026] After the third compression molding, it is crushed, heat-treated again at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com