Vehicle laminated glass multi-section hinge baking-bending mold and application thereof

A technology of laminated glass and hinges, applied in the field of multi-section hinge baking and bending molds, can solve the problems of obvious mold marks, glass cannot be formed, and inverse spherical surfaces are generated, and achieve the effect of improving optical performance, stabilizing product quality, and reducing floating distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

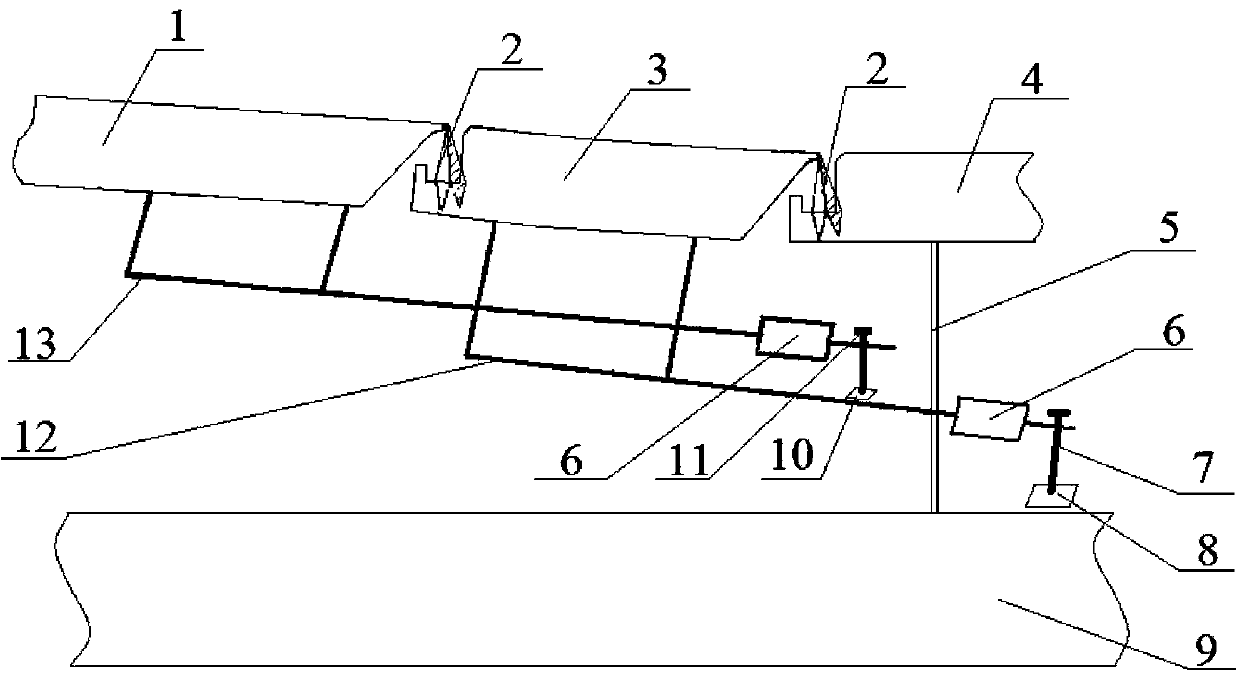

[0022] A multi-joint hinge baking and bending mold for automobile laminated glass, such as figure 1 As shown, it includes a base 9, a fixed forming ring 4, an inner segment forming ring 3, an outer segment forming ring 1, an inner segment balancing force arm 12 and an outer segment balancing force arm 13, and the fixed forming ring 4 is fixed on the base 9 to form a fixed Both sides of the ring 4 are hinged to the inner side of the inner segment forming ring 3, and the outer side of the inner segment forming ring 3 is hinged to the outer segment forming ring 1. The inner segment forming ring 3 is arranged on the inner segment balance arm 12, and the outer segment forming ring 1 is arranged on the outer Section balance arm 13. Wherein, the fixed forming ring 4 is hinged with the inner segment forming ring 3 to form a hinge opening 2 , and the inner segment forming ring 3 and the outer segment forming ring 1 are hinged to form a hinge opening 2 . The inner section balance arm 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com