Method for forming slender bent irregularly-shaped hole in aluminum alloy casting

A technology of aluminum alloy castings and special-shaped holes, which is applied in the directions of casting mold components, casting molding equipment, casting molds, etc., can solve the problems of inability to make shells, difficult extraction of metal cores, and difficult shell making, etc. Difficult to extract effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

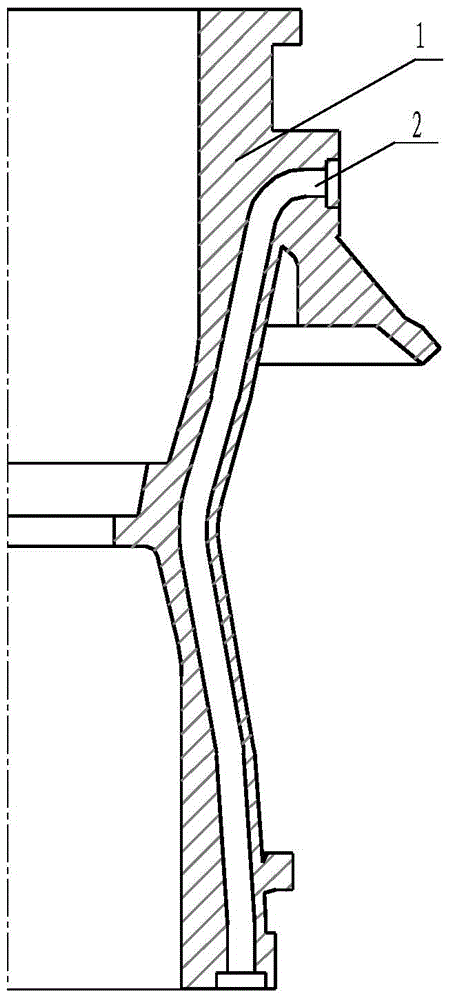

Image

Examples

Embodiment Construction

[0020] Case 1: Intermediate receiver

[0021] 1) Make stainless steel metal pipe fittings according to the shape and size of the slender and special-shaped hole in the casting diagram of the intermediate case. The diameter is 8mm, the pipe wall thickness is 1mm, and the material is 1Cr18Ni9Ti, which can ensure the stability of composition and size during the pouring process of aluminum alloy castings.

[0022] 2) Grinding, trimming and inspection of metal pipes;

[0023] 3) Put the metal tube into the wax mold and fix it, and carry out wax mold pressing;

[0024] 4) Seal the exposed hole at the end of the pre-embedded steel pipe with wax;

[0025] 5) Use X-rays to inspect the embedded parts in the wax mold;

[0026] 6) Carry out the production process of general-purpose aluminum alloy precision castings: wax mold trimming, assembly, shell making, dewaxing, shell roasting, melting and pouring, shelling, cutting and grinding, etc.;

[0027] 7) X-ray check whether the shape an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com